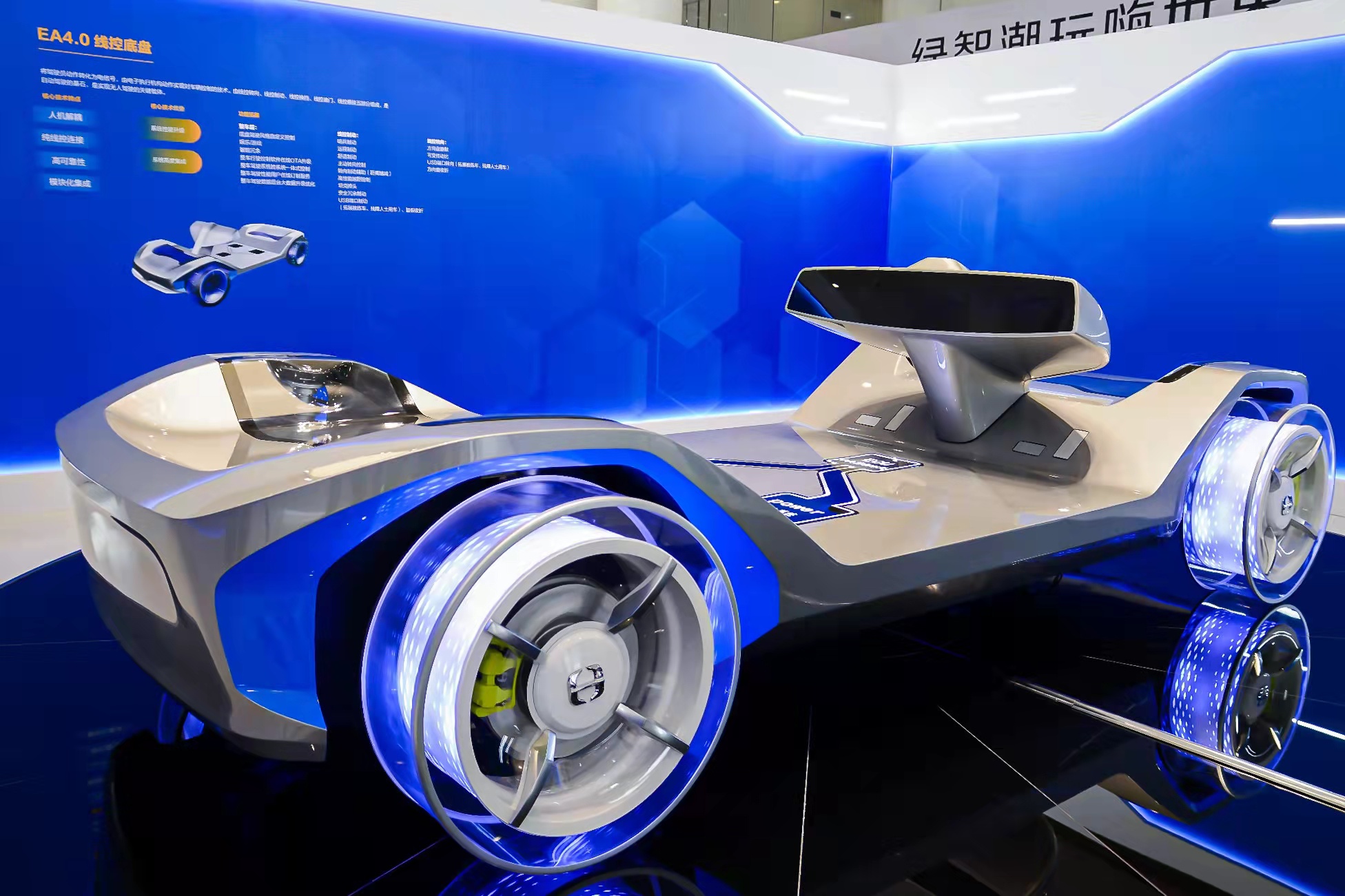

On October 28th, 2021, Great Wall Motors held an online popular science event called “Coffee Intelligence 2.0 Smart Line Control Chassis Open Class”. This product, the Smart Line Control Chassis, was first released globally at the 8th Great Wall Motors Technology Festival in June 2021. It is a technology platform built with the goal of L4 level and above autonomous driving, and will be mass-produced in 2023.

For high-level autonomous driving, the industry generally pays more attention to the perception and decision-making part, which values visual sensors, chips, and algorithms. However, advanced perception and decision-making cannot exist without efficient and reliable execution support. Therefore, it can be seen that traditional automotive mechanical parts will also undergo new changes with the advent of autonomous driving.

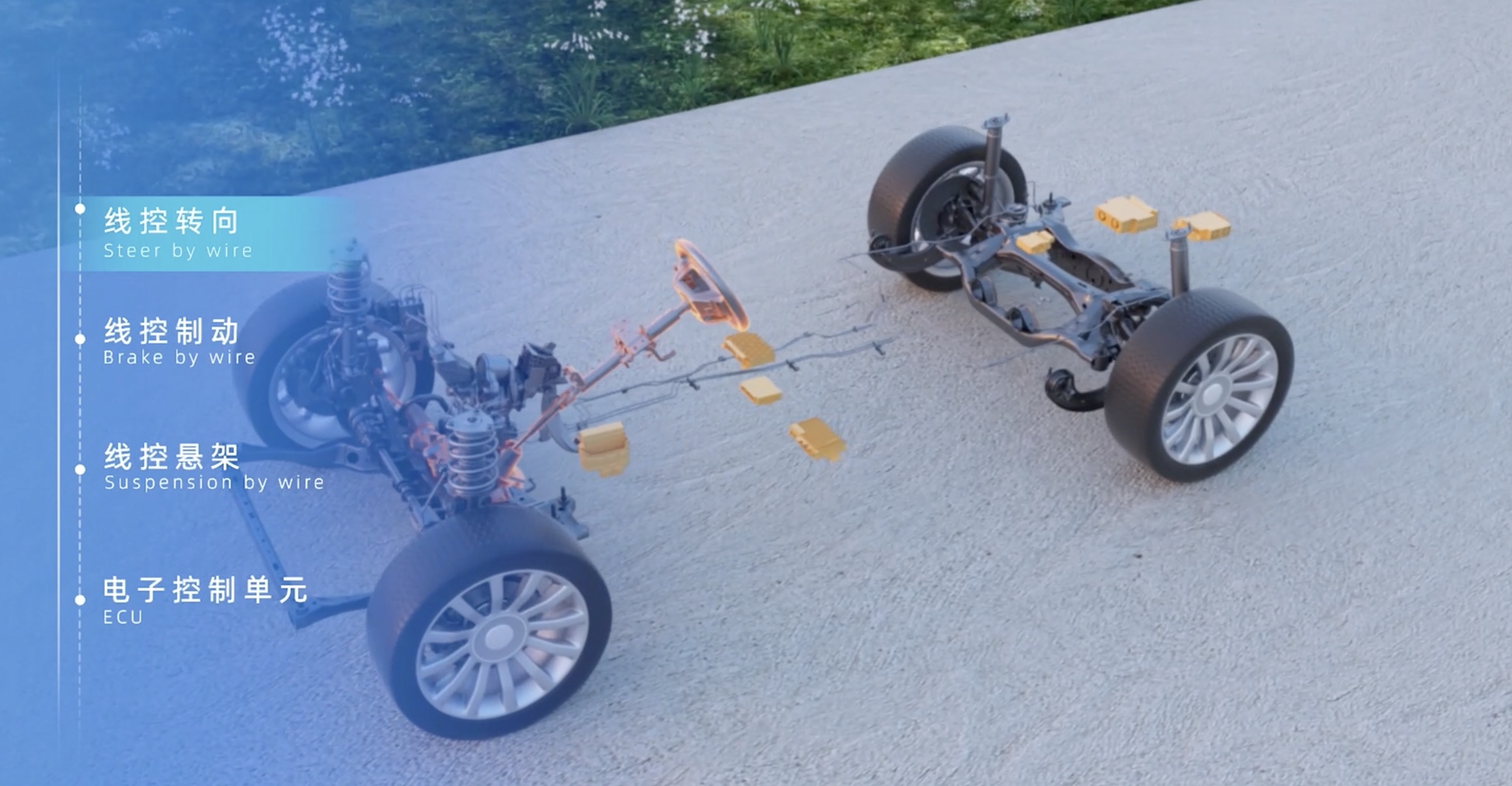

Steering, braking, shifting, throttle, and suspension have always been the five core execution systems on the chassis. Therefore, to achieve the full functionality of the Smart Line Control Chassis, all five of these core systems are essential. Among them, the most important and difficult to overcome are the line control braking system and line control steering system.

The Great Wall Line Control Chassis is based on the GEEP 4.0 new electronic and electrical architecture, and integrates the five core chassis systems, including steering, braking, shifting, throttle, and suspension, through line control mode.

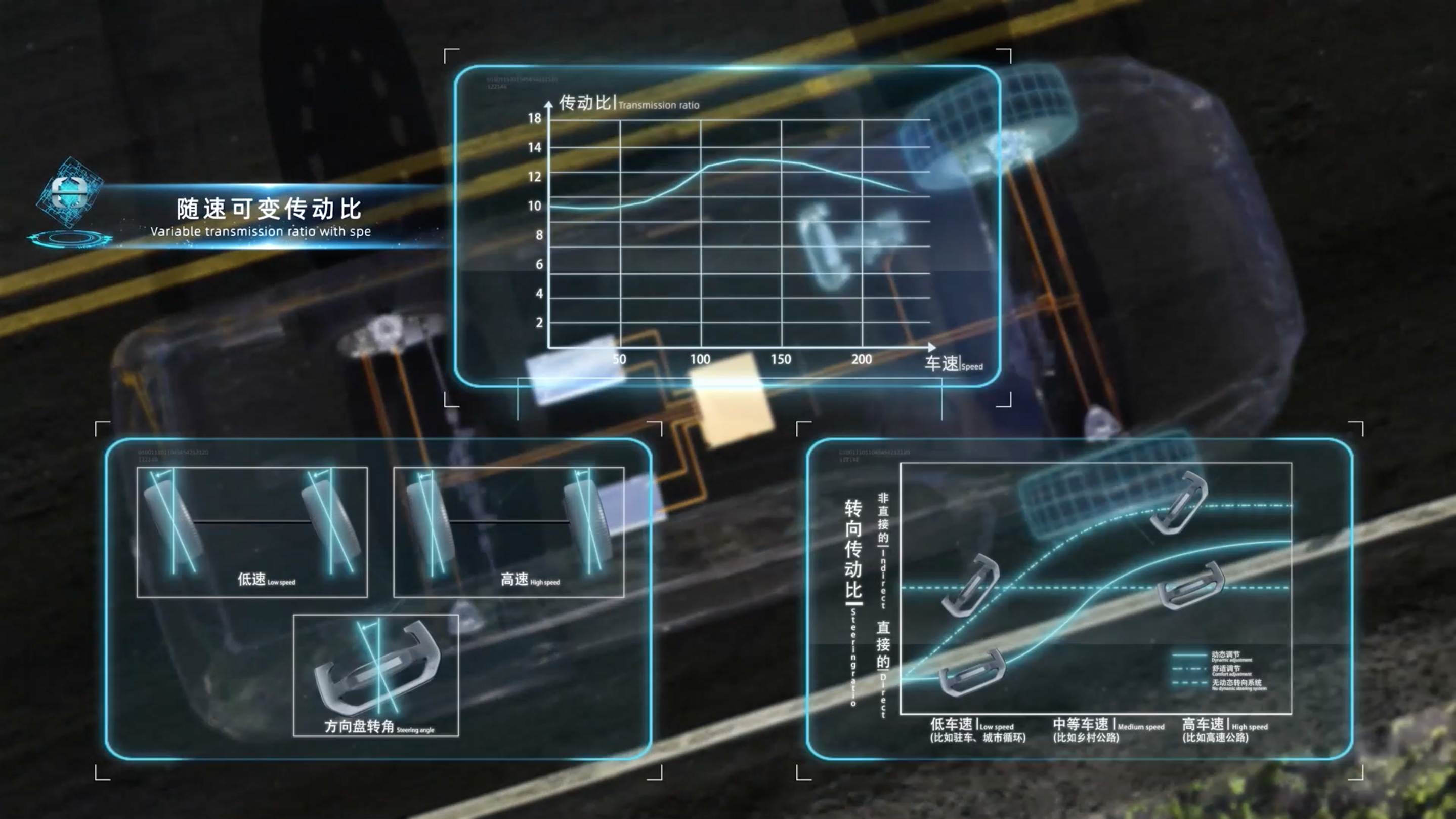

According to Great Wall Motors, this wire-controlled steering system is the first in China to support L4 and above autonomous driving technology. The technology completely eliminates mechanical connections, and the steering wheel is equivalent to an angle sensor, which can achieve functions that traditional power steering cannot, such as folding and flipping.

Thanks to mechanical decoupling, the steering ratio is no longer fixed and can be actively adjusted or freely set between 9-16. The steering feel can also simulate different operating experiences according to demand.

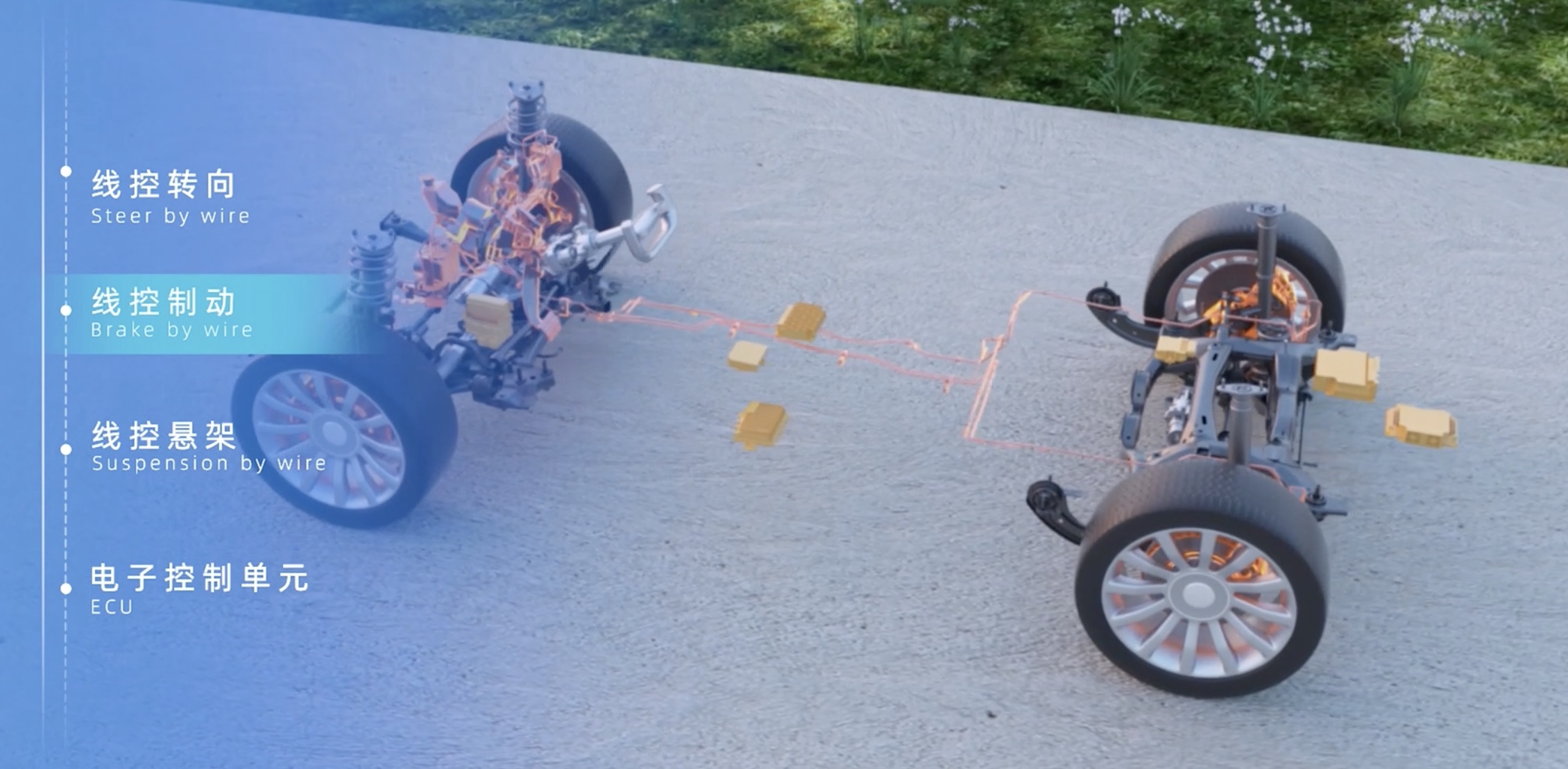

Great Wall Motors’ electronic mechanical wire-controlled braking system uses an electric motor to directly clamp the friction plates, which is equivalent to eliminating components such as the brake master cylinder, brake booster, brake oil pipe and ESP pump. This achieves a 10% weight reduction. At the same time, this mode has the advantages of higher control accuracy and faster response speed. Because the response time can be shortened by 0.35 seconds, this means that the braking distance of 100 km/h-0 can be shortened by 4.8 meters, which is equivalent to reducing the stopping distance of one body length, improving safety.

The tool attribute of autonomous driving means that reliability and safety are the most important, and Great Wall Motors has achieved the highest system function safety level ASIL D in the industry, which is 100 times that of ASIL C. For the wire-controlled chassis steering and wire-controlled braking systems of Great Wall Motors’ intelligent wire-controlled chassis, a triple redundancy design is adopted from the power supply to the sensor, controller, and actuator, that is, a triple redundant system. Compared with the mainstream dual redundancy in the market, it not only adds an extra safety guarantee, but even if all three sets of systems fail, there is still cross-system redundancy to reduce accident risk to a certain extent.

When the steering system fails completely, the wire-controlled braking system can apply different braking forces to the two sides of the wheels to generate a turning torque; when the wire-controlled braking system fails completely, the system can achieve vehicle deceleration by increasing the kinetic energy recovery force.Actually, wire-controlled chassis is not a new technology, and the main problem lies in cost. Compared with the additional cost of sensors, controllers, motors, and customized hardware added by the traditional power-assisted mode, wire-controlled mode is still in the stage of co-driving with humans under the current level of autonomous driving. One of the technical difficulties that wire-controlled mode currently faces is the tuning of control quality, because the decoupled products require human simulations to fully simulate feedback that conforms to driving habits. However, this work is largely based on experiential learning and engineering accumulation. Any brand that wants to achieve such a leap will face new challenges.

Currently, there is a startup called Yoo-run Technology that has emerged this year. The company, founded by Li Peng, who used to work for Great Wall Motors, has set its sights on a vehicle platform that combines wire-controlled chassis technology, aiming to create a universal platform for new emerging forces and reduce the development cost of mechanical parts, so as to shift the focus to the product attributes themselves.

In Israel overseas, there is also a wire-controlled skateboard platform company called REE, which completed a SPAC merger and listing in July.

The competition for wire-controlled chassis/platform may truly heat up with the official entry of main engine plants such as Great Wall Motors.

🔗Information Source: Great Wall Motors

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.