Author: Wang Lingfang

JeH2 Technology, responsible for SAIC Group’s fuel cell strategy, has released new achievements again.

On October 28th, JeH2 Technology held a “Source·Inspiring the Future” new product launch event. JeH2 Technology launched the first fuel cell stack platform- M4 fuel cell stack platform.

JeH2 Technology named the entire product series “JeH2 QiYuan”, meaning the source of cosmic energy. The first fuel cell stack based on the platform, JeH2 QiYuan M4H, and the fuel cell systems JeH2 QiYuan P4H and P4L were also unveiled at the event.

The M4 fuel cell stack platform products launched by JeH2 Technology can cover power ranges from 30 kW to 230 kW, with a life span of up to 15,000 hours. The rated power density is 4.2 kW/L, and the peak power density is as high as 5.1 kW/L.

First-launch M4 Fuel Cell Stack Platform

Lu Bingbing, General Manager of Shanghai JeH2 Technology Co., Ltd. said that JeH2 Technology’s M4 platform has four highlights: homemade high-performance membrane electrode, non-precious metal coated bipolar plate, intelligent and efficient manufacturing technology, and safe and reliable application guarantee.

First of all, JeH2 Technology’s membrane electrode is self-made.

Lu Bingbing said that the membrane electrode of their M4 platform has greatly improved in power density, platinum loading, and durability. “Our power density has increased by 30% compared to the previous generation, reaching 1.3W/CM2. The platinum loading has been reduced by 23%, now ≤0.23g/KW, and the durability has been improved by 50%.”

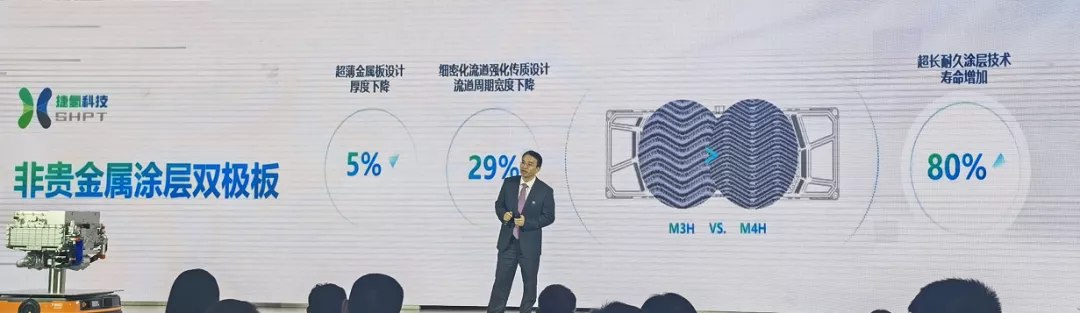

Secondly, in terms of non-precious metal-coated bipolar plates, JeH2 Technology has made efforts in three aspects.

Firstly, by using thinner metal plates in the design of the metal plate, the thickness has been reduced by 5%. Secondly, adopting a more refined flow channel design to strengthen mass transfer, the width of the flow channel period has been reduced by 29%. Thirdly, adopting a brand new ultra-long durability coating technology to increase the lifespan of the bipolar plates by 80%.

Thirdly, an intelligent and efficient manufacturing technology was developed. JeH2 Technology’s batch production of high-efficiency membrane electrode has three characteristics: first, mass production of high-consistency slurry preparation and direct coating technology of the catalytic layer; secondly, adopting membrane electrode roll-to-roll production; thirdly, the production line speed of the membrane electrode can reach 800PPH (800 pieces per hour).

Lu Bingbing said that JeH2 Technology has mastered the entire process and technology of membrane electrode production from slurry preparation, with complete design, production, and testing capabilities.After designing, producing, and testing the entire proton exchange membrane (PEM) electrode, Jie Hydrogen Technology has gained the ability to independently iterate, upgrade, and improve its products. They continuously improve their product’s competitiveness through the application, research and development, and planning of each generation.

Regarding the assembly of the stack, Lu Bingbing stated that their stack production automation level is very high. The robot can grab the main materials, namely the bipolar plate and the PEM, and achieve multi-precision automatic stacking. “Our entire material stacking speed can reach 4.5 seconds per piece and our assembly accuracy can reach ±0.1 millimeters. At the same time, you can see that we have an eight-axis synchronous tightening, which can ensure that our torque consistency reaches the best and the residual stress inside is minimized.”

Furthermore, Lu Bingbing also mentioned that they have exceeded the national and industry standards in terms of safety and reliability.

Jie Hydrogen’s first products for the new M4 stack platform are the P4H and P4L:

(1) Jie Hydrogen P4H Fuel Cell System

This fuel cell system uses the Jie Hydrogen M4H stack and increases the system power from the previous generation’s 92 kW to 130 kW. It not only has high-performance output but also uses the PROME Smart intelligent algorithm, which greatly improves system efficiency. At the same time, the high-integration design reduces the primary parts by 42%, further reducing the product’s size and weight. The smaller “size” contains more energy: Jie Hydrogen P4H system has a volume power density of 1020 W/L and a mass power density of 722 W/kg, which can fully adapt to passenger cars and commercial vehicles.

(2) Jie Hydrogen P4L Fuel Cell System

On the new M4 stack platform, Jie Hydrogen can also create personalized products that adapt to different scenarios. Jie Hydrogen P4L is one of them, with a rated power of 80 kW.No matter it is the JEHYN P4H or the JEHYN P4L, they both have the vehicle-level anti-vibration and impact resistance performance as well as IP67 protection level, with extremely high reliability and durability exceeding 15,000hrs, increasing by 50% compared to the previous generation of products. Moreover, the product functional components can achieve 100% offline individual maintenance. All of these will significantly reduce the maintenance cost of the entire vehicle and comprehensively enhance the user experience.

At the conference, JEHYN Technology also held a signing ceremony with many strategic partners, including Shanghai Automotive Group Co., Ltd. Technical Center, Guangxi Yuchai Machinery Co., Ltd., King Long United Automotive Industry (Suzhou) Co., Ltd., Beijing Fourth Paradigm Intelligent Technology Co., Ltd., Shanghai Yixun Chuangneng New Energy Technology Co., Ltd., Anhui Heli Co., Ltd., Shaanxi Viina Digital Technology Co., Ltd., and Qingdao Yangguang Hydrogen Energy Technology Group Co., Ltd. to jointly explore various application scenarios and cooperative supporting measures for fuel cell vehicles, promote the industrialization and landing of research and development achievements, and promote the promotion and demonstration of fuel cell vehicles in various regions to create a hydrogen “ecosystem”.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.