Author: Chang Yan

I don’t know if you feel it, but this is a very fast article.

Because I am writing this article while sitting on the high-speed train from Nanjing to Shanghai, and completing the creation at a speed of 300 km/h.

In a certain sense, the high-speed train is an extreme of electric vehicles. From the perspective of a passenger’s intuition, there is no excessively intelligent function, but you can feel the power of electric propulsion to the extreme.

But this is enough to excite people.

From my first ride on a bullet train in 2007 to the current Fuxinghao high-speed train, every advancement of electric power has brought us faster speeds and more comfortable cabin experiences, and these bring about more efficient efficiency and more direct pleasure.

Therefore, an interesting or meaningful electric vehicle must also not forget to create a synchronous and growing electric drive system.

Like the NIO ET7.

Efficiency, Performance, and Silence

In the introduction of the entire system, these three words have the highest frequency of appearance.

This is like the key words printed in the efficacy column behind prescription drugs, direct and important.

As NIO’s first sedan, the ET7 is already highly anticipated in terms of absolute performance and quietness; as a new platform and intelligent model of NIO’s transformation, its efficiency will become the foundation for all functions to be implemented. Moreover, everyone also hopes that the new model can regain a game in terms of energy consumption performance compared to NIO’s previous models.

These are the questions that the NIO ET7 is trying to answer through the entire electric drive system.

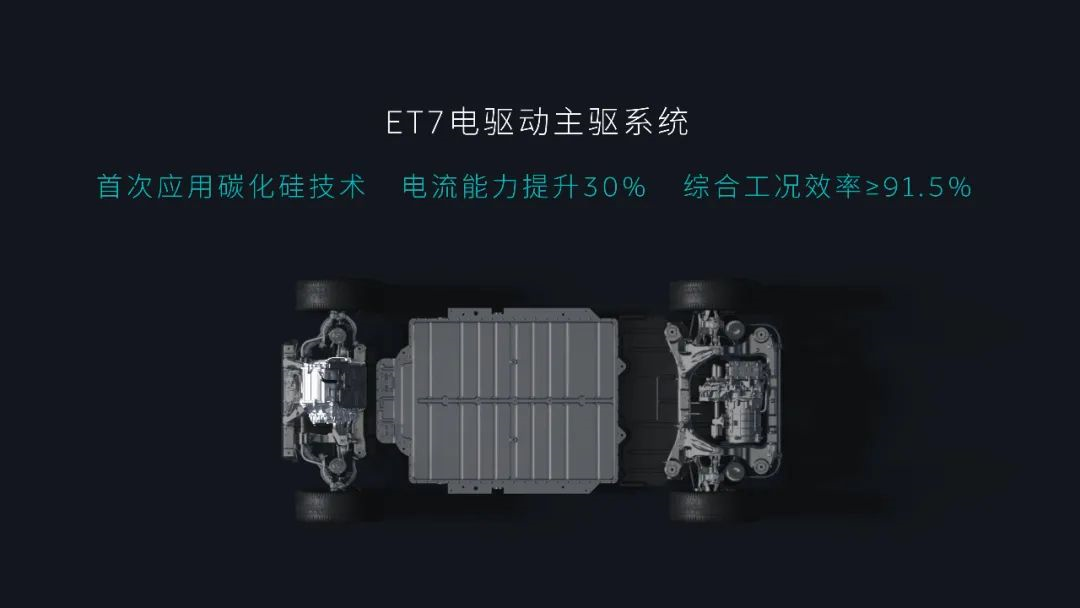

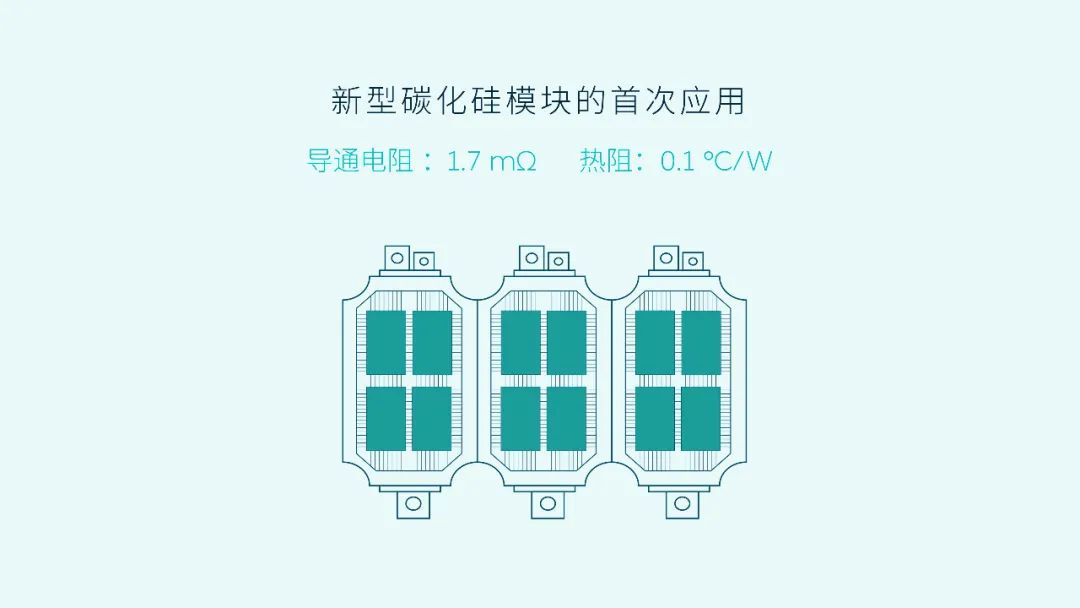

The ET7 has become NIO’s first vehicle product to adopt silicon carbide (SiC) power modules.

When it comes to this technology, NIO’s Senior Vice President, Zeng Shuxiang, specifically said: “This is Global TOP3”. The first two are Tesla and BYD, and whether ET7 can stand firm in the top three globally depends on who can deliver between the Lucid Air and ET7, but this is not important. What is important is that this is an advanced technology with rare applications.

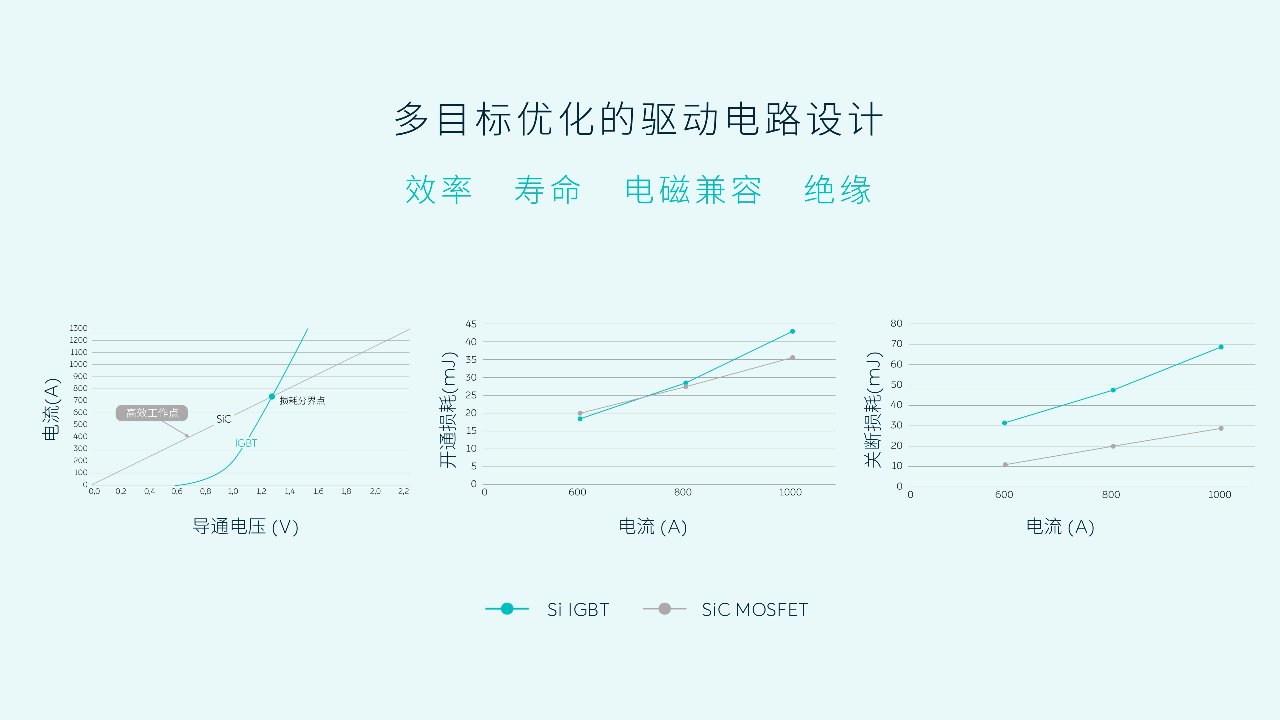

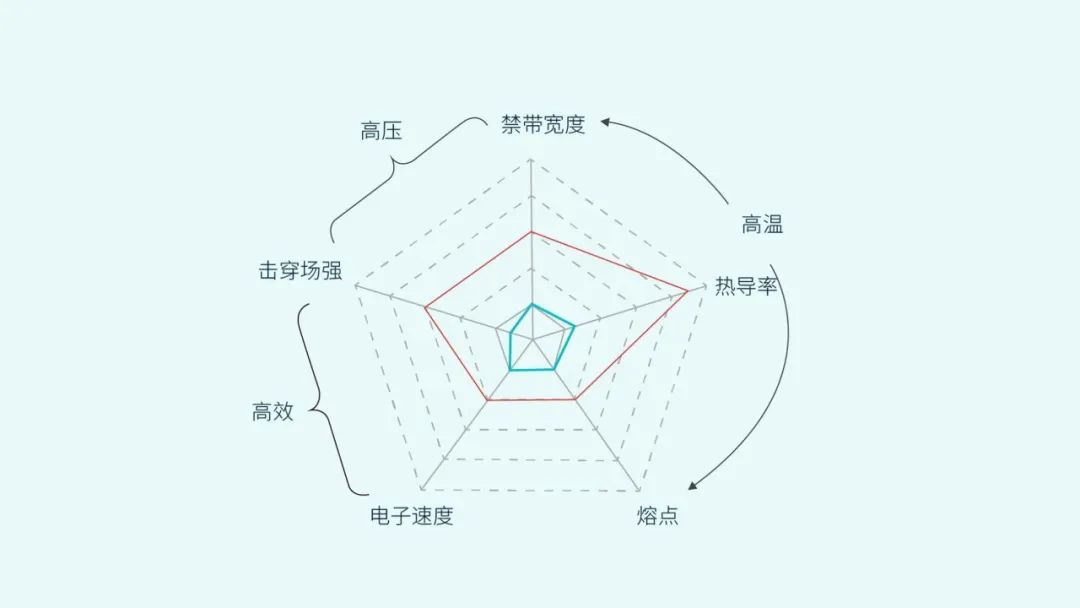

Carbonized silicon is a third-generation wide bandgap semiconductor material with excellent electrical properties and high temperature resistance, which can increase the maximum current capacity by 30% in the same volume and is suitable for a wider voltage range. The switching speed is not only fast, but the power loss during switching is also lower.

Carbonized silicon is a third-generation wide bandgap semiconductor material with excellent electrical properties and high temperature resistance, which can increase the maximum current capacity by 30% in the same volume and is suitable for a wider voltage range. The switching speed is not only fast, but the power loss during switching is also lower.

Designing a permanent magnet synchronous motor controller based on carbonized silicon can greatly improve the system efficiency. For example, using the 180 kW permanent magnet synchronous motor of ET7 as an example, the overall comprehensive loss of the motor has been reduced by 4%-6% compared to the previous generation. In addition, because the efficiency of carbonized silicon components is higher in low current working state, it means that ET7 can perform better in most city driving conditions, and the mileage performance will also be improved.

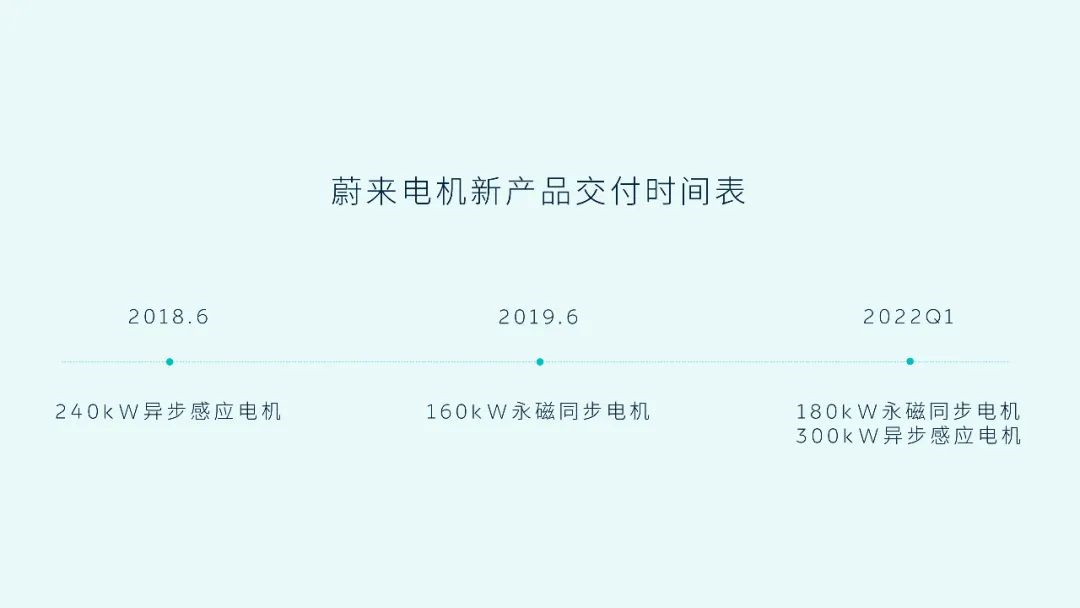

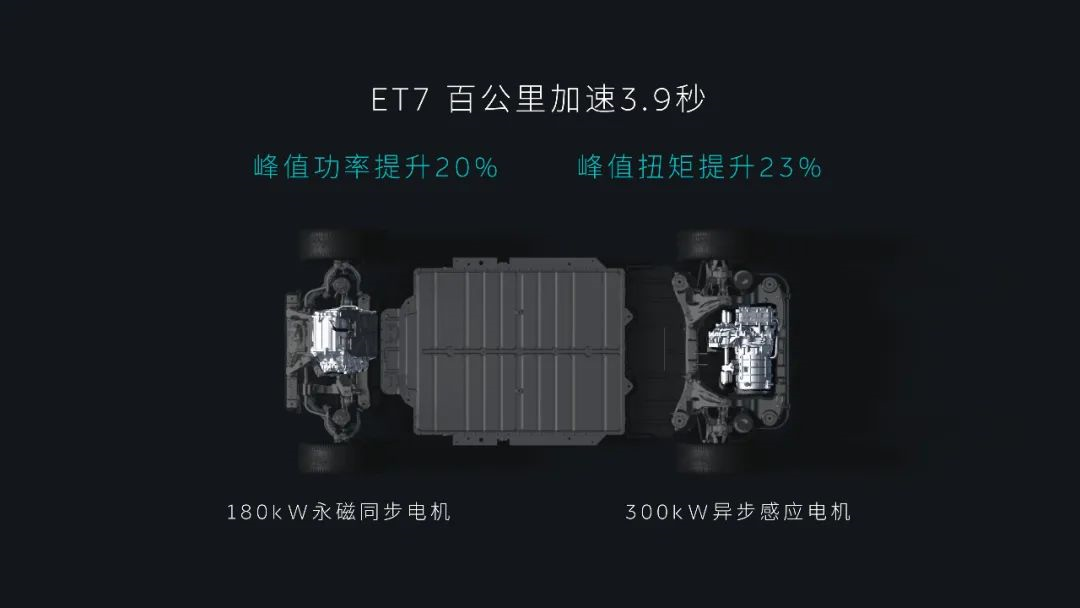

For NIO’s current main electric drive configuration, both the front and rear motors of ET7 have achieved proportional performance improvement. The maximum power of the front permanent magnet synchronous motor of ET7 is 180 kW, and the maximum power of the rear asynchronous induction motor is 300 kW. The peak power has increased by 20% compared to the previous 160 kW + 240 kW, and the peak torque of the system has also increased by 23%.

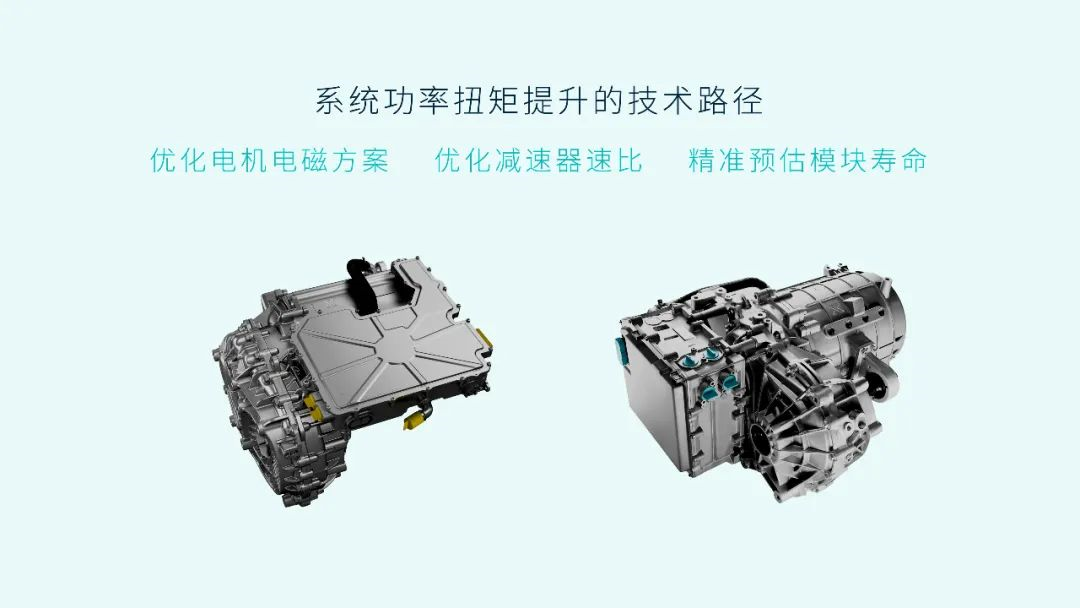

In addition to the impact of the aforementioned controller current increase, these improvements also include support for motor electromagnetic schemes and gear ratio adjustments.

The real refinement is on the optimization of NVH in the electric drive system.

It is also a contradiction to think that in the era of gasoline cars, we have already agreed to accept the convention that any product with strong horsepower will have a deep and stirring sound wave. But in the era of electric cars, we want both – fast running vehicles and quiet ones.

Correspondingly, on the one hand, the mechanical parameters such as the speed of the motor will become higher, and on the other hand, better design and workmanship are needed to reduce possible noise.

On the hardware front, EDS assembly modal optimization with suspended fusion control, motor non-uniform air gap and high positive rotating air gap magnetic density, tooth shaft structure optimization design achieves more precision coupling and manufacturing-level, lowering the possibility of adverse experiences such as noise and vibrations during operation.

On the hardware front, EDS assembly modal optimization with suspended fusion control, motor non-uniform air gap and high positive rotating air gap magnetic density, tooth shaft structure optimization design achieves more precision coupling and manufacturing-level, lowering the possibility of adverse experiences such as noise and vibrations during operation.

On the software front, ET7 has optimized the controller harmonic injection and control strategy for higher-frequency scenarios.

For example, in the current generation electric drive system, NIO has developed the ability to use the waste heat of the motor to heat the battery, providing up to 4 kW of heating power. In this scenario, the current injection and control requirements for the motor are different from those under normal operating conditions. Similarly, engineers use software harmonic control algorithms to eliminate noise in this scenario.

Oh, by the way, the motor heating battery function will be upgraded to the current electric drive system in the future, but due to hardware changes, previous owners will not be able to upgrade this function.

NIO Electric Drive Logic

Almost simultaneously, NIO ET7 appeared in the summer and winter seasons.

This is not a dream, because the ET7 is undergoing electric drive system testing in multiple locations at the same time.

This includes Sanya, which is like a summer paradise, and New Zealand, which is in the winter season at the same time.

Oh, by the way, it also appeared on the familiar Sichuan-Tibet line a few days ago…

The testing work is proceeding rapidly, and it is driven by the sudden acceleration of the NIO brand’s fate with the ET7 project.

In 2019, the project was initiated, but at that time, due to NIO’s financial problems, progress was relatively slow. In the second quarter of 2020, the entire development began to accelerate. In July, the silicon carbide project was completed and approved, and “all the silicon carbide module companies in the world came to us.”

According to Zeng Shuxiang’s introduction, NIO’s electric drive R&D resources increased by 100% in the past year, and the entire team is working hard to complete the project as scheduled. “We do not call it overtime, we call it work,” he joked and introduced the work ethics of the NIO electric drive team.

As a result, the brand-new electric drive system of ET7 has revealed many unique NIO product logics and cognition.

For instance, the shape and interface of ET7’s electric drive module are as compatible as possible with the previous generation’s electric drive system. This brings the benefits that a large number of body-related components and high- and low-voltage wiring harness interfaces can be directly reused, reducing costs and accelerating the development of new car models and potential upgrades for older models.

Another example, as more and more manufacturers start to adopt the full permanent magnet synchronous motor technology and continue to increase the power limit of a single permanent magnet motor, NIO still adheres to the combination of permanent magnet synchronous and asynchronous induction motors on ET7, and continuously iterates and updates the technical indicators of both motors. This is also a long-term observation-worthy technical choice.

Of course, this actually also provides more possibilities for the adjustment of NIO’s future electric drive technology routes. Following NIO’s style of producing one generation and developing one generation, whether it will adopt more significantly changed electric drive solutions on follow-up vehicle models and platforms will be the focus of attention at this year’s NIO Day.

Is it Necessary to Develop Electric Drivetrains on Our Own?

At the beginning of the communication meeting, I understood a truth.

Developing electric drivetrains on our own is very expensive.

According to the introduction, from 2015 to now, NIO has invested approximately 150 million yuan in electric drivetrain development, spent approximately 130 million yuan on experiments, spent 1 billion yuan on purchasing experimental platforms over six years, and spent nearly 30 million yuan on various software development tools.

“Among the new forces in the industry, no one has spent this much.”

So, someone asked during the Q&A session, do you think all car manufacturers should develop electric drivetrains on their own?

Zeng Shutao’s answer was that this has a lot to do with brand positioning. At the beginning, NIO’s positioning also had a heavy value of being a high-performance brand, so it was not easy to achieve industry-high performance by simply buying external mature products.

But now, NIO has full-stack self-developed capabilities in electric drivetrains.

In NIO’s view, self-developed electric drive full-stack technology does not simply mean producing the motor themselves, or having the ability to integrate mechanics. Instead, it embodies many technical dimensions of capability, such as whether the software is developed in-house, whether the main chip is self-selected, and whether the boxes, modules, and controllers are self-developed.

In NIO’s view, self-developed electric drive full-stack technology does not simply mean producing the motor themselves, or having the ability to integrate mechanics. Instead, it embodies many technical dimensions of capability, such as whether the software is developed in-house, whether the main chip is self-selected, and whether the boxes, modules, and controllers are self-developed.

On the first page of the communication meeting PPT, it is stated that NIO’s electric drive system has obtained and applied for 215 patents, including 81 invention patents.

This has brought NIO a higher level of freedom in the supply chain, product definition, and development cycle. We have the opportunity to see NIO bring more functions, improve integration and development efficiency, while reducing the entire life cycle cost, in the long run, for electric drive systems.

This objective is called “from defining Chinese-leading to defining world-leading.”

Lastly, let’s conclude with three statements by Bin Li:

- Time is worth spending money on.

- No matter how difficult it gets, we can’t compromise on research and development.

- As for R&D, we should not always think in terms of addition, but also consider subtraction.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.