On November 1st, 2021, IM Auto’s first mass-produced model, IM L7, achieved an impressive performance in the product quality inspection test conducted by the National Motor Vehicle Quality Inspection and Testing Center (Shanghai). It recorded a 0-100 km/h acceleration time of 3.87 seconds and a braking distance of 32.69 meters from 100 km/h to a stop, while also demonstrating its maximum sustained lateral acceleration, or “skidpad,” of 0.968 G, showcasing its extreme handling capabilities.

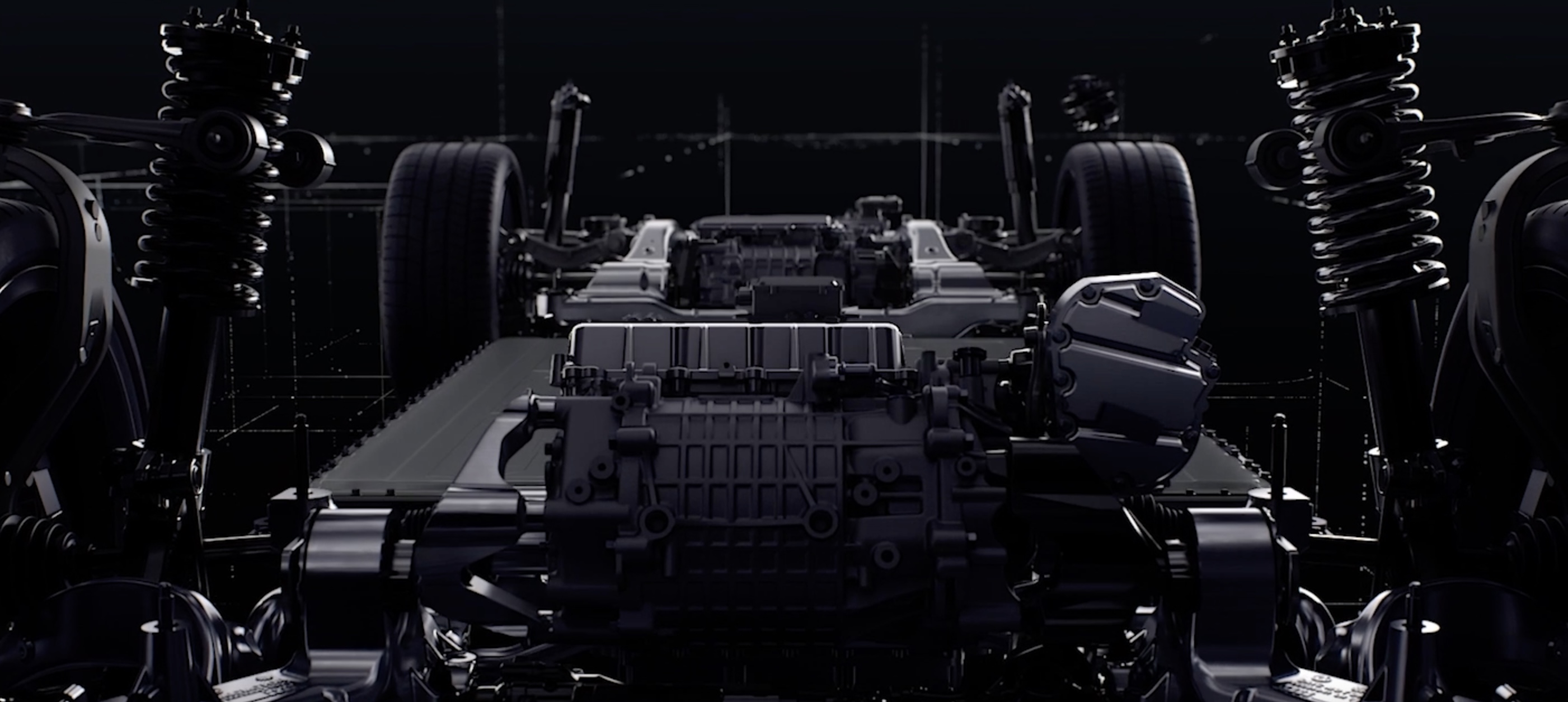

The combined total output of the front and rear dual permanent magnet synchronous motors is 578 hp/725 N·m, equivalent to a high-performance 4.0 T V8 engine in a gasoline car. More than half of the power is output by the main driving motor located at the rear of the vehicle. This motor also adopts advanced technologies that represent high-performance motors, including an 8-layer “hair-pin” flat wire winding and a direct-pour oil cooling system.

Compared with traditional windings, the flat wire winding increases the slot-fill factor by 20%, meaning that the copper wire density is higher, which allows equivalent power to be achieved with a smaller motor volume.

Accelerating quickly in an electric car is not difficult, but maintaining performance continuously requires effort in cooling capability. Compared to other cooling methods, the direct-pour oil cooling design can greatly enhance the cooling performance of the main driving motor. Moreover, the cooling system can achieve active on-demand control and directional lubrication. Such a cooling mode is not only more energy-efficient but also improves the sustainable performance of the motor by 46% compared to traditional water-cooling solutions. Lower heat decay ensures that the IM L7 can achieve more than 10 consecutive 100-kilometer accelerations.

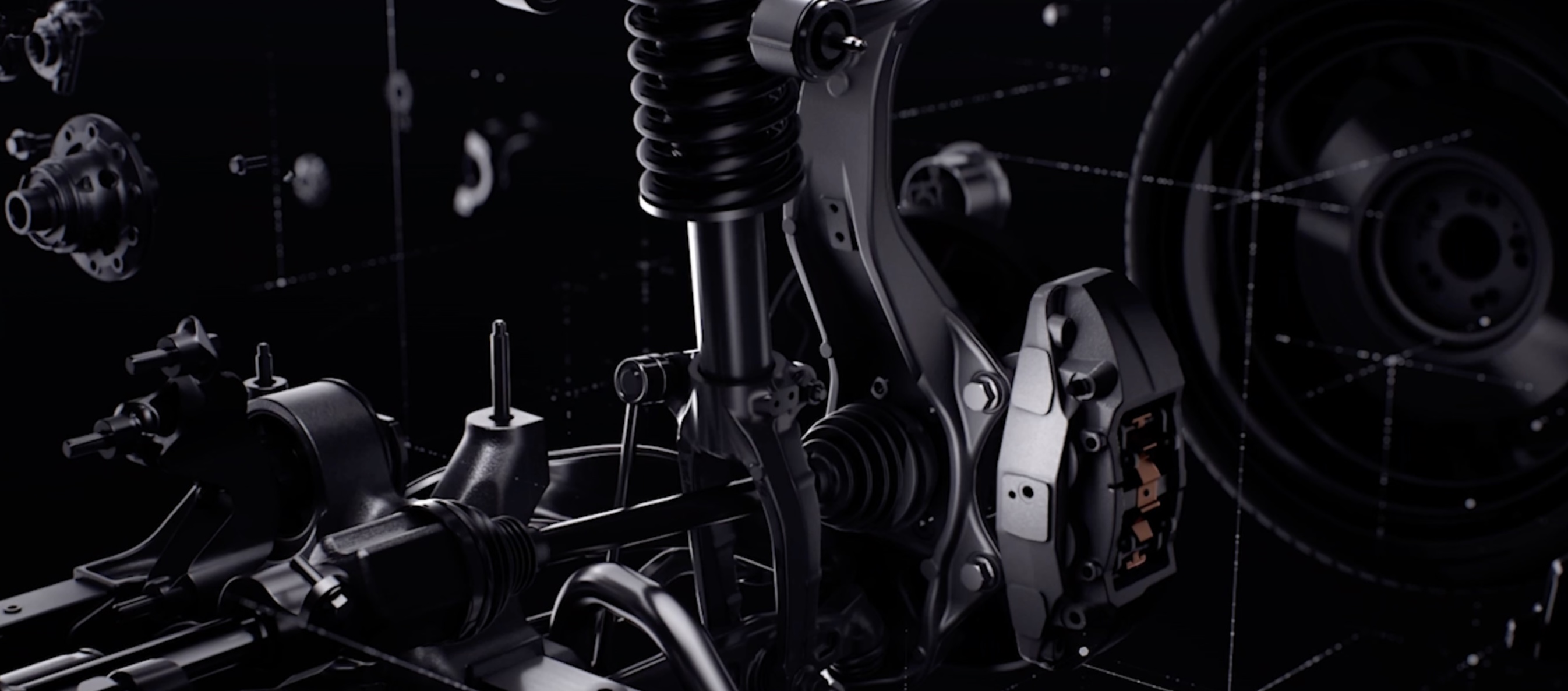

The customized Brembo all-aluminum opposed four-piston front brake caliper is lighter in weight and stronger in strength compared to traditional floating calipers. At the same time, the diameter of the front and rear brake discs is 365 mm and 356 mm respectively. This means a larger contact area and heat dissipation area, increasing response as well as key braking performance.

In addition, the original customized P ZERO performance tires from Pirelli on the IM L7 have been selected in conjunction with the Williams Advanced Engineering team, using tire size and formula that are most compatible with the IM L7 to optimize sports performance while also considering comfort and quietness, featuring PNCS (Pirelli Noise Cancelling System).

With the support of Williams’ tuning and four-wheel steering technology, the IM L7 has the high-performance capability of a steady-state maximum lateral acceleration of up to 0.968 G. The higher this data is, the faster a car can pass through a curve without slipping, which means a higher maximum cornering limit.

The excellent handling of the IM L7 also provides convenience in daily driving. Thanks to the suspension structure of the rear axle, which has a full external ball head and a five-link design, the IM L7 can achieve a 12° rear-wheel steering function in both directions. Beyond the size of a C-class car, the L7 has a remarkably agile 10.8-meter turning diameter, which is a very rare configuration in the same class of cars.

🔗Source: IM Auto

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.