Author: Xiaodong Xu

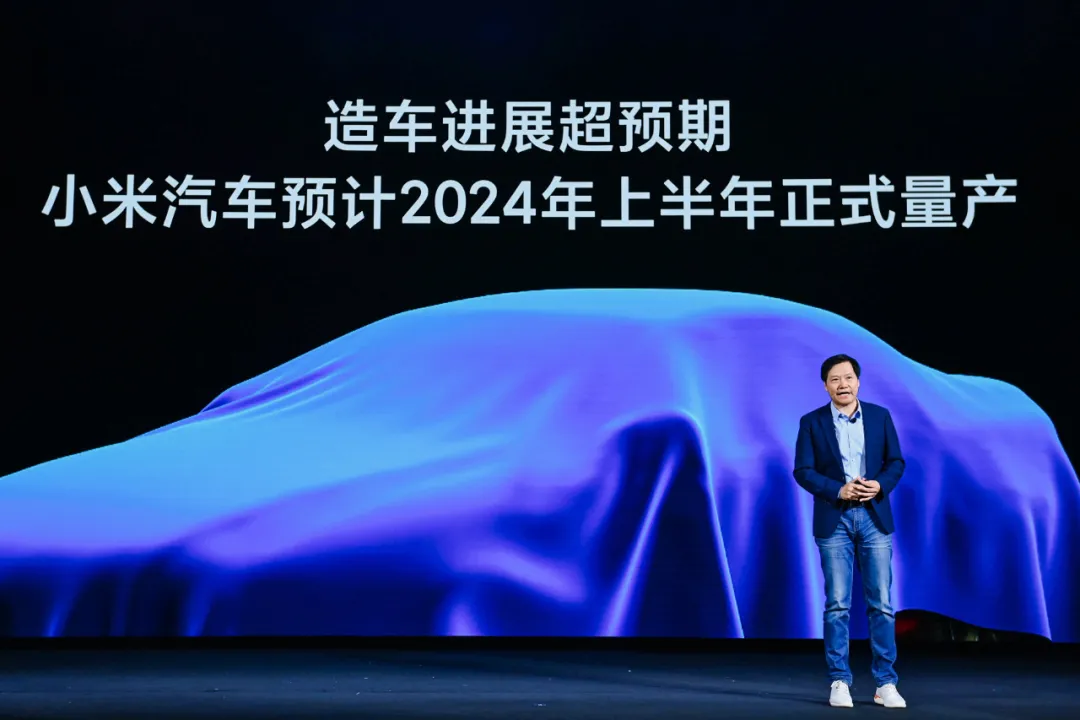

On October 19th, Xiaomi Group Chairman Lei Jun announced at an investor day conference that the progress of Xiaomi’s car-making and team work far exceeded his expectations, and Xiaomi’s car is expected to enter mass production in the first half of 2024.

Is entering mass production in the first half of 2024 a fast pace? Xiaomi entered the electric vehicle industry in 2021, will it be able to keep up? And what challenges will Xiaomi’s new energy vehicles face in the market?

First, let’s talk about how cars are transformed from flat blueprints to three-dimensional models.

Is 2024 Fast Enough?

At the investor day conference, the car covered with blue cloth behind Lei Jun also attracted the attention of many netizens, but careful netizens found that it was an image that could be directly bought online.

Obviously, Xiaomi’s car-making plan is still in an early stage, with no specific car model design, nor even a concept map. With only two years left until the first half of 2024, is it reliable for Xiaomi to enter mass production?

Let’s take a look at the process of making a car first.

Firstly, product planning, which is the stage Xiaomi is currently in. Product planning is the analysis of future market demand, deciding what type of car to make based on market research, and determining the production target and direction. This generally takes about six months or more.

Previously, from a number of public information sources, we also learned that Lei Jun visited BYD in April, SAIC-GM’s Wuling Hongguang Mini in May, and then visited Great Wall Motors, SAIC passenger cars, and FAW, among others.

According to Xiaomi, from the announcement of car-making to the formal announcement of the independent company on September 1st, the Xiaomi automotive team conducted a large number of user surveys and industry chain investigations, conducted more than 2000 interviews, visited more than 10 industry peers and dozens of industry partners, and promoted the definition of Xiaomi’s automotive products and the building of the team.

Therefore, the first stage of car-making, which is product planning, should be pretty much ready for Xiaomi.

Then, it comes to the most critical stage of vehicle development, which generally takes about 12-14 months. This stage involves the development of the power system, chassis development, and so on. During this period, we can first see the offline delivery of the mules. The main purpose of the mules is for early verification of chassis, structural parts, under-body and safety parts.

After the donkey car stage, the vehicle’s design scheme is determined, which means that the appearance is now simulated during the model car phase. At this stage, the shape of the vehicle’s interior and exterior is roughly determined, but the vehicle’s components are still assembled from handmade samples and soft models. This stage is basically referred to as a “car”. We can refer to Jidu Automobile in this stage. In March, Jidu hired former Cadillac designer Frank Wu to lead its design studio. On July 7th, Baidu CEO Robin Li visited Jidu’s first model clay. Two months later, Jidu’s simulated car model appeared in Anting, Shanghai. And on that day, Jidu had been established for only 207 days.

After the donkey car stage, the vehicle’s design scheme is determined, which means that the appearance is now simulated during the model car phase. At this stage, the shape of the vehicle’s interior and exterior is roughly determined, but the vehicle’s components are still assembled from handmade samples and soft models. This stage is basically referred to as a “car”. We can refer to Jidu Automobile in this stage. In March, Jidu hired former Cadillac designer Frank Wu to lead its design studio. On July 7th, Baidu CEO Robin Li visited Jidu’s first model clay. Two months later, Jidu’s simulated car model appeared in Anting, Shanghai. And on that day, Jidu had been established for only 207 days.

Of course, Xiaomi’s speed cannot compare with Jidu’s. Strictly speaking, Jidu is not purely a car company that starts from scratch. Its first model is based on the Geely SEA platform, which has a solid engineering foundation. This is a first-mover advantage that Xiaomi cannot buy even if it spent all its money.(Pictures are excluded in this paragraph)

In the next stage, the engineering test car should be launched, marking that the whole vehicle development has entered the mature stage. The engineering research and development part has been completed and entered the testing and verification stage. At this stage, the vehicle’s parts have also changed from handmade samples and soft models to large-scale production of hard model parts.

There are also a variety of durability tests, such as high-altitude testing, high-temperature testing, high-altitude testing, and so on. These tests will also take 6-12 months. For example, the Nio ET7 completed high-altitude testing on the Sichuan-Tibet Line on October 19, and the delivery time of the ET7 is scheduled for the first quarter of next year.

Finally, it is time to prepare for mass production. Every aspect of the inspection of the factory production line, such as whether the gap between the car doors is large, and whether the sealing rubber strip is firm, will be checked. After these adjustments and verifications are completed, it means that the entire vehicle development is completed and it is about to be delivered. The time from production to delivery is getting faster and faster. For example, the mass-produced cars of Zeekr 001 and XPeng P5 went offline around October 20th, and both cars were planned to be delivered at the end of October.

Of course, the above-mentioned details that I mentioned are only the tip of the iceberg in the entire car-making process, and there are many processes that have not been mentioned. The engineers work hard, and I want to give them a thumbs up.A car usually takes about 4 years from design to mass production. However, nowadays the process can be faster. Taking NIO as an example, NIO ES8 was proposed in June 2015 and delivered in June 2018, lasting 36 months. NIO has adopted some strategies to accelerate the research and development process, such as building a whole vehicle trial production line at their NIO electric drive factory in Nanjing to verify the work.

Currently, NIO is also accelerating the product landing speed by spending money to buy time through strategies such as conducting high-altitude tests of ET7 in the cold region of China’s Heihe and sending the test results to New Zealand in the southern hemisphere.

Xiaomi announced the production of cars in late March 2021, and will start mass production in the first half of 2024. As a newcomer to the car industry, Xiaomi is already moving at a relatively fast speed. It is expected that Xiaomi will spare no effort in the areas where they can “buy time with money”.

Lei Jun announced at an investor meeting that Xiaomi’s progress in car production exceeded his expectations, which is reasonable.

Now let’s talk about whether Xiaomi is too late to enter the market.

The answer is clear, it’s not too late.

For a pure electric car company, there are three most important aspects: organization, products, and manufacturing.

In terms of organization, Xiaomi has included “Mr. Key” Hu Zhengnan, who used to be the President of the Research Institute, Senior Vice President, and Director of the Product Technology Management Committee at Geely Automobile. He was responsible for developing the Geely Haohan SEA architecture, which was first implemented in the Zeekr 001.

At the same time, Xiaomi’s influence will undoubtedly attract many top talents. Lei Jun himself is offering double the salary compared to traditional car companies and there is a possibility of independent listing of Xiaomi’s automobile sector in the capital market, making them more attractive to high-profile talents. Xiaomi Group also held an extraordinary general meeting of shareholders on October 25, 2021, approving the adoption of the Xiaomi EV’s stock incentive plan, which grants a maximum of 1 billion shares, accounting for 10% of the total number of shares issued.

On October 28, a job offer from Xiaomi’s car division was circulated online, offering an annual salary of 600,000 yuan and 1 million stock options for senior engineers. Who could resist such an attractive offer?

Lastly, in terms of products, Xiaomi has paved the way for their car manufacturing stage through their previous experiences.Compared to 2015, the supply chain in the smart electric vehicle industry is now more comprehensive and stable.

On the battery front, CATL has consistently held the top spot in global power battery shipments. There are also other domestic suppliers such as BYD, AESC, Guoxuan and CALB, which means there is no need to worry about battery supply. In addition, Xiaomi has invested in Honeycomb Energy, which is involved in both power battery manufacturing and power battery material fields.

Regarding the motor, there is currently no significant difference between different suppliers’ motor solutions, although for special cases such as NIO’s ET7, which requires a high-performance motor with peak power of over 300 kW, self-developed motors may be necessary. However, Xiaomi’s strategic planning will undoubtedly prioritize meeting the needs of the general public for its target sales volume of 100,000 vehicles in the first year. Hence, procurement can fully solve the issue of electric drive.

As for the electronic control, the SiC (silicon carbide) power modules, which are only available with a few manufacturers such as Tesla, BYD, NIO, and Lucid Motors, will become more widely adopted. However, by 2024, Tesla and BYD, who have completed mass production of SiC, may have advanced to the next stage. Xiaomi’s pace is, therefore, crucial.

Overall, Xiaomi does not seem to devote time to self-development in hardware. Instead, it will resort to more direct means by buying its way into solutions.

Compared to the three-electric system, intelligence is the true challenge for Xiaomi, as seen in its related deployment.

In the aspect of autonomous driving, Xiaomi acquired the autonomous driving technology firm Deepmotion as well as invested in the ADAS technology provider Zoomin technology and the lidar sensor provider Hesaitech, for a total of nearly 500 million yuan. However, autonomous driving development may be the most critical step for Xiaomi in making cars.

In July of this year, Xiaomi began recruiting for its autonomous driving department and has now established a team of 300 people, most of whom are former leaders from various internal departments of Xiaomi Group. This highlights the importance of autonomous driving within Xiaomi. Fortunately, with the advancement of technology, the current iteration of autonomous driving technology does not require the same trial and error process as before, which should speed up development.In terms of chips, Xiaomi has prepared in advance. The global chip shortage has also made more automakers realize the importance of chips. Xiaomi chose to start from the source and invested in the vehicle-level MCU company Yuntu Semiconductor. For in-vehicle chips, Xiaomi’s subsidiary, Changjiang Industry Fund, led the investment in Black Sesame Intelligence.

Regarding the smart cockpit, I just want to say that moving Xiao Ai into the car would be perfect 🙂

For Xiaomi, the difficulty of developing a smart cockpit is much lower than the previous items. The core of the smart cockpit lies in the user experience composed of UI, human-computer interaction, and digital ecology. Xiaomi has been deeply rooted in the consumer electronics field for 10 years and has obviously experienced the ups and downs in these areas. The biggest challenge faced by Xiaomi lies in the brand new application scenario of the car and the stricter application conditions for vehicle-level hardware engineering.

In addition, the biggest problem with electric cars at this stage is range anxiety, especially in non-first and second-tier cities and northern cities.

However, in 2024, the popularization of the 800V high-voltage platform, the continuous improvement of basic facilities such as supercharging stations and supercharging piles, and the iteration of CTP and even CTC battery technology will greatly improve the range of electric cars, and the charging speed will far exceed the current level. Range anxiety will be greatly reduced.

This will allow Xiaomi’s first car model to have a good replenishment experience from the birth.

PPT finally lands, mass production is the ultimate test for automakers. Xiaomi has also started early layout in manufacturing.

At Xiaomi’s Investor Day, Lei Jun revealed that the first factory will be located in Beijing Yizhuang. In addition to the factory, Xiaomi also has a big problem with production qualifications. NIO acquired production qualifications through JAC, XPeng earlier acquired them through Haima, later purchased FD’s production qualifications, and started self-production. IDEAL also bought LIFAN’s production qualifications and started self-production.

Similarly, Xiaomi will face this problem. Either outsource production or buy production qualifications for self-production. In addition to the Mercedes-Benz factory, there is no other automotive factory in Beijing Yizhuang. Therefore, it is very likely that Xiaomi will choose to build its own factory for production. So where does the production qualification come from?

Caixin reported that the relevant authorities in Beijing are actively promoting Xiaomi’s acquisition of Baowo’s production qualification, and will transfer Baowo’s 180,000 vehicle production capacity to Xiaomi’s car project. However, Baowo’s factory is in Miyun, and from the current situation, Xiaomi may not necessarily choose Baowo for outsourcing, but it is very likely to acquire Baowo’s production qualifications.

Baowo has dual qualifications for fuel cars and new energy cars, which may be exactly what Xiaomi’s car making needs most now.## Pros and Cons

Apart from the advantage of entering the fast lane of pure electric vehicle development mentioned above, Xiaomai’s fully prepared funding, rapid expansion, intervention from Lei Jun himself, Xiaomi’s own influence, and intelligent and complete ecological chain all give Xiaomai advantages over other startups in car-making.

However, Xiaomai still faces numerous challenges in the market. For example, in the field of intelligent driving, can Xiaomai catch up with the leading companies in less than 3 years?

Looking back at the development of new forces, it took three years to develop NIO ES8 from research and development to market launch, while XPENG P7 took 30 months. Even so, the intelligent assisted driving of ES8 and P7 was still postponed and had to be gradually upgraded through OTA in the later stage.

But that was in 2018 and 2019 when the entire industry had just started with intelligent assisted driving, and consumers had a significant tolerance for it, and the competition was not enough.

By 2024, new force companies, including Tesla and Weichai, are bound to make significant progress in intelligent assisted driving. The white-hot competition in the market will significantly reduce consumers’ tolerance for new brands. For Xiaomai, which has just entered the road of intelligent assisted driving, time is now extremely tight.

Imagine what would happen if a car cannot do even high-speed assisted navigation in 2024, how competitive will they be in the market?

Xiaomai’s product positioning is mid-to-high-end models, which can be inferred from the range of 150,000 to 500,000 yuan, making them direct competitors with Weichai and Tesla.

In 2021, Weichai’s annual delivery volume can basically reach almost 100,000 vehicles. In the next few years, delivery volume will inevitably increase in a step-wise manner with the development of new energy vehicles. For example, Ideon has set a sales target of 1.6 million vehicles by 2025.

Similarly, by 2024, new forces such as Weichai have already gone through nearly 10 years of growth, and the model coverage of segment markets is even more precise.Nio will launch three vehicle models in 2022, and its sub-brand will also appear. XPeng will launch two to three vehicle models annually after 2023, and even plans to produce flying cars in 2024. By 2023, there will be four vehicle models available from Li Auto. The new automakers’ existing models will also receive facelifts. Don’t forget about Tesla, a formidable opponent. The next-gen Model has yet to arrive.

According to reports, Tesla’s Shanghai Gigafactory’s weekly production capacity has reached 14,000 vehicles, equating to an annual production capacity of over 700,000 vehicles.

During Tesla’s Q3 earnings call, Tesla CFO Zachary Kirkhorn stated that Tesla’s annual target growth rate for production capacity in the four major factories in Fremont, Shanghai, Texas, and Berlin is 50%. This means that by 2024, without constructing new factories, the production capacity of just the Shanghai factory may reach 1.5 million vehicles annually. If there are new factories, Tesla’s production capacity in China may be even higher. With such high production capacity and a starting price of RMB 160,000 (USD 25,000) for the Model Next Gen, the market competitiveness of Tesla is self-evident.

Therefore, it is a significant unknown whether Xiaomi’s first vehicle model, which is set to begin production in 2024, will be able to stand firmly in the market. Additionally, Tesla’s comprehensive abilities in vehicle engineering, mechanical quality, and supply chain management cannot be ignored – after all, producing vehicles is vastly different from producing consumer electronics.

As Lei Jun stated, “For Xiaomi’s auto business, the first battle is the final battle!” In this make-or-break battle, let’s wait and see what achievements Xiaomi’s auto business can accomplish.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.