Author: Unknown LYNX

The heat of the Chengdu Auto Show in China has just subsided, and the Munich Auto Show in Germany has come one after another.

In the afternoon of September 6th Beijing time, the first Munich Auto Show was officially opened. The full name of this auto show is “2021 International Automobile and Smart Mobility Exhibition” (IAA Mobility), which was formerly known as the familiar Frankfurt Auto Show. Due to the impact of the epidemic, the venue for this year’s event has been relocated to Munich. This is the first exhibition of the world’s top five traditional auto shows to resume since the outbreak of the global COVID-19 pandemic.

As the forefront of the global automobile industry, Germany naturally represents the wind vane of the industry. At this auto show, European car companies led by hosts Volkswagen, Mercedes-Benz, and BMW will naturally bring the most cutting-edge technological innovation and showcase the old giants’ thoughts and explorations on the future of electrification, intelligence, and connected travel.

On the eve of the auto show, Mercedes-Benz once again emphasized its emphasis on electrification with products such as EQE and EQG concept cars. BMW, the old rival of Mercedes-Benz, seems to think further, focusing on a keyword related to environmental protection—”circular” for the theme of its exhibition.

However, whether it is because BMW is too eager to highlight its concept or because programmers are not doing their job properly, Mr. Zipse, Chairman of the BMW Group, appeared in front of global audiences in such an awkward way at the online press conference for the auto show, as shown in the following figure.

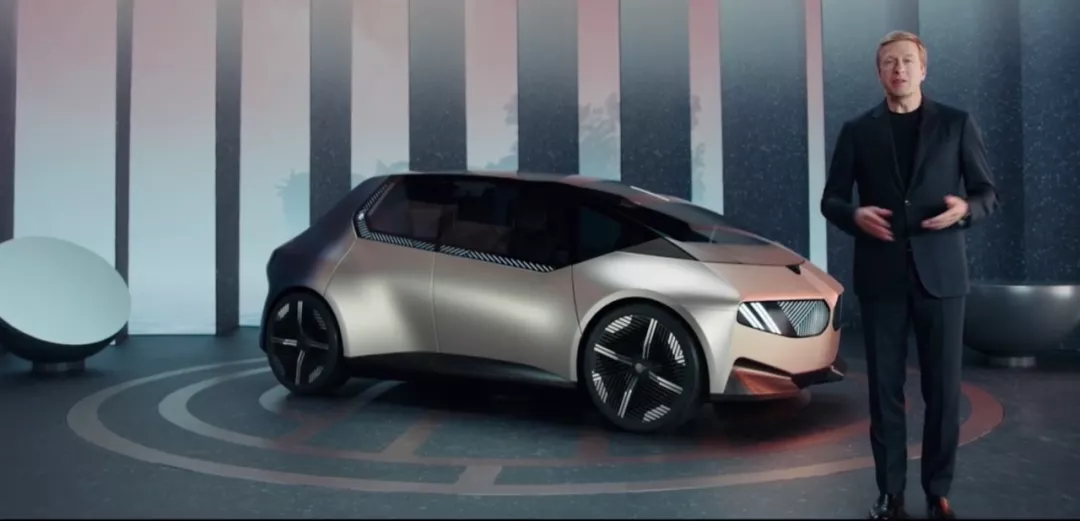

When the style returned to normal, the conference also returned to the topic. BMW proposed the four principles of “rethinking, reducing, reusing, and recycling” based on the circular economy and brought a concept car born from this principle—the BMW i Vision Circular.

The concept of circular economy is easy to understand, which is to build luxurious and enjoyable travel products with minimum resource consumption. The BMW i Vision Circular is BMW’s answer to this topic.

In the front part of the car, the BMW i Vision Circular reduced the use of materials, without chrome plating, no borders, and no traditional pillar design, but the BMW classic double-kidney design was still preserved in the form of digital animation.

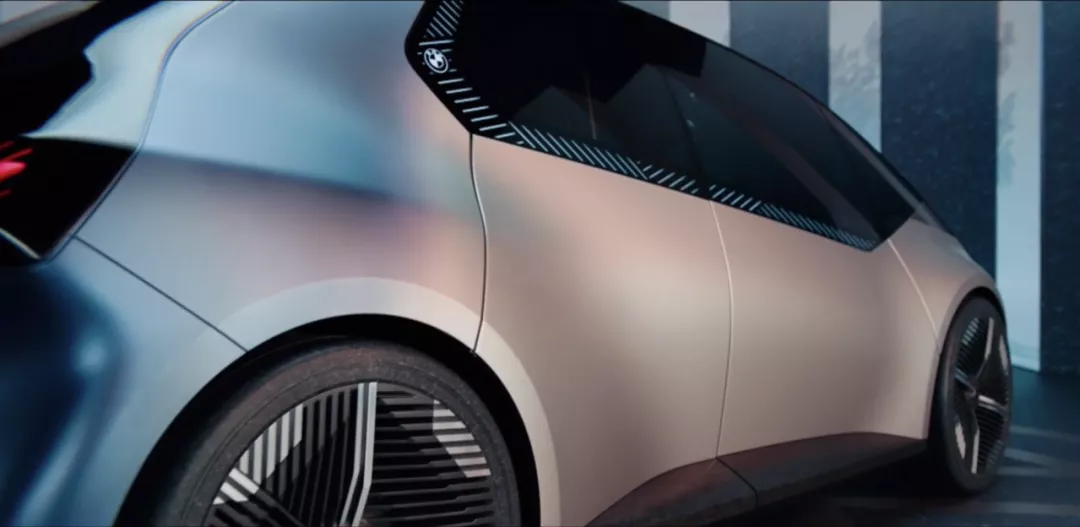

The BMW i concept car is decorated with slender digital interfaces around the body and windows, extending to the classic Hofmeister kink, while inheriting the classic design language. These digital interfaces have both display and control functions and can show information about the vehicle’s status, lighting up when the user approaches.

In order to emphasize the concept of sustainability and environmental protection, the body of the concept car is made of recycled aluminum. The car body does not use paint, but the metal is anodized to create a special light gold color.

The BMW i concept car has a body length of 4 meters, but with a pure electric drive system, the wheels are arranged as close to the corners of the vehicle as possible to ensure spacious interior space. The blue rubber tires are made from certified sustainable natural rubber and colored recycled rubber particles, creating a unique terrazzo effect.

At the rear, the BMW i concept car continues the minimalist style. The tail is made of heat-treated steel, and its blue-purple surface creates a gradient effect with the body color. The two metal materials are kept relatively independent, which is conducive to recycling and reuse.

The rear lights and other display surfaces are integrated into the dark glass tailgate, echoing the front face. When the vehicle is parked, only the flattened BMW logo is visible on the glass surface; all functional lighting elements and front-face pattern lines will be activated when the vehicle is opened.

In addition, the narrow shark fin at the top of the concept car’s roof combines communication and antenna technology, providing information about the vehicle’s status such as start-stop status and battery charging level.

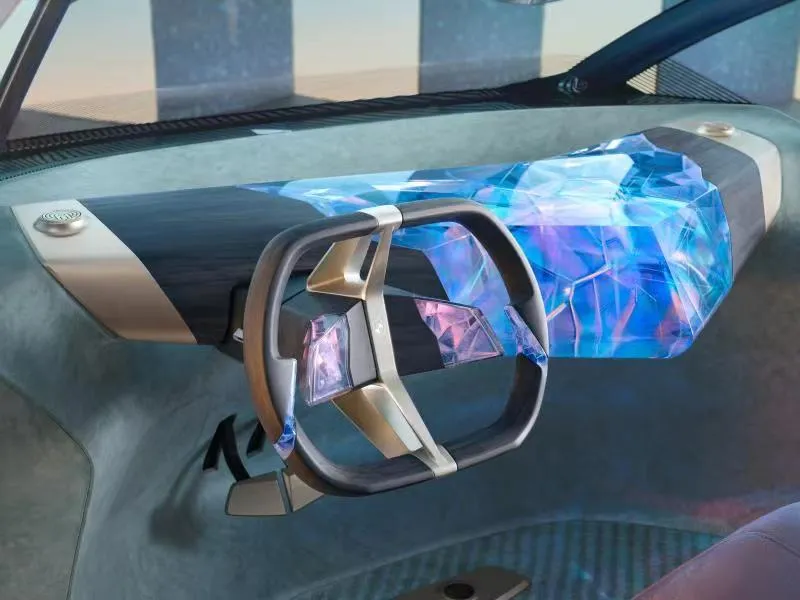

The BMW i Circular Concept Car continues its design philosophy of minimalism, luxury, intelligence, and sustainability. There is a prominent geometric central control screen in the center of the car – this sculptural control screen will feature the new BMW “phygital” user interface. The instrument panel information will be projected onto the windshield in a V-shaped sculpture.

The BMW i Circular Concept Car continues its design philosophy of minimalism, luxury, intelligence, and sustainability. There is a prominent geometric central control screen in the center of the car – this sculptural control screen will feature the new BMW “phygital” user interface. The instrument panel information will be projected onto the windshield in a V-shaped sculpture.

The steering wheel is made using recycled wood powder and 3D printing. The wood powder material gives the steering wheel a natural and warm visual effect while further simplifying materials and components. The panoramic sunroof consists of two lightweight panels that slide to adjust the sunshade effect, achieving excellent performance without the need for new electronic components or technology.

The fabric surface of the four independent seats in the car is made from recycled plastic, and the frames are embellished with light gold aluminum, providing a velvety texture.

At the same time, the entire seat material is cleverly integrated with a rope so that metal and fabric can be easily separated for recycling during subsequent recycling processes.

In addition, the design of this concept car fully applies the principles of the circular economy, achieving 100% use of recycled materials and 100% recyclability.

To maximize the reuse of vehicle materials, BMW has specially created the “joyful fusion” design – using only one socket wrench, the wheels, seats, and dashboard can be easily disassembled into various components, ensuring the convenience of subsequent disassembly and recycling processes.

During the production process, BMW will also establish digital archives for these materials to facilitate accurate identification of each component for subsequent recycling processes and to ensure that they enter the appropriate material circulation process.

In short, according to BMW’s official statement, the BMW i Circular Concept Car is an important step in its commitment to creating the “greenest electric car” vision, and circular technology has become the second cornerstone of the BMW Group after electrification.

The BMW i Circular Concept Car is a reflection of BMW’s continuous efforts to achieve energy-saving and carbon emission reduction goals. During the auto show, the BMW Group announced that it will further increase the previously proposed carbon emission reduction goal:

By 2030, the average carbon emissions per single vehicle throughout its entire lifecycle will be reduced by 40% compared to 2019 (previously one-third reduction), including a 20% reduction in the supply chain end, an 80% reduction in production and a 50% reduction in the usage phase (previously 40% reduction). The goal is to achieve climate neutrality throughout the entire value chain by 2050.

To achieve this goal, BMW has proposed the four principles of “rethink, reduce, reuse, and recycle” based on the circular economy.

Rethink: Designing models based on circularity, exploring new materials, technologies, processes, and ideas.

BMW will consider product technology, manufacturing processes, and the function of each component in a completely new way, and then reduce or redesign them to meet material recycling requirements, ensuring that vehicles are “sustainable from birth.”

Reduce: Reduce the use of raw materials, further reduce carbon emissions per single vehicle, and promote the development of electrification.

BMW will incorporate the entire lifecycle of the car, including production and upstream supply chain, into the “carbon reduction” plan: by 2030, the goal is to reduce carbon emissions per single vehicle throughout the entire lifecycle by at least 40% compared to 2019.

At the production level, BMW will minimize the use of rare raw materials. For example, the fifth-generation eDrive electric drive system will no longer use rare earths. At the same time, the company is increasing the proportion of reused materials to reduce carbon dioxide emissions. For example, the amount of carbon dioxide saved by using secondary aluminum is about 4-6 times that of primary aluminum, while that of steel and thermoplastic is about 2-5 times.

The usage stage of a car accounts for 70% of its total carbon emissions throughout its entire lifecycle. The biggest driving force to reduce this carbon emission is electrification. In the next 10 years, BMW expects to deliver approximately 10 million pure electric vehicles globally. By 2030, pure electric vehicle models are expected to account for half of BMW’s global sales, and the MINI brand will only provide pure electric vehicle models.

Further Utilization: Enable Vehicles to “Last Longer and Stay Newer” with Innovative and Digital Technologies

To minimize the extraction of primary raw materials, BMW will prioritize the use of “recyclable materials” in vehicle development-going forward, renewable materials will be used whenever their quality and supply conditions permit. By 2025, the “New Generation” of BMW cars will greatly increase the proportion of reused materials (such as recycled steel, plastics, and aluminium) used.

At the same time, BMW will extend and expand product lifecycles through digital technologies and other means, providing products with a longer useful life.

Recycling Again: Continuously Improve Raw Material Utilization

Currently, nearly 30% of recyclable and reusable materials are used on average in vehicle manufacturing processes. In the future, BMW plans to gradually increase this proportion to 50%.

To achieve this goal, BMW vehicles will use single materials wherever possible and be easy to disassemble, avoiding bonded or composite materials to ensure the separation and recycling of critical material groups in a “closed-loop” framework.

After reading BMW’s i Circular Concept Car and the circular economy strategy released at the Munich Auto Show, I was reminded of a wonderful metaphor used by William Li, chairman of NIO, in discussing battery recycling: “In the best-case scenario, the battery pack can be completely recycled and reused. ‘Make the recovered sausage into a pig again.'”

BMW has clearly gone further this time, extending the vision of circular reuse to the entire life cycle of the car.

So perhaps when BMW’s “i Circular” really succeeds in 2030, the debate over whether “electric cars are truly environmentally friendly” will finally come to a close.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.