FMCW Lidar Popular Science Part 2: The Importance of 1550 nm Laser Wavelength

This is the second part of the FMCW Lidar popular science series. Click here to read the previous article: “FMCW Lidar Popular Science Part 1: Basic Concepts, Technical Routes, Advantages, Controversies, and Misunderstandings”.

An FMCW Lidar mainly consists of a laser, detector, coherent optical path, and scanning components. Among these key parts, the following aspects are particularly noteworthy:

Laser Wavelength: 1550 nm

Why 1550 nm?

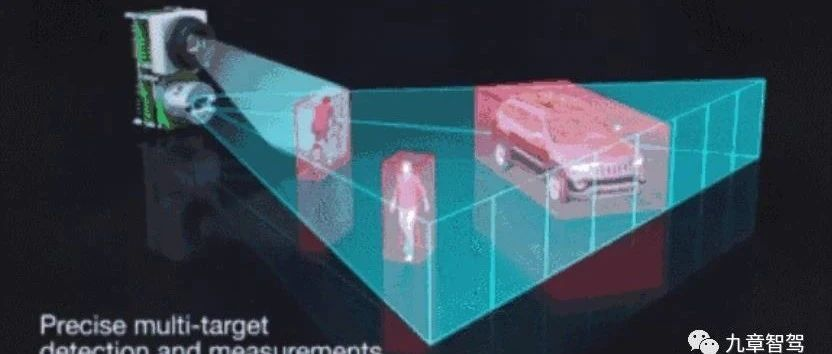

Currently, the laser wavelength of TOF Lidars is mainly 905 nm, while Luminar, Hesai Technology, and TuSimple use 1550 nm. All FMCW Lidars, on the other hand, use 1550 nm exclusively. What is the reason for this?

Andy Sun, CTO of RoboSense, said: “When we make any product, we first need to consider the maturity of the supply chain. Because you can’t make all the parts yourself.”

Specifically, for FMCW Lidars, laser emission doesn’t have to be exclusively 1550 nm. 905 nm can also be used. From a technical perspective, there is no essential difference between using 1550 nm or 905 nm. However, in the field of optical communication, devices that are compatible with FMCW Lidar are all based on 1550 nm wavelength band. The supply chain of these devices is relatively mature, and their cost is controllable. However, the cost is too high if FMCW Lidars were made based on 905 nm.

In addition, considering the human eye safety requirements of continuous light, 1550 nm has a maximum optical power upper limit that is 40 times larger than 905 nm. Under the coherent amplification principle of FMCW, theoretically, 1550 nm can detect targets that are 40 times further away than 905 nm.

Several founders and technical directors of FMCW Lidar companies agreed that “supply chain maturity” is the key factor.

Among them, a technical director said: “To ensure that the returning light interferes with the local light for detection, the coherent requirements for the laser are very high (even if there is a microsecond delay between the returning light and the reflected light, there is still good coherence).” In the industry, lasers with good coherence are referred to as “narrow linewidth lasers”. At present, narrow linewidth lasers are only based on 1550 nm.

Furthermore, this technical director also stated that FMCW Lidars need to improve their integration level. High-integration multi-channel products usually need to be based on silicon photonics, and silicon photonics can only be matched with 1550 nm.

However, the director of photonics IC design of Sense Photonics, Lei Wu, said that the lasers they used are 1310 nm, “which are heavily used in communication and are very cheap.”The laser used in FMCW LiDAR and the 1550 nm laser used in TOF LiDAR have the same material (indium phosphide), but different structures. FMCW requires a narrow linewidth (to ensure coherence) and low noise, which leads to completely different performance, yields, and costs compared to TOF.

An industry practitioner states that currently, the 1550 laser for FMCW LiDAR is much more expensive than that for TOF LiDAR, and cannot be mass-produced domestically.

Advantages of 1550 nm Laser

The advantages of the 1550 nm laser have already been mentioned in the introduction to TOF LiDAR. The most critical advantage is that it will not affect human eye safety, so the power can be set higher, which in turn achieves a longer detection range than 905 nm lasers. In addition, the 1550 nm laser has better ability to overcome sunlight noise than the 905 nm laser, even in TOF LiDAR.

Disadvantages and Controversies of 1550 nm Laser

(1) High cost and difficult to reduce in the short term

The material used in the 1550 nm laser is not silicon CMOS, but indium phosphide. Moreover, it requires an external power supply and a complex electronic control device, which makes the cost high. In addition, the 1550 nm laser also needs to be used with expensive indium gallium arsenide APD.

An architect of a LiDAR manufacturer believes that although the quantity of 1550 nm laser used in optical communication is not small, the cost has not come down. Therefore, it is difficult to expect it to decrease in LiDAR.

The architect said: “When you have millions of units, the cost can definitely be much lower compared to the current hundreds or thousands, but it is still much more expensive than 905. This is determined by the physical properties of the material, just like you can’t expect the price of a gold ring to be the same as that of a copper ring just because you buy a lot of them.”

(2) Easy to be absorbed by water mist and unable to work normally in rainy days

Most LiDAR manufacturers mentioned in their communication with “Jiuzhang IMa” that the 1550 nm laser is very easy to be absorbed by water mist (a few millimeters thick water layer can absorb all the energy of the 1550 nm laser, and the professional term in optical communication field is “water absorption”), making it difficult to reflect back, and thus unable to work normally in rainy days.

An anonymous founder of an FMCW LiDAR company said: “People in our circle are all talking nonsense, saying that the 1550 nm laser has good penetration and strong anti-interference ability. I have done tests, and to the 1550 nm laser, the wall is just a black piece, and it gets better after water flows down.””Multiple experiments have shown that our FMCW Lidar is blind whenever encountering a thin water film of two millimeters. This issue is unsolvable, thus FMCW Lidar can only be used on cloudy or slightly rainy days, but not on heavy rainy days.

The responsible person from a certain TOF Lidar manufacturer said, “the reason why 1550 nm has a smaller impact on human eyes is that it is easily absorbed by liquid water–before the Laser gets to the retina, it is absorbed by the water inside the eyeball. However, being easily absorbed by liquid water will indeed result in the inability of the lidar using the 1550 nm laser to detect when there is water on the ground or when pedestrians’ clothes are wet, or in a decrease in detection ability.”

However, Yao Jian, CEO of Gaoweii Technology, does not fully agree with the above statement. Yao Jian said, “There are two types of coherence in FMCW, one is frequency modulation, and the other is phase modulation. If it is frequency modulation, the 1550 nm laser is indeed more affected by rainwater, for example, the detection distance drops from 500 meters to 50 meters. However, with our phase modulation technology, the detection distance in heavy rain can still reach about 50% of the usual distance.”

On the other hand, the CEO of a certain FMCW Lidar company, Mr. Xi, said, “In TOF, the 1550 nm laser is easily absorbed by rain and fog, which will cause a significant attenuation of the detection distance and serious noise. However, in FMCW, coherent detection is used, and the signal-to-noise ratio is higher. Therefore, with the same 1550 nm laser, the ability of the lidar to produce stable point clouds by penetrating rain and fog will be stronger.”

In addition, Andy Sun, CTO of Lovo, believes that only looking at the absorption rate of different wavelengths by water is incomplete because after encountering rainwater, only part of the laser is absorbed, and there are many changes related to scattering and refraction. In these two parts, the performance of different wavelengths is also different. For example, short waves have stronger scattering, so it is necessary to consider comprehensively.

Andy Sun said that in 2019, a French scientific research team conducted a lot of theoretical analysis and experiments and found that the performance of the two laser wavelengths, 905 nm and 1550 nm, in rainy and foggy weather was almost the same – the overall absorption rate of 1550 nm was only less than 10% higher than that of 905 nm. This is completely masked by safety considerations for human eyes, and 1550 nm can provide an advantage in terms of greater output power.

Mr. Xi, the CEO of a certain FMCW Lidar company, also mentioned this group of experiments from France.

Nevertheless, conservative car companies such as Volvo and Audi plan to use Luminar’s 1550-based TOF Lidar, which may mean that in the eyes of these automakers, the inability to work properly on rainy days is not a serious problem.

(3) It cannot absolutely ensure “human eye safety”.During the interview, the author raised a question: if several autonomous vehicles equipped with LiDARs gather together and the lasers are emitted simultaneously, the power will be very high when the lasers converge together and directly hit the human eye, which will affect human eye safety.

The response from a certain Time of Flight (TOF) LiDAR manufacturer was that if the power is high at 905 nanometers, it will damage the retina, but the retina is similar to a pixel of a photosensitive image of a mobile phone. When the laser is emitted from different places, different pixels on the retina are affected. Therefore, even if the power is relatively high, it will not burn all of the tens of millions of pixels. However, the situation is different for 1550 nanometers. If the power is high enough to burn, the entire area will be burnt. The human eye is sensitive to the energy hitting on a certain pixel at 905 nanometers, while it is sensitive to the total energy at 1550 nanometers.

In short, 1550 nanometer lasers also have safety issues with human eyes; the laser did not hit the retina, but was absorbed by the cornea. If the power is too high, the cornea will be damaged.

Chipization and Integration of Lasers and Detectors

Single photon, number of channels, and point frequency

During the interview, “Nine Chapters of Intelligent Driving” repeatedly asked a question: whether FMCW LiDAR would have many lasers like some TOF LiDAR or only one laser. Most people’s answer was that theoretically, there could be dozens or even hundreds of lasers, but in practice, manufacturers for cost considerations often use only one laser. FMCW LiDAR is also known as “Single-Photon LiDAR”.

However, although there are few lasers, with the assistance of the spectrometer, the actual number of lines emitted can be quite numerous, such as Mobileye’s FMCW LiDAR, which is said to have 184 lines. There may be more than one laser, but certainly not dozens or hundreds.

According to Andy Sun, CTO of RoboSense, “The number of channels that can be used depends on the total optical power of the laser and the setting of the spectrometer.” (It should be noted that there can be only one laser at the transmitting end, but the number of detectors on the receiving end is completely consistent with the number of channels.)

“When using a spectrometer to split a beam of light into thousands of beams, will the power of each beam be too low?” When the founder of a LiDAR company was asked this question, the answer was, “I can just increase the power at the front end, can’t I? I could split 1 watt into 10 beams, which is the same as you using 10 100 milliwatts, isn’t it? However, the cost of the former is definitely much lower than the latter.”

In TOF LiDAR, the total point frequency = the emission frequency of a single laser X the number of lasers. Then, in FMCW, will the number of lasers limit the point frequency?According to a responsible person of a TOF LiDAR manufacturer, the point frequency of FMCW LiDAR is indeed lower than that of TOF LiDAR. However, this is not because there are fewer lasers, but because “TOF ranging requires 2 microseconds once, while FMCW ranging requires 20 microseconds once,” as the CEO of a certain FMCW LiDAR company, Mr. Xi, explained. Unlike TOF, the point frequency of FMCW LiDAR does not depend on the emission frequency of the laser itself, but on the data processing speed of the back-end signal modulation and demodulation. Since the laser is continuously emitting and the back-end data processing is also continuous, the faster the back-end data processing speed, the higher the point frequency generated by the front-end.

In simple terms, the point frequency of TOF LiDAR is “supply-driven”, while the point frequency of FMCW LiDAR is “demand-driven”.

However, no matter what, it is a well-known fact that the point frequency of FMCW LiDAR is lower than that of TOF LiDAR. According to Yao Jian, CEO of LightOn Technologies, “We can achieve 10-15 frames per second now, which is enough. For TOF LiDAR, the higher the point frequency, the better. But for FMCW LiDAR, because each point has velocity information, it is not significant to increase the point cloud density at all costs.

(For why the point cloud density is not so important once the velocity information is available, please refer to the first article in this series “FMCW LiDAR Popularization (Part 1): Basic concepts, technical routes, advantages, and misunderstandings”.)

On the other hand, He Runpeng, CMO of RoboSense, believes that because FMCW LiDAR has higher signal-to-noise ratio, it can achieve good detection even if the resolution (point cloud density) is not so high.

In short, speed data and signal-to-noise ratio jointly reduce the requirements of FMCW LiDAR for point frequency.

Low-cost detectors

Unlike TOF LiDAR detectors that require high-cost APD (avalanche photodiodes) and SPAD (single-photon avalanche photodiodes), the detectors of FMCW LiDAR only need lower-cost PIN. Why?According to Wu Lei, the IC Design Director of Zhigang Photonics, in TOF, the signal will experience a loss of nearly 100db after the beam is emitted. In order to ensure detection effectiveness, the detector needs to amplify the attenuated signal, and this amplification factor is called “gain”. APD and SPA are detectors with larger gains and are therefore more expensive. However, in FMCW, half of the beam is left locally before it is emitted, and although there is still loss during the return of light, the local light is still present. When these two parts are combined, the light signal is amplified (there is already gain in the optical chip, which is called “coherent gain”).

Furthermore, in TOF, APD amplifies both the signal and the noise together, whereas in FMCW, the “coherent gain” is free from noise.

Therefore, detectors with small gains and lower costs in FMCW Lidars are sufficient for use.

Integrating the Detector and Laser into One

Now, companies that manufacture TOF Lidars such as Velodyne and Ouster are discussing the chipization of laser transceivers. So how is this achieved in FMCW Lidars?

In TOF Lidars, even with high integration, the detector and laser are still deployed on different chips. Are it possible to integrate them onto the same chip in FMCW? This question was repeatedly asked in this interview series of “Nine Chapters SDVs”.

The answer is: yes.

According to a manager from a certain FMCW Lidar company, the FMCW Lidar detector has been successfully integrated onto a silicon photonic chip (which integrates functions such as spectrometers, modulators, polarization control, and coherent mixer array). Most companies take this approach, while the laser is a III-V compound semiconductor and cannot be directly integrated onto the silicon photonic chip. However, after the laser is processed on another wafer, it can be attached to the silicon photonic chip through special processes.

Andy Sun, CTO of RoboSense, said that the current practice of companies is to package the laser independently and then couple it to the silicon photonic chip through fiber optics, known as “external laser packaging”. Andy Sun believes that external laser packaging is only a transitional form, and companies such as Intel are already moving towards “internal laser packaging”.

Mr. Xi, CEO of a domestic FMCW Lidar company, also said that they are currently exploring the process of integrating the detector and laser into the same ASIC chip, “first realizing the chipization of the transceiver module”.

According to Wu Lei, Zhigang Photonics has also independently developed integrated optical chips and matching optical modules (integrating lasers, detectors, and lenses), and is developing ASIC chips (integrating analog front-end and digital signal processing) to achieve the chipization of the transceiver first.However, in May of this year, Zhu Xiaoqi, Chairman and General Manager of Weiyuan Photonics, pointed out in a speech entitled “Challenges in integrating FMCW LiDAR from the perspective of silicon photonics technology” that it is very difficult to integrate III-V laser chips with silicon-based chips. “Whether it is the mode field of the waveguide output by the optical fiber, or the mode field of the waveguide directly output, they are much larger than the mode field of the silicon-based single-mode waveguide, and at the same time, the coefficients of these materials are completely different.”

Andy Sun, Zhu Xiaoqi, and others all admitted that Intel has found a way to integrate lasers into silicon photonic chips. They said, “This is Intel’s patent.”

According to Zhu Xiaoqi’s speech, in Intel’s solution, the light-emitting section of the laser itself is still made of III-V materials, but it is integrated with silicon crystals and silicon photonic chips through a process called “heterogeneous integration”. The process of this solution is:

1) Take a silicon wafer, after burying layer and monocrystalline silicon, etch a single-mode waveguide on the monocrystalline silicon.

2) Prepare an epitaxial wafer, including the substrate, and cut the wafer into individual chips.

3) Bond the chip to the prepared silicon single-mode waveguide in an inverted way. After it is finished, use some chemical methods to remove the InP substrate, and then do etching.

4) Dope n pole, do n pole electroplating, p pole and p pole electroplating, and do some plasma annealing.

5) Expose the light on the already made single-mode waveguide.

Andy Sun said that in the long run, everyone will integrate lasers and detectors into the same silicon photonic chip. At present, major foundries that provide silicon photonic processes are also developing their own laser integration processes, and believe that corresponding process choices will soon appear. The person in charge of a certain TOF laser radar manufacturer also believes that if they can avoid Intel’s intellectual property rights, other manufacturers may also be able to accomplish this process in the end.

However, Andy Sun also admitted that it is very difficult to integrate lasers into silicon photonic chips. He said that the cost of Intel’s approach is that the efficiency of the chip is not high, and the peak power that can be reached is not high, “so it may require integrating many lasers on it.”

Zhu Xiaoqi’s views on Intel’s approach are consistent with Andy Sun’s.

Zhu Xiaoqi said in his speech: “The size of the silicon waveguide is still limited by a particularly small size and the mode field cannot be made large. Therefore, even if light can be generated through this method, the light generated is very, very small. I have seen literature and reports that generally do not exceed 10 milliwatts, and the quantum efficiency is also very, very low, and can only be used for short-distance transmission. If it is to be used for large-scale light emission, it is actually very difficult.”

Zhu Xiaoqi also admitted that “Intel has done a relatively good job”, but he is not very optimistic about the prospects for other manufacturers to replicate this approach. “The process is very difficult, the output power of the laser is very, very low, and it is not suitable for FMCW LiDAR.”### Integration of Optical Lenses with Lasers and Detectors

In a previous speech, Yao Jian mentioned that due to certain limitations, it was difficult to integrate most parts of a TOF LiDAR except for signal processing and MEMS scanning. This meant that even optical lenses were hard to chip-enable. But what about FMCW LiDAR? This was a question that was repeatedly asked in the “Nine Chapters Autonomous Driving” interview series.

The CEO of a certain FMCW LiDAR company did not agree with the statement that “optical lenses in TOF cannot be integrated.” According to him, optical lenses can be integrated even in TOF. “Optical semiconductor technology can be used to chip-enable lenses made of single-crystal silicon. It doesn’t matter if it’s TOF or FMCW LiDAR.”

Nonetheless, everyone agreed that in FMCW LiDAR, optical lenses can be chip-enabled. The founder of an unnamed FMCW LiDAR company said, “Optical lenses can be chip-enabled. There is a professional term called ‘McKinnon’s super lens,’ which makes the lens very thin and then sticks it to the chip. This is like sticking two silicon wafers together, but this technology is not yet mature.”

Andy Sun said, “In fact, when using OPA for scanning, a separate lens is not needed because the OPA array itself is a lens with an entrance hole and an exit hole.” This was also the same opinion held by the head of a certain TOF LiDAR manufacturer.

Scanning Scheme & Integration of Scanning and Transmitting/Receiving

Scanning Scheme: OPA is the Ultimate Solution

There are various scanning methods for TOF LiDAR, such as rotating mirrors, MEMS, prisms, flash, and MEMS, but what about FMCW LiDAR? It is evident that most FMCW LiDAR manufacturers have chosen OPA scanning scheme.

However, many interviewees believed that the aforementioned scanning methods can be paired with FMCW. The founder of a certain FMCW LiDAR company said, “You can say that FMCW is naturally more compatible with OPA scanning, but that doesn’t mean FMCW can’t be done without OPA. It can use rotating mirrors, or MEMS, or prisms.”

A certain company in China currently uses dual-prism scanning and MEMS scanning for its FMCW and LiDAR respectively, Zhigan Photonics uses prism scanning, and Light Spoon Technology currently uses mechanical scanning but will switch to MEMS next year (Light Spoon only makes transmit/receive systems while scanning systems are outsourced).

Yao Jian said, “To achieve long-range detection, OPA can only be paired with FMCW, but FMCW doesn’t necessarily have to be paired with OPA.” However, all interviewees agreed that OPA is the ideal scanning scheme for FMCW LiDAR, “it is the ultimate solution.”## Why is OPA so highly thought of and what are its advantages?

OPA stands for Optical Phased Array, which adjusts the phase of each phase shifter in an array to achieve laser emission in a specific direction using the interference principle (similar to how two circles of water waves can cancel each other out or reinforce each other).

Many experts, including Wu Lei, the chief designer of photoelectron IC at Chipbond Technology, consider OPA to be a true solid-state scanner without any mechanical components.

In addition to OPA, Flash of the TOF LiDAR is also considered “pure solid-state”. However, the key difference between OPA and Flash is that “Flash is like a flashlight, emitting a surface light without an independent scanning component. The light energy at each point is relatively small, resulting in a shorter detection range. OPA, on the other hand, is a point scan with more concentrated energy, enabling longer detection range with equivalent power”.

Yao Jian explains that when a person is looking at something, even though the field of view is very large, when a mosquito flies over, the person’s eyes will focus on the mosquito immediately, rather than scanning line by line, which is not only inefficient but also prone to omissions in situations where many mosquitoes fly in and out. OPA is like, when 100 mosquitoes fly over, the light beam can immediately focus on all 100 mosquitoes, achieving high efficiency without any missed targets.

However, a certain TOF LiDAR manufacturer disagrees with this viewpoint, believing that electronic scanning cannot be intelligent to such an extent. According to them, you have to know that there is a mosquito first before focusing on that direction, which is akin to “knowing the result and then striving for the process”. Since you already know the target and its location, why would you want to scan it?

Mr. Xi also believes that OPA does not have a focusing function, and “it was originally a parallel light, and it still is after leaving, just from a different angle.” Mr. Xi said that OPA actually utilizes the diffraction coherence principle of light, achieved by changing the refractive index or dielectric constant of the materials to deflect light, and the faster the change, the faster the deflection.

The same TOF LiDAR manufacturer stated that theoretically, OPA can be used as an optical lens after maturity.An anonymous founder of an FMCW Lidar company said, “Certainly, FMCW does not necessarily have to be paired with OPA, but the FMCW’s transceiver system needs to use silicon photonics technology to reduce costs. If the scanning module also uses OPA based on silicon photonics technology, wouldn’t it be easier to integrate both the transceiver and the scanner?”

Andy Sun also believes that both FMCW and OPA need to be realized through a silicon photonics technology platform. Therefore, whether it is the initial two chips or the final single chip, FMCW+OPA is a natural and inevitable technological choice.

However, although OPA is considered the “sexiest ultimate route,” the process of realizing it will be relatively long.

Yao Jian said, “In ten years, Lidar will definitely be FMCW+OPA, but OPA is still in the laboratory now.”

The integration of scanning and transceiving

Since both OPA and the transmitter are based on silicon photonics technology, it is only natural to integrate the two modules together. This is not a bold guess, but rather something that some companies are already practicing.

The chairman and general manager of Weiyuan Photonics, Zhu Xiaoqi, said that integrating OPA scanning components with coherent optical paths and detectors on the same silicon wafer is something that the communication industry is already doing. The next step is to solve the integration problem between III-V family chips (laser) and silicon-based chips, and to integrate scanning and transceiving together, which is a natural result.

It is generally believed in the industry that in Intel’s FMCW Lidar, the scanning system and the laser transceiving system are integrated on the same chip.

Why can Intel do this? An FMCW Lidar company founder introduced to the author, “Intel’s silicon photonics already has a light source on it (only they have it), so their silicon photonics is no longer silicon photonics in the traditional sense, because it has indium phosphide and silicon on it. Its silicon photonics, I think should be called ‘heterogeneous light’, which is two different and exceptional materials. So, only they can go this route.”

However, it is reported that LightIC, a Silicon Valley company, is also attempting this technological path.

In domestic companies, Luowei CTO Andy Sun and others have stated that this is also the direction they are striving for.

According to Andy Sun, the scanning and transceiving of millimeter-wave radars are integrated together, and their modulation method is FMCW.

Because the scanning system can be integrated with the transceiving system, Xu Li, CEO of LightX, has repeatedly emphasized that FMCW Lidar can “achieve a higher degree of chipization than TOF,” and Xu even called it “real chipization”.However, in a previous speech, Zhu Xiaoqi pointed out that there is a significant coupling loss between the OPA and the light source, which is a difficult problem for the entire industry to solve. The progress in solving this problem will largely determine the progress of true “chipification” of FMCW lidars.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.