This article is reproduced from the autocarweekly public account.

Author: Ao Ao Hu

Apart from the Internet-famous “cloud rating” car accident time, the car body shell is perhaps the least noticed thing on a car.

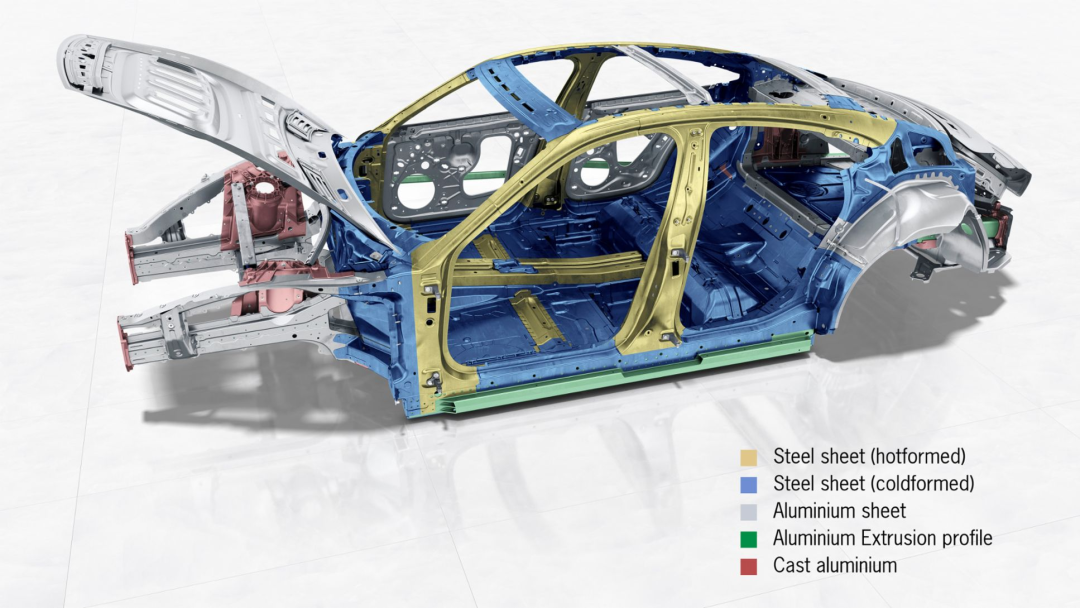

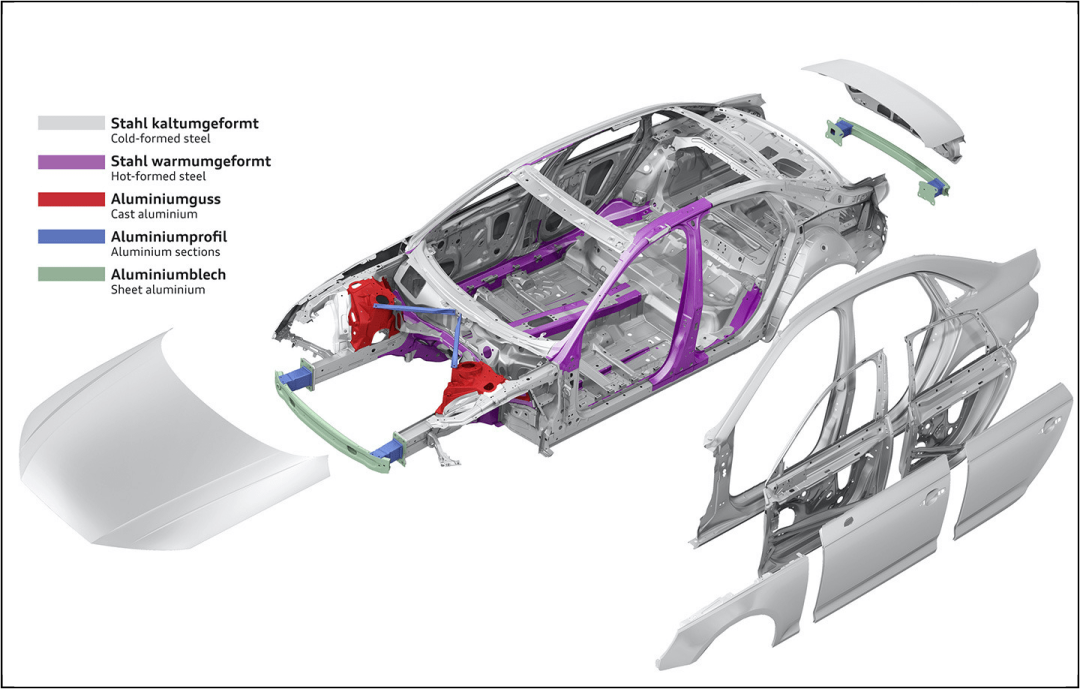

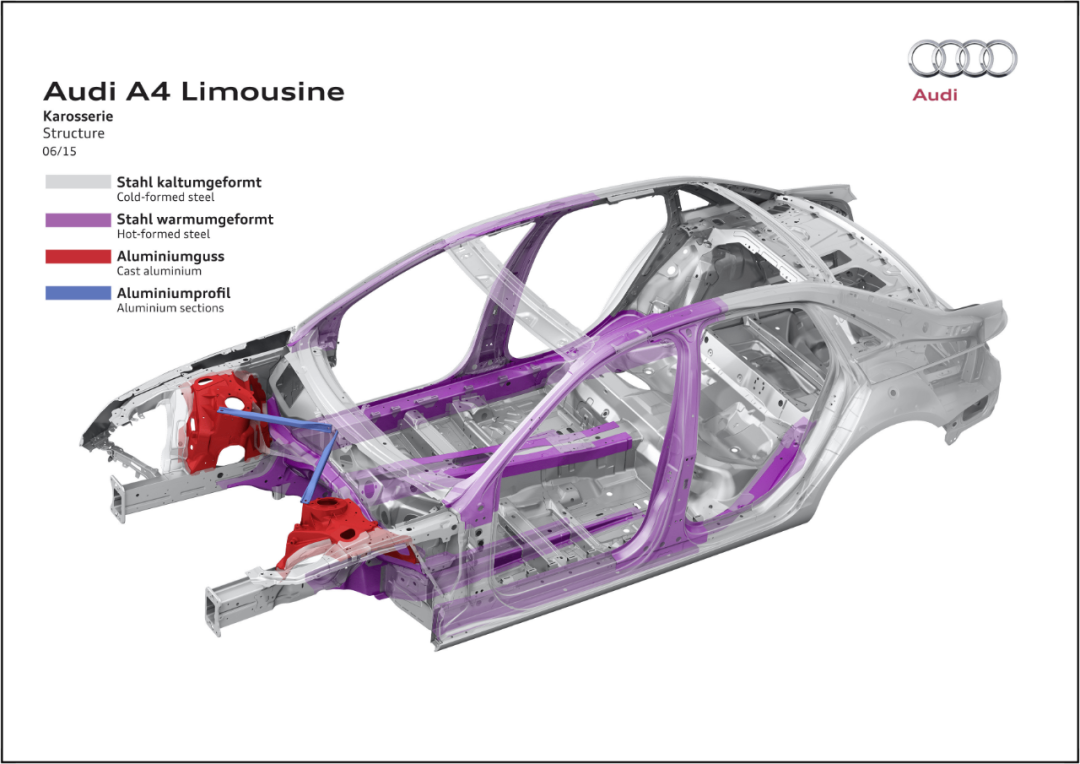

Although most reputable car companies include a few body structure diagrams in their media kits, and often display bare car bodies at release events, to many industry insiders, these colorful and incomprehensible things are often nothing more than a passing glance.

People are concerned about how much horsepower the engine has, how much fuel and electricity it consumes, how many inches the car’s large screen is, how many luxury features it has, and whether it performs well in terms of comfort… Who would have thought that the seemingly ordinary and unchanging iron shell would also affect all of this?

Revealing the True “Shell”

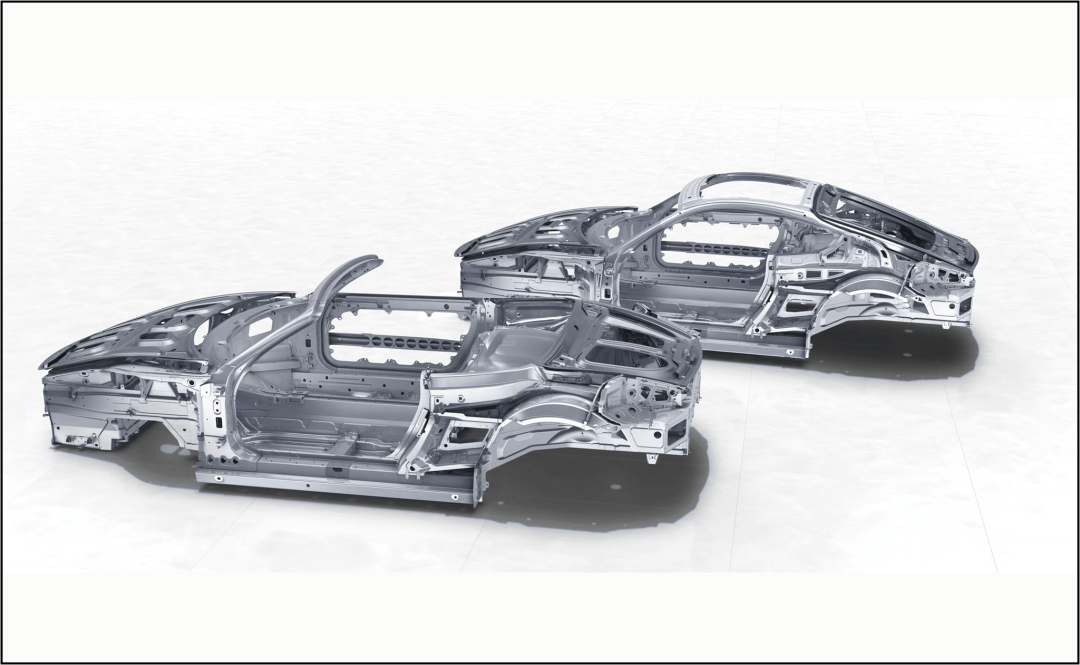

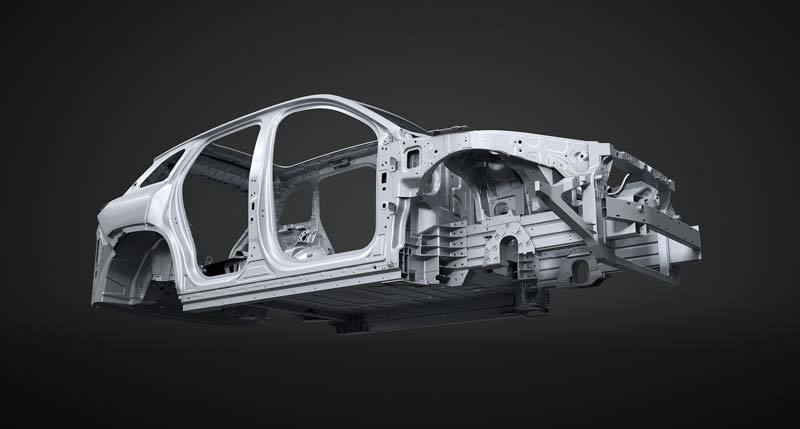

What we often refer to as the “body-in-white (BIW)”, refers to the entire car body structure that has been stamped and welded but not painted, commonly known as the “car shell” or “car frame”.

Generally speaking, the context of including or excluding covering parts needs to be distinguished when referring to the scope of the BIW. The covering parts of the body, such as doors, front hood, tailgate/trunk lid, fenders, etc. (commonly known as the “four doors and two lids”), are usually not involved in the construction of the vehicle’s stiffness. In other words, they are the true “just a shell”. Whether a fender or bumper is dented by a bicycle has nothing to do with the safety of the vehicle.

The connection between the car door and the body itself only has a few points such as pivot and lock, which cannot “help” with the vibration and deformation of the car caused by external forces. (However, covering parts do have some effect on collisions, such as most car doors having collision beams inside. Here, it is necessary to distinguish between “stiffness” and “strength.” Please refer to “99% of people don’t know that ‘stiff’ and ‘strong’ are two different things” for more information.)

The covering parts, like the interior of a vehicle, can be affected by the vibration of the body. As they are easy to replace and do not affect the original design of the body structure, there is sometimes a phenomenon of “aluminum replacing steel” when introducing overseas models in China (this point is not to be discussed). However, since the covering parts have almost no effect on the stiffness, the main damage caused by such changes is in weight reduction.

The covering parts, like the interior of a vehicle, can be affected by the vibration of the body. As they are easy to replace and do not affect the original design of the body structure, there is sometimes a phenomenon of “aluminum replacing steel” when introducing overseas models in China (this point is not to be discussed). However, since the covering parts have almost no effect on the stiffness, the main damage caused by such changes is in weight reduction.

Covering parts account for 1/4-1/6 of the total weight of the body, and the extremely lightweight supercars may have even less. Some performance vehicles use aluminum, and even carbon fiber for door panels, front and rear covers, and roofs. However, due to the covering parts themselves not weighing much, the actual effect of weight reduction and reducing the center of gravity is limited (especially compared to the visual effect). For example, the carbon fiber roof of the Lexus LC only lowered the center of gravity of the vehicle by 1.2 mm.

In general, unless specifically emphasized, the “white body” we refer to is the narrow concept of the body without covering parts.

The Stiffer, the Quieter?

Setting aside the covering parts of the body, the core structure of the white body is the main focus.

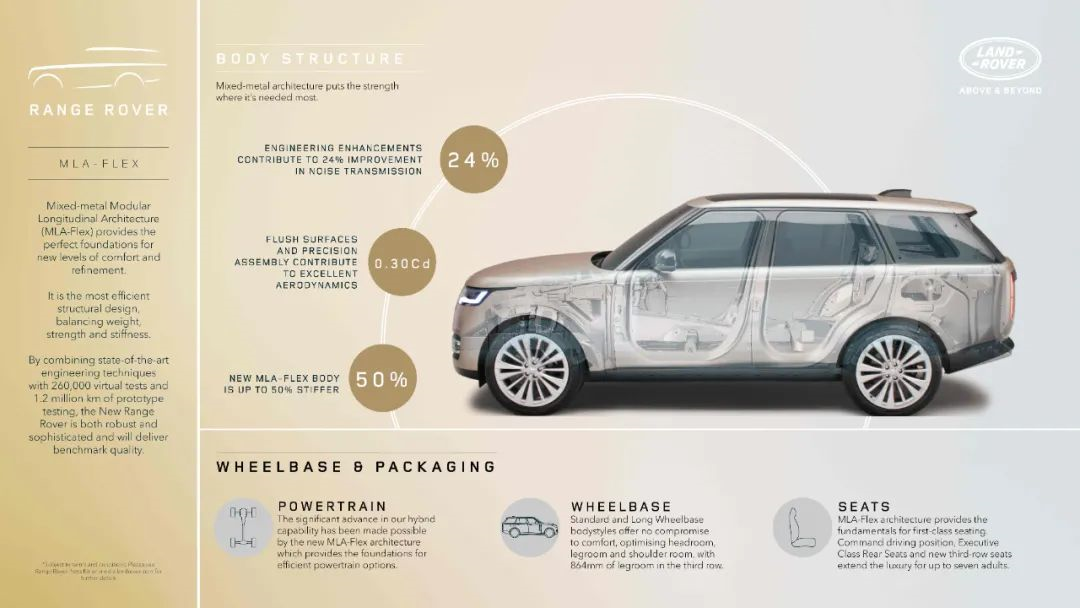

Stiffness is one of the most important performance indicators of the white body, especially torsional stiffness. This is also the performance data most easily obtained from the mainstream market channels, especially for manufacturers who go all out on white body performance. NIO has always been proud of its astonishing data of up to 44,140 N·m/° (which is indeed quite high), while Magna’s BAIC ArcFox often boasts its body stiffness of 55,000 N·m/°.

(However, it should be noted that electric vehicles have a natural advantage in the stiffness war.)

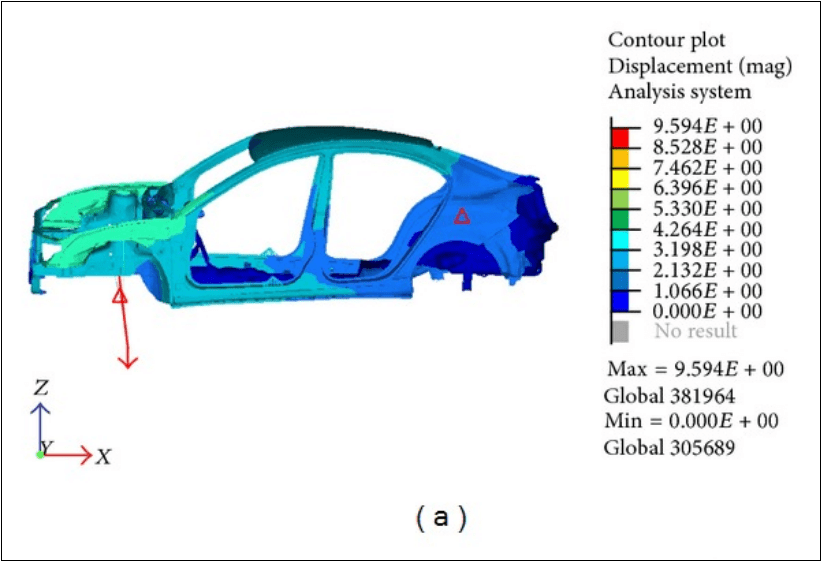

The so-called stiffness refers to the ability of the body to resist plastic deformation caused by external stress. 44140 N·m/° means that a torque of 44,140 N·m needs to be imposed to cause a one-degree torsional deformation of the body. Obviously, the higher this number, the stronger the body’s ability to resist deformation, and the smaller the deformation under the same external force.

During the process of vehicle operation, the bumpy road surface and mechanical operation will continuously exert stress on the vehicle body. From a macro perspective, the body is a sturdy steel cage, but from a micro perspective, the body undergoes almost constant micro deformation. In extreme situations such as racetrack racing or off-road rescue, body deformation may expand to macroscopic effects.

Some SUV manufacturers will drive their cars on a cross-axis, with diagonal wheels on the ground, to test whether the doors can be opened and closed normally. Don’t laugh, there are many SUV models that either cannot open the doors due to deformation of the body (door frame) or cannot close them after they are opened (it takes normal road surface to close the doors). This is the amplification and visualization of body deformation.

Some SUV manufacturers will drive their cars on a cross-axis, with diagonal wheels on the ground, to test whether the doors can be opened and closed normally. Don’t laugh, there are many SUV models that either cannot open the doors due to deformation of the body (door frame) or cannot close them after they are opened (it takes normal road surface to close the doors). This is the amplification and visualization of body deformation.

The same applies to track racing. The deformation of the body during extreme driving is enough to cause the front and rear suspension to deviate from the original settings. Therefore, for high-performance and super sports cars, body rigidity is also of utmost importance, which is why aluminum and carbon fiber are favored by supercars, mainly because they balance lightweight and body rigidity.

Back to non-extreme situations.

For ordinary people like us, body rigidity significantly affects a car’s NVH performance, which translates to vibration, noise, quietness, and comfort in daily contexts. When choosing a test drive, you may not have thought that comfort, the most familiar dimension to all, is affected not only by engine noise, sound insulation measures, tires, and wind resistance, but also by the body.

This is because the rigidity of the body directly determines the modal frequency of the body. The so-called modal frequency is a crude understanding of the inherent vibration frequency of the body. In a high school physics class, the PE teacher told us that every object has a natural frequency, and when the frequency of external stimulation approaches this natural frequency, resonance will occur, causing a significant increase in vibration energy. Once there was a group of soldiers crossing a bridge, and the bridge collapsed suddenly when they were walking on it due to resonance.

The higher the stiffness, the higher the modal frequency. This is easy to understand. The harder something is, the less likely it is to deform, and the higher the frequency required to make it resonate. On a paved road, the vibrational excitation frequency from the road is positively correlated with the vehicle’s travel speed. Therefore, the more attention paid to cruise comfort and high-speed comfort, the higher the modal frequency and stiffness of the white body needed.

In addition to wind noise, tire noise, and engine noise, structural noise is also an important component of the noise in the vehicle during its normal operation. If you find that a car vibrates severely like a vibrating rod every time it reaches a certain speed, it is an obvious structural noise caused by resonance.

If the body’s stiffness and modal frequency are too low, the vibration excitation from the road at normal speeds may cause the body to approach its natural frequency and produce resonance. The newer the generation of cars, the more high-end luxury cars, and the more comfort-oriented models, the higher the necessary stiffness and modal frequency to push the resonant speed of the vehicle as far from the legal speed limit as possible.

Why do luxury cars often “unconsciously” drive fast, why do cheap cars often feel scared at a not-so-high speed, why do luxury cars with the same performance have less “speed sense” than small cars, and why do “GT” models that emphasize high-speed cruising become a totem – not only because of psychological effects.

In addition, a considerable part of the interior noise comes from the vibration and friction between interior components. Therefore, if the body stiffness is higher, the deformation and vibration will be smaller, and engineers can allow smaller clearances between interior components, which in our eyes means “better workmanship and more delicate”. This is also one of the reasons why manufacturers, especially luxury carmakers, increase body stiffness.

The never-ending stiffness war

The principle of “you get what you pay for” applies broadly in terms of the big picture. In a horizontal comparison, high-end cars often have higher body stiffness than cheap cars during the same period. In a vertical comparison, the seemingly calm body manufacturing industry has never stopped the war of stiffness over the past century.

Today, the stiffness of the majority of mainstream mid-sized cars is in the range of 20,000 to 35,000 N·m/° (very inexactly, only for rough reference), and an excellent body can approach 40,000 N·m/°, while above 40,000 N·m/° belongs to the realm of executive luxury cars such as the Mercedes-Benz S-Class, BMW 7 Series, and Audi A8.

(It is generally divided into torsional stiffness and bending stiffness when measuring body stiffness, and there is also a distinction between static stiffness and dynamic stiffness, but for ease of understanding, we will not distinguish here.)

It should be noted that different body types have natural differences in terms of stiffness. For example, as mentioned in “Why aren’t liftbacks popular?” earlier, it is more difficult for liftbacks like two-door cars, wagons, and SUVs to achieve the same body stiffness as three-box cars. Convertibles are even more difficult because they have no upper structure – whether it’s a soft top or hard top, it’s just a “shed” that doesn’t contribute to stiffness – and stiffness will inevitably be at the bottom under the same technical and cost conditions.

So you can also understand why the representative model of “most comfortable” has always been a three-box sedan.

Pure electric vehicles bring another exception. Because an electric vehicle needs to install a battery pack in the bottom of the vehicle, the robust battery case, tightly protected by a steel shell, inadvertently becomes a stiffness “buff” for the electric vehicle body. For example, as mentioned earlier, NIO and Jinkou have easily exceeded the “40,000 yuan mark” of S class/7 series/A8 with much lower prices.

It’s easier to explain the problem by converting fuel to electricity: the torsional rigidity of the BMW X3 fuel version body is about 25,000 N・m/°, while the pure electric version iX3 with the battery pack directly reaches 52,500 N・m/°, and the Audi e-tron is also up to 50,000 N・m/°. Despite their much lower prices than executive sedans, NIO and Jinkou are not losing money.

The so-called pure electric vehicle is the future, and “environmental protection” is just one of the reasons, not all of them. However, not all electric vehicles have realized the “stiffness dividend”, and some have given up the stiffness advantage in exchange for material costs savings. The conclusion of overall comparison needs to be specifically analyzed at the individual level.

What determines the high or low stiffness of the structure? Cross-sectional area, material thickness, and elastic modulus are the only three factors.

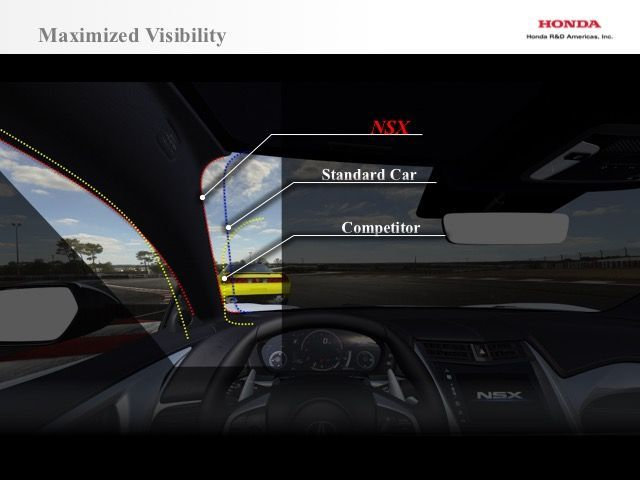

Cross-sectional area, such as the overall width of the A-pillar and the overall height of the threshold, thicker “pillars” contribute more to stiffness; material thickness, a 2 mm steel plate made of the same cross-sectional area is definitely stiffer than a 1 mm steel plate; as for the elastic modulus, it is determined by the material characteristics itself.

The elastic modulus has an interesting feature: it is almost only related to the chemical composition of the material. You should know that automotive steel often comes in different strengths, but whether it is high-strength steel or low-strength steel, their elastic moduli are almost the same. In other words, all descriptions that directly attribute “the use of high-strength steel in large quantities” as the direct reason for “good body rigidity” are wrong and can be ignored.

It’s not easy to improve stiffness. These three factors are not “easy ones”. Increase the cross-sectional area? The A-pillar, B-pillar, and C-pillar are related to visibility and blind spots, while the height and width of the threshold will make it difficult to get on and off (that’s why supercar thresholds are wide), the transverse and longitudinal beams inside the vehicle body affect the space of the engine compartment and passenger cabin.Increase the material thickness? Using steel and just thickening it will lead to a heavier car body. To achieve the same performance, a larger power system is needed. A larger engine and heavier car body will increase fuel consumption. To reduce car weight and fuel consumption, luxury equipment must be removed or sound insulation and shock absorption measures reduced – the problem then returns to comfort.

Replacing materials? It is possible to replace steel with aluminum and aluminum with carbon fiber. Although the elastic modulus of aluminum is only 1/3 that of steel, it has a lower weight/density ratio and can have a greater thickness, thus achieving high rigidity (carbon fiber is similar but better and more expensive). However, the cost of aluminum is several times that of steel, and the cost of carbon fiber starts at tens of times that of steel. If it is a steel-aluminum hybrid, other connection technologies need to be welded, and the production line needs to be adjusted, which increases cost.

As I always say: there is no such thing as a free lunch.

The car body is important because it determines, even defines, a car’s innate characteristics. For example, stiffness and mode determine the starting point of NVH, and even though various sound insulation and vibration reduction measures can be used to improve the final performance of NVH, investment or sacrifices in other areas such as weight, cost, and technology are always required.

For example, the degree of lightweighting of the car body determines the basic performance and energy consumption of the vehicle, and of course, various weight reduction measures and more efficient power systems can be used in the future. Still, a lightweight white body that meets the requirements does not require sacrificing part of the luxury equipment, using more advanced and more expensive technology as a cost.

That is why I say that the technological level and performance of the white body, as a foundation, determine the possible range of all aspects of the entire vehicle: where the floor is, and where the ceiling is. It’s a bit like a bachelor’s degree, which is not absolutely important. If the undergraduate school is not good, there is still the opportunity to take postgraduate entrance exams, and ultimately, it depends on actual ability in the society. But from a macro perspective of society, a higher starting point for education will generally lead to a more successful life that conforms to success psychology.

The car body is a foundation, but it is only a foundation; conversely, it is only a foundation, but it lays the foundation for everything.

As a consumer, it is difficult to accurately understand the performance of a certain car’s white body, and even automotive media practitioners mostly cannot obtain sufficient information. For example, the modal frequency of the car body will not appear in any publicly available materials provided by any car company. Thankfully, car body stiffness has begun to receive attention in recent years, but it is only limited to manufacturers that invest heavily in car bodies and have good performance and are willing to present them as endorsements of technological level.However, as a translator in the automotive industry, you must understand that the car body plays an essential role and has significant significance for a car, no less than other aspects that people commonly discuss. Despite this, “the shell of the car” is consistently undervalued due to reasons such as indirect impact, difficulty explaining, lack of sex appeal, and not being explosive, so everyone collectively ignores it.

If you realize all of this, it is necessary to recognize dialectically that the car body should not be overemphasized as being absolutely important; in reality, there is nothing that is “absolutely important.” Similar to power, transmission, suspension, and so on, the car body is just one of the subsystems that comprise and define an automobile. And what we eventually want is a complete car.

Strategically, we should attach importance to the car body, but on a tactical level, it should be viewed equally as other subsystems.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.