Has the Era of Electric Cars Come?

This year, Tesla released a car that really caught my attention. With a price of over a million RMB, it has a 2.1 second acceleration time for 0-100 km/h. But straight-line speed is not everything, real men need to be fast on corners.

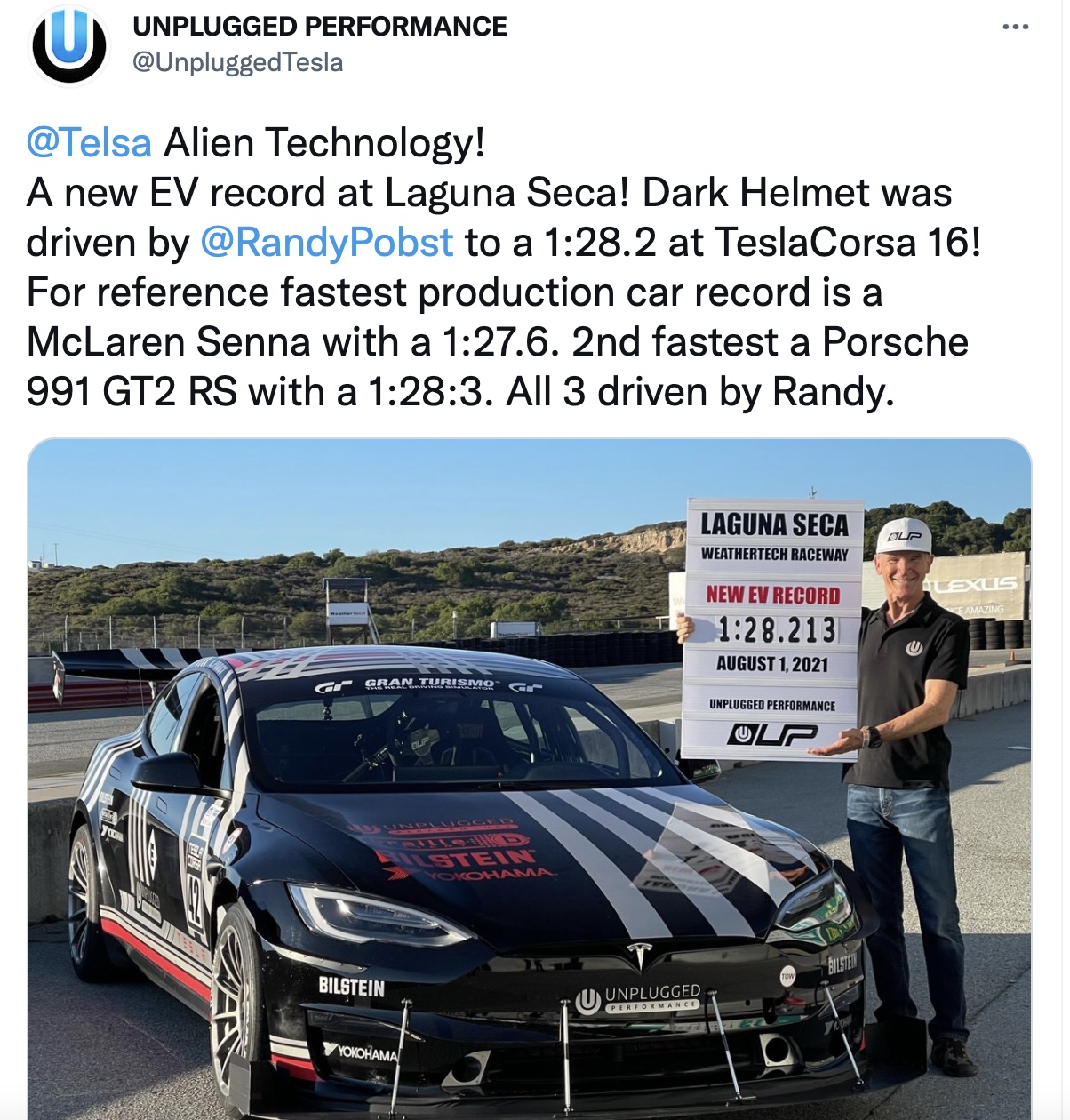

Therefore, a company in the United States called Unplugged Performance, which specializes in Tesla modification, upgraded the Plaid slightly by adding commonly seen racing modifications such as brakes, suspension, tires, and anti-roll bars, while keeping the screen for the gear-shift. As a result, they made a Plaid whose power had not been touched, that is slightly faster than the 911 GT2 RS. This car hit a lap time at Laguna Seca raceway that is only surpassed by the current production car model Senna from McLaren.

And you don’t need to doubt the authenticity and comparability of this lap time, because all three lap times were recorded by racing veteran Randy Pobst who has been making headlines for several years by achieving record lap times at various tracks.

Tesla is really strong…

In an era when a two-ton family sedan with a three-meter wheelbase can pose a threat to a supercar due to its (relatively) cheap electric power and low center of gravity, what else besides high prices and intimidating aesthetics of supercars can give me the confidence to fork out at least two hundred grand or even more?

Regarding this issue, today I will take the opportunity to explain the technical details of the McLaren’s latest supercar Artura, which costs around 2.38 million RMB, and let’s think about it together.

Given the extremely long length of this article, those who are not interested in the technology can skip directly to the end.

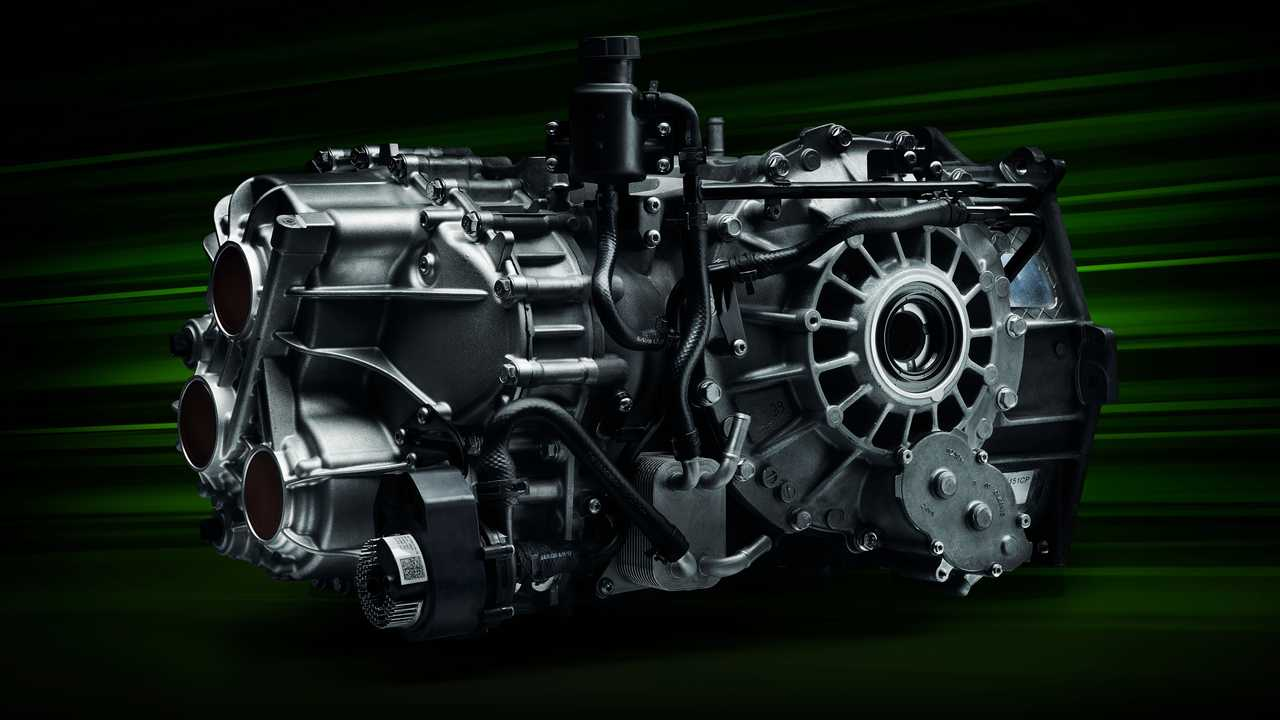

Engine

The motor can only provide power, but the engine can be the soul.

V6 Great Rear Supercar

This somewhat “corny” phrase aptly summarizes the only shared selling point between the McLaren Artura and the Toyota Crown. Both are V6 engines, both are rear-wheel drive. A 3.0L displacement is rare for a rear-wheel drive sedan that was sold for 200,000 to 300,000 RMB in China’s domestic market at that time.

However, such a displacement may seem inadequate for a supercar. But fret not, McLaren’s V6 is not the same as Toyota’s V6 that can be found on any street corner.

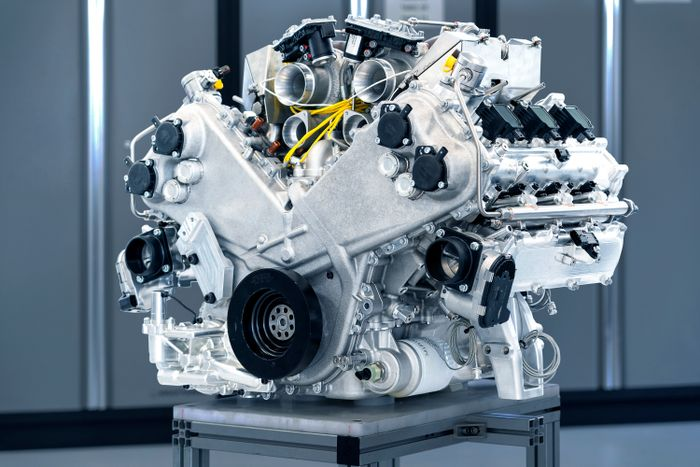

The First Mass-Produced 120-Degree V6 Engine

The 120-degree angle of this engine is the most interesting feature. At present, apart from the Ferrari 296 GTB, there is no other car with such a weird engine in the market.

In terms of power, the M630 V6 twin-turbocharged engine is second only to the 4.0L V8 engines equipped on the Elva and Senna in its brand’s engine lineup.

While ensuring powerful performance, the engine has outstanding lightweight advantages. It weighs only 160 kg, which is 50 kg lighter and 220 mm shorter than McLaren’s 4.0L V8 engine.

It also has excellent fuel economy. Although money might not be a problem, being able to run a few more laps before refueling on race day is an added bonus.

The new car’s V6 engine has a displacement of 2,993 cc, a lower center of gravity, and a dry sump oil pan with a VVT mechanism. Although the bore and stroke are respectively 84.0 mm and 90.0 mm, making it a typical long-stroke engine, it should not be conducive to high-speed rotation. However, the M630’s maximum speed can reach up to 8,200 rpm, even reaching 8,500 rpm in an instant, like that of a high-speed naturally aspirated engine. At the same time, the peak torque of 585 N·m has a large output platform and can be stably output from 2,250-7,000 rpm.

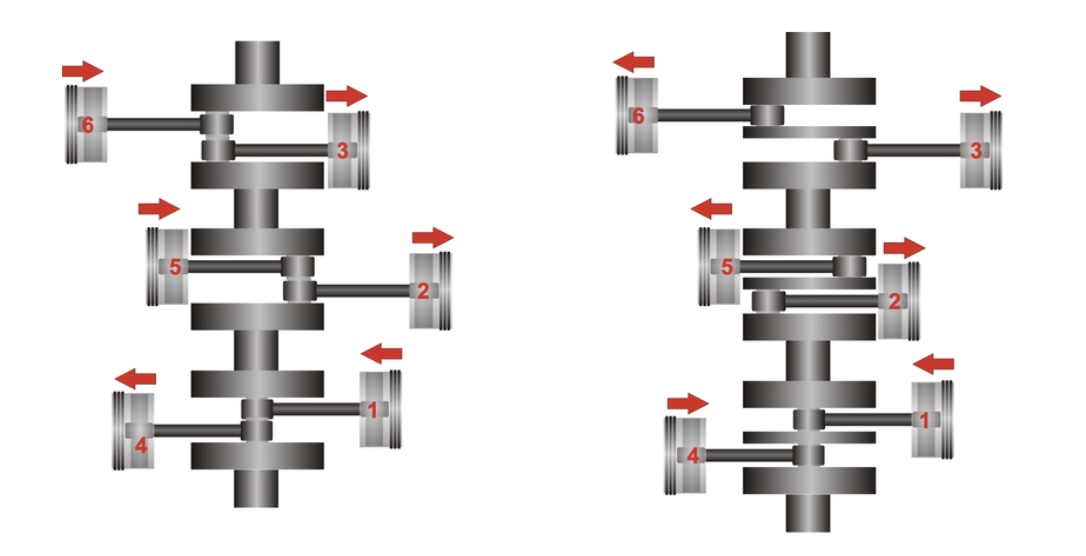

The new car’s engine has a 120-degree angle with an outer-inward-outward “hot vee” arrangement. Many people may wonder:>They have achieved 120 degrees, why not make it like the flat-six layout of a Porsche?

The answer is simple. Apart from the angle between cylinders, the biggest difference between a V-type engine and a flat-six engine is the crankshaft design. The McLaren’s wide-angle V6 design allows for shared crank pins, which can create a shorter and lighter crankshaft with fewer crankpins (3 vs. 6) as compared to all conventional V6s. This design offers higher strength and lower weight, which is more suitable for high-speed, high-power, and high-stress applications.

Moreover, the “hot vee” layout makes it more convenient to layout the intake and exhaust pipes while controlling the overall width, which also improves engine performance and environmental protection. Using shorter and equal-length exhaust flow paths to connect a turbocharger allows the engine to achieve better turbo response.

In terms of turbocharger response, McLaren has introduced ball bearing technology to reduce internal friction, thereby increasing turbocharger rotation speed more quickly. The electronic control wastegate matched with the turbocharger can instantly adjust the wastegate position without being restricted by system pressure, effectively reducing turbo lag and substantially shortening response time.

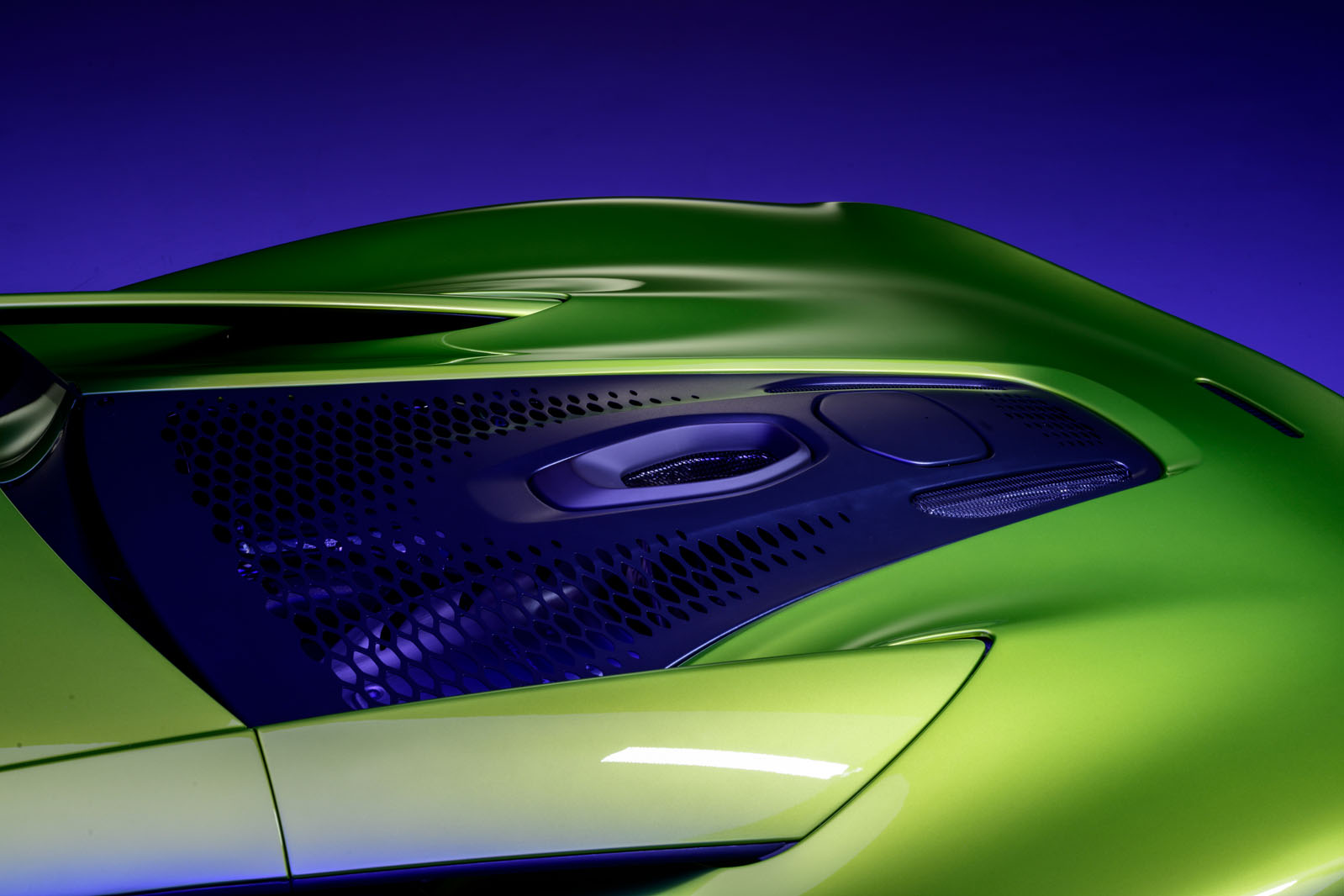

A multi-layer, composite thermal insulation shield tightly surrounds the “hot vee” structure. Such a closed design can prevent the huge heat generated by the turbocharger from dissipating through the rear of the vehicle and affecting the performance of other components. Meanwhile, the exhaust port is connected to the back of the high-temperature radiator fan, which discharges excess hot air like a chimney.

The cylinder body, cylinder head, and piston are all made of aluminum, and the coating on the inner wall of the cylinder body eliminates the need for separate cylinder liners, reducing the cylinder gap, weight, and size. This is also the first mass-produced car with a partially 3D printed cylinder head and cylinder body structure.

According to official information:

This technology is more widely used in F1™ racing cars rather than road racing cars to ensure efficient and precise cooling. For example, the size of the micro-coolant passage between the cylinders is only 2 millimeters.

The more accurate and finer cooling water passage is also the reason why this engine can achieve such a compact size. If produced using traditional technology, it may not be able to achieve satisfactory size and performance.The timing chain and other mechanisms at the back of the engine represent another innovative design highlight, further optimizing the design layout and cabin environment. This helps to improve the NVH performance of the cabin. After all, in an era where Generation Z buyers with surprising amounts of disposable income are running rampant, what they want is not just rough toys. What they want is a sound that is quiet, and the best NVH.

According to McLaren, the transition sound between stepping on and releasing the gas pedal is unmatched in the history of the McLaren brand by Artura. To achieve this, McLaren has taken a series of improvement measures, including shortening the length of the exhaust system. The exhaust is directly discharged from the “hot vee” structure at the rear, reducing weight and providing more space for the new car’s rear diffuser. The lightweight exhaust system is tuned, allowing you to enjoy the sound (can the official give me a clean version of the sound?):

Transmission system

It seems that talking about gearboxes in Garage 42 is now considered non-heritage behavior, but I still have to talk about the highlights of McLaren’s new gearbox. After all, one of the essences of a supercar is appreciating exquisite mechanical design and ingenious machining processes.

Gearbox

The brand new eight-speed gearbox is specifically designed and developed for Artura, and it is light and small. It has been upgraded from seven to eight gears, so Artura can use the lower change in engine speed after the first seven gears to maintain high power in a wider range of gear ratios. With a shift time of 200 milliseconds, it can achieve acceleration performance in various states. The eighth gear is an overdrive gear, enhancing fuel economy during high-speed highway driving.Interesting to note that the gearbox does not offer a mechanical reverse gear, because the Artura is a hybrid supercar and the reverse function is achieved by the ultra-thin electric motor integrated within the clutch bell housing.

Despite having an additional gear compared to the seven-speed gearbox matched with the McLaren V8 model, the new gearbox has a 40mm shorter gear cluster length because it uses nested clutches instead of parallel ones.

Both electric and mechanical oil pumps are equipped, with the electric pump playing a necessary role during pure-electric driving when the engine and gearbox are disconnected. In addition, the electric pump can work in tandem with the mechanical pump, allowing the latter to be further reduced in size.

The gearbox cooling system features two new mid-temperature radiators (MTR). In addition to being connected to the high-temperature radiator circuit, each mid-temperature radiator is connected to the air intake at the top of the flywheel housing bottom, pre-cooling the clutch to a lower temperature than the engine and gearbox by means of water.

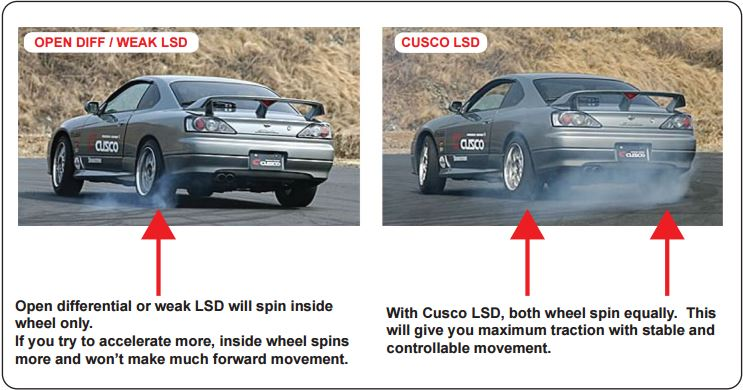

Differential

The all-new Artura is McLaren’s first model to be equipped with an electronic differential (E-diff), and even the first McLaren model to be equipped with a limited-slip differential. Yes, its big brother, the McLaren P1, uses an open differential structure like a grocery shopping car.

McLaren had its own set of explanations for this issue. They believed that the effect of a limited-slip differential could be extended through the function of ESP: braking the drive wheel on one side alone to achieve a similar effect.

However, compared to mechanically limited-slip differentials that can only work passively, the use of electronic differentials helps to enhance control level, better manage rear axle torque, and respond instantly to the instantaneous torque output of the electric motor.

The electronic differential can actively transfer torque, while the mechanical differential can allocate power to only one side of the wheel at most. In addition, the mechanical differential cannot respond quickly or accurately to ensure that the vehicle’s driving performance remains synchronized with changes in the throttle. This is also the reason why McLaren actively refuted its previous views: it was ultimately for performance.

The Artura’s electronic differential can also accurately calculate and control the degree of understeer and oversteer, constantly fine-tuning the balance between agility and stability of the vehicle, and facilitating the driver to drift on the track or increase yaw gain through throttle control. Thanks to more precise parameter control, the traction force during cornering is increased.

The all-new Artura is also equipped with McLaren’s Variable Drift Control (VDC) system. This innovative configuration allows drivers to adjust the degree of traction control and oversteer control assistance through a slider on the central entertainment display. In plain English, moms no longer have to worry about me failing to drift and losing face.Currently, among all the electric vehicles on the market, only the Porsche Taycan is equipped with an electronic differential, while the Tesla Model S Plaid achieves the same active torque distribution function through dual rear motors. However, neither of them has the ability to allow drivers to adjust the drifting angle themselves. After all, supercar manufacturers pay more attention to tuning, which is one of the added values of a supercar.

Electrification

Yes, it’s the era to talk about electrification for fuel supercars as well.

If my investigation is thorough enough, the Artura should be the first car to use a domain-based Ethernet architecture as the core backbone network. This technology fully caters to the industry trend of vehicle architecture transformation and reshaping.

The domain-based Ethernet system integrates four major controllers, each placed in a core part of the vehicle to optimize data transmission rate and cable length. The controllers are connected to the central gateway through Ethernet to achieve efficient interconnection. All interconnectivity functions that run through the entire vehicle from the front to the back do not require independent lines and control systems, but are transmitted through the central “main channel.”

All communication follows a unified standard and can coexist harmoniously on the same Ethernet network. Data transmission still radiates from various domains through LIN (Local Interconnect Network) and CAN (Controller Area Network) to achieve subsystem communication, but the processing power has been improved. Although it is not as pure as Tesla and some new players, the application of domain-based interconnect technology brings significant advantages. The length of the car’s cable is reduced by 25%, while the weight is reduced by over 10%. For supercars that do not require a lot of communication bandwidth, its lightweight significance is even greater.

Although, the Artura may also become the best McLaren in terms of electronic system reliability by relying on Ethernet.

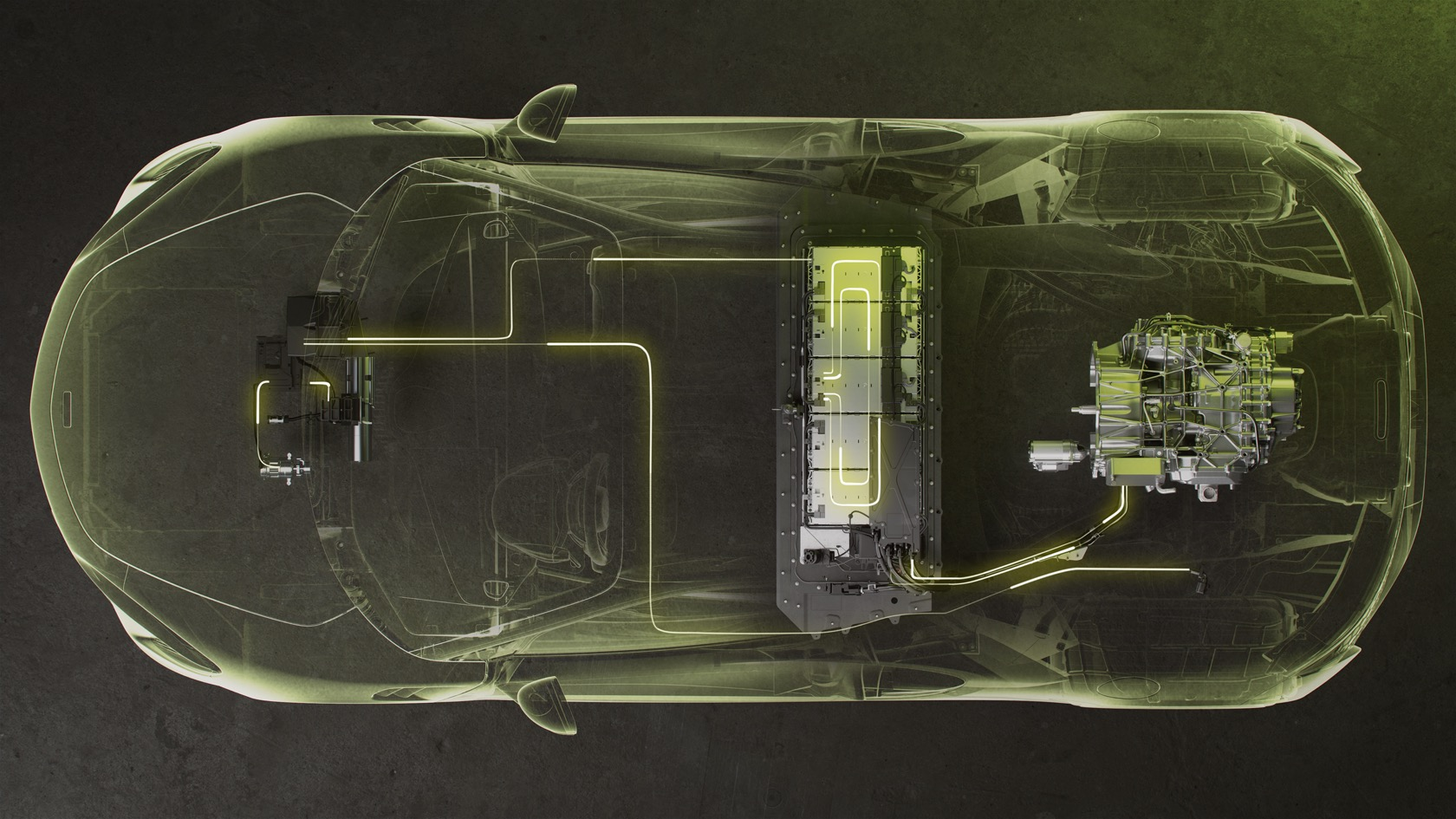

Motor

If only relying on a small displacement turbocharged engine, in terms of responsiveness, it may not even be able to compete with a standard range Tesla Model 3. This is also the problem that all fuel-powered models currently face. If the electrification of these home-use cars is mainly to solve emission and fuel consumption issues, the electrification of supercars is mainly to make up for the low-speed torque and response speed of the engine.Although the configuration of the 120-degree V6 represents a simpler single-scroll turbo with three cylinders on each side, which is exceptional in terms of response and turbo lag even at extremely low speeds, there is no doubt that the turbine size is impressive given its 585 horsepower and 3.0L displacement. Hence, we need motors in supercars too. Artura marks the first application of axial-flux electric motors in mass-produced road cars. Radial-flux electric motors, which have magnetic material around their rotors, are widely used in the automotive industry. However, axial-flux electric motors are totally different. They have a stator sandwiched between two rotor hubs that enable super-high power and torque density while being smaller and lighter.

The electric motor integrated in the all-new Artura only weighs 15.4 kg, including its interface, which is even less than half of the 38-kg weight of the radial-flux electric motor in the McLaren P1™. The maximum power output of this new type of electric motor is 95 horsepower (70 kW), with a power density of 4.6 kW/kg, which is 33% higher than that of the electric motor in the McLaren P1™. Yes, this is the development of technology.

In addition, the peak torque of up to 225 N·m is equally impressive. The electric motor is powered by a power battery group and can drive the all-new Artura up to 30 km in pure electric mode with a top speed of 130 km/h. As the torque output characteristics of the electric motor and the V6 engine do not reach their respective peak torques synchronously, the overall peak torque of the all-new Artura is 720 N·m.

Finally, the comprehensive power and torque outputs of this high-performance hybrid power system are 680 horsepower and 720 N·m, respectively, and the electric motor’s torque output ensures instant throttle response. The new car can complete the 0-100 km/h acceleration in just 3 seconds and the 0-300 km/h acceleration in 21.5 seconds.

Some may feel that the maximum electric range of only 30 km is not satisfactory, but the battery does add weight. Moreover, for Artura, it should be enough to drive in and out of neighborhoods at night without disturbing sleeping neighbors who should not be disturbed.

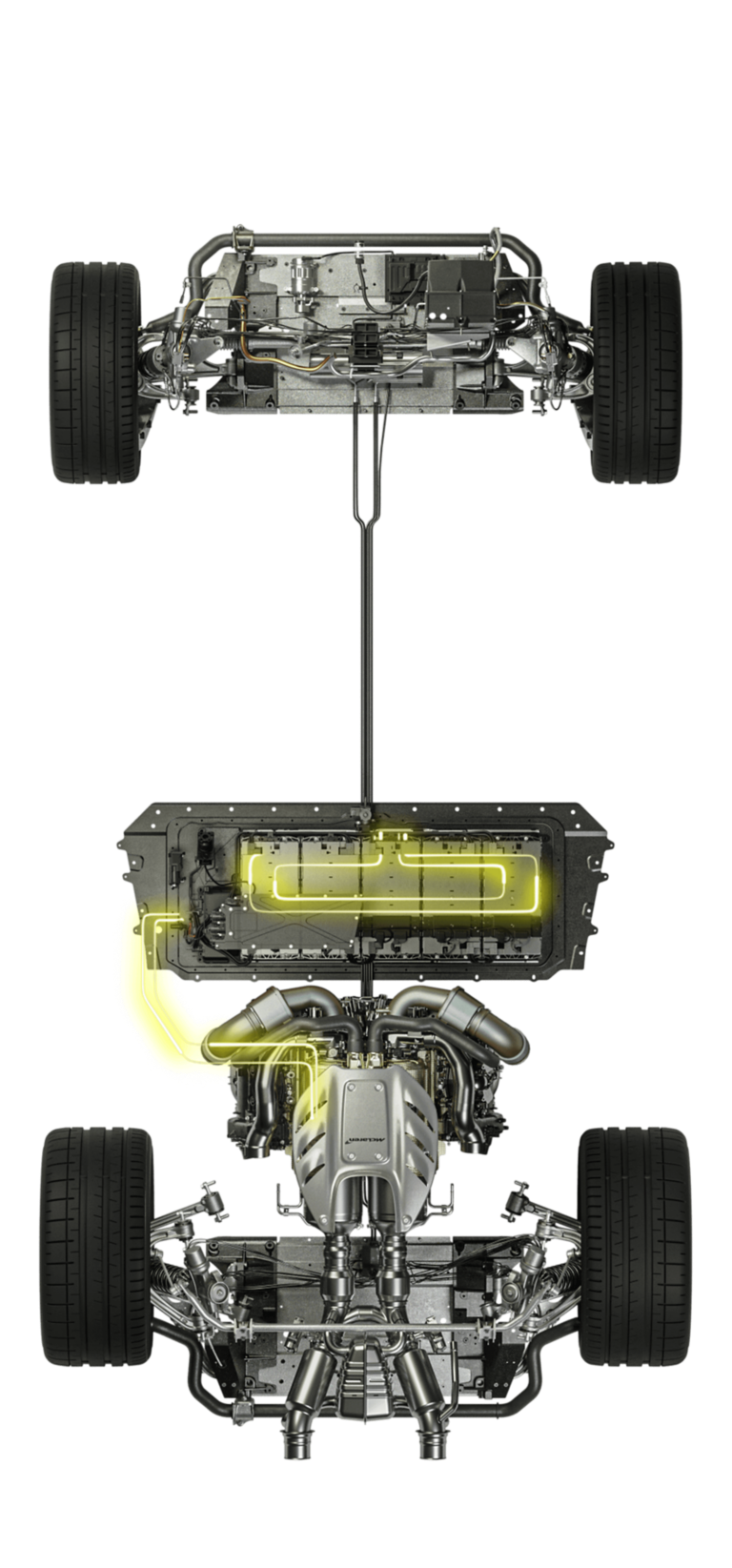

Battery

The 7.4 kWh battery pack consists of five lithium-ion battery modules and is equipped with a cooling manifold. The battery management unit is arranged in parallel with the battery module, while the integrated design of the power distribution unit (PDU) saves space. The battery is indirectly cooled by the refrigerant inside the manifold channel. The refrigerant circuit starts at the location of the newly installed electric heating, ventilation, and air conditioning system in front of the monocoque chassis. The further optimized battery cooling effect brings more excellent power performance, ensuring stable pure electric range.

The 7.4 kWh battery pack consists of five lithium-ion battery modules and is equipped with a cooling manifold. The battery management unit is arranged in parallel with the battery module, while the integrated design of the power distribution unit (PDU) saves space. The battery is indirectly cooled by the refrigerant inside the manifold channel. The refrigerant circuit starts at the location of the newly installed electric heating, ventilation, and air conditioning system in front of the monocoque chassis. The further optimized battery cooling effect brings more excellent power performance, ensuring stable pure electric range.

The battery pack is completely wrapped in a fire-resistant hood, placed on a structural carbon fiber base plate, and fixed as a whole at the rear of the carbon fiber monocoque chassis by bolts. The base plate is made of aluminum inserts and structural foam core layers, which provide comprehensive collision protection for the bottom of the battery pack. The battery pack’s side and top, along with the fuel tank above, are protected by a space structure specially opened by the monocoque chassis. At the same time, the engine, gearbox, and rear suspension can also act as expensive cannon fodder to avoid direct impact of the battery in rear-end accidents. The battery is also installed as low as possible to further reduce the vehicle’s center of gravity.

The battery pack delivers high-voltage direct current power to the integrated power unit (IPU) at the front of the vehicle. The DC-DC converter, on-board charger, and front distribution unit are integrated, and the internal power electronic equipment is shared, which helps reduce weight. The DC-DC converter converts the high-voltage DC power output from the battery into low-voltage DC power to power the vehicle’s 12 V system. The electronic equipment can also convert AC power from the plug-in vehicle charger into DC power required for battery charging.

New Artura owners can maintain the battery’s charging status by starting the engine, including using the “set 100% charge” function (i.e., the battery priority function), and prioritize using the internal combustion engine to charge the battery before entering urban areas or other situations. Owners can also charge the vehicle’s power battery by plugging in an external power source. Using a standard electric vehicle power supply cable, it takes about 2.5 hours to charge the battery from 0 to 80%. During driving, the battery can also recover energy from the internal combustion engine according to the selected driving mode, which can be controlled by the driver in the cabin.

Many power reserve functions ensure that the battery never completely discharges, including power reserves for cranking the internal combustion engine when starting the vehicle, power reserves for reverse gear, and power reserves for delaying parking the vehicle.

The power distribution unit inside the battery allocates power to the high-end advanced, ultra-lightweight motor controller (MCU). The battery’s high-voltage DC power is converted to AC power here to power the electric motor during acceleration. Compared with the similar configuration of McLaren P1™, this motor controller reduces weight by about 68%, further demonstrating McLaren’s technical strength.

Chassis

Mr. Jamie Corstorphine, McLaren Automotive’s Product Strategy Director, said:

‘Without exaggeration, the new McLaren lightweight carbon fiber architecture is the core of the new Artura ultralight engineering design concept. In the development process of this new high-performance hybrid supercar, we have fully used the professional skills of the brand in advanced composite materials and other lightweight materials over the past decades. With advanced global technology and techniques, we have significantly reduced the weight of the new car, effectively offsetting the weight increase of the hybrid system compared to the traditional gasoline system, giving the new car higher energy efficiency and bringing outstanding responsiveness and dynamic performance expected by customers.’

The McLaren Lightweight Carbon Fiber Architecture (MCLA) was developed over four years and is the first architecture designed and built by McLaren Composites Technology Center (MCTC). This new technology center is equipped with first-class facilities and is located in the Sheffield area. This flexible and exceptionally tough expandable platform architecture opens a new era for McLaren supercars.

MCLA is composed of three major components, namely a new carbon fiber monocoque cockpit, a new chassis with aluminum crash beams and rear subframes, and the first-to-market domain-based Ethernet electrification architecture. The carbon fiber monocoque chassis is the core of MCLA.

Almost 40 years ago, McLaren pioneered composite technology in the F1™ racing field and then applied the technology to its first road car, the McLaren F1, with carbon fiber frames and bodywork that first introduced it into the field of road racing. The 2009 McLaren 12C introduced a unique integrated carbon fiber frame, which increased stiffness by 25% compared to an equivalent all-metal frame, while reducing weight by 25% compared to an equivalent aluminum frame.

The all-new Artura introduces a revolutionary breakthrough in both the realm of road and track racing. The performance of the McLaren’s mono-cell chassis establishes a new benchmark: the new car’s carbon fiber mono-cell chassis has added battery safety protection, and its overall collision protection and load-bearing performance are even more outstanding. Surprisingly, its lightweight trait remains outstanding. Even with the addition of the battery compartment, aerodynamic body surface, B-pillar, and door fasteners, the weight is only 82 kilograms, which is a major reason why the new car still maintains a low weight despite adding 130 kilograms of hybrid components.

The all-new Artura introduces a revolutionary breakthrough in both the realm of road and track racing. The performance of the McLaren’s mono-cell chassis establishes a new benchmark: the new car’s carbon fiber mono-cell chassis has added battery safety protection, and its overall collision protection and load-bearing performance are even more outstanding. Surprisingly, its lightweight trait remains outstanding. Even with the addition of the battery compartment, aerodynamic body surface, B-pillar, and door fasteners, the weight is only 82 kilograms, which is a major reason why the new car still maintains a low weight despite adding 130 kilograms of hybrid components.

Moreover, the mono-cell chassis also plays a crucial role in optimizing aerodynamics and heat management. The chamfered design at the rear edge of the front wheel arch can export airflow from the wheel arch and make it flow along the bottom of the door. The extended door shell intercepts the airflow in this channel and directs it backward into the air intake, providing cooling airflow to the lower part of the high-temperature radiator (HTR).

Chassis

If the core of a supercar is the engine, then its essence lies in the chassis, and its soul in handling. However, for those who do not understand it, I suggest skipping this section.

In the electric age, anyone can have horsepower. Anyone can have a double wishbone and multilink suspension, but good handling is a system engineering. And a supercar is the ultimate product of this even more pure system engineering.

*To avoid ambiguity, I define “chassis” as the part related to walking, such as suspension and braking, but not belonging to the scope of the transmission system.

Suspension

Compared with those very fast electric cars, the advantage of putting the engine in the middle of a supercar still exists.

- Lighter weight;

- More concentrated weight;

- Higher chassis rigidity;

- More athletic suspension geometry;

- Less compromise on cost.

The McLaren engineering team ensures that the new car possesses two commonly unattainable characteristics: improved flexibility and stability. This goal is achieved through a completely new rear suspension design concept and McLaren’s first-ever electronically controlled rear differential.

The chassis settings can be electrically calibrated through three control modes: Comfort, Sport, and Track modes. Each mode has different damper parameter settings. For example, choosing Comfort mode will bring a relaxed and comfortable city driving experience, while choosing Track mode will enhance damper control to improve dynamic response. The electronic differential can also change the corresponding settings by switching between Comfort, Sport, and Track modes.

Experienced drivers can also use advanced electronic stability control (ESC) system to assist them under specific conditions. The ESC system provides three modes to choose from: “ESC On”, “ESC Dynamic”, and “ESC Off”, which are distinguished from the control and power modes, making it easy for drivers to control the degree of system intervention.

The new Artura’s steering column is directly mounted on the dashboard’s rigid crossbeam, and McLaren has always preferred electronic hydraulic power steering over electric power steering, which allows for ideal driver-focused instant response and delicate feedback. Although it is not as energy-efficient, it is still worth it compared to driving pleasure.

Although McLaren has always favored the double-wishbone suspension form, the commonly seen lower suspension arm structure in the new McLaren Artura has been split in two, becoming a multi-link component. By splitting the lower arm in two and increasing the distance between the control arm and the steering joint as much as possible, the connection point is further separated, greatly optimizing the rear axle’s camber stiffness.

The rear suspension distributed on both sides of the vehicle reduces non-sprung mass by 2.4 kilograms respectively, which is beneficial to the riding experience and grip level. The control arm is also located in front of the hub, rather than behind it, shifting the weight distribution toward the vehicle center.

As a result, the vehicle achieves better braking and acceleration control, and overall stability performance is significantly improved, and the grip level during cornering is also enhanced.

The continuously variable twin-valve hydraulic damper enables independent adjustment of compression and rebound dampers, which enhances grip. The direct-wound spring and mechanical sway bar are combined with the new-generation McLaren active suspension control system (PDC II).

The active suspension control system “reads” the road information through data received by sensors rather than responding to information collected by cameras. Feedback data provided by four wheel accelerometers, three body accelerometers, two pressure sensors on each damper, and numerous sensors measuring steering angle, vehicle speed, angular velocity, and lateral acceleration can be analyzed and processed in 2 milliseconds to ensure optimal vehicle dynamics.

Brakes

The braking system equipped in the all-new Artura features a new generation of carbon ceramic brakes and forged aluminum calipers (front: six-piston monobloc; rear: four-piston), which shares the same family with McLaren 600LT and 720S. The front and rear carbon ceramic brake discs have sizes of 390 mm and 380 mm respectively, which, together with the newly designed rear axle, provide excellent high-speed braking power and stability.

The braking system equipped in the all-new Artura features a new generation of carbon ceramic brakes and forged aluminum calipers (front: six-piston monobloc; rear: four-piston), which shares the same family with McLaren 600LT and 720S. The front and rear carbon ceramic brake discs have sizes of 390 mm and 380 mm respectively, which, together with the newly designed rear axle, provide excellent high-speed braking power and stability.

The all-new Artura also adopts the F1-style integrated brake caliper cooling duct from the McLaren 765LT model. This technology guides cooling air into the front brake caliper and brake disc, which can lower brake pad temperature during track driving.

The all-new McLaren Artura uses a tailored brake booster and an electric vacuum pump to ensure consistent pedal pressure for the vehicle, whether it is driven independently by the internal combustion engine or electric motor. The new vehicle does not support regenerative braking to charge the battery because the engine can provide sufficient power to ensure pedal feedback consistency.

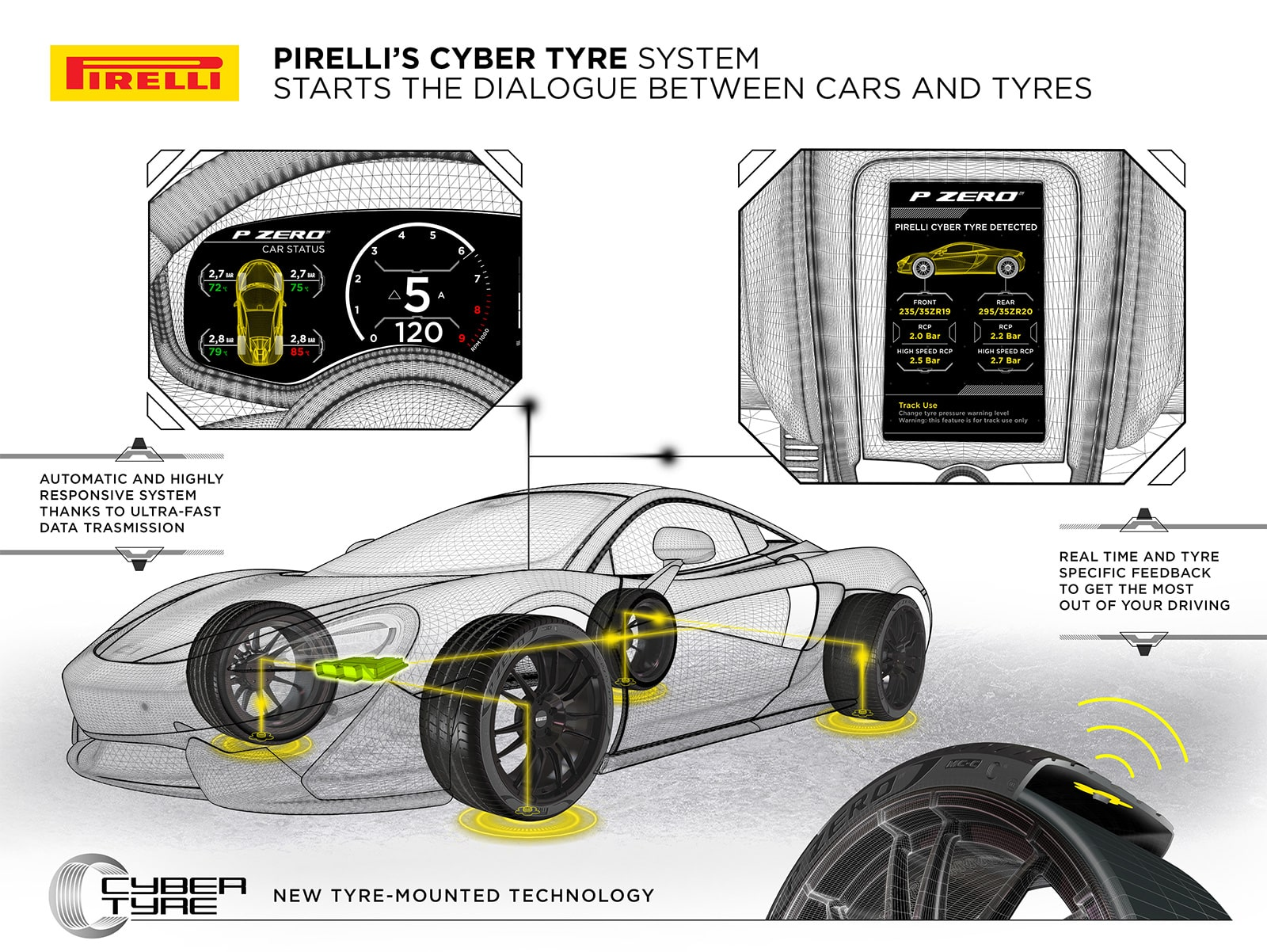

Tires

As McLaren’s tire partner, Pirelli provides three custom tire models for the all-new Artura, which aims to help the new car fully demonstrate its outstanding dynamic performance and exceptional capabilities. The front tire size is 235/35 R19, and the rear tire size is 295/35 R20, both marked with “MC-C,” indicating that they are McLaren-specific Cyber Tyre® tires from Pirelli.

The innovative Cyber Tyre® system from Pirelli is composed of software and hardware integrated into the new vehicle’s electronic control system. Each tire contains an electronic “chip” that can generate high-value data streams based on specific conditions and transmit them to various stability control systems in the new vehicle, thereby providing optimized tire performance.

Cyber Tyre® can accurately monitor temperature and pressure in real-time, and provide a richer data set than hub sensors. With the help of this information, drivers can set the tire to the recommended level to optimize performance. When the driver re-enters the car, the added “Parking Mode” will automatically refresh the relevant information.

In addition, in “Track Mode,” drivers can change the tire pressure threshold through the entertainment system display screen, further enhancing the esports-like immersive experience of track driving.

Cabin

Actually, McLaren has pioneered the vertical screen trend since the 12C, not for occupying the display area on the center console, but for compressing the left and right spaces and bringing the driver and the front passenger closer to the center of the vehicle. This trick has carried on to the present day, but now it is presented in an independent screen mode with an interactive device that resembles a crown.

Actually, McLaren has pioneered the vertical screen trend since the 12C, not for occupying the display area on the center console, but for compressing the left and right spaces and bringing the driver and the front passenger closer to the center of the vehicle. This trick has carried on to the present day, but now it is presented in an independent screen mode with an interactive device that resembles a crown.

In accordance with McLaren’s fine tradition, the steering wheel has no buttons, only two large paddle shifters at the back (connected left and right in a lever form) for drivers to enjoy.

With more and more cars using LCD instrument clusters, the size of the cluster has become larger due to greedy display information. This has brought about a problem: the display content is easily blocked by the steering wheel.

McLaren’s solution is to link the instrument cluster with the steering column. As long as you move the steering wheel, the instrument cluster will move with it. This not only ensures that the steering wheel and your shoulder height relationship are more appropriate, but also prevents the rev counter from being obscured.

Above the shade of the instrument cluster, there are reachable mode selection buttons on both sides. The functions related to driving are presented with mechanical buttons, which may gradually become something that can only be enjoyed on supercars.

There are many other interior details, but unfortunately we have written too much and have to cut it short here. (However, this article is still the most detailed technical introduction to McLaren Artura on the whole internet.)

The logic of consumer goods for immediate needs is not appropriate.

Comparison between supercars and watches

Mechanical watches have always been an expensive and exclusive item. However, with the emergence of quartz watches, the price of watches has been lowered, and the appearance of G-Shock has once again returned to the functional nature of watches.With the emergence of smartphones, watches as daily tools have been further deemed as superfluous. Furthermore, the advent of smartphones has sentenced the death of functional phones.

However, with the revolutions and functional death, has the mechanical watch become cheaper? No, instead it has become more expensive. Why? Because it has detached from its functional essence and evolved into a luxury item. Their value lies in their brand, and the appreciation for the product lies in the exquisite craftsmanship and luxurious materials that don’t necessarily have practical uses.

Similarly, classic cars are like mechanical watches, sports cars are like sports equipment, and supercars are like items possessing the characteristics of both, due to their rarity and high value.

As the world’s first hybrid 120-degree V6 engine with a full carbon fiber chassis sports car, the McLaren Artura is a luxury product possessing the characteristics of limited-edition mechanical watches and professional sports watches, featuring domain controller architecture-based Ethernet as in-car communication, high craftsmanship, unique design, and a sexy turbo chimney.

McLaren and Archaeopteryx, are two brands that have entered the luxury product market in a short time by focusing on a niche market. The six-cylinder model is even more expensive than McLaren GT’s eight-cylinder models, because McLaren, with its ability to tell a story and provide quality products, is enough to arouse a crisis of traditional supercar products.Under the influence of street culture brought about by the black community and the digitalization of new forms such as NFTs, the luxury industry is being covered by the haze of homogenization. For supercars, relying too much on brand heritage can lead to barriers in emissions, and the narrative of craftsman culture and exquisite craftsmanship is not affordable for everyone. However, functional value anchors of sports luxury brands can create new valuation systems and have been thriving in recent years. On the other hand, the experience-driven product positioning and marketing ecosystem in the smart car industry has enabled it to flourish.

Under these circumstances, the higher-end population obviously needs high-end products to endorse their identity in higher-end situations. The accumulation of supercars in terms of performance is the best line of defense, and continuous improvement in experience is the best growth point.

A carbon fiber body and mid-engine are the ultimate performance labels that are only allowed to exist in this price range; the unique mechanical structure of the V6 and the support of hybrid technology appear to weaken the genes of supercars, but in fact, they ensure responsive and smoother power output quality that rivals electric vehicles without too much weight increasing (which is also one of the biggest differences between gasoline cars and electric cars).

As a younger supercar brand, McLaren also embodies resoluteness and agility in technology transfer. High-end sports experience will never lack human participation. And there will always be buyers for high-end sports equipment that can provide customized choices. The logic of supercars is the same, right?

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.