Power batteries are like “fire”

In 2020, the global sales volume of new energy vehicles reached 3.311 million units, of which China’s sales volume of new energy vehicles had reached 1.367 million units. The “New Energy Vehicle Industry Development Plan (2021-2035)” issued by the Ministry of Industry and Information Technology in 2019 indicates that the proportion of new energy vehicle sales will reach 25% by 2025. In the middle of last year, Zhang Hong, the Secretary-General of the New Energy Branch of the China Automobile Circulation Association, said in an interview: “In 2019, the sales volume of automobiles in China was 25.769 million units. Calculated at an annual compound growth rate of 2%, the sales volume of new cars in the Chinese automobile market will reach 32.28 million units in 2025, corresponding to 8.07 million units of new energy vehicles.” 8 million, this number is so fascinating.

Along with the soaring sales volume of new energy vehicles, power battery companies’ market values have also repeatedly hit new highs under the impetus of investor enthusiasm. Inside and outside the industry, the situation is thriving. But we also need to see that accidents caused by power battery safety, auxiliary/autonomous driving issues are increasingly appearing in our field of vision.

According to statistics, in 2020, a total of 31 recalls were made for new energy vehicles in China, involving 94,100 vehicles, mainly due to the power battery of new energy vehicles.

Today, we will focus on the safety issue of power batteries by referring to Great Wall Motor’s new energy vehicle battery.

Power batteries are like “fire”

Whether it is intentional enlargement of the media or not, we often see pictures of new energy vehicles burning, some caused by collisions, and some spontaneously igniting, even if I watch it every time, the scenes of burning and explosion are comparable to blockbuster movies.

After excluding the same cause of accidents as gasoline vehicles, we are only left with the fear of this “battery explosive package” which burns fiercely and explodes. Many elderly people around me always sneer at pure electric drive new energy vehicles due to battery safety issues.

To be honest, if I had been shown this kind of video a few years ago and told me that new energy vehicles are so unsafe, don’t buy them, I would have definitely nodded like a garlicky head.

But in a spirit of seeking truth from facts, I will show you why power batteries are not safe.

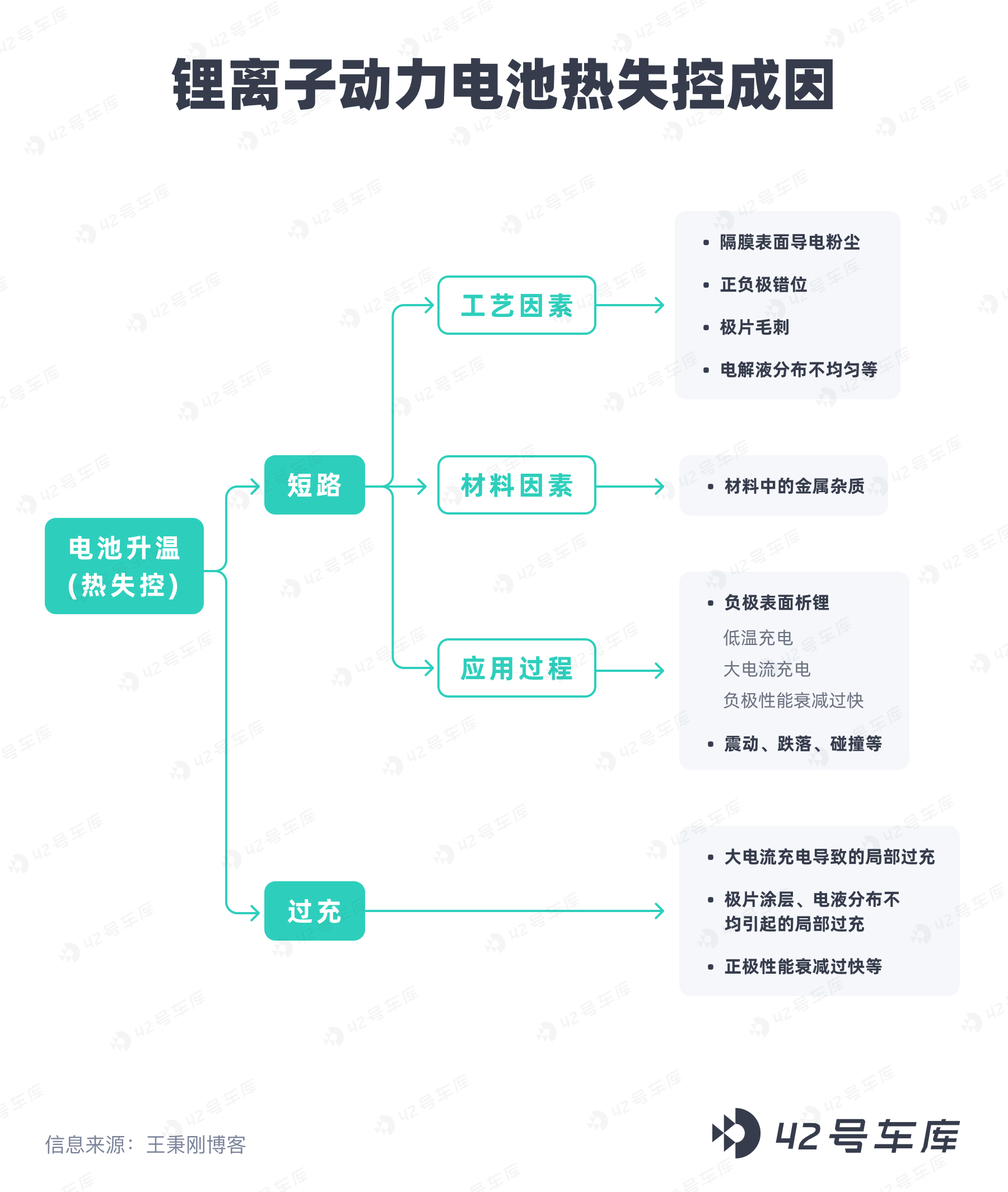

Essentially, this is mainly due to “thermal runaway” of batteries. This thermal runaway refers to abnormal battery temperature and voltage rise. When the heat production rate of exothermic reaction is higher than the heat dissipation rate of the power battery, the pressure and temperature inside the battery suddenly rise, entering an uncontrollable self-heating state. If not controlled, it will lead to battery combustion. The causes of this phenomenon are divided into two categories: short circuit and overcharge. They are induced by various specific factors, which I will not elaborate on here, and you can refer to the picture.In Professor Ai Xinping’s analysis at Wuhan University, there are many potential exothermic reactions in addition to the normal charge and discharge reactions of lithium-ion batteries. Exothermic reactions can occur when the battery temperature itself is high or the voltage is too high during charging. The main exothermic reactions include:

-

The decomposition of the SEI film when the temperature is above 130 ℃, causing a large amount of reduction and decomposition of the electrolyte on the exposed high-activity negative carbon surface, resulting in an increase in battery temperature, which is the root cause of battery thermal runaway;

-

The exothermic decomposition of the charged positive electrode and the further electrolyte decomposition triggered by reactive oxygen exacerbate the accumulation of heat inside the battery and promote thermal runaway;

-

The thermal decomposition of the electrolyte leads to the release of heat, accelerating the temperature rise of the battery;

-

The reaction between the binder and the high-activity negative electrode. The starting temperature of the reaction between LixC6 (lithium-based negative electrode material) and PVDF (polyvinylidene fluoride) is about 240℃, the peak is 290℃, and the reaction heat is 1,500 J/g.

It can be seen that the main overcharge reaction is the oxidation and decomposition of organic electrolyte, which produces organic small molecule gases, leading to an increase in battery pressure and temperature. It can be said that in addition to the thermal runaway caused by collisions that we often see, even if the power battery stays still, it is always thinking about “fire”.

Power batteries generally “burn first and then explode”

Here’s an old story that everyone should remember. In 2016, there was the “Samsung battery gate”. The flagship model of Galaxy Note 7, which used Samsung SDI batteries, frequently exploded and was even “banned from flying”. Please pay attention to my words. I said “explode”, because at that time, the lithium-ion battery of the mobile phone did not have a safety valve or the safety valve was not sensitive, so it exploded first and then caught fire.

Let’s recall the electric vehicle accident videos we have watched. Most of them follow the process of “smoking first, burning later, and then exploding”. Because the safety valve of the power battery works relatively timely, when the battery abnormally heats up and the pressure is too high, the safety valve will open and discharge the high-temperature and high-pressure gas mixture.

Let’s get back to the topic. Regardless of what causes the battery to become thermally unstable, the main solution is to control and weaken the effects of thermal runaway.

How to prevent the battery from “fire”?

Now that we know why the battery keeps thinking about “fire”, we have various ways to make power batteries safer. Professor Ai Xinping emphasized that “to fundamentally solve the problem, we need to study new technologies for preventing short circuits, overcharge, thermal runaway, combustion, and non-flammable electrolytes, and establish a battery’s self-triggered safety protection mechanism”.To improve the overall thermal stability of batteries, various solutions have been developed in the EV industry, including cell design and manufacturing, PTC current-limiting devices, pressure relief valves, and heat-sealed diaphragms. As EVs pursue longer driving range, the energy density of the battery is increased by stacking more cells which creates an accumulation of heat. Effective heat dissipation solutions are required to avoid safety hazards.

Most automakers use similar technical solutions to “tame” the battery. The basic idea is to lock the cells within small compartments to prevent heat from escaping, as demonstrated in the recent releases of the “Amber” and “Muscovite” battery management systems by ORA, which was introduced in I Went to a Crash Test, But No Cars This Time.

However, the “Yu the Great” battery of Great Wall Motors takes a different approach, which is the same as the famous ancient Chinese flood control strategy. It guides the heat source to achieve effective heat control. There is no right or wrong approach as long as battery safety is guaranteed.

According to Cao Yongqiang, the Chief Designer of Power Battery at GWM:

“Inspired by Yu the Great’s flood control strategy, the technology aims to unblock obstructions to heat flow and control heat by technological means.”

The “Yu the Great” battery integrates different chemistries of cells and battery pack specifications. In addition to the NCM811 ternary lithium battery with an energy density of up to 190 Wh/kg, the technology is also compatible with future higher energy density ternary lithium batteries with increased nickel content, NCA cells, cobalt-free cells, and even lithium iron phosphate cells. The “Yu the Great” battery technology is also compatible with different pack applications that meet future CTC(cell to chassis) solutions.

The main focus of our attention is the claim that the “Yu the Great” battery can prevent a single or multiple cells from causing a thermal runaway and avoiding fire and explosion, regardless of the cell’s location.### Thermal Isolation

-

Cell Protection: Double-layer composite material is used between cells to isolate thermal sources and withstand flame impact. It solves the problem of traditional aerogel’s intolerance to impact and also addresses the needs of different chemical systems’ cell expansion in physical space.

-

Module Protection: High-temperature insulation composite material is used between modules to prevent flame impact and long-term thermal conduction. The protective cover is designed with directional explosion outlets to quickly discharge the high-temperature gas and flame inside the module, avoiding the spread of heat inside the module.

Bidirectional flow

In the event of thermal runaway, a large amount of high-temperature and high-pressure gas and flame will be generated. By simulating and designing multiple types of flow channels, the flow intensity and ratio can be precisely controlled to guide the thermal source to flow along the predetermined trajectory, reducing the heat impact on adjacent modules and preventing reignition.

Heat Distribution

By building combustion models, thermodynamics and fluid mechanics fitting simulations, and impact strength and pressure calculations, virtual technology can be used to achieve uniform distribution of gas and flame in different structural channels.

Directional Explosion

This is the core technology of Great Wall Battery. By diverting, guiding, and exchanging flow, the thermal source is quickly guided to the fire extinguishing channel and safely discharged. In the live broadcast, the CEO Caoyongqiang claimed that the temperature discharged outside the vehicle would eventually be reduced to below 100℃, and a proprietary discharge channel was set up to prevent people from coming into contact with the vehicle.

Currently, Great Wall has overcome the difficulties of regulating pressure and flow uniformity in the channels, eliminating heat concentration and making gas and flame flow evenly in the channels.

High-Temperature Insulation

To eliminate the insulation damage caused by high temperature to the copper busbar harness during thermal runaway, and to prevent high-voltage arcing from damaging the metal casing, high-temperature insulation protection design is applied to high-voltage connections and high-voltage safety areas.

Automatic Firefighting

A multi-layer asymmetric honeycomb structure is set up at the directional explosion outlet to achieve rapid flame suppression and cooling. By designing for multipoint, even distribution, and small size, volume is effectively reduced, weight is lowered, and cooling effect is enhanced.

Positive Pressure Oxygen Block

Based on the honeycomb pore size and the unit gas mass flow rate, the pressure inside the container is kept higher than outside to avoid secondary combustion caused by the entry of oxygen.

Smart Cooling

According to the official statement, when the battery management system recognizes that cells have triggered thermal runaway, the entire vehicle’s cooling system is quickly activated through BMS and cloud monitoring to cool down the battery. A design scheme that integrates a single large cooling plate with the casing is used to effectively prevent leakage and explosion problems caused by high temperature in pipes. Depending on the thermal runaway temperature status of cells and modules, the cooling system can intelligently adjust its opening and closing time, flow rate, and flow volume to achieve different cooling strategies.## How did Dayu Battery perform in the test?

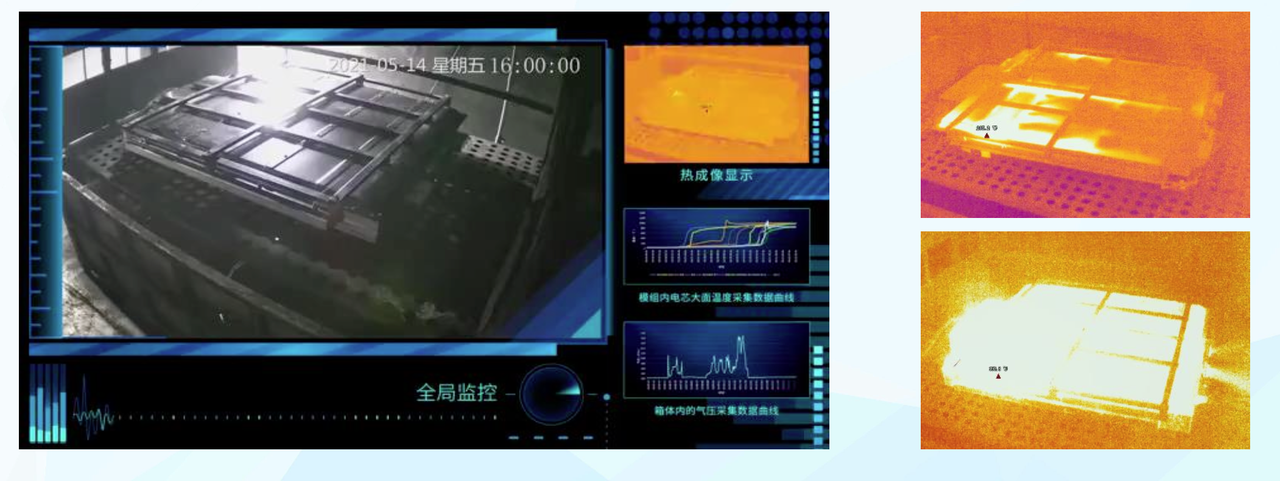

After introducing so many technological innovations of Dayu Battery, we need to see its specific performance. According to the testing standard: GB 38031-2020 “Safety Requirements for Power Lithium-ion Batteries for Electric Vehicles,” three consecutive thermal runaway incidents were triggered by multiple cell congregations during the test process, and the internal pressure of the battery pack reached three peaks, with the highest temperature reaching 1,037°C and the instant highest pressure of about 16 kPa. The highest temperature of overflow smoke was controlled below 100°C through the design of the tail extinguishing box to avoid secondary injuries to people and objects. Throughout the test, there was no fire or explosion indeed.

The reason why the tri-element 811 battery was selected for the test this time is that NCM (nickel-cobalt-manganese) tri-element 811 is the class with the highest energy density in domestically produced power batteries, and its safety is quite controversial. The heating test method has more heat sources than the puncture method, and it starts heating directly from the middle of two intermediate cells, which can trigger thermal runaway of two cells at the same time. In general, more stringent testing conditions have been applied.

Conclusion

Great Wall has a broad layout on the industry and technology sides. For our battery part today, Great Wall has established FENGYUAN Energy, which is specialized in the technical development of tri-element, iron-lithium, and cobalt-free multi-chemical system cells, modules, packs, and BMS. It has even acquired upstream raw material suppliers, Australian lithium mine enterprise shares, to obtain lithium mine resources.

The emergence of Dayu Battery technology has further strengthened the integrated technology on battery safety and basically interconnected the entire process from battery development and production to battery sales and installation on vehicles, which can enhance battery safety from different dimensions.

Of course, test results only represent the performance of this technology under standardized testing conditions and are a more referential content for consumers. This technology will not be widely used in the new energy vehicle series under the Great Wall until 2022 and will be first installed on the first model of the Salon brand. According to the news, the preliminary design has been completed and will be tested comprehensively in December, and it is expected to be launched in June 2022. Well, let’s look forward to the new Salon car on the market next year.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.