Introduction

Recently, the automobile industry has been discussing the shortage of “chips” in the industry. Due to the shortage of automotive chips, some OEMs have even had to temporarily suspend production.

So, what are automotive chips? What is causing the shortage of automotive chips? Let’s briefly organize it here.

What Are Chips?

Some Concepts

When we talk about automotive chips, let’s start with chips. The basic concepts of semiconductors, transistors, integrated circuits, etc. cannot be ignored:

-

Semiconductors refer to materials with conductivity between conductors and insulators at room temperature.

-

Transistors are semiconductor devices that have various functions such as rectification, amplification, switching, and voltage regulation.

-

Integrated circuits integrate a certain number of transistors, resistors, capacitors, and other circuits with specific functions through semiconductor processes.

-

Chips are a collective term for semiconductor components that integrate circuits. They are usually made of silicon semiconductors as wafers and then integrated with circuits.

Chips are the carrier of integrated circuits, and the two terms can usually be used interchangeably. But chips emphasize the entity of integrated circuits, and integrated circuits emphasize the circuits themselves.

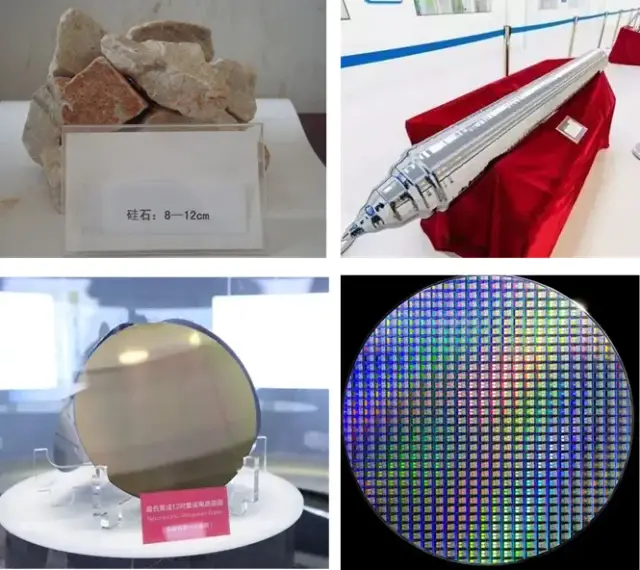

Some Parameters

The process of chip manufacturing can be briefly described as: first, refine the silicon rock, melt, pull it into a single crystal silicon cylinder and cut it into a wafer; then, according to the chip design circuit, integrate the circuit on the wafer through photolithography, etching, doping, etc.; finally, the chip is cut from the wafer, packaged, and tested.

-

Chip process: The width of the gate of the transistor on the chip. The smaller the number, the higher the transistor density and the higher the chip performance. The gradually decreasing chip process number represents the direction of chip technology advancement.

-

Wafer size: Currently, the main wafer sizes are 6 inches, 8 inches, and 12 inches. Increasing the diameter of wafers is to improve the utilization of single crystal silicon and reduce costs, but the larger the wafer, the worse the consistency of the process, and the higher the equipment cost of the larger wafer process.

-

Chip size: The larger the silicon wafer, the greater the probability of impurities, so the yield of larger chips is lower. In addition, the wiring of large chips is longer than that of small chips, so the delay is more obvious, and the driving current is much larger. This leads to a more cumbersome overall design, and performance will still suffer.

Some Abbreviations

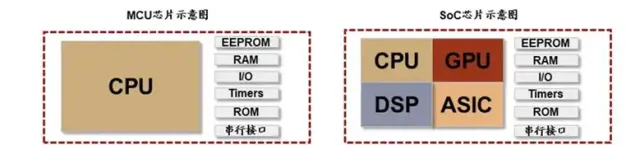

According to the function and implementation architecture, chips are divided into CPU, GPU, DSP, FPGA, ASIC, etc. According to the integration level, they include MCU and SoC:

-

CPU, Central Processing Unit: Good at processing logical control, scheduling, management, and coordination abilities are strong, and computing ability is secondary;

-

GPU, Graphics Processing Unit: Good at processing image signals. It was originally designed to deal with large-scale parallel computing required for image processing.- DSP, Digital Signal Processor: A chip that implements digital signal processing technology and can be used to quickly implement various digital signal processing algorithms;

-

FPGA, Field-Programmable Gate Array: A semi-custom chip with hardware programmability, but with high development difficulty and high price;

-

ASIC, Application Specific Integrated Circuit: A customized chip designed to meet specific requirements, with advantages such as small size, low power consumption, and low cost, but with limited flexibility, high one-time R&D costs, and long development cycles;

-

MCU, Microcontroller Unit: A chip-level device that generally only contains one processing unit, such as a CPU, and integrates storage and interface units;

-

SoC, System on Chip: A system-level chip that generally contains multiple processing units, such as a CPU, GPU, DSP, NPU, etc., and integrates storage and interface units.

What Are Automotive Chips?

Automotive Grade Requirements

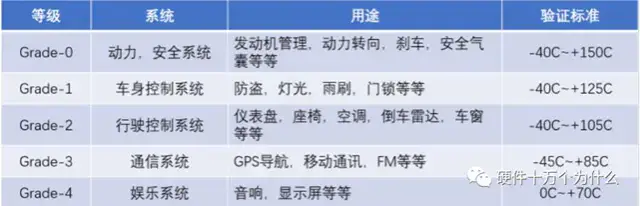

Chips can be divided into consumer chips, industrial chips, automotive chips, and military chips according to their application scenarios. Automotive chips are one of the application scenarios for chips, and automotive chips need to have automotive grade.

Automotive grade chips do not require high processing technology but have high quality requirements. The certification process includes quality management standards ISO/TS 16949, reliability standards AEC-Q100, functional safety standards ISO26262, etc.

Different chips for different purposes in the car also have different requirements. The automotive electronics standard formulated by the United States divides it into 5 levels. The requirements for chips from high to low in various systems of the car are as follows: power safety system > body control system > driving control system > communication system > entertainment system.

Types of Chips

Automotive chips are classified according to their functions, including control chips, power chips, sensor chips, and storage chips:

-

Control chips: According to the degree of integration, there are mainly microcontroller unit (MCU) and system on chip (SoC);

-

Power chips: The mainstream structures are IGBT and MOSFET. Low-voltage MOSFETs are generally used in gasoline vehicles, while IGBTs and high-voltage MOSFETs dominate the BEV market;

-

Sensor chips: They are divided into two categories: vehicle perception and environmental perception.- Storage chips are divided into memory RAM and flash memory flash. Memory loses data when power is cut off, while flash memory does not.

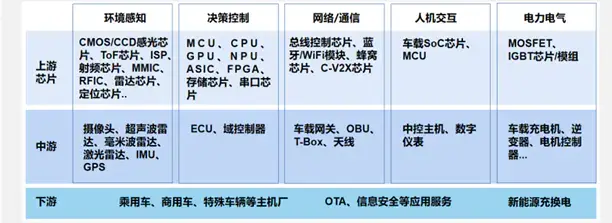

The main application areas of automotive chips on vehicles are: environmental perception, decision control, network/communication, human-machine interaction, and electrical power.

Development trends

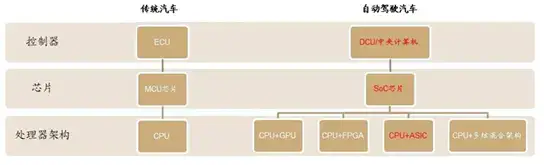

In traditional cars, MCU chips are the largest proportion of semiconductor devices. With the development of cars, the following trends have emerged:

-

The electronicization of cars has led to a continuous increase in the number of ECUs, which continues to drive up the demand for MCU;

-

The intelligence of cars is driving up the demand for environment perception sensor chips;

-

The development of intelligent cabins and autonomous driving is driving the need for stronger SoC chips;

-

The development of new energy vehicles has led to strong demand for power chips such as IGBT and MOSFET.

Autonomous Driving Chips

Development Phases

There are three development phases for autonomous driving, each with different applications for autonomous driving chips:

Sensor chip phase: Bosch and other Tier1 suppliers have installed millimeter-wave radar on cars to implement ACC and AEB, generally processing data on Xilinx chips. At the same time, Mobileye uses cameras to achieve AEB and LKA, using its self-developed EyeQ series chips for calculations. After each has developed for a period of time, radar and cameras are combined to achieve ICA, with cameras generally being the primary sensors;

Transition to domain control phase: Tesla, as a representative, developed a domain controller based on Nvidia’s Drive PX chip for decision-making, still using Mobileye in the early stages, but adding cameras to collect road data. After Tesla had enough data, the original information from the sensors began to be processed inside the domain controller, then merged and decided on their own;

Centralized computing phase:once the original information from the sensors is processed entirely within the domain controller, it is no longer necessary to install Xilinx’s computing chips in the camera or radar system. At the same time, the types and numbers of sensors continue to increase, and the architecture of autonomous driving computing evolves towards centralized computing architecture. Even car manufacturers like Tesla develop their own autonomous driving chips.

Mainstream Architecture

Currently, the three mainstream SoC chip architectures for autonomous driving are: CPU+FPGA, CPU+GPU+ASIC, CPU+ASIC:

- CPU+FPGA: such as Google Waymo, Baidu Apollo;- CPU+GPU+ASIC: Examples include Nvidia Xavier = CPU+GPU+ASIC (DLA deep learning accelerator + PVA visual accelerator), Tesla FSD = CPU+GPU+ASIC (NPU deep neural network accelerator);

- CPU+ASIC: Examples include Mobileye EyeQ5 = CPU+ASIC (CVP traditional vision + DLA deep learning + MA multi-threaded acceleration), Horizon Journey 2 = CPU+ASIC (BPU-AI task processing);

- While autonomous driving algorithms are not yet mature, CPU+GPU+ASIC architecture is still mainstream. Once matured, custom-designed mass-produced AI chips (ASIC) will gradually replace high-power GPUs, and CPU+ASIC architecture will become mainstream.

- Professional AI chips (ASIC) are designed specifically for AI algorithms, with advantages such as smaller size, lower power consumption, higher reliability, and higher performance, but with the disadvantage of high development costs and long cycles.

- In the automotive chip market, multinational companies dominate, with over 90% of China’s automotive chips relying on imports. Currently, MCU chips, which are the most widely used in cars, are monopolized by companies such as NXP, Texas Instruments, and Renesas, and there are few opportunities for newcomers.

- With the development of automotive intelligence, consumer chip giants have entered the automotive chip field. Currently, the intelligent cockpit chips are monopolized by Qualcomm, Nvidia, NXP and other companies. Nvidia and Intel have taken the lead in self-driving chips, and domestic chip manufacturers such as Huawei, Horizon, and Black Sesame have seized opportunities.

- Traditional automotive chip manufacturers are Tier2, and MCU products are handed over to Tier1 to make ECU, DCU and other controller products. However, as cars develop towards on-board computing platforms, SoC chip suppliers that have the ability to provide full-stack software and hardware may become the new Tier1. Examples include Nvidia working with XPeng, Horizon working with Changan, and Mobileye working with Geely.The direct cause of the shortage of automotive chips is the combination of the impact of the epidemic and the insufficient production capacity due to the excessive concentration of chip manufacturers. The fundamental cause, however, is the mismatch between the development speed of automotive chip manufacturers and the rigid demand for automotive chips driven by the rapid development of automotive electrification, intelligence, and new energy vehicles.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.