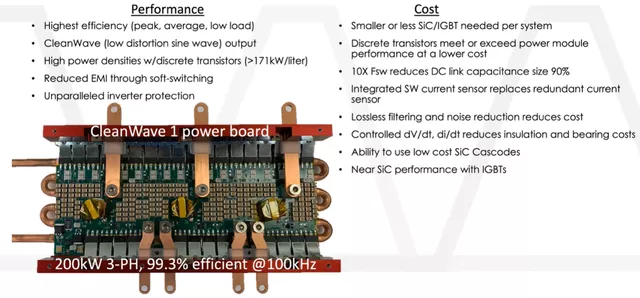

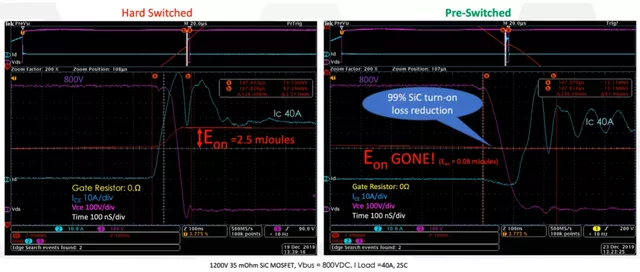

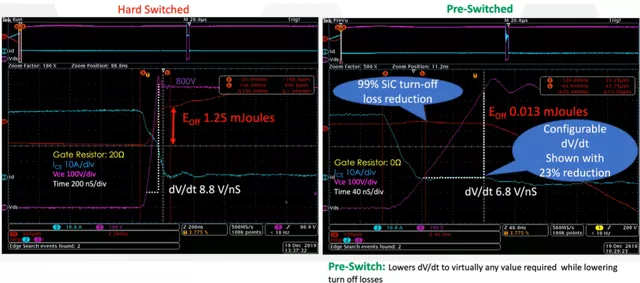

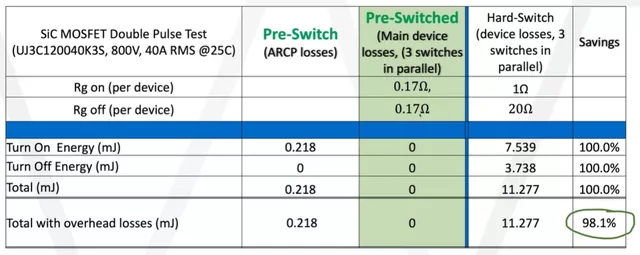

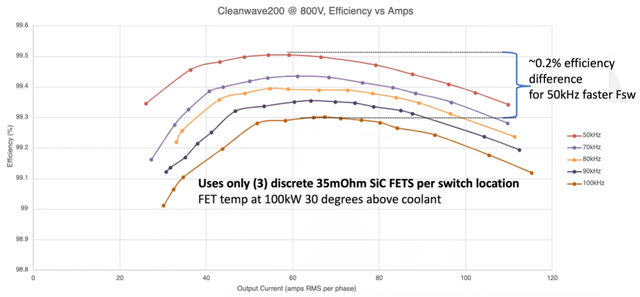

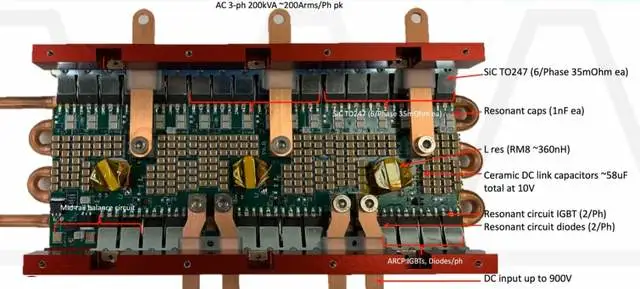

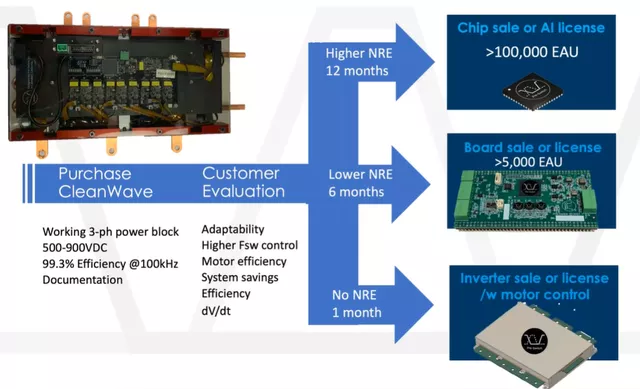

Recently, I have undergone a complete transformation and started exploring on a large scale globally. I believe that the automotive industry is undergoing a period of transformation, characterized by new technologies providing different answers through different approaches. For example, Pre-Switch uses AI to control the SIC device and increase the inverter switching speed, reducing driving system losses and achieving greater EV range. According to the company’s test data, the peak efficiency of the inverter can exceed 99.3% at 100kHz (SiC 35mΩ MOSFET).

Now let’s take a closer look at how this company operates.

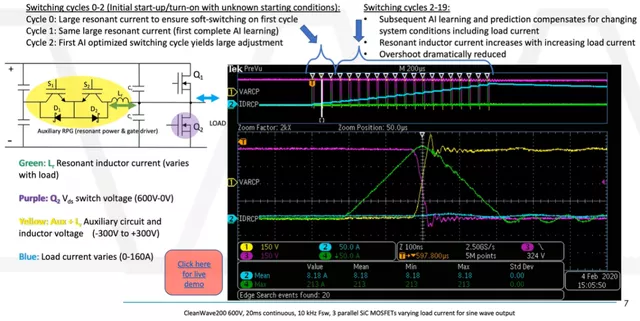

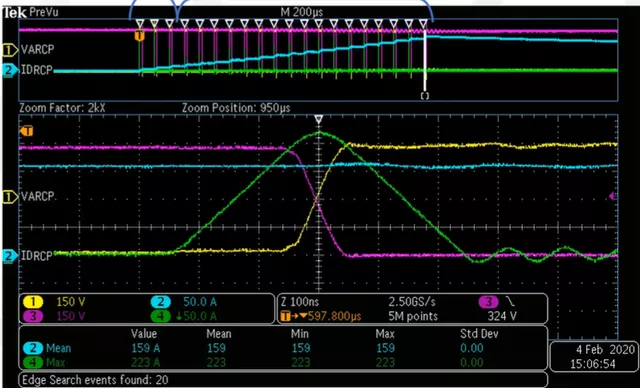

Operating Mechanism and AI Performance

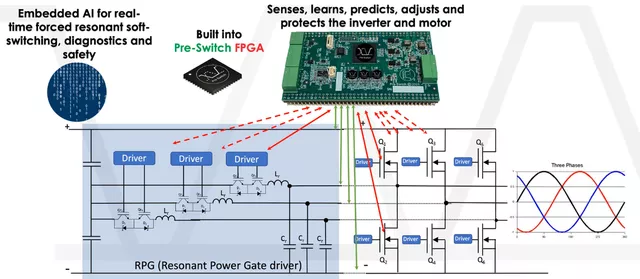

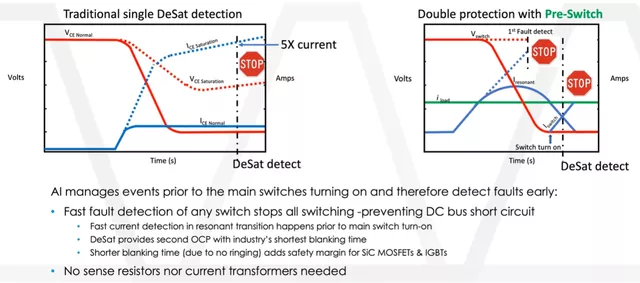

In essence, this system is an integrated algorithm drive circuit that chipizes the inverter controls. It includes two control components, one for driving existing SiC and the other for driving Resonant Power Gate for resonant power.

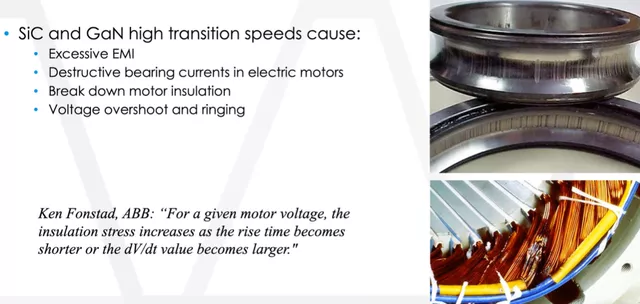

The application of SiC and Gan requires higher requirements for engineers because of EMI, 800V shaft voltage corrosion, overcharge voltage, and ringing effects.

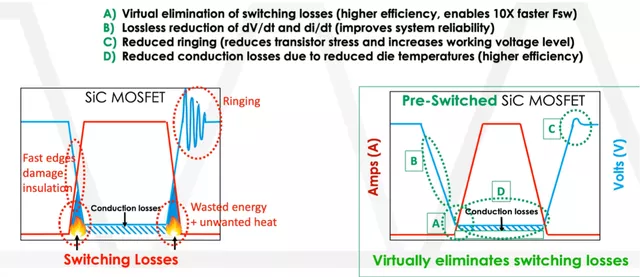

I really like this company’s idea, mainly because it provides a systematic solution to package and solve problems, reducing switching losses, dV/dt and di/dt, ringing effects, and conduction losses at different stages of the switching process.

Note: This company actually has cognition of this field, and we need to verify its reliability with a sample.

This comparison has some meaning compared to poor students.

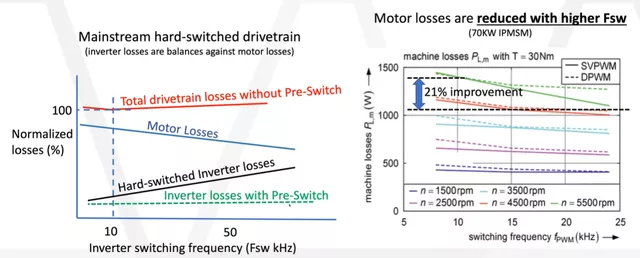

All of the above is related to the inverter, which can reduce motor losses by improving inverter control.

My previous idea was wrong. Based on SiC, with the improvement of technology, various means can gradually widen the gap with IGBT, and traditional methods can be used to control the third-generation semiconductor, but new technology and new methods can achieve greater improvement.

“`

“`

Summary: I look forward to domestic engineers breaking through themselves and pushing up the limits of new generations of power semiconductors, continuously improving the energy efficiency of electric vehicles. This is an acceleration process for the development speed of our entire industry.

“`

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.