Author: Sun Xiaoshu

On September 23, NIO officially released the 75 kWh ternary iron-lithium standard range battery pack, and the vehicle equipped with this battery pack will start delivering to users in November this year.

The release of the ternary iron-lithium battery pack is definitely one of the most important events in the field of NIO electric drive, because in addition to being used in new vehicles and vehicles to be sold, the ternary iron-lithium battery pack will also enter NIO’s battery swapping system and be used by all existing users.

It can be said that controversies surrounding iron-lithium, the fusion of ternary and iron-lithium, and consumer skepticism are three big challenges facing the ternary iron-lithium battery pack.

Iron-Lithium Not High-End Enough?

At the same time as the release of the ternary iron-lithium battery pack, NIO updated the configuration adjustment information for all models. Compared with the original 70 kWh ternary battery pack, the ternary iron-lithium battery pack has a capacity increase of 5 kWh and an increased subsidy amount (for example, the subsidy for EC6 has increased by 1800 yuan).

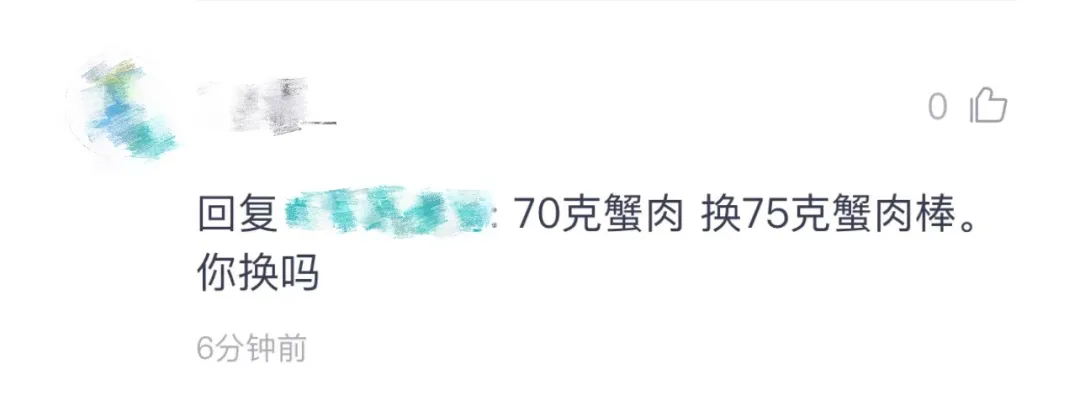

Although the increase in energy and subsidies seems to be a double blessing, we have discovered “harsh” opinions in the comment section of the NIO App, saying that “75 kWh is not as good as 70 kWh” because in current consumer perception, the phosphate iron-lithium battery is not as high-end as the ternary lithium battery. But is this really the case?

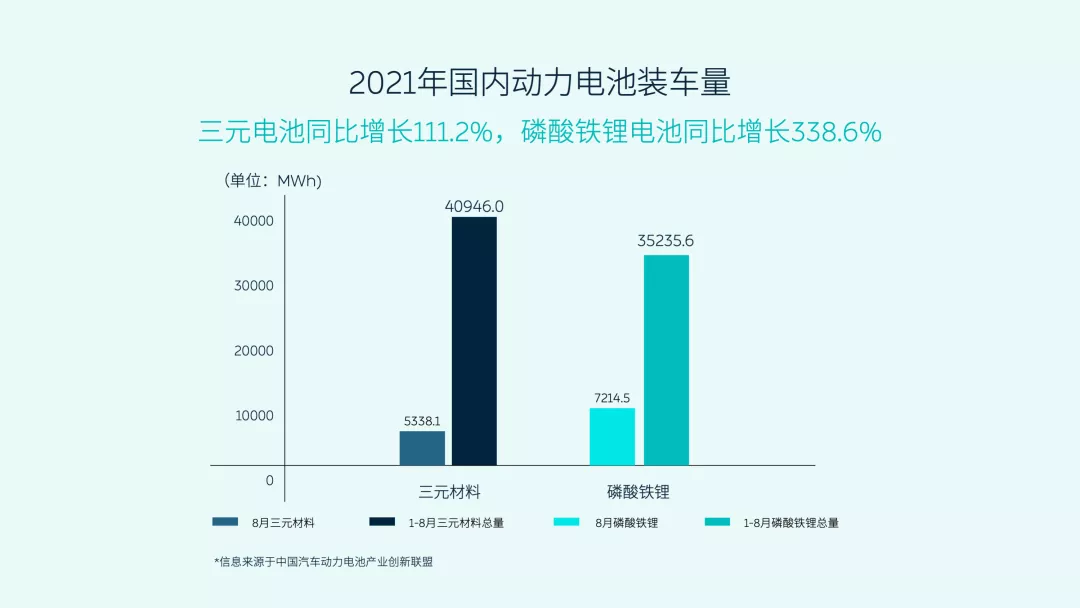

An undeniable fact is that with the improvement of the energy density of phosphate iron-lithium and the integration level of battery packs, the installed base of phosphate iron-lithium batteries has grown much faster than ternary lithium batteries in recent years.

In the first eight months of 2021, the installed base of domestic ternary lithium batteries increased by 111.2% YoY, while that of phosphate iron-lithium increased by 338.6% YoY, and the YoY growth of iron-lithium was three times that of ternary lithium.

Some people may argue that although the installation volume of phosphate iron-lithium batteries is rising rapidly, high-end electric vehicles still commonly use ternary lithium batteries, which is proof of the higher-end performance of ternary lithium batteries.

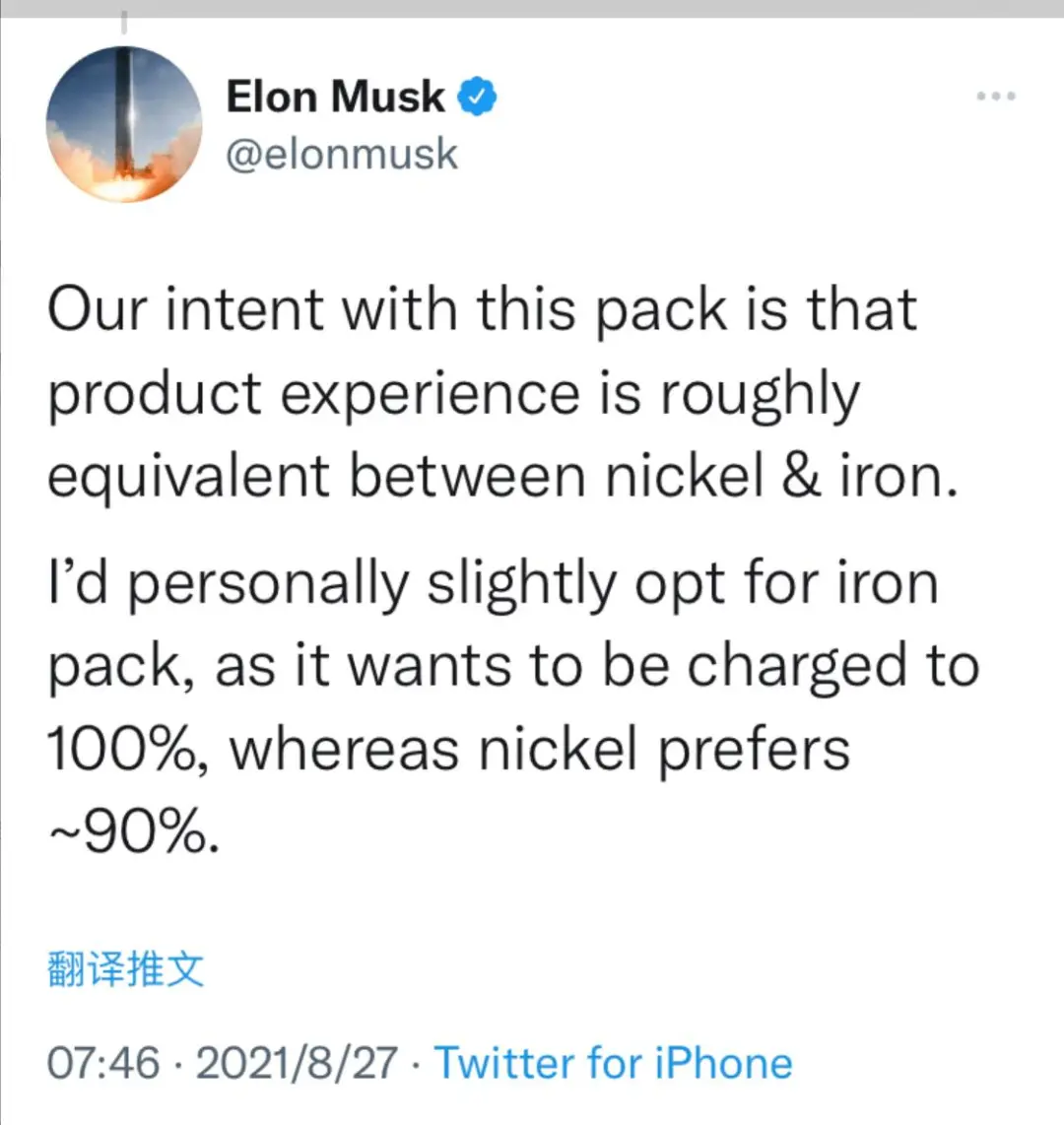

However, a noteworthy trend is that before NIO, an increasing number of premium brands have been actively embracing phosphate iron-lithium batteries. Tesla’s standard range upgrade version of the Model 3 and Model Y globally have switched to phosphate iron-lithium batteries, and Elon Musk sent tweets in August promoting the phosphate iron-lithium version of the Model 3 to US users.

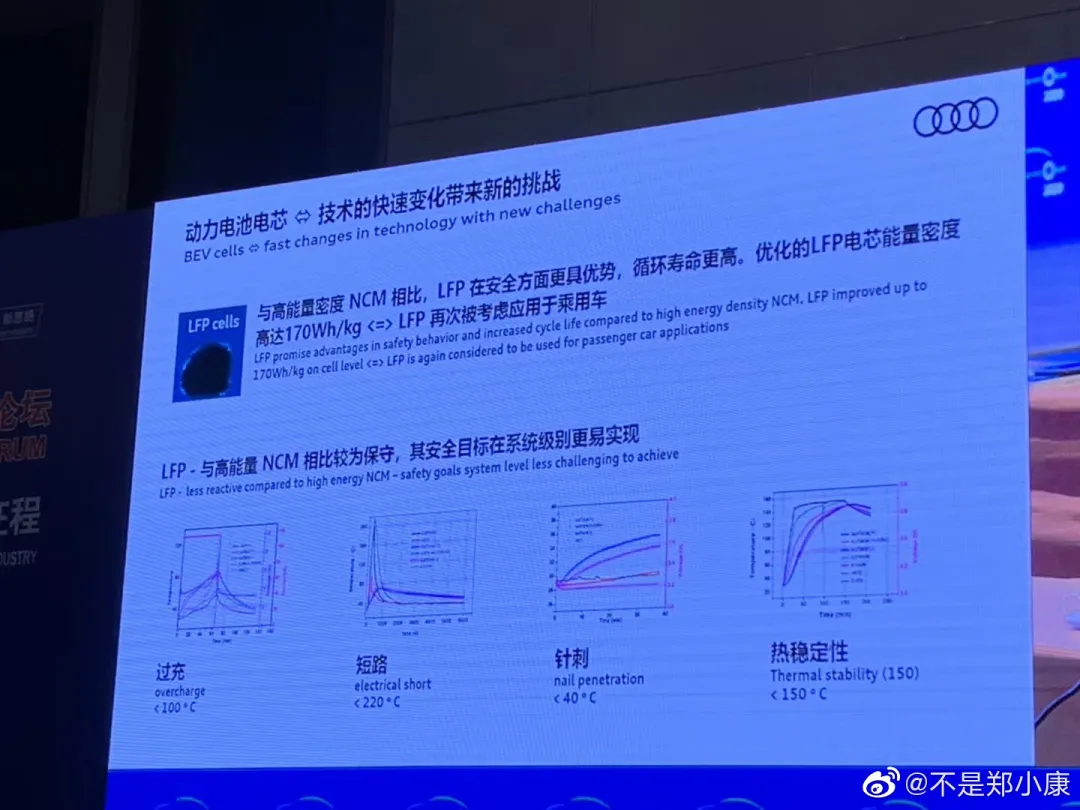

Earlier, Li Yunfei, the general manager of BYD Sales Co., Ltd., congratulated BYD’s blade battery for going global and officially settling in a certain international brand on social media. Insiders told Star News that this “international brand” is Audi, a high-end brand under the Volkswagen Group.

Ola Kallenius, CEO of Daimler, also mentioned at the Mercedes-Benz 2020 strategic communication meeting that in the long term, lithium iron phosphate will be one of the components of the Mercedes-Benz long-term power battery materials along with ternary lithium and solid-state batteries. What could be a better example than the world’s largest luxury brand, Mercedes-Benz, pointing to lithium iron phosphate?

Essentially, battery materials are nothing more than combinations of chemical elements in the periodic table. In the early stages of electrification in the automotive industry, ternary lithium batteries with higher energy density and better low-temperature performance were sought after by many automakers including Tesla and NIO.

However, from another perspective, ternary lithium also has problems with lower chemical stability, lower cycle times, and greater cost pressures, while the characteristics of iron phosphate are almost the opposite of ternary lithium batteries: lower energy density, poorer low-temperature performance, stronger thermal stability, longer cycle life, and lower cost. It should be noted that neither of them is a comprehensive development type player in power battery capacity hexagon.

Of course, for NIO, choosing lithium iron phosphate faces a more difficult situation than Mercedes-Benz: as mentioned at the beginning of the article, based on the battery swap network, ternary iron phosphate battery packs will ultimately affect all NIO owners. Therefore, NIO needs to solve all the problems of lithium iron phosphate in terms of user experience.

Ternary Lithium + Iron Phosphate

Ternary lithium batteries have high energy density, good low-temperature performance, and strong charging ability; iron phosphate batteries have low cost, strong safety, and high cycle times. If we combine the advantages of ternary lithium and iron phosphate, we can create a perfect power battery capacity hexagon, which is an innovative engineering that looks very beautiful and also the original intention of NIO’s introduction of ternary iron phosphate battery packs.

The idea is full, but the reality is bony. The real combination of ternary and iron-lithium batteries requires overcoming many technical, engineering and operational difficulties. This is not an easy task for NIO to accomplish.

The problem of SoC estimation accuracy has always been a challenge for iron-lithium batteries, and NIO’s solution is to bring in ternary lithium batteries with higher SoC estimation accuracy as a “ruler”. However, the new problem brought by the combination of ternary and iron-lithium is how to match and unify the SoC curve with very different characteristics. This is definitely a headache for BMS engineers.

NIO, who believes to have a better BMS foundation, also took more than 7 months to deal with this problem. Therefore, NIO introduced hardware innovation on the basis of software, such as high-power DCDC, which can achieve quick, real-time, and balanced calibration of battery capacity.

The low-temperature performance degradation of iron-lithium is another tricky technical problem that needs to be solved when combining ternary and iron-lithium. At present, the mainstream solution to the low-temperature performance of iron-lithium is to preheat the battery at low temperature through big data learning of owners’ driving habits, and continuously improve this mechanism through OTA upgrades.

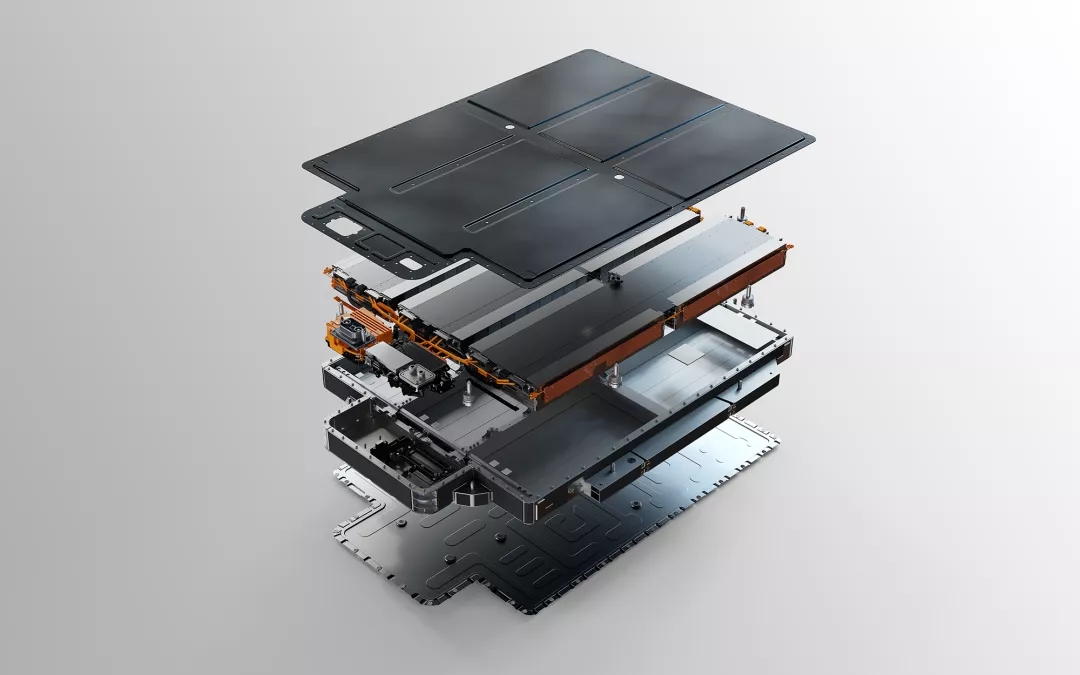

NIO provides a different solution and chooses structural innovation. There is a temperature difference inside the power battery because the heat is conducted faster at the edge, and the corner position is the low-temperature area of the battery pack. Therefore, NIO arranges the ternary lithium batteries in the “front two back four” mode at the four corners of the battery pack, so that the better low-temperature performance of ternary lithium batteries can play a warming role.

However, NIO’s ternary iron-lithium batteries are placed in a CTP battery pack, and the expansion behavior of the two types of batteries is different. The interface material between the two battery cores must be specially designed to avoid deformation of the battery cores, which will affect the performance of the entire battery.

In addition to the arrangement of ternary lithium batteries in the four corner low-temperature area, NIO also updated the battery pack structure with “full heat dissipation path physical isolation”. Finally, it ensures the low-temperature performance of ternary iron-lithium batteries through hardware, active heat compensation software management, and mainstream big data analysis.Engineering and manufacturing is another obstacle on the road to fusion of ternary lithium iron batteries. Ternary lithium iron is a completely new technological route, and innovative hardware design inevitably involves a lot of new parts customization and re-molding of, for example, a completely new battery cell brick, which requires coordination and development with suppliers, as well as the necessary reserves of engineering capabilities and industry status endorsements.

When we raise our gaze to the strategic decision-making level of the enterprise, without significantly affecting the user experience, the cost advantage of ternary lithium iron batteries can effectively improve the long-term income of the enterprise, which is extremely important for NIO.

However, it cannot be ignored that the existence of BMS algorithm development, a completely new battery cell brick, high dynamic DCDC, a large number of simulation tests, etc., dictates that the upfront research and development investment in ternary lithium iron batteries will not be low, and needs to be mass-produced on a large scale to even out costs and achieve a cost reduction purpose. NIO’s Vice President of Battery Systems, Zeng Shizhe, has stated that at present, the cost difference between ternary lithium iron and ternary lithium may not be significant.

User Experience

For a new product, a new technology, whether it can dispel consumers’ doubts and ultimately persuade them to cough up money and give positive feedback depends on whether the users’ input and output are proportional.

When we focus on NIO’s ternary lithium iron batteries from the perspective of users, we find that car owners get 5 kWh of additional electrical energy, and new car owners receive more new energy subsidies, at the cost of not getting a pure ternary lithium battery pack.

If we regard the additional car purchase subsidy as a small encouragement from NIO to new users to try out new technology, and the 5 kWh as a small benefit to all users, then ignoring them, it is possible to roughly and directly compare the user experiences brought about by ternary lithium iron and “pure” ternary lithium to judge whether this exchange is worthwhile.

Unlike the previously released sodium lithium sandwich-type hybrid arrangement by CATL, the ternary lithium in NIO’s ternary lithium iron is only arranged at the edge of the battery pack, and iron is the mainstay in NIO’s ternary lithium iron battery. Therefore, when it comes to user experience, SoC estimation and low-temperature attenuation related to iron are still the main areas of concern.First, let’s talk about SoC. According to official information from NIO, through innovation in software algorithms and hardware applications, the estimation error of SoC for the ternary iron lithium battery pack can be reduced to about 3%, achieving the same level as ternary lithium batteries. If the official data is accurate, there will be no difference in user experience between ternary iron lithium and ternary lithium batteries in terms of SoC estimation.

The focus is actually on another pain point of iron phosphate lithium batteries, which is the performance degradation at low temperatures in winter. Regarding the low-temperature endurance performance of ternary iron lithium batteries, according to NIO, “the battery pack has a 25% reduction in low-temperature endurance loss compared with the iron phosphate lithium battery pack.”

Wait a minute, the comparison reference for SoC estimation is ternary lithium batteries, so ternary iron lithium and pure ternary are on par. But when it comes to low-temperature endurance, the reference changes to iron phosphate, with a 25% reduction in low-temperature endurance loss compared to iron phosphate. However, compared with ternary, how does it perform? After all, users will always compare with ternary lithium batteries.

NIO’s product marketing department responded on the NIO app: “According to current tests, under the condition of minus 10 degrees Celsius, a 75 kWh ternary iron lithium battery pack can run about 20 kilometers further than a 70 kWh original ternary lithium battery pack.”

So based on the official information provided by NIO, the user experience for the 75 kWh ternary iron lithium battery pack can basically match the original 70 kWh ternary lithium battery pack.

Regarding user experience, this has actually always been NIO’s most distinctive corporate feature. Li Bin, the founder of NIO, has repeatedly stated in public that NIO is committed to becoming the company with the highest customer satisfaction in the world. In order to improve the user experience, NIO is willing to invest disproportionately.

Actually, NIO had its first 68 kWh iron phosphate lithium battery pack a long time ago, but Li Bin cancelled the installation of the 68 kWh iron lithium battery pack because the user experience was not as good as the ternary. In terms of actual endurance performance in daily use, the 68 kWh iron phosphate lithium battery pack has already reached the same level as the 70 kWh ternary lithium battery pack because in daily use, the maximum capacity of ternary batteries is often limited to 90%, while iron lithium batteries can be fully charged.Compared with the previous lithium iron phosphate battery, the most obvious change of the current ternary lithium battery is the increase of electric quantity from 68 kWh to 75 kWh. However, the most important improvements are the estimation of State of Charge (SoC) and the performance at low temperature, which are closely related to user experience.

Standing in the perspective of user experience, we can better understand why NIO chose ternary lithium. On the road of reducing costs which is a necessary process for any company, ternary lithium can better balance user experience, and this is related to what NIO pursues.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.