On the morning of August 23, 2021, Zhiqi Motors held a media event at Anting Innovation Park, featuring the styling and wind resistance coefficient of its flagship luxury pure electric high-performance sedan, the L7. From left to right in the picture, Zhiqi Motors Joint CEO Liu Tao, Zhiqi Motors Aerodynamics Project Leader Zuo Huihui, and Zhiqi Motors Design Project Leader Xu Dengtao were the keynote speakers at the event.

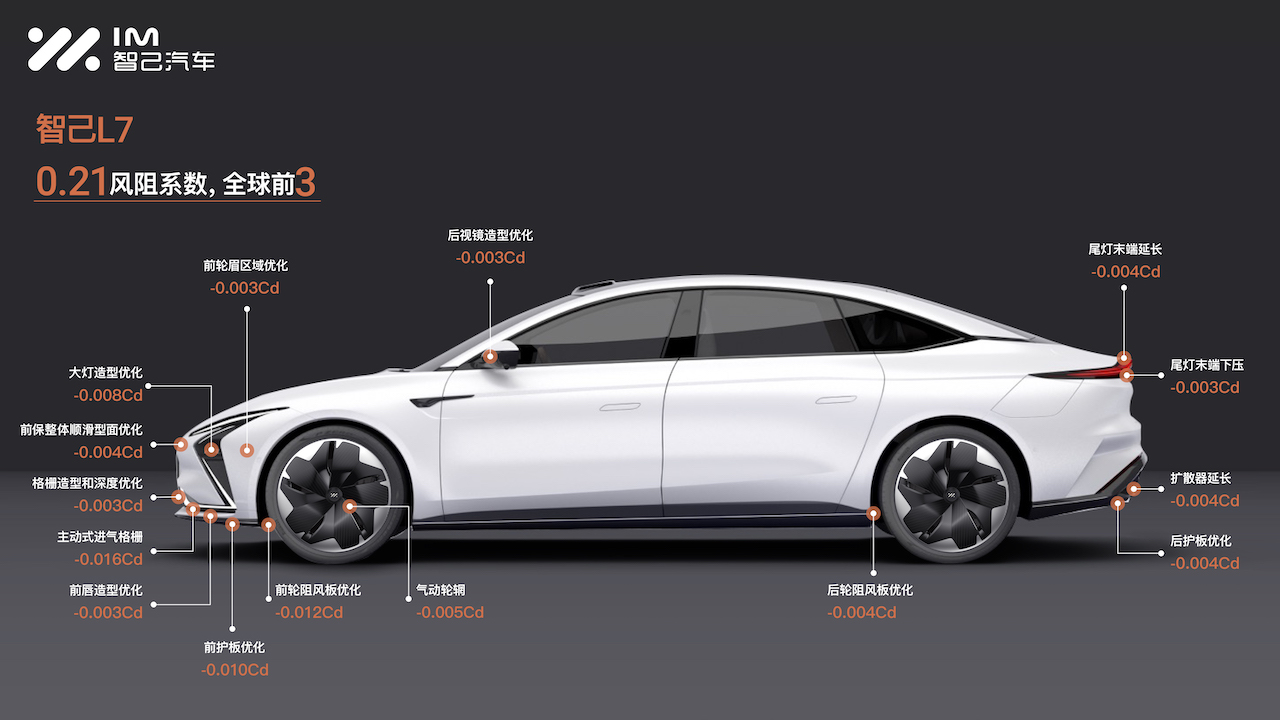

Last week, Zhiqi Motors announced that its first mass-produced product, the L7, achieved the third-lowest wind resistance coefficient in the world (related reading: With only 0.21, Zhiqi L7 wind resistance coefficient certified by China Automotive Technology and Research Center).

Wind resistance has a significant impact on the range of cars, especially electric vehicles. The wind resistance coefficient is one of the factors that determine the size of the wind resistance (the other two factors are the frontal projection area and the vehicle speed, related reading: Do you really understand the wind resistance coefficient?). But reducing one “count” (reducing the wind resistance coefficient by 0.01) is a huge challenge.

Advanced pure electric architecture creates water droplet contour

When releasing the Model S Plaid, Musk said, “Tests where the wheels don’t move are fake because it makes the data look better.” As seen from the figure, the test environment simulated a speed of 120 km/h, and the wheel blur tells us that the number 0.21 was obtained when the wheel was rotating.

Water droplets falling freely in the air have extremely low wind resistance and also present a smooth contour. The 25.9-degree front window angle and 16-degree rear window top angle largely determine the aerodynamic characteristics of Zhiqi L7. More horizontal windshield angles, continuous body contours, and lower fronts can bring lower wind resistance coefficients. However, not all cars have the confidence to achieve this shape.This is a game that is constrained by platform, cost, and design ideas. For example, slimmer A-pillars and disappearing B-pillar beams may not be achievable on previous platforms due to safety performance. However, the IM L7 is able to achieve such a smooth design while ensuring that the body’s torsional stiffness is close to 30,000 Nm/deg, because as the joint CEO Liu Tao said, there needs to be enough “bandwidth” on the platform to achieve the freedom of design. This is also why the L7 can only be achieved based on the latest pure electric platform.

At the same time, Liu Tao also pointed out that with the price of 408,800 RMB, this car can also use better materials such as ultra-high-strength steel in inconspicuous places such as the firewall, to ensure a more solid foundation for the freedom of design in other places.

Overcoming traditional designer thinking is also a challenge in designing a new electric vehicle, because the packaging brought by the pure electric platform and the richness of scenarios brought by intelligence are not possessed by previous models. Designer Xu Dengtao frankly said that he has not paid attention to the works of peers in the past two years. Instead, he appreciates some crossover works of designers in other fields to ensure that he will not be trapped by traditional automotive thinking.

This is also why IM collaborated with Thomas Heatherwick, the chief designer of the UK’s Heatherwick Studio, to create a concept car named Airo, which was also showcased at the Goodwood Festival of Speed recently.

Accumulated Aerodynamic Parts

-

Active air intake grille, adjust the balance of heat dissipation and wind resistance according to working conditions;

-

Aerodynamic wheels, the closed low-drag shape can reduce the surrounding turbulence;

-

Aerodynamic taillights, which also serve as a flow control plate, and the slight upward tilt effectively improves the turbulence at the rear of the vehicle;

-

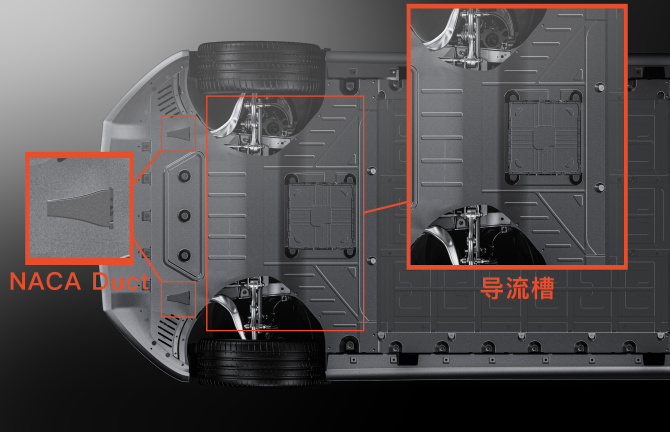

Aerodynamic underbody shield, the aerodynamic guide groove design on the full-coverage aerodynamic underbody shield is derived from the aerodynamic principles of golf ball surface. It can play a role in accelerating the flow rate and effectively improve the vortex flow at the rear of the vehicle, increase the pressure at the rear of the vehicle, and reduce resistance.

From Green Train to High-Speed Train

In order to improve the aerodynamic performance, L7 has gone through ten rounds of design iterations, with research and development investment reaching millions. The cumulative aerodynamic drag coefficient has decreased by 30%, which is equivalent to the level of high-speed trains (0.48), down from ordinary trains (0.7).

IM’s investment in aerodynamics is also a great effort. A total of 5 rounds of wind tunnel tests were performed on the L7 prototype, with a cumulative test time of more than 150 hours. In contrast, NIO EC6 had only 16 hours. In terms of simulation calculations, IM conducted nearly 900 calculations, 45 times more than the XPeng P7.

IM’s joint CEO Liu Tao said that the optimization of the aerodynamic drag coefficient in the picture is the result of collisions between designer Xu Dengtao and engineer Zuo Huihui’s ideas, with the former not wanting to compromise on aesthetics and the latter not wanting to compromise on performance. Liu Tao welcomes such collisions, as they mean that the product is making progress towards a new balance, which is good for them personally, the company, and consumers.

🔗 Source: IM Auto

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.