Test Results for Great Wall’s Dayu Battery

“During the occurrence of three consecutive incidents of thermal runaway triggered by multiple battery cell aggregation, the temperature reached a maximum of 1037℃, and the internal pressure of the battery pack peaked three times with the highest instant pressure reaching approximately 16kPa. Through the design of tail-mounted smoke suppressors, the highest temperature of the outflowing smoke can be controlled below 100℃.”

This was the detailed disclosure of Great Wall’s core technology at the “Dayu Battery Technology Media Preview” held in Beijing on September 24th.

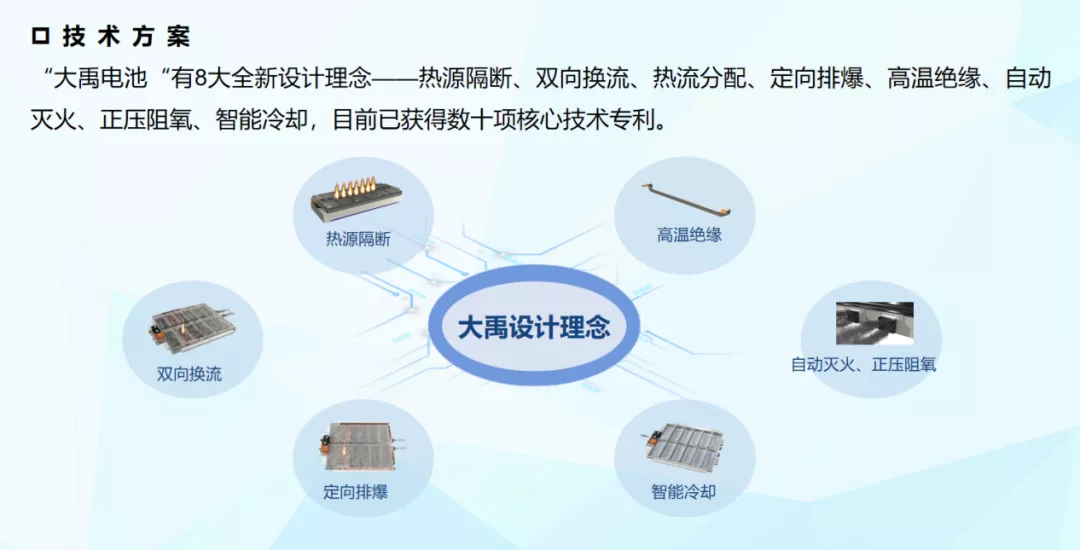

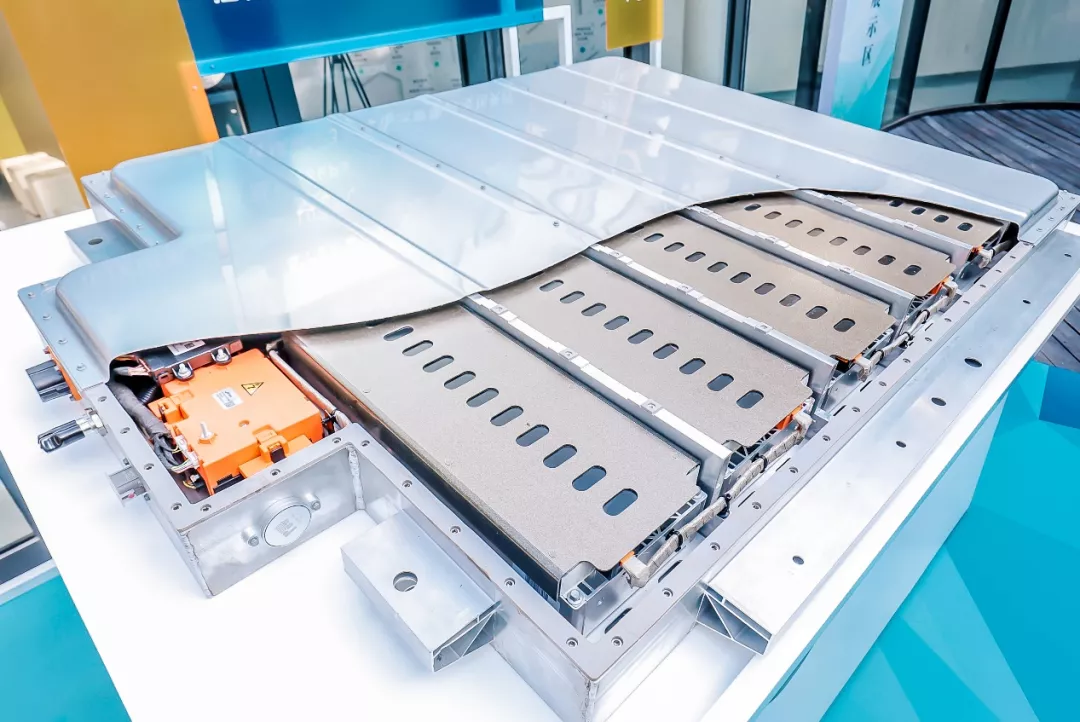

The Dayu battery boasts eight core technologies: thermal barrier, bidirectional current conversion, thermal flow distribution, directional explosion suppression, high-temperature insulation, automatic firefighting, positive pressure oxygen blocking, and intelligent cooling. Ultimately, it can achieve “full coverage of battery cell chemistry system,” “battery cell in any position,” and “single or multiple battery cells” without fire or explosion in the event of thermal runaway.

The Dayu battery also has good compatibility with future battery cell chemistry systems and different PACK application technologies.

Great Wall stated that the Dayu battery technology will be fully applied to its new energy series models in 2022. The first to use this technology will be the Salon brand’s first model.

In addition to personal use, Great Wall is also opening up patents for the Dayu battery. Over 60 patents will be available free of charge to the entire society.

The Design Concept of “Clearing Blockages”

“Clearing blockages” should be the biggest difference between the Dayu battery technology and other battery technologies.

In the view of Cao Yongqiang, the chief designer of Great Wall’s power battery, battery safety involves multiple aspects such as electrochemical safety, mechanical safety, electrical safety, vehicle integration, functional safety, and thermal safety. Regarding battery cells, the industry currently uses techniques such as positive electrode doping modification, ceramic coating, and special electrolytes to improve safety. However, battery cells still face challenges such as internal defects, consistency differences, and overuse and cannot achieve absolute “zero thermal runaway.”

Therefore, safety at the battery system level is particularly important.

Great Wall uses a matrix design approach in battery cell testing, system matching, safety design, virtual simulation, and test verification across four levels: battery cells, modules, battery systems, and vehicles to achieve battery safety protection.

The main design concept of the “Dayu Battery” is to “clear blockages.” It changes the traditional battery cell control technology that focuses on blocking and channels the flame and gas flow produced during thermal runaway through the designed channels to safely discharge the battery pack.

According to Cao Yongqiang’s words, this is a process of “control”, “guidance”, and “evacuation”. “Control” is to safely and effectively control the heat source through materials at the module and cell level. “Guidance” is to let it flow along the safety channel safely through bidirectional discharge and directional explosion-proof precision design. “Evacuation” will quickly and nearby guide it into the channel during the flow process, and quickly remove it outside the package under high pressure. After the discharge, it will be suppressed and the long-term conduction will be reduced through materials.

Implementation: Eight Core Technologies

With the design concept, in terms of technical implementation, Zhangjing Qi Motors has implemented it by eight core technologies: thermal isolation, bidirectional commutation, thermal flow distribution, directional explosion-proof, high-temperature insulation, automatic extinguishing, positive pressure prevention of oxygen, and intelligent cooling.

Cao Yongqiang introduced that there are many patented technologies in each of these core technologies, and dozens of core technology patents have been obtained so far.

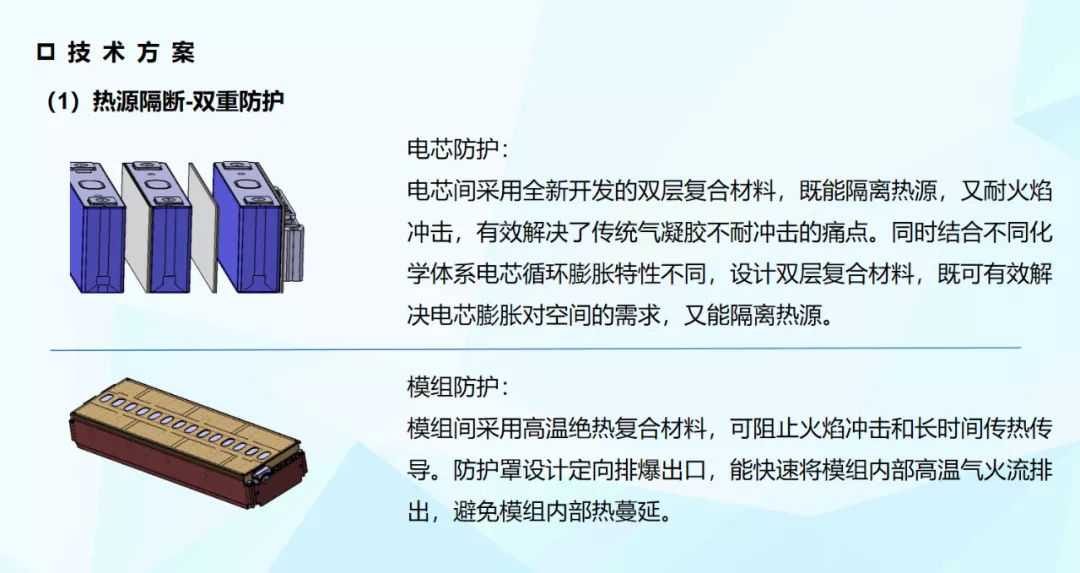

(1) Thermal Isolation

Firstly, thermal isolation has the most significant advantage of double protection from the cell and module levels.

For the cell, all cells use newly developed double-layer composite materials, which can not only isolate heat sources but also withstand flame impact, effectively solving the pain point of traditional aerogel’s non-impact resistance. At the same time, combining the different expansion characteristics of the cell’s different chemical systems, a double layer of composite materials is designed, which can not only effectively solve the cell expansion requirement for space but also isolate the heat source.

For the module, high-temperature insulation composite materials are used between each module to prevent flame impact and long-term heat transfer. The protective cover is designed with directional explosion-proof outlet, which can quickly discharge the high-temperature gas and flame inside the module, avoiding the internal heat spread.

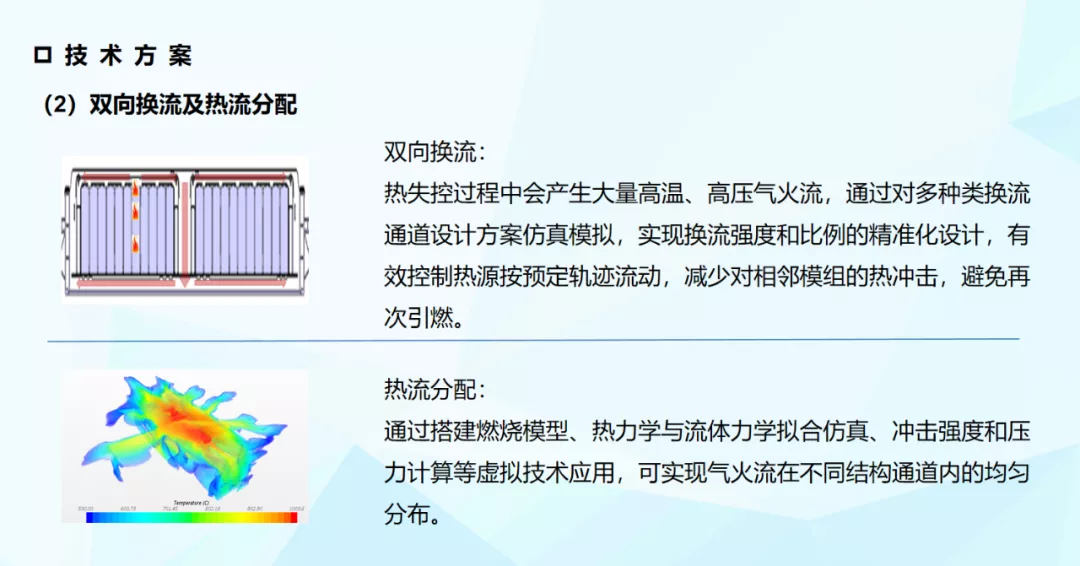

(2) Bidirectional Commutation

During the thermal runaway process of the battery, a large amount of high-temperature and high-pressure gas and flame will be generated. The Cao Yongqiang’s technology team simulates and designs multiple types of commutation channel design schemes to achieve accurate design of commutation intensity and proportion, effectively controlling the heat source to flow according to the predetermined trajectory and reducing the heat impact on adjacent modules, which can avoid re-ignition.

(3) Thermal Flow Distribution

It is achieved by virtual technology applications such as building combustion models, fitting simulations of thermodynamics and fluid mechanics, and calculating impact intensity and pressure. The gas and flame flow can be uniformly distributed in different structural channels.Caoyongqiang introduced that within the battery pack, they have designed longitudinal channels that are connected to the flow channels at the bottom. This means that under the pressure, it can flow up and down.

As for the flow trajectory, Caoyongqiang and his team have carefully designed it through extensive simulations to accurately design the strength and proportion of the gas-liquid flow. They analyze the heat, the impact of airflow strength, and temperature changes, and guide the flow according to the heat source trajectory to avoid drastic thermal shocks to adjacent cells and modules, triggering a second thermal runaway.

(4) Directed Explosion Suppression

This is Big Yu’s most core technology. It quickly guides the source of fire to the fire extinguishing channel and safely discharges it through diversion, flow guidance, and flow reversal. The technology has overcome the difficulty of regulating pressure and flow uniformly in the channels, eliminated heat concentration, and made the gas-liquid flow flow evenly in the channels.

Caoyongqiang explained that through directed explosion suppression and flow reversal, high-temperature gases, such as NCM811 batteries, can be quickly reduced from over 1000°C to below 200°C.

(5) Automatic Fire Extinguishing

Great Wall Motors has set up a multi-layer asymmetric honeycomb structure at the outlet of the directed explosion suppression in the battery pack to achieve rapid flame suppression and cooling. Through point-to-point distribution, uniform distribution, and miniaturization design, the volume is effectively reduced, the weight is reduced, and the cooling effect is improved. At this time, the temperature of the gas-liquid flow discharged out of the battery pack is already below 100°C.

As for the discharge of heat sources, Great Wall Motors has also designed it. Caoyongqiang said that the location of the heat source discharge is a safety area of the vehicle, and the discharged gas will not cause secondary harm to the surrounding people and objects. This is the design concept of fixed-point discharge.

(6) Positive Pressure Oxygen Blocking

Based on the cellular aperture and unit gas mass flux, the pressure inside the pack is kept higher than that outside to avoid secondary combustion caused by the entry of oxygen.

In the view of Caoyongqiang, positive pressure oxygen blocking is very important because the secondary combustion caused by the entry of oxygen is explosive and difficult to suppress. Therefore, they have chosen the optimal indicators for the size of the fire suppression hole in the channel and fire suppression design through multiple tests to ensure that the pressure inside the battery pack is always higher than that outside to prevent air from entering the inside.

(7) High-temperature Insulation

High-temperature insulation is to insulate and protect the high-voltage components inside the battery pack because in the process of high temperature and time, the traditional design of high-temperature insulation layer will be burned out, and the metal components inside the battery pack will arc.

Caoyongqiang explained that once a high voltage arc is triggered, the metal component will be instantly punctured, and a large hole will appear in the battery pack, and flames will rush out. Therefore, it is necessary to design high-temperature insulation protection for the high-voltage connections and high-voltage safety areas inside the battery pack.

(8) Intelligent Cooling

Great Wall Motors has an intelligent cooling monitoring and automatic cooling startup system for battery safety. When the battery management system detects that the battery cell has triggered thermal runaway, it can quickly activate the cooling system of the whole vehicle by double monitoring with BMS and the cloud, and suppress heat diffusion.

Cao Yongqiang particularly emphasized their integrated design of a large cold plate. “Due to the large number of connection tracks and joints, it is easy to cause rupture or poor connection, which will result in the failure of the entire cooling system.”

Dayu Battery’s cooling system adopts a single large cold plate integrated design with the box body, which can effectively avoid pipeline leakage and burst problems caused by high temperature, and can intelligently regulate the opening and closing time, flow rate, and flow volume of the cooling system according to the temperature status of the battery cell and module, and achieve efficient cooling strategies under different thermal runaway conditions.

Simulation Analysis: Shortening Development Cycle and Risk

In order to verify the safety of Dayu Battery technology, Great Wall Motors conducted simulation analysis experiments and built a package-level thermal runaway combustion model. According to Cao Yongqiang, the combustion model realizes multi-dimensional fitting simulation of both airflow and flame, subverting the traditional way of developing before testing in the field of thermal runaway, and achieving full digital thermal runaway virtual simulation under the condition of no actual package.

Cao Yongqiang said that the traditional mode is to design a battery pack first, process and sample it, assemble it, lift the battery pack to the testing site for testing, and then conduct wire harness collection and monitoring, which is time-consuming and requires a lot of personnel investment, and there may still be many situations that cannot be detected.

To solve this problem, Great Wall Motors has pioneered the virtual testing technology of thermal runaway. Before the battery pack design is finalized, they can conduct thermal runaway testing. Before the battery pack design is frozen, they have conducted dozens or hundreds of thermal runaway tests, so they know the temperature of every position and the state of every battery cell inside the battery pack very well.

The real-time pressure inside the battery pack can also be identified through simulation methods in the early stage. This has brought great convenience to their work, because they can know how much pressure each original component and protective component needs to bear, and choose suitable types directly based on pressure.

They also simulated how the temperature spreads in the battery pack after thermal runaway, and the impact of spreading to different dimensions and levels. Cao Yongqiang said that they can completely grasp the flow distribution in real-time, and can extract values such as flow rate and heat quantity, and adjust the working mode of the cooling system accordingly.## Testing Results and Application Fields

Of course, the design effect still needs to be verified through testing.

According to the test standards: GB 38031-2020 “Safety requirements for electric vehicle power batteries”, Great Wall Motors selected the most challenging ternary 811 system high-nickel high-capacity cells in the industry for testing.

By heating to trigger thermal runaway, a testing method of consecutive triggering by two cells was adopted, and the middle cell of the module was selected as the triggering location.

During the test, thermal runaway was triggered by multiple cells aggregation for three consecutive times, and the temperature reached up to 1037℃, and the pressure inside the battery pack reached three peaks, with the highest instant pressure of about 16kPa. The smoke overflow from the battery pack was suppressed by the fire extinguishing system, and the highest temperature was below 100℃, avoiding secondary harm to the surroundings.

Cao Yongqiang explained that for the ternary 811 system cells, although the severity of needle puncture and heating is similar, the amount of heat generated by heating is much more severe than that of needle puncture. Therefore, heating was adopted for testing.

Of course, the compatibility of battery technology is also essential. The Dayu battery technology can not only meet the cells of different chemical systems in the future but also satisfy the application technologies of different PACKs, including the future CTC (Cell to Chassis) battery PACK and fusion technology.

Regarding the cost and whether the weight of the battery pack has increased, Cao Yongqiang said that the materials they selected are very easy to purchase, and as a technological improvement, they did not increase the weight of the battery pack additionally. On the contrary, the application of materials was reduced locally. Therefore, there were no significant changes in cost and the weight of the battery pack.

In terms of industrialization, the Dayu battery technology will be fully applied to Great Wall Motor’s new energy series models in 2022. Among them, the first model of the Salon brand will be equipped with the Dayu battery technology and unveiled.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.