On October 15th, SAIC-GM Ultium Altium Super Factory was officially put into operation in Jinqiao, Pudong New Area, Shanghai.

As one of SAIC-GM’s important projects of 50 billion RMB investment in new technology areas such as electrification and intelligent interconnection, Altium Super Factory was upgraded from the former SAIC-GM Power Battery System Development Center, with the production and testing capability of power battery systems, and the product line includes battery systems such as mild hybrid, plug-in hybrid, and pure electric.

Battery Production Process

On the day of the production ceremony, I visited the Jinqiao Altium Super Factory and reviewed the entire process of Altium battery production:

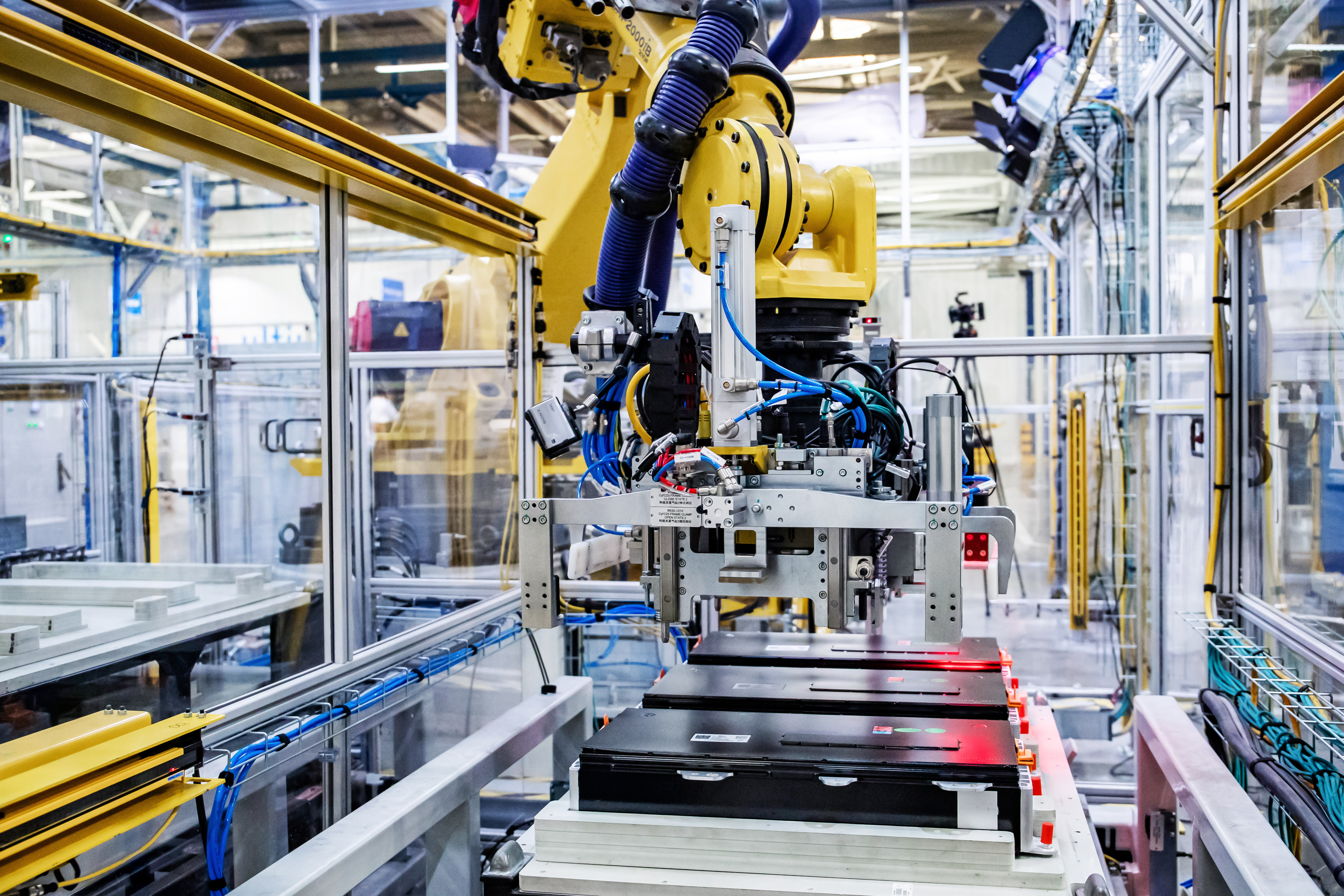

01 Testing of bottom plate incoming materials

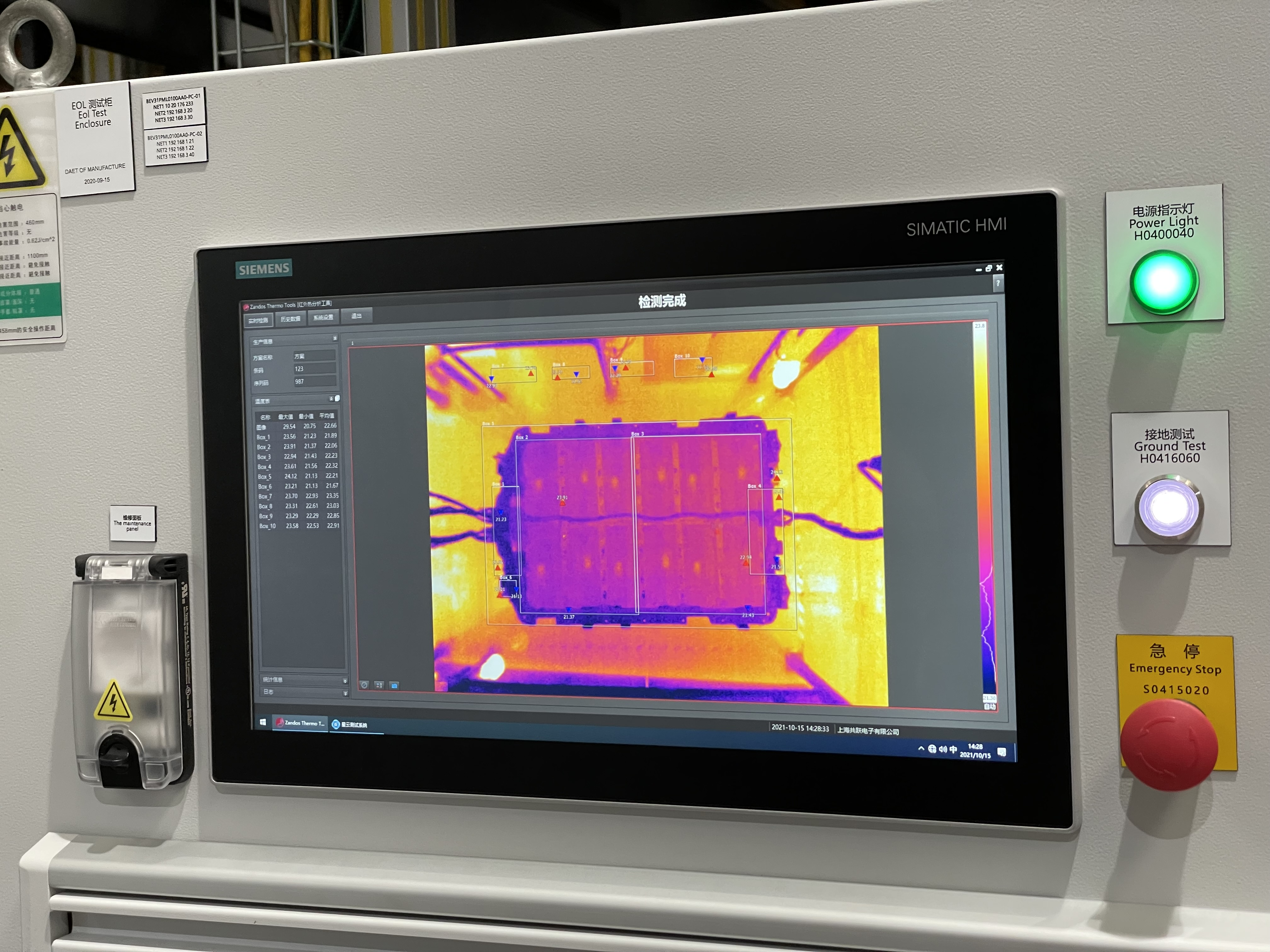

02 Wireless communication detection of incoming module

The factory’s battery modules came from CATL’s 811 formula, with the addition of wireless communication modules, allowing for direct testing through wireless communication during incoming materials.

03 Module fixation (positioning, tightening)

04 High-voltage connector wires, cooling water pipes, battery system distribution box (BDU), and other control installations.#### 05 Charging and Discharging Test

06 Nucleus Box

07 Explosion-proof Valve Installation and Box Sealing Test

In the battery assembly workshop, 100% airtightness testing is conducted on incoming materials, processes and assemblies using high-precision airtightness instruments. The airtightness testing limit for the entire battery pack is 10 times stricter than the industry average limit, and the results can be traced throughout the entire lifecycle.

The use of wireless communication technology brings many advantages to the battery and production:

-

Avoids damage to parts caused by traditional battery testing plug-in connectors;

-

Improves assembly quality and production line efficiency.

-

Through wireless communication technology, the low-voltage communication harness of the battery is eliminated, reducing 90% of the wire harness of the battery pack. In addition to real-time monitoring of the battery status, OTA is also supported. However, the space freed up by the reduced wire harness has limited effect on improving the physical energy density.

Other Information

-

SAIC-GM and Pan Asia Technical Automotive Center (PATAC) participated in the synchronous design and development of the bottom-level architecture of the Oter Energy electric vehicle platform;

-

Based on a highly localized business chain system, over 95% of the parts are locally procured.- By 2025, SAIC-GM will launch more than 10 domestically-produced new energy vehicle models based on the Altium electric vehicle platform, covering its three major brands as well as multiple categories and sub-markets.

The SAIC-GM Ultium Altium super factory, along with the Pan-Asia New Energy System Test Building and Guangde Battery Safety Testing Laboratory, which were put into use in March, will enable SAIC-GM to have a complete new energy system capability from technology research and development, test verification, production and manufacturing to local procurement.

Source: SAIC-GM

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.