The following video is from “007: Casino Royale”:

In this scene, the Aston Martin DBS is completely wrecked in a seven-rollover crash, breaking the Guinness record for the number of car rolls in a movie stunt.

This scene is not computer-generated, nor is it modeled. It is actually performed with real cars. However, it is not easy for a sports car to roll, especially the low center of gravity and wide wheelbase of the Aston Martin DBS.

To achieve this effect, the production team used various methods, even trying to use a high-angle ramp to assist, but it was in vain. After all, the DBS is a sports car with a low center of gravity and wide wheelbase, making it difficult to flip over with just a slope. Finally, the “007” production team had to install an air cannon under the car’s chassis, and after some tail-flicking maneuvers, they used the force of impact to directly shoot the DBS into the air.

The scene of the DBS flipping over in “007” was filmed at the Millbrook Proving Ground in Bedfordshire, England.

Ironically, or should I say, “reverse irony,” this is also the site where the car’s chassis was developed. It’s interesting to see a failure being staged at the very place where the car was supposed to become stronger.

Returning from the spy movie from more than a decade ago to the present, we can see that the UK is still the center of the racing world. As the headquarters of seven F1 teams and numerous professional car testing sites, the UK remains a stronghold of motorsports.

Millbrook is one of the largest and most famous professional automotive performance testing sites in the UK, with over 72 kilometers of test tracks centered around B roads. Many high-performance sports cars, racing cars, and military vehicles choose to be tested here.

Millbrook is one of the largest and most famous professional automotive performance testing sites in the UK, with over 72 kilometers of test tracks centered around B roads. Many high-performance sports cars, racing cars, and military vehicles choose to be tested here.

In order to develop the chassis of the L7, IM Automobile didn’t let obstacles like the pandemic, language barriers, time zone differences, and funding stop them, and sent several engineering samples to the UK. IM’s team worked together with the WAE team through simultaneous R&D for a full 180 days to give the electric vehicle authentic driving pleasure.

Yes, IM’s own IM L7 went to the UK, just for the pursuit of their products. Among domestic brands, only IM places such emphasis on driving feel and puts in this much effort in R&D in my impression.

WAE

So, what level of existence is Williams Advanced Engineering (WAE)?

Williams Advanced Engineering (WAE), originating from the Williams F1 racing team, which has won 9 championships among manufacturers and 7 championships among drivers, is located adjacent to the F1 team headquarters. WAE has extensive experience in F1 and other racing development and performance tuning.

Although the Williams F1 team’s performance is not eye-catching, they are one of the few engineering companies established from F1 participation to provide feedback to civilian cars.

Aerodynamics, thermal management, lightweight composite structures, energy storage systems, and electric drive are WAE’s strengths. Of course, WAE also provides technical support for non-F1 top-level racing competition vehicles such as Formula E, ETCR, and Extreme E. And as long as the money is in place, they can provide a complete solution.

As a technology group born out of F1, WAE’s portfolio of works can be quite impressive, and not just limited to electric vehicles. Let’s take a look at WAE’s top portfolio below.

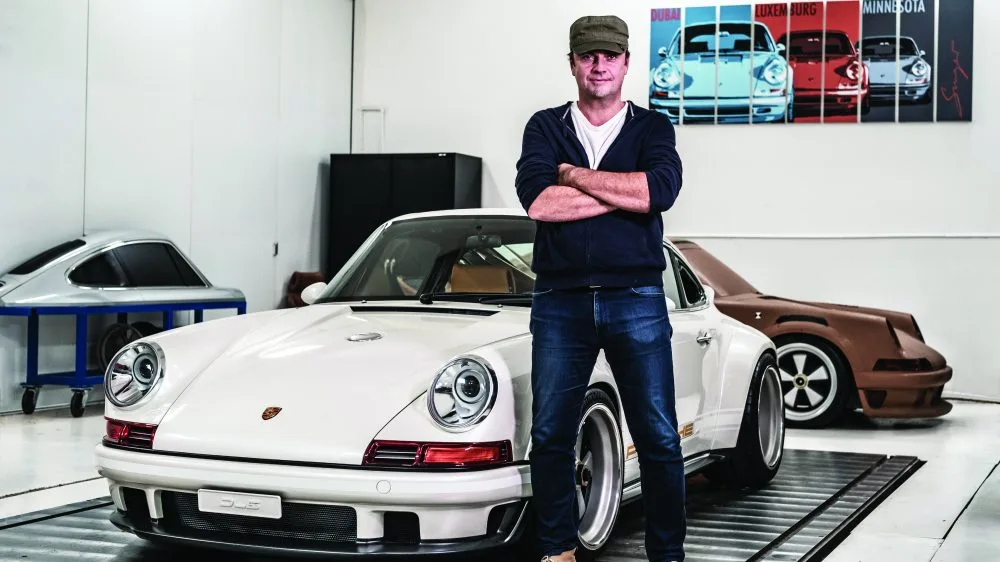

Singer DLS

A former car designer later became a singer, and eventually returned to his old business due to his love for the classic 911, starting a vintage car restoration business, which is now known as the world-renowned company, Singer.

However, as a car designer, founder Rob Dickson raised the restoration requirements to a level beyond the original factory standards, entering the field of industrial art creation. Its subsidiary, the Singer DLS, can be said to be a brand new car except for the body shell and basic running components sourced from outside the 964.

And the 500 horsepower water-cooled, horizontally-opposed six-cylinder naturally aspirated engine behind the “Good God” rear end is the work of WAE. The transparent air intake behind the rear triangle window and the ceramic-coated exhaust pipe are simply stunning.

WAE’s projects also include:

Jaguar C-X75 supercar prototype

Development of aerodynamic package for GT-R NISMO Track Pack

Nissan BladeGlider

Electric propulsion system of Aston Martin Rapide E

Battery pack of Lotus Evija

## Zhi Ji L7

## Zhi Ji L7

Balance brought by electric drive

At the chassis communication meeting, Paul McNamara, the Technical Director, represented WAE, which is particular about the project, and affirmed the high-end brand image and engineering excellence of Zhi Ji Automotive.

As one of the few high-end intelligent electric vehicle brands in China, Zhi Ji Automotive is indeed an excellent business card for WAE targeting the Chinese market by focusing on luxury electric vehicles. This cooperation can be said to be a win-win.

The dual-motor all-wheel-drive version of Zhi Ji L7 has a power output of 544 horsepower and 700 N·m, equivalent to the performance of a high-performance sedan with a million-dollar 4.0T V8 engine, achieving a 0-100 km/h acceleration time of 3.9 seconds. The story of Williams starts from this 3.9 seconds. Because a car with a length of nearly 5.1 meters and a wheelbase of 3.1 meters needs not only 3.9 seconds, but also comprehensive strength including chassis performance.

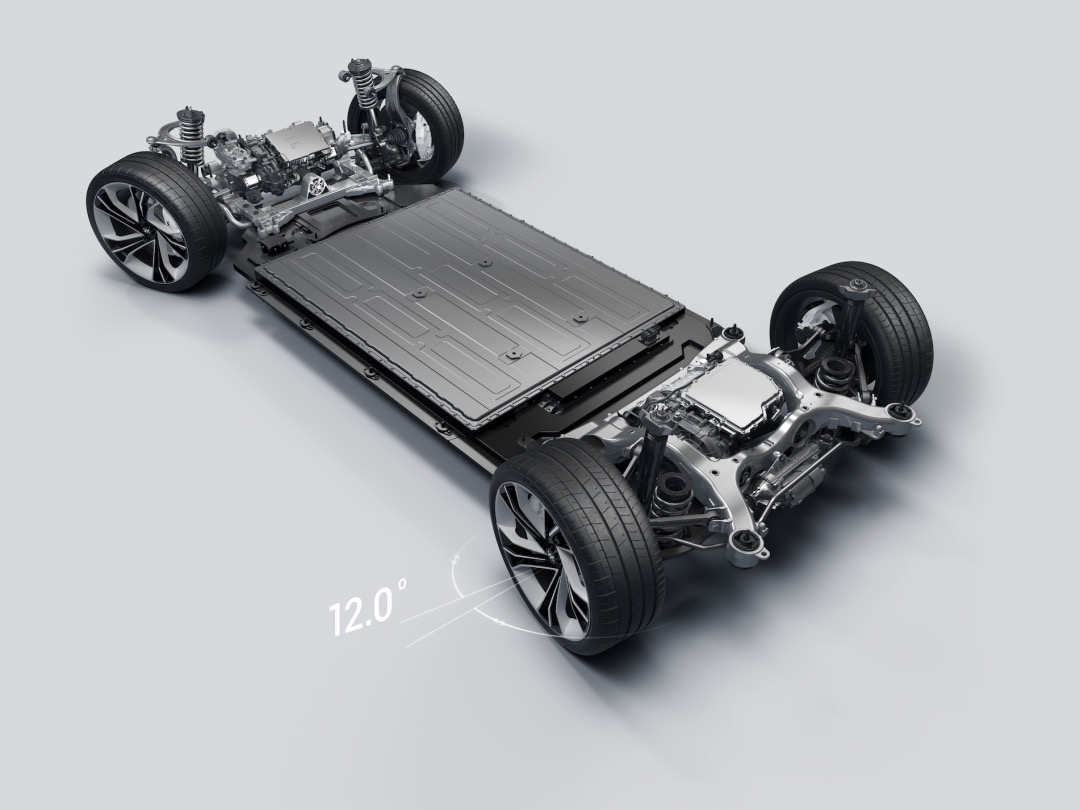

No matter who holds the reins, without a good foundation, there is no way to achieve higher goals. Compared with the similarly sized BMW 5 Series, the Zhi Ji L7 has a 66mm lower center of gravity. The 490mm height of center of gravity and the front and rear wheelbase of 1,650mm and 1,660mm, respectively, bring high stability.

NHTSA (National Highway Traffic Safety Administration) has an expression for how difficult it is for a car to roll over. The calculation formula for the anti-roll coefficient is t/2h (t is the wheelbase and h is the height of center of gravity). The coefficient of 1.25-1.45 is rated four stars, while 1.45-1.6 is rated five stars. After this simple calculation, the anti-roll coefficient of Zhi Ji L7 reaches 1.69, achieving over five-star stability.

If the disadvantage of electric vehicles compared to gasoline-powered vehicles in terms of performance is weight, then the ideal center of gravity position is an excellent compensation.The center of gravity of electric vehicles is not only very low, but also very centralized. In this regard, IM’s achievement is a front-to-rear weight ratio of 50:50. This data, which is commonly seen in sports-oriented front and rear drive gasoline vehicle models, has always been considered the most balanced front-to-rear axle weight distribution setting for handling and stability.

The heaviest component in an electric car is the battery, which has a mass of around 500 kg. The fact that the heaviest component is located in the center and lowest point of the car is a crucial factor in reducing the polar moment of inertia. This is also why electric cars, which typically weigh 200-300 kg more than gasoline cars of the same size, can be driven like mid-engine sports cars that are so agile.

Double Ball Joint Double Wishbone Front Suspension?

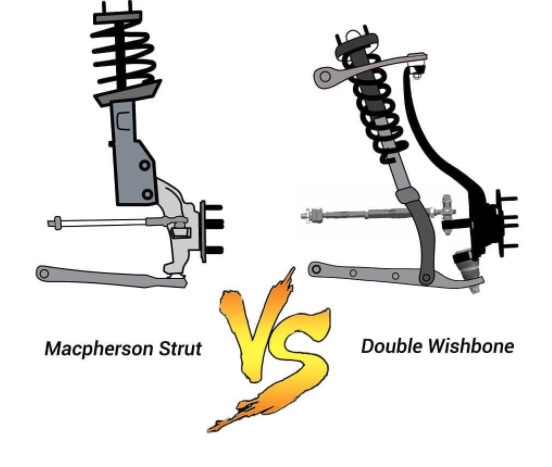

If you ask what is the essential suspension system for luxury cars and sports cars today, the answer must be “front double wishbone, rear multi-link”.

The IM L7 obviously adopts this configuration. But they are more specific and complex, namely a double ball joint double wishbone front suspension and a full ball head five-link rear suspension. Let’s first talk about the former.

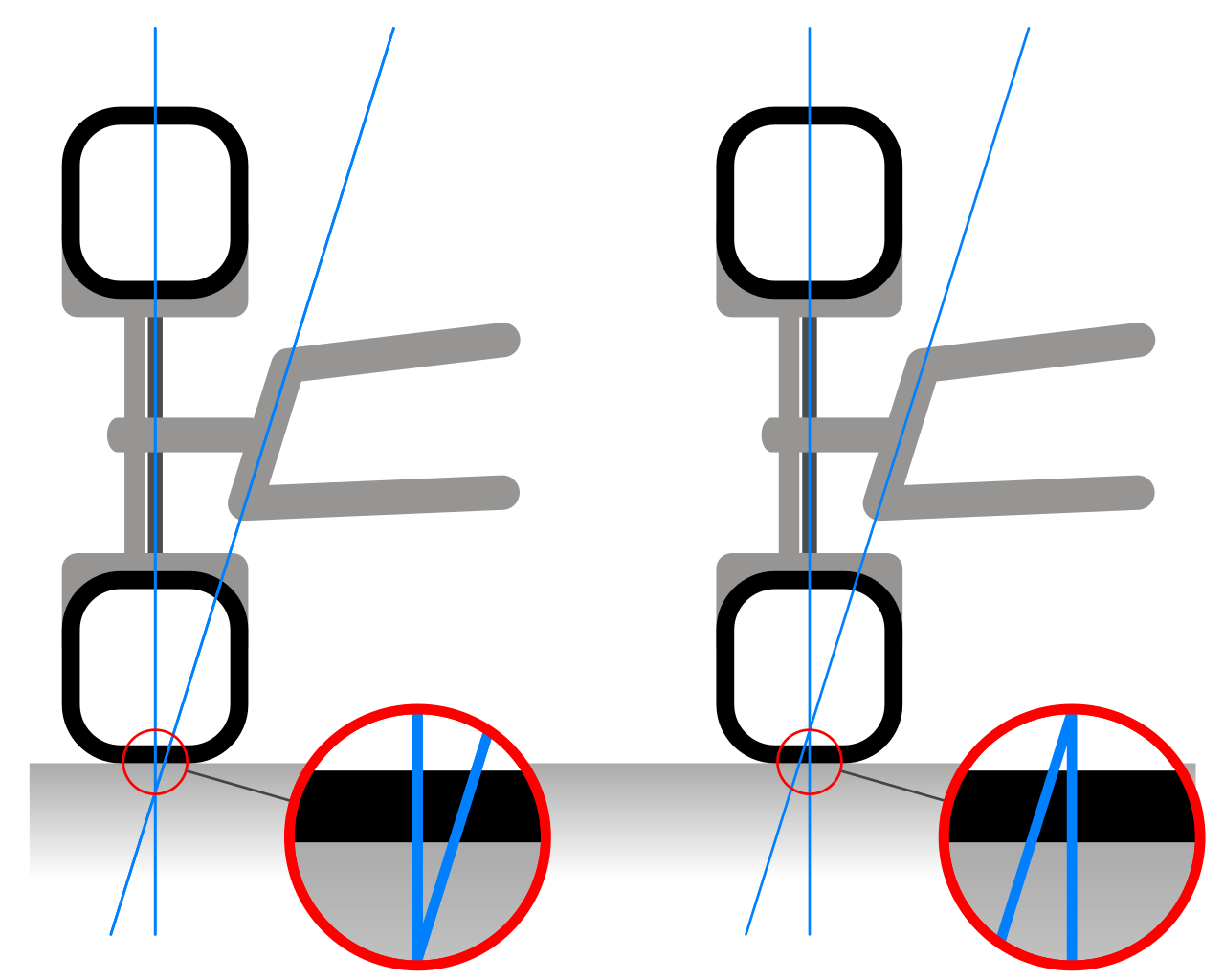

There are two common types of front suspension systems shown in the figure above. The one on the left is the typical MacPherson suspension used in economical car models, while the one on the right is the double wishbone suspension commonly used in high-end cars. Just because it has an extra upper control arm. The two swing arms of the double wishbone suspension can not only bear lateral force, allowing the shock absorber to be under compression force in the direction of compression, but also make dynamic tilt compensation through the design of unequal lengths of the upper and lower control arms, allowing the tire in bending to better grip the ground. Except for cost, the double wishbone suspension basically crushes the MacPherson suspension in all aspects.

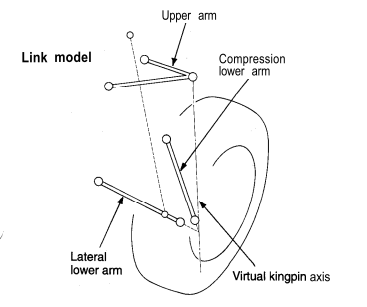

In IM L7, the lower control arm is split into two links, resulting in two ball joints.

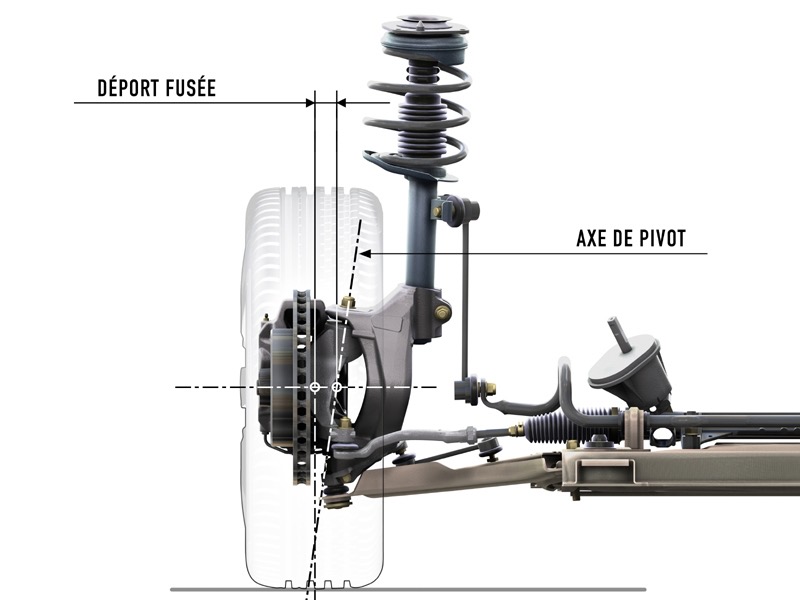

With this design, the intersection of the extended lines of the two lower links and the connection line of the upper control arm ball joint becomes the virtual kingpin axis. By adjusting the angle and length of the swing arm, the virtual kingpin position can be optimized for the dynamic performance of the chassis.

1. Reduce torque steering. For the dual-motor model L7, the front wheels also have considerable driving force. In this case, suspension geometry tuning is needed to avoid the problem of the vehicle’s front-end behavior. By shortening the distance between the wheel center and the main pin (the distance between two points in the schematic diagram that are horizontal with the wheel center), the torque that causes the wheels to turn when accelerating can be reduced.

1. Reduce torque steering. For the dual-motor model L7, the front wheels also have considerable driving force. In this case, suspension geometry tuning is needed to avoid the problem of the vehicle’s front-end behavior. By shortening the distance between the wheel center and the main pin (the distance between two points in the schematic diagram that are horizontal with the wheel center), the torque that causes the wheels to turn when accelerating can be reduced.

- Braking stability. When the focus of the virtual main pin’s ground extension line and the point where it passes through the wheel center are far enough from the connection point with the ground, the vehicle will generate a steering torque during braking to correct the direction deviation. For example, when driving on an asymmetric road surface where one side is wet and the other is dry, stepping on the brake will generate a force that increases with braking force and resist the deviation during braking, making emergency stops on uneven and slippery road surfaces more stable.

Five-link rear suspension with a fully independent subframe

All five linkages on the rear suspension of the IM L7 are linked in a ballhead style, which is a crucial factor for the rear-wheel steering system to generate a bidirectional and total steering angle of 12 degrees.

The rear suspension of the Jaguar F-Pace shown above has a lower arm that is an H-arm with four support points at both ends, which can fully isolate the lateral and longitudinal forces, theoretically more favorable for comfort. However, it also means that it loses the rear-wheel steering ability and can only rely on compression bushings to achieve slight steering angles. In contrast, the outer ballhead design of the IM L7 has a larger range of motion and the rear-wheel steering system only needs to overcome friction resistance between the ballheads. Moreover, rear-wheel steering is a standard feature on all IM L7 models and does not require any additional subscription fees.

The sleeve of IM L7 is different from the previous ones seen by everyone, with metal inserts in the sleeves, which are called pre-pressure belt-insertion sleeves. Pre-pressure belt-insertion sleeves are used in all swing arm and connecting rod sleeves on the front and rear suspensions of IM L7.

The sleeve of IM L7 is different from the previous ones seen by everyone, with metal inserts in the sleeves, which are called pre-pressure belt-insertion sleeves. Pre-pressure belt-insertion sleeves are used in all swing arm and connecting rod sleeves on the front and rear suspensions of IM L7.

The advantage of this kind of sleeve lies in its utilization of the non-linear properties of rubber. By using very low hardness rubber material, it achieves a stiffness that exceeds that of ordinary sleeves of the same hardness by more than three times, which not only improves handling performance, but also brings better comfort and NVH performance at the same time as the turning response.

CDC Electronic Shock Absorber

IM L7 adopts the second generation CDC electronic shock absorber from ZF Sachs. Unlike air suspension that requires air filling and releasing to adjust the stiffness of the spring, CDC rapidly adjusts the damping value by changing the size of the damping orifice inside the shock absorber valve body through an electromagnetic valve to switch the suspension between soft and hard.

Many people mistakenly believe that air suspension is more comfortable, but this idea is one-sided. Firstly, air suspension replaces metal springs with air bags, and its main function is to adjust the ride height. However, unless it is the three-compartment air suspension on million-dollar luxury cars, the higher the vehicle ride height, the higher the spring stiffness actually is. Such a characteristic is obviously different from everyone’s understanding of comfort, and as a sedan, height adjustment is not essential.

The Williams Advanced Engineering team has developed three driving modes: comfort mode, daily driving mode, and sport mode, which, combined with different power output methods and the different pedal feel brought by the One Box IBS brake master cylinder from Continental, demonstrate a distinctive driving experience.

At the same time, on-site engineers indicated that as a part of SOA, the later stage will achieve more scene-based application tuning of the CDC electronic shock absorber of IM L7 through the fusion of vehicle speed, high-precision maps, and cameras, by OTA upgrades.

Tires, Steering and Brakes

At present, two tire sets are known, which are 245/45 R19 front and 275/40 R19 rear, and 245/40 R20 front and 275/35 R20 rear, the latter of which adopts a formula that focuses more on sports performance.After selecting the size, Zhi Ji and Williams Advanced Engineering team chose the Pirelli P Zero tires which are the most familiar to Williams, and specially customized them for L7. With the support of Williams, optimization has been done on the tire’s triangular adhesive form, cord rebound height, steel belt angle, tire face adhesive formula, and tire rolling resistance coefficient.

Of course, Pirelli’s PNSC technology is also present. The special silencing cotton on the inside of the tire ensures the ability to absorb noise without affecting comfort and performance.

In terms of braking, Brembo recently announced that the Zhi Ji L7 will be equipped with Brembo FNC front brake discs (Ø 365 X 30 mm) and front brake spray-painted four-piston calipers as standard across the range. The FNC surface hardening process can effectively improve the scratch resistance of the brake disc, and significantly enhance the anti-sticking and wear resistance, fatigue resistance, and other characteristics of the brake disc. As for the caliper, a special brake pad chamfering is used to optimize NVH.

From the development car, it can be seen that the front caliper is installed in a rearward position, that is, behind the axis. There are many benefits to arranging the brake caliper behind the axle.

Firstly, the two calipers together weigh about 10 kg. If this weight can be made closer to the center of gravity of the car, theoretically, it can make the steering response more agile. Secondly, because of the arrangement, cooling of the rear-axis caliper is more convenient.

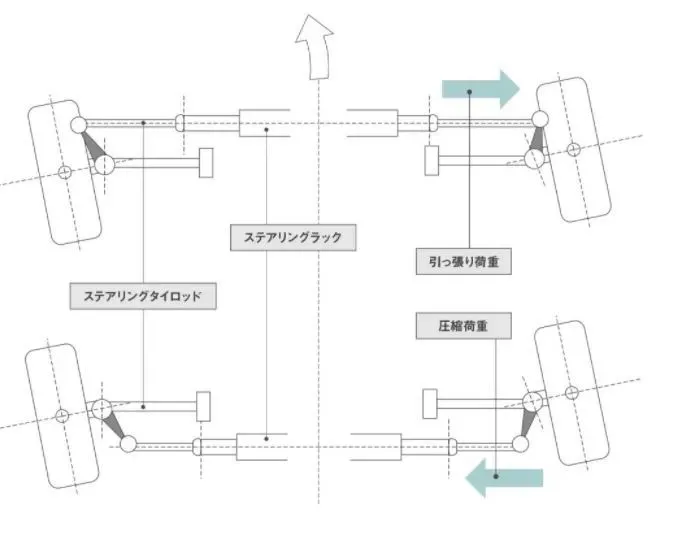

If you further analyze the stress distribution during braking and compare the two caliper positions, you will find that the reactive force generated by the rear-axis caliper during braking can offset part of the ground support force on the wheel hub bearing, rather than stacking like the front-axis caliper. This can relieve the burden on the wheel hub bearing for an electric car weighing 2,300 kg.The most crucial advantage of the rear axle brake caliper lies in its ability to place the steering link in front, which is a must-have for most luxury and sports cars. The advantage of front axle steering is that it provides genuine feedback to the driver. Vehicles using front axle steering design will have heavier steering as lateral acceleration increases, while vehicles using rear axle steering design have the opposite characteristic, with lighter steering as lateral acceleration increases.

In terms of stability, front axle steering also has a significant advantage. When the tires are under load during turning, the suspension bushings will experience a certain degree of compression. For the vehicle with front axle steering, the steering link provides support in the front, leading to a slight reduction in steering angle and a tendency for understeering. This characteristic helps to improve the stability of the vehicle during extreme cornering. Vehicles with rear axle steering, on the other hand, need to compensate by designing the suspension geometry and adding extra work under such circumstances.

Electric vehicles have lowered the performance threshold

Every once in a while, I change my dream car in my mind. It’s a fact that I’m quite inclusive, but my understanding of cars has always been changing.

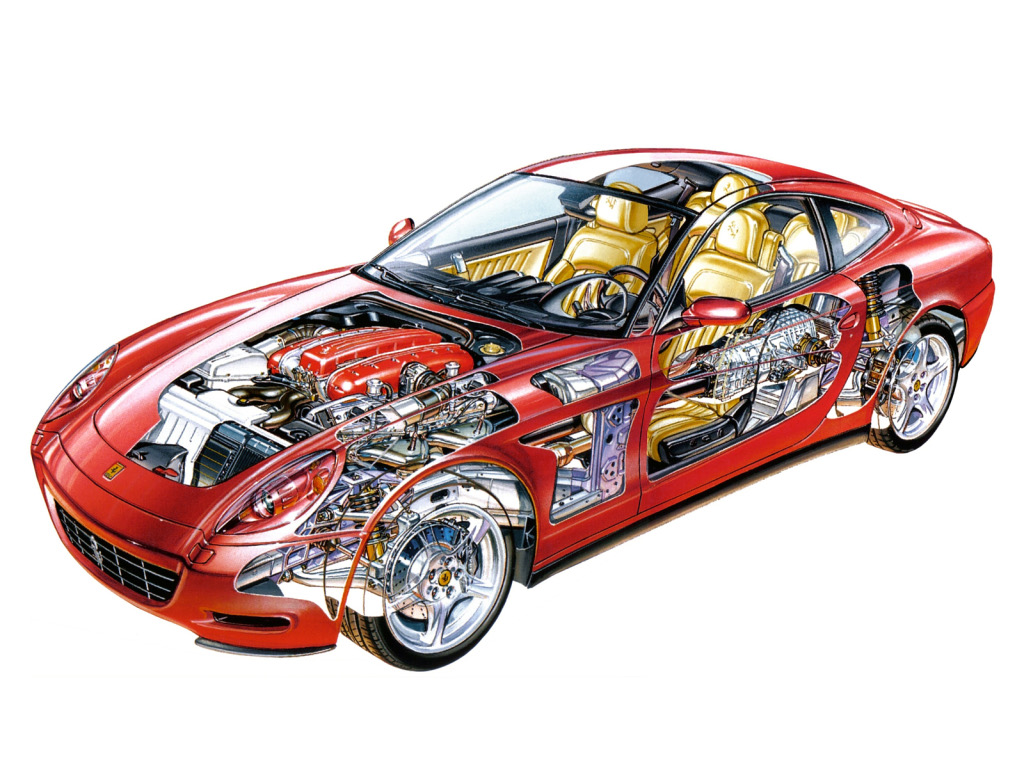

Recently, I fell in love with the Ferrari 612 Scaglietti again. Produced from 2004 to 2011, this Ferrari was the first Ferrari that could truly seat people in the back, and it has the most beautiful lines in my heart.

This 6 million-yuan car has a powerful 540-horsepower engine. However, according to the data from the Ministry of Industry and Information Technology, the IM L7, which sells for 408,800 yuan, can output about 570 horsepower and it’s also four-wheel drive.

To achieve such output of power and maintain a good front-to-rear weight ratio, the former car had to cram a 5.7-liter naturally aspirated engine behind the front axle, resulting in a very slender and classical body proportion. However, this Ferrari with a wheelbase of 2,990 mm has less rear space than even a Corolla.Nowadays, with more flexible motor layouts and batteries that can easily output high power, electric vehicles have effortlessly surpassed these luxury internal combustion engines in terms of power. Therefore, appreciating a Ferrari 612 today is similar to appreciating the beauty of craftsmanship and design, rather than engineering superiority. In fact, the center of gravity of the IM L7 is even lower than this expensive Ferrari, and its acceleration to 100 kilometers per hour is 0.3 seconds faster.

Therefore, whether a car is good or comfortable to drive actually depends more and more on better chassis configurations and tuning skills. And I firmly believe that only electric cars with outstanding performance in three areas have the potential to break through stages 1 to 10 of the electric vehicle market and qualify as luxury cars.

In the era of electrification, driving behavior will continue to exist.

In the automotive industry that has entered the era of electrification, intelligence, and network interconnection, everything seems to have become more consumer electronics-oriented. The process of buying a car is becoming more and more like buying a mobile phone, and all indicators are presented in a few simple numbers on a monochrome background.

This is an era in which a digital blogger who knows nothing about cars can create waves by talking about the number of seconds it takes for an electric vehicle to accelerate from 0 to 100 kilometers per hour, the number of kilowatt-hours in the battery, and the number of TOPS in the chip. This is also an era in which mobile phone manufacturers announce that they are making cars and car manufacturers announce that they are making mobile phones, causing industry convergence.

Well, there is a path dependence in entrepreneurship. Similarly, making and promoting products are also.

Because in my understanding, no matter how strong a car’s three-electric performance is, and how smart its intelligent driving is, it still does not constitute the essence of a car. As long as a car has a throttle pedal, a brake pedal, and a steering wheel, we cannot ignore the essence of a car: driving.

Chassis performance determines the driving experience. Actually, even without a steering wheel or pedals, a car will still have a chassis that connects it to the ground and passengers.

What I mean is:

Even if “how it drives” is not considered, there is still “how it feels to sit in it.”

By the way, the wheels on the engineering verification vehicle are not Rays TE37 wheels. It’s just that WAE intentionally chose wheels with a weight similar to that of the production version wheels of the L7.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.