*This article was reproduced from the autocarweekly public account.

Author: Aoao Hu

The era of “gasoline to electric” has passed, and we do not miss it.

Today, any car manufacturer that does not have its own, native, dedicated pure electric vehicle platform can be considered either unwilling or unable to meet the advent of the pure electric era. Consumers who have experienced the pitfalls of “gasoline to electric” are highly aware of the importance of a pure electric platform instead of one based on a combustion engine.

However, words can be deceiving, both from manufacturers and from media outlets that may be biased. Even when a car company is subjectively intending to design a pure electric platform, in reality, it may not completely overthrow the structural design of combustion engine vehicles and may not fully utilize the inherent advantages of pure electric vehicles.

Alternatively, consider starting from scratch to design a so-called “universal platform” compatible with both gasoline and electric power, but only use it to produce pure electric cars. Isn’t this also called a “dedicated electric platform”? Rather than being lost in promotional language or trusting solely in the words of car companies, it is better to see beyond the surface and understand the true nature of these so-called “pure electric platforms”.

Gasoline cars have been around for a century, and most people on this Earth have only ever ridden in them. For a layperson who does not delve deep into the essence of a car, it is easy to overlook the sacrifices and compromises that were made for the internal combustion engine, as well as the limitations and restrictions it imposes.

Nowadays, we often say that batteries are difficult to manage, but isn’t the combustion engine equally so? It is just that we have been accustomed to it for a hundred years.

But we have all heard the saying that “electric vehicles break through the limitations of the internal combustion engine”. From this, we can already gain some insights. The internal combustion engine and its related transmission system occupy a large space in the entire front of modern cars, releasing a massive amount of heat and weighing several hundred kilos.

In the back, whether it’s the longitudinal transmission of a rear-wheel-drive car or the exhaust system in the middle of a front-wheel-drive car, a central channel must be left through the vehicle, forming an obvious bump near the front firewall. This central channel runs almost through the entire car, forming the usual bulge on the rear center floor and the central armrest box on the front row.Due to the relationship between the transverse gearbox and the central transmission shaft, the central passage of rear-wheel drive and all-wheel drive cars is always larger in scale than that of front-wheel drive cars, and this even subtly affects people’s aesthetic view, with a spacious front center armrest area becoming a hallmark of luxury cars. Front-wheel drive cars with four-wheel drive versions also often take up more space in the central passage than front-wheel drive cars with only front-wheel drive versions.

If it is a fuel-based platform based on longitudinal engines or a so-called universal platform for electric vehicles, you can easily spot this type of structure.

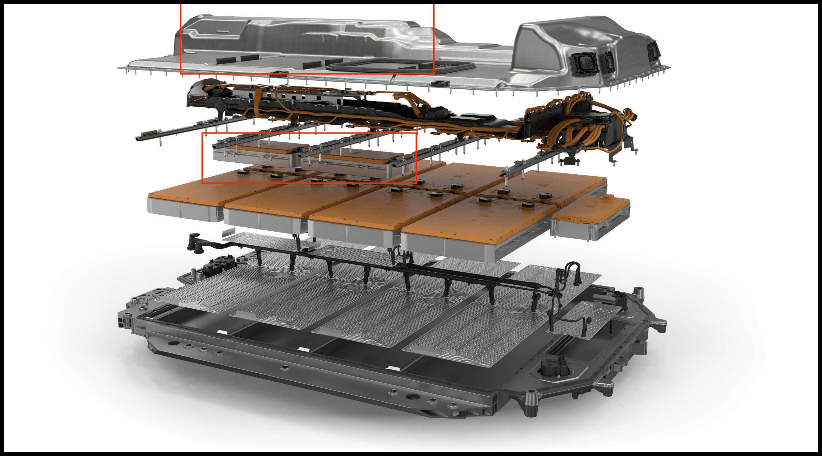

For the space inherited from fuel-based vehicles that must be idle, BMW’s solution is to add two small battery module combinations on top of the lowest layer of the battery pack. However, the best way for the battery system of electric vehicles is to be completely flat, so that each part of the battery core has essentially the same heat dissipation conditions. Most of the stacking module gap-plugging battery core is found in this type of non-pure electric exclusive platform electric vehicle.

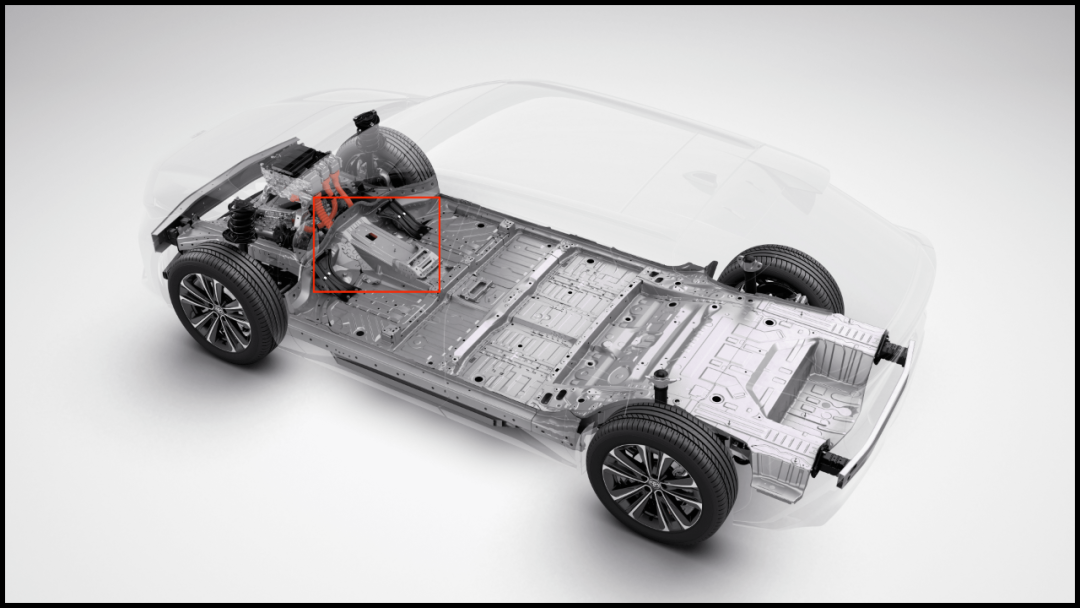

The problem facing front-wheel drive cars is that the firewall is too close to the cabin, which is essentially due to fuel-based cars with a transverse engine needing to place the internal combustion engine ahead of the front axle, leaving as much space as possible between the front and rear axles for the cabin. If an electric vehicle is developed based on a front-wheel drive fuel-based platform or if a new pure electric platform adopts an old structure design, a protrusion structure such as that found in the Toyota bZ platform may occur.

Its cause is that the front steering mechanism and steering linkage are located behind the front axle, occupying the space for routing the high pressure line behind, so a protrusion must be added to “support” the line. The location of the steering linkage behind the front axle is a by-product of the transverse front-wheel drive engine being positioned ahead of the front axle, a historical legacy issue.

The left and right sides of the battery pack structure can also illustrate the issue. The actual structure of the battery pack is located inside the tire and leaves plenty of collision protection space, which is common among automakers just starting to develop electric vehicles. BMW also took a conservative approach in the iX3, but extended the battery pack outward to increase interior space in the i4 and iX.

The left and right sides of the battery pack structure can also illustrate the issue. The actual structure of the battery pack is located inside the tire and leaves plenty of collision protection space, which is common among automakers just starting to develop electric vehicles. BMW also took a conservative approach in the iX3, but extended the battery pack outward to increase interior space in the i4 and iX.

At the same time, the anti-collision structure on the side of the bZ platform’s battery pack is clearly independent of the body floor structure, suggesting that this structure and the vehicle’s anti-side impact are not completely unified in design, which may affect the vehicle’s weight and ultimately impact energy consumption and range.

Although the Toyota bZ platform is a newly launched pure electric platform and is widely regarded as Toyota’s first exclusive pure electric platform, it still shows many remnants of combustion engine vehicle structures. The reason for this is another larger topic.

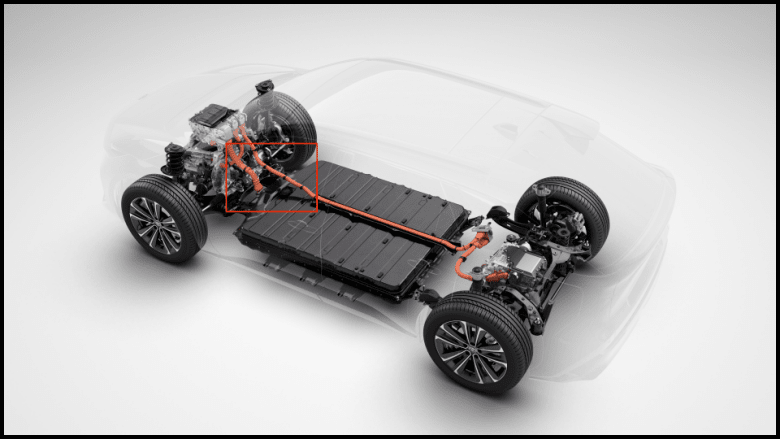

Honda recently launched its own pure electric plan, announcing two pure electric e:N platforms at once: e:N F and e:N W. e:N F only provides front-wheel drive, while e:N W has both rear-wheel drive and all-wheel drive configurations. When you see the electric platform associated with front-wheel drive, you should be very cautious.

Upon closer inspection, e:N F and Toyota bZ have the same rear steering rod, and there is even greater space between the front axle and the battery pack on e:N F. This means that Honda’s electric vehicles built on the e:N F platform will never have the same range as true pure electric platform models of the same size. Under such constraints, whether it is a true pure electric platform or not is no longer of much importance.

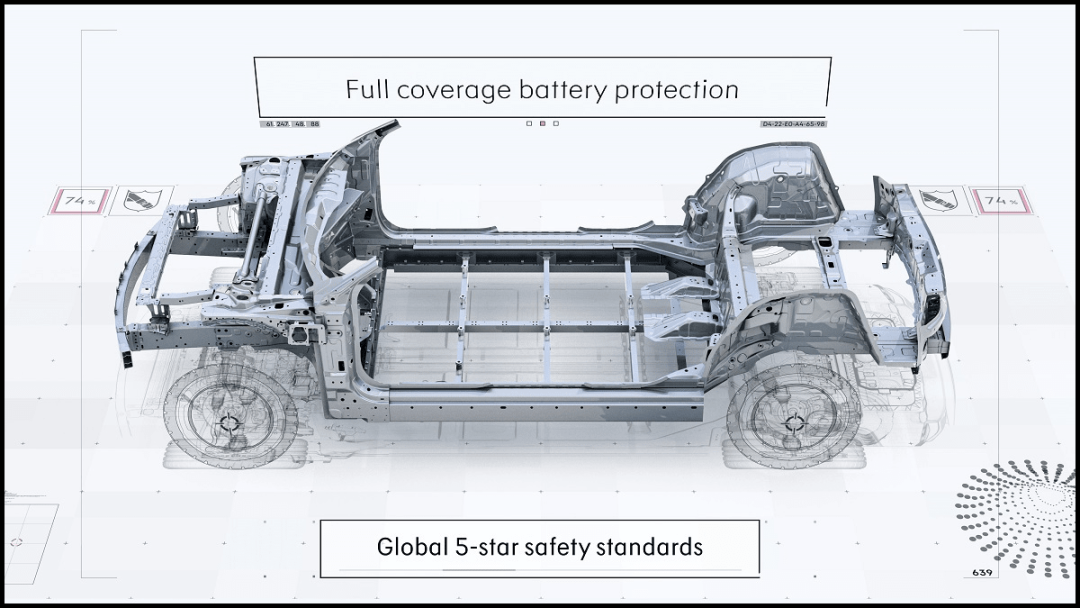

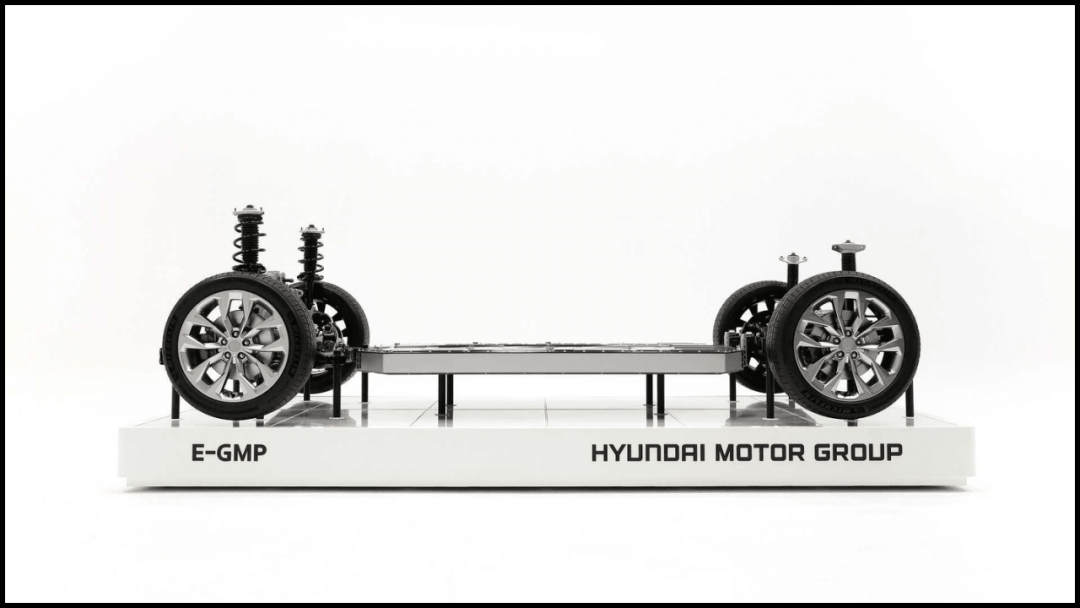

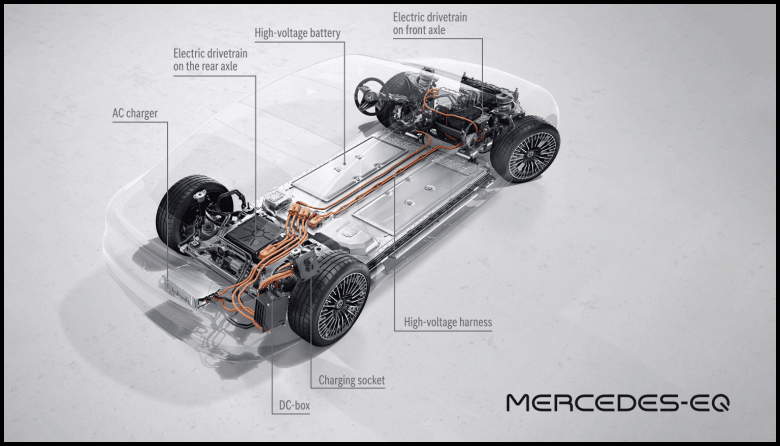

On the other hand, the major pure electric platforms such as Volkswagen’s MEB, Hyundai’s E-GMP, GM’s Ultium, and Geely’s SEA (PMA-1) have similar features: unusually regular single-layer flat batteries, maximum interior space between front and rear axles, smaller front and rear suspension, and no unnecessary body structures.

The Volkswagen Group’s two pure electric exclusive platforms, MEB and PPE, can serve as examples. Both adopt a fully flat battery pack design, which means that the body bottom no longer has the concave-convex structure of a fuel car, and the battery layout is not restricted. Both have chosen a more convenient rear fast charging interface, so they can achieve a high-pressure system rear position with a shorter wire harness and incidentally have a rear-drive-based driving system. As rear-drive is the main focus, the inexpensive rear suspension structure is no longer applicable, and both are equipped with a five-link rear suspension.

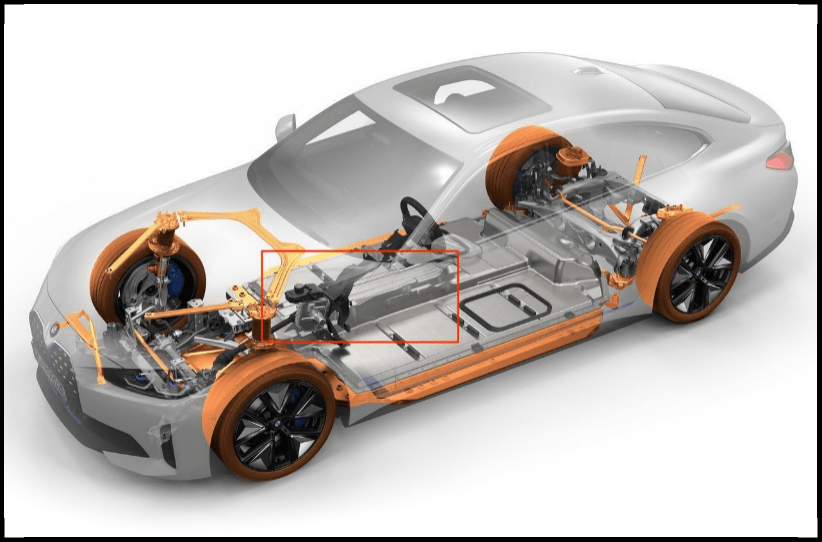

The MEB platform focuses on the mid-to-low-end market, while the PPE is aimed at the mid-to-high-end market. The main differences between the two (currently known) are that the MEB only opted for a Macpherson structure front suspension, whereas the PPE naturally requires a double-wishbone front suspension. In addition, the MEB’s battery selection mainly relies on changing the number of battery modules to change the charge quantity, while the PPE provides more flexible options for battery height and vehicle ground clearance, which can adapt to a wider range of vehicle heights and is advantageous for Audi and Porsche in developing coupe models.

The changes brought about by pure electric drive to automotive design are fundamental, and even today, it is inconceivable that people have fully explored the definitive form of the pure electric era. To truly unleash the full potential of electric vehicles under current technological conditions, a dedicated platform that thinks entirely from a pure electric perspective is an essential prerequisite.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.