I want to organize some concerned data here.

Firstly, let’s compare the differences between the lithium iron phosphate version of the same battery manufacturer Tesla and the three-element NCM811 of P7, and then compare the differences between the lithium iron phosphate cells of the BYD Blade Battery used by the Han EV and this Tesla cell.

Differences between Tesla and P7 Cells

I’ll make a direct comparison of these two cells.

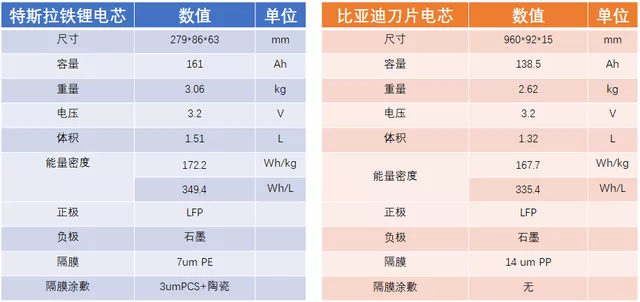

Tesla’s cell is customized according to the previous module. The two common characteristics of these two cells are facing cars, so the height is shorter than all NINGDE TIMES cells before. From this point of view, the mature technology of short cells has enabled NINGDE TIMES to enter the car market. From the differences between cells, there are significant differences in the thickness of the coated separator, and the overall energy density of cells differs by 46.6% in Wh/g and 51.2% in Wh/L.

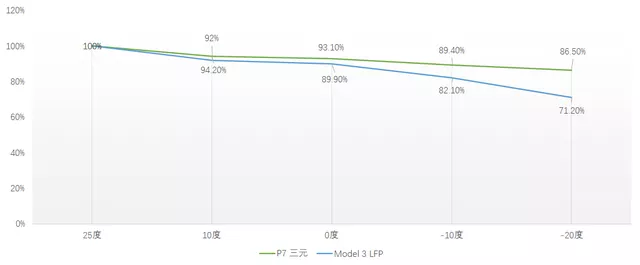

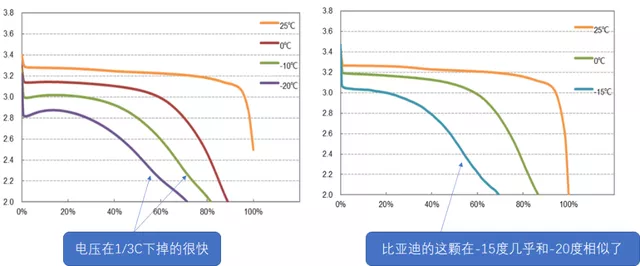

In terms of data, the capacity retention rate of lithium iron phosphate is indeed a bit worse in low temperature: the difference between the two cells is 3.2% at 0 degrees, 7.30% at -10 degrees, and 15.30% at -20 degrees.

From this data, Tesla’s low-temperature strategy is to start heating as soon as possible, and quickly raise the cell temperature above 0 degrees. Personally, I think there are still many obstacles to the use of lithium iron phosphate in areas north of Beijing.

Currently, the methods that have been considered domestically all involve the sub-pulse heating strategy of cells. I expect that after mass production of lithium iron phosphate in the next three months, there will still be some complaints.

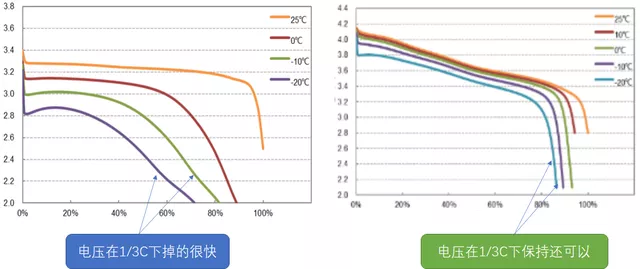

This is mainly because at low temperatures, the voltage of the lithium iron phosphate drops very quickly, as shown below. Although the capacity retention rate can still barely reach 71.2%, this voltage is already in a particularly low area, so I estimate that this battery may have been specially treated for actual use in extremely cold conditions.

Can BYD’s Blade Battery Compete?

Below is a comparison of two lithium iron phosphate (LFP) suppliers. There is a difference in the separator, with one using a 14um PP and the other previously stated. However, there is little difference in energy density in terms of specific parameters. Overall, BYD’s innovative structure results in higher efficiency despite a lower energy density.

Note: after the release of the Model Y LFP version, we can discuss and compare this cell.

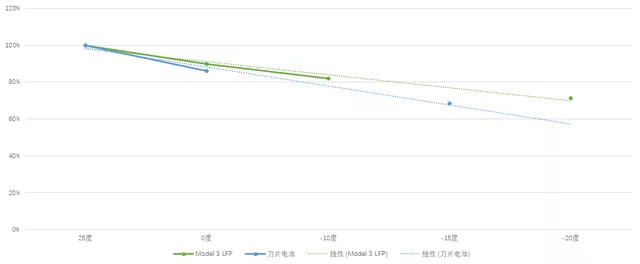

In terms of low-temperature characteristics, the two cells perform almost identically because they use raw materials from the same phosphoric iron lithium material factory. Ningde’s other characteristics may be better, so at -20°C and -15°C, the two cells perform similarly. However, I believe there is little difference between the blade used for Tesla and the Ningde LFP battery.

Similarly, the voltage drops too quickly. If the battery is cold and the state of charge is not full, the car will quickly drain.

In summary, I personally think that LFP batteries will not perform particularly well in cold regions in winter, so special battery management strategies are needed. Due to the particular voltage curve and changes in impedance, the promotion of LFP batteries needs to be accompanied by strategies for self-heating and heating of the battery, and we can review this later.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.