Author: James Yang Jianwen

Is the 800V high-voltage platform really necessary? That’s a good question.

Before addressing this question, let’s take a look at this news from CCTV:

“During the National Day holiday, some owners of new energy vehicles encountered difficulties queuing up to charge. A new energy vehicle owner told reporters that he had been looking for charging stations from Shijiazhuang to Beijing, queuing up at every highway service area, and did not charge until he arrived at the service area closest to Beijing. Another new energy vehicle owner told CCTV reporters that he charged for 3 hours on a 4-hour trip, taking a total of 7 hours.”

Even in 2021, range anxiety is still a major challenge for many people.

Under this pain point, everyone has turned to the 800V high-voltage platform as a way out. People believe that using the 800V platform can completely solve this problem, and many car companies have announced their layout of the 800V high-voltage platform.

However, is this really the only way out?

What is the 800V high-voltage platform?

Let’s first explain what the high-voltage platform of a car is.

Inside a car, there are many components, and even more so after electrification.

The purpose of the voltage platform is to match the power demands of different components. Some components require lower voltage, such as vehicle electronics, entertainment equipment, and controllers (usually powered by a 12V voltage platform), while others require higher voltage, such as battery systems, high-voltage electric drive systems, and charging systems (400V/800V), thus creating a division between high and low voltage platforms. What we want to talk about is the latter, the 800V high-voltage platform.

At present, the vast majority of car companies in the industry still use the 400V high-voltage platform. The term 800V high-voltage platform appeared on a large scale in our field only after the launch of the Porsche Taycan.

At that time, the slogan of Taycan was: Peak charging power can reach 350 kW (but currently peak power can only reach 270 kW, and only 200 kW can be given domestically).

When Taycan was launched in China, Porsche demonstrated charging with its own 800V charging station for a Taycan, only using less than half an hour (28.5 minutes) from 5% to 84%, leaving a deep impression.

The 800V high-voltage platform is closely associated with faster charging speeds. Since then, we have seen more and more automakers using the 800V high-voltage platform, such as:

The 800V high-voltage platform is closely associated with faster charging speeds. Since then, we have seen more and more automakers using the 800V high-voltage platform, such as:

-

BYD: The all-new e-platform 3.0 uses 800V high-voltage charging technology, achieving 5-minute charging and 150 km range.

-

Huawei: Plans to launch the FC1 fast-charging solution with 750V and 200 kW this year. The solution can achieve 30%-80% State Of Charge (SOC) in 15 minutes. In 2023, the FC2 fast-charging solution with 1000V and 400 kW will be launched.

-

Zeekr: The SEA Haohan Intelligent Evolutionary Experience Architecture used by Zeekr can be matched with the 800V voltage platform, supporting 360 kW super-fast charging.

-

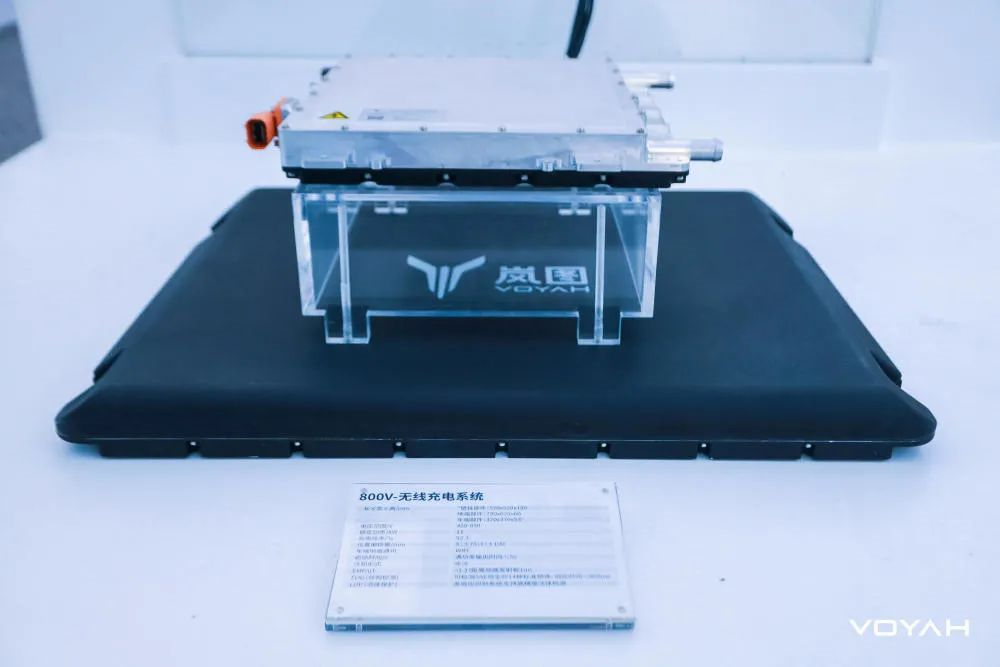

Voyah: Equipped with an 800V high-voltage fast-charging system that supports a maximum of 350 kW super-fast charging, providing 400 km of driving range with only 10 minutes of charging.

-

Polestar: 800V is under development.

-

Li Auto: The 800V architecture will be used for its pure electric models, reducing the charging time to 10-15 minutes.

-

GAC Aion: Launched the 880V high-voltage platform, achieving a maximum charging power of up to 480 kW. During the test drive, the car’s battery was charged from 30% to 80% in less than 5 minutes (4 minutes and 50 seconds).

Undoubtedly, the adoption of the 800V high-voltage platform makes electric vehicles more durable and capable of supporting higher currents and voltages, resulting in faster charging speed, as well as stronger driving performance.

However, it should not be ignored that the related supply chain of the 800V high-voltage platform is not yet mature at the moment. Even for Porsche Taycan, some high-voltage components are still adapted to the 400V platform, such as the air conditioning compressor. Therefore, a DC/DC converter is still needed to lower 800V DC to 400V DC for the air conditioning compressor until the next-generation 800V air conditioning compressor is introduced, which is a supply chain issue.

What’s more, there are not many charging piles that match the 800V high-voltage platform on the market, and most of the charging piles still adapt to the 400V platform. Even for Porsche, the maximum charging power based on the Chinese standard 800V can only be achieved at a rate of 200 kW. Also, the higher the power of the charging pile, the greater the requirement of the electric power capacity, and the greater the burden on the power grid. This is another problem to be solved.

In short, it is not easy to implement the 800V technology. This is also why we have not seen any other mass-produced models with the 800V high-voltage platform since Taycan in the short term (although the e-tron GT is on the same platform as Taycan, it has not yet been officially launched).

However, the 800V high-voltage platform is not the only solution to “slow charging”.

Low Voltage High Current

Take Tesla as an example. Tesla does not use an 800V platform now, but except for the Model 3 Standard Range upgrade, other models support peak charging power of up to 250 kW.

For example, in the case of Model 3 Long Range, in the peak power state, the amount of charging in 5 minutes can drive about 120 kilometers, and the average charging time of users can be reduced by about 50% under ideal conditions. This charging experience is already very good.

Another example is the EXTREME EKSA 001, which also adopts high current in low voltage. Although 001 does not use an 800V platform, it is not weak in charging efficiency.

Under the 400V voltage architecture, ZEEKR 001 can reach a high charging rate of 2.2C and a maximum charging current of 600A. In the previous official tests of EXTREME EKSA, it achieved a charging power of 223 kW in 5 minutes, a range of 120 kilometers, and a peak charging power on its own extreme charging piles.

Notice that these manufacturers’ car models do not use the 800V high-voltage platform, but this does not affect their very fast charging efficiency.

Obviously, even under the 400V platform, through the optimization of electronic and electrical architecture and the matching development of core components, continuous exploration of the potential of the 400V platform can bring significant improvements in charging efficiency.

“Human High-Quality Charging Pile”

In addition to working on the car itself, infrastructure is actually an area that has been neglected.

According to the data of the China Electric Vehicle Charging Infrastructure Promotion Alliance: as of August 2021, the total number of charging infrastructure nationwide has reached 2.105 million, with a year-on-year increase of 52.3%. Although the numbers look dazzling on paper, in fact, the quality of most charging piles is not high, and charging times can take several hours.

To illustrate, our long-term vehicle Marvel R charged from 14% to 91% in about 1 hour on a 120kW charger, but if we change to a 40kW charger, the time would need to be extended to 3-4 hours.To solve the problem of difficult charging, it might be a good idea to start with building a more comprehensive charging network.

Tesla is a typical representative that has built a strong and stable energy supplement network with high and stable charging power. Supercharging has become a protective barrier for Tesla, and the high-quality energy supplement network is an indispensable factor in the success of Tesla.

Under the influence of Tesla and new forces, we see more and more brands beginning to realize the importance of high-quality charging piles and starting to lay out their own infrastructure:

- Pudu Technology: PuduCharge piles with 240-360 kW power. This year, PuduTech plans to build its domestic charging network in ten Chinese cities, including Beijing, Shanghai, Guangzhou, Shenzhen, Hangzhou, Ningbo, Xi’an, Changsha, Wuhan, and Chengdu.

- GAC Aion: 480 kW high-power charging pile with up to 600 kW peak charging power. By 2025, GAC Aion plans to build 2,000 super charging stations in 300 cities nationwide.

- Jitang Automobiles: 180 kW supercharging piles (will be upgraded to 360 kW later). In 2021, Jitang plans to invest in building 24 exclusive supercharging stations and 16 destination charging stations in Beijing, Shanghai, Shenzhen, Guangzhou, and Suzhou, as well as 84 certified stations and 267 recommended stations.

- Even the giant Volkswagen has formed a joint venture with FAW, Star Charge, and JAC Motors to establish a new energy company, CAMS, to deploy 120 kW high-quality charging piles (later upgraded to 180 kW supercharging piles). By the end of 2021, CAMS plans to build more than 500 supercharging stations and 6,000+ charging terminals in eight core cities for electric vehicles.

In summary, my purpose in writing this article is simple: to dispel some of the misunderstandings about the 800V platform.

Although there are many advantages to the 800V platform, it does not mean that there is only one way to “charge faster.” As the article points out, it is also feasible to build more “human-quality charging piles” and continue to explore the potential of the 400V platform.

It is foreseeable that the 800V high-voltage platform will be a big trend in the industry, but it is not yet fully mature. It will take some time to match the supply chain system and infrastructure.

Although many automakers have announced their plans for the 800V high-voltage platform, from the perspective of technological development, this is a good thing. However, I don’t want to see OEMs blindly follow the trend and adopt 800V platforms just to keep up with their competitors. Companies should make corresponding technical plans based on their own needs.The best one is always the one that suits you.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.