During a business trip with my colleagues, I wanted to summarize some information based on decomposition, especially for the main direction of lithium iron phosphate and NCM batteries, to roughly estimate the amount of raw materials needed.

Note: The report “An In-depth Explanation of Lithium Iron Phosphate from a Production Process Perspective” by Lin Huang is worth reading. Please take some time to read it when you’re free.

Information from Company Research

From a large-scale evaluation perspective, according to what I heard from the lithium iron phosphate battery companies I’ve researched, about 2,000-2,500 tons of cathode material is needed for 1 GWh of lithium iron phosphate batteries. And roughly 0.25 tons of lithium carbonate is needed for one ton of lithium iron phosphate materials.

From a micro perspective, for a 60kWh lithium iron phosphate battery, a car needs 30kg of lithium carbonate;

From a macro perspective, if we base on one car with a 60kWh battery, 100,000 cars need 6GWh; 1,000,000 cars need 60GWh. The corresponding demand for lithium carbonate is 30,000 tons. Based on the output of 166,000 tons of lithium carbonate in China in 2020, an increase of 4.4% YoY, of which 106,000 tons are battery-grade lithium carbonate and 60,000 tons are industrial-grade lithium carbonate. This means 100,000 tons of battery-grade lithium carbonate can be used for 200GWh of lithium iron phosphate batteries.

Note: There was another saying at that time that 0.25 tons of lithium carbonate can be used to make 10,000 tons of cathode lithium iron phosphate materials for 4-5GWh batteries. This is related to the difference in energy density.

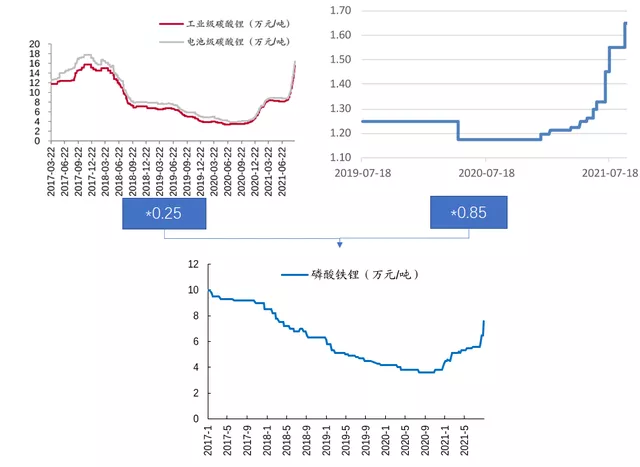

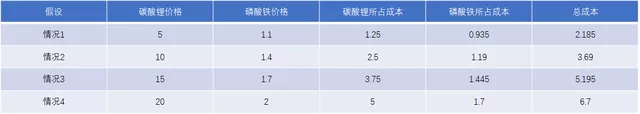

From a logical point of view, the price of lithium carbonate can be directly included in the cost at around 1/4, and the price of lithium iron phosphate can be directly included in the cost at 0.85, so we can roughly calculate the BOM cost.

The cost of lithium iron phosphate is 21,850 yuan for 50,000 tons of lithium carbonate and 11,000 yuan of lithium iron phosphate. Based on the current price system, if lithium carbonate costs 150,000 yuan and lithium iron phosphate costs 17,000 yuan, then the cost of iron phosphate will rise to 51,950 yuan. If the price is estimated at 200,000 yuan per ton of lithium carbonate and 20,000 yuan per ton of lithium iron phosphate, this price will rise to 67,000 yuan.

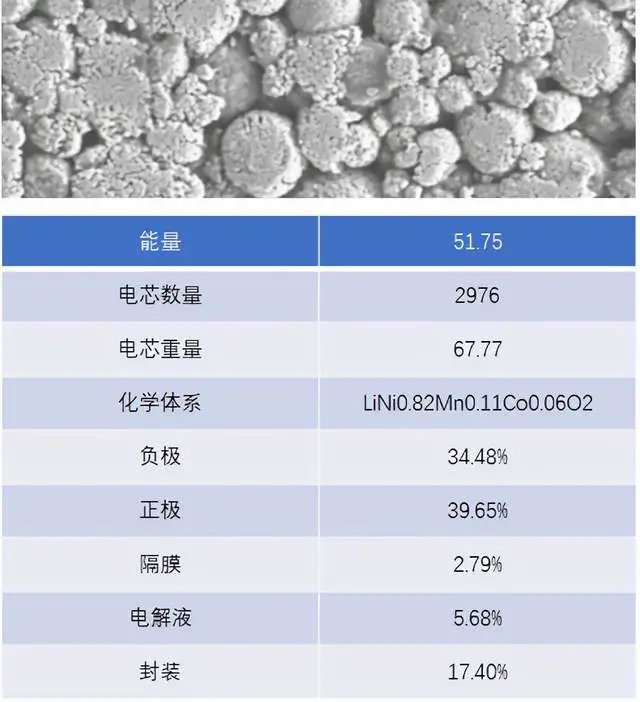

What if we use a ternary system?If we take Tesla’s use of LG products as an example, the materials can be roughly broken down as follows: 51.75 kWh, with the weight of the battery cell at 201.68kg, the weight of the corresponding positive electrode material at 80kg, the weight of nickel at 65.57kg, and the weight of cobalt at 4.8kg.

According to a price of 100,000 yuan per ton (100 yuan/kg), the price of nickel is 6,550 yuan, and the price of cobalt is 1,679 yuan per ton based on a price of 350,000 yuan per ton (350 yuan/kg). Together, they cost approximately 2,334 yuan.

If we take the 51.75 kWh of the three-element battery system as a benchmark, 100 million units of the Model 3 three-element version (51GWh) will require 65,000 tons of nickel and 0.48 million tons of cobalt. The global cobalt production in 2020 was roughly 140,000 tons.

In summary, being in high altitude and suffering from altitude sickness makes one feel a bit dizzy, so I roughly wrote down these contents for readers’ reference. Any areas in need of revision will be improved later. The main purpose is to provide some basic reference based on these data.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.