“Lock Battery” Incident of Guangqi Toyota iA5: Why “Lock Battery” and Power Reduction Happened

Author: Wang Lingfang

The “lock battery” incident of Guangqi Toyota iA5 has become a hot topic recently.

According to media reports, some Guangqi Toyota iA5 owners have lodged complaints and sought consumer rights protection from the Quality Development Bureau of the State Administration for Market Regulation.

Consumers believe that from July 18th to July 23rd, the manufacturer upgraded the battery management system (BMS) of Guangqi Toyota iA5 model through backend OTA without the consent of consumers, which significantly reduced the available capacity and output power of the battery, leading to the depreciation of the asset they purchased, infringement of consumer rights, and even affecting driving safety.

Consumers believe that this is the manufacturer’s attempt to evade recall responsibility.

It is worth mentioning that on July 15th, an iA5 vehicle caught fire during charging before the “lock battery” incident happened.

Similar incidents of “lock battery” and power reduction frequently occur in the industry. For example, in 2019, Tesla suffered several self-ignition accidents globally. Afterwards, for safety reasons, Tesla adopted a protective upgrade for older models through OTA software upgrades, which mainly included controlling available power (reducing available power), controlling charging speed (decreasing charging speed), increasing hidden power (increasing remaining power when displayed as 0), and strengthening parking temperature control (increasing power consumption).

Consumers initiated lawsuits in response to this. In May 2021, Tesla was found guilty of reducing charging speed and available power and was required to pay 136,000 kroner (about 16,000 US dollars) to each of the 30 car owners involved in Norway.

The “lock battery” incident of Guangqi Toyota is not the first case in China, and related complaints and reports also happen from time to time.

What are the reasons behind these incidents? Can there be any solutions?

In response, EV Observer has conducted in-depth discussions with experts and heads of electric core enterprises, battery system suppliers and battery department of car enterprises.

Industry insiders believe that the “lock battery” behavior of Guangqi Toyota iA5 is likely due to the insufficient safety redundancy capacity retained prior to the accident. After the safety accident, they reduced the safety hazard by “locking battery.”

The lack of experience in new energy vehicle field or attempt for opportunism from car makers has brought extremely negative impacts: car companies not only lose their good brand images, but also customers’ trust, which is not worth the loss.

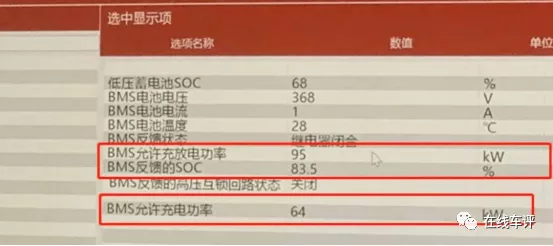

Why “Lock Battery” and Power Reduction?According to media reports, after OTA upgrade, the original electric capacity of the GA5 of GAC Toyota decreased by nearly 10 kWh, and the actual driving range was reduced by nearly 100 km. Not only was the battery capacity reduced, but the output power of the electric motor that could output 100% power was locked to below 60%.

Why lock the battery capacity?

The answer is for safety and lifespan considerations. In 2016, engineers at DFCV Technology Center published an article “The Impact of Discharge Depth on Battery Life”, which analyzed the battery status at different states of charge (SOC).

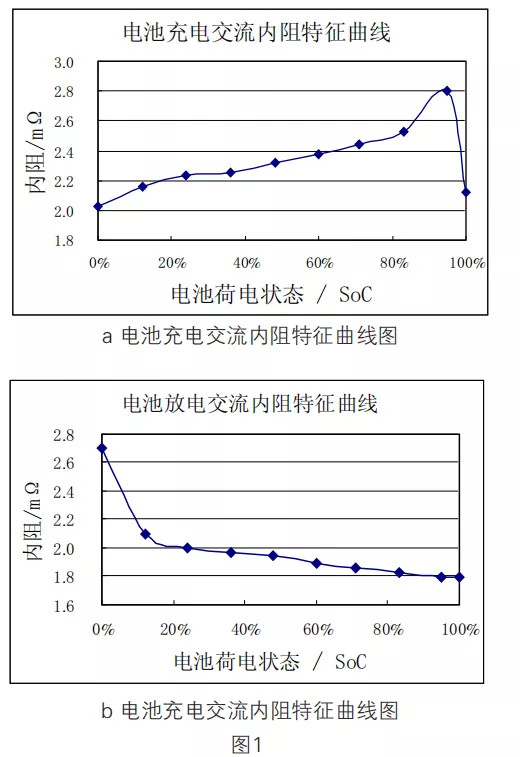

Experimental data on lithium-ion batteries shows that when 80%<SOC<95%, the AC impedance of the battery increases sharply, and some active lithium ions accumulate and attach near the electrode, forming “lithium dendrites” or other lithium compounds, increasing the probability of secondary reactions, causing the internal resistance of the battery to increase and resulting in partial capacity loss.

Experimental data shows that when SOC>80%, the AC impedance of the battery increases by about 40%, and when DOD>80%, the AC impedance increases by about 35%, which has the most significant impact on the deterioration of battery internal resistance. Therefore, using the battery within the range of DOD<80% and 20%<SOC<80% has a smaller impact on the battery internal resistance, which is conducive to extending the lifespan of the battery.

Therefore, reducing the depth of charge and discharge is beneficial for the safety and lifespan of the battery.

Regarding this, Ms. Zhang, the head of the battery department of a car manufacturer, gave a more straightforward example in an interview with the “Electric Vehicle Observer”: Just like a rubber band, the more it is stretched, the more elastic loss it will experience, and it will break after a few times. If the stretching is smaller, the lifespan of the rubber band will be longer.

Ms. Zhang believes that the behavior of locking the battery capacity should be more accurately described as dynamically adjusting the usage window because the battery’s storage capacity still exists.

Ms. Zhang believes that although the single driving range is shorter, the use of the battery is more reasonable, and the overall driving range of the entire lifecycle has been extended, which is still beneficial for consumers.

What about reducing the power output?

Mr. Ma, the relevant person in charge of a battery system production enterprise, said that reducing power output is to compensate for the shortened driving range caused by the decrease in battery capacity.The direct impact of the power reduction is the decrease in acceleration performance. “Without prior notice, the driver will misjudge the vehicle’s performance.” Mr. Ma gave an example. At an intersection, a left turn that could normally be passed in 2 seconds now takes 4 seconds. This can indeed bring potential safety hazards.

Mr. Tao, an iA5 owner, expressed his indignation to “Electric Vehicle Observer”: “When we bought it, we were pursuing a large battery and long endurance. You also advertised it that way. If you lock the battery and keep quiet about it, isn’t that bullying people?”

Mr. Ma can fully understand the consumer rights protection actions. “If it were a gasoline car, it would be equivalent to me buying a 2.0T displacement engine and using it as a 1.6. The difference in performance can be worth tens of thousands of dollars. It’s like buying a B-class car, and you turn it into an A or even A00-class car. Of course, consumers cannot accept it.”

Insufficient Safety Capacity Reserves for Batteries?

Since the discharge depth affects the battery’s life, general car manufacturers will require a certain amount of reserved capacity that does not participate in normal charging and discharging.

However, how much to reserve is a game.

Mr. Zhen, the person in charge of a certain battery company, said that battery companies and automakers have been playing games. For safety and longevity, battery companies hope to leave a little more. Automakers want better parameters, so they are always trying to leave as little as possible. “Anyway, if there is a problem with the battery, it is the battery factory’s problem. Unless there is a risk of fire, the car factory generally does not want to leave much.”

In Mr. Zhen’s view, automakers’ squeezing of costs and performance and vicious competition among battery companies cannot rule out that some companies leave too low of a safety margin.

The technical director of a certain battery cell company also expressed a similar view: “Battery capacity is all calculated in money. Car companies naturally do not want to store too much electricity.”

“Electric Vehicle Observer” randomly selected several sedans with a range of about 500 kilometers from Autohome and found that the vehicle’s battery capacity is roughly around 60 kWh. iA5 from GAC Toyota has a range of 510 kilometers with less than 60 kWh of capacity.

Whether this has left enough safety capacity, only automakers know the truth.

So, what is the industry’s unified requirement for the battery’s safety capacity? Mr. Zhen confessed that this cannot be unified, and it is closely related to battery consistency, inherent quality and stability, state of health (SOH), and especially battery temperature.

Although safety capacity cannot be unified, there are some habitual practices in the industry for discharge depth.Mr. Ma said that generally conservative enterprises control the depth of discharge to about 85%, but some car companies will set the depth of discharge to 95% in order to achieve maximum range due to limitations in the interior space of the vehicle. This is an extreme case. Mr. Zhen also said that some companies leave only 5-6% of safety margin.

helplessness of charging operators

Since battery safety is related to the depth of charge and discharge, can adjustments be made during the charging stage?

To this end, Electric Vehicle Observer consulted Ju Qiang, chief scientist of TELD.

Ju Qiang frankly said that the charging pile is a passive side during the entire charging process. According to the national standard, the vehicle’s BMS issues a charging instruction, and the charging pile provides the corresponding current and voltage according to the instruction.

However, according to statistics from the national regulatory platform, most battery spontaneous combustion accidents occur during the charging stage and the idle stage after charging, that is, most accidents occur at charging stations.

Even if accidents are caused by battery spontaneous combustion and not related to charging piles, accidents still cause great losses and troubles to charging operators, such as station closures, station dismantling, administrative sanctions, compensation for vehicle damage, and public opinion impact. Therefore, TELD has also begun to monitor the safety of vehicle power batteries from the charging side, and immediately stops charging when abnormalities are found in order to control the occurrence of thermal runaway of the battery.

Of course, as a barrier, charging operators will also track the BMS data of vehicles. This requires the vehicle to be charged at their operated stations for a long time before feedback on the battery can be monitored. If there is a hidden danger, the operator will adjust the charging strategy, such as not giving the vehicle a full charge.This is also a solution similar to “locking the battery.”

Ju Qiang said that their strategy is also graded and layered. For example, for high-risk vehicles, full charging is restricted, which is also a protective strategy for charging stations and other vehicles. For example, strategic adjustments are made according to cities. Some cities are more sensitive, and relevant departments will require operators to adjust the charging depth to 95% or 90%.

Ju Qiang said that they have many strategies, and they design relevant strategies by combining multiple dimensions such as vehicle model and user.

However, there are also many helplessness. “For example, if the charging operator wants to calibrate each vehicle, the information provided by the vehicle must include the VIN. Early on, some car companies intentionally provided incorrect VINs to prevent calibration of the vehicle; For example, a certain foreign brand’s BMS gives a fixed battery temperature of 28-29℃, which is unfair to both operators and vehicle owners.” Ju Qiang said that they have notified such companies by letter.

“This is like taking preventive measures. If they don’t provide real data, our charging station will not give them a full charge, and will limit the SOC to reduce the risk.”Except for TeSLa, StarCharge has also started to monitor and warn the safety of charging electric vehicle batteries on the charging side. The safety protection and warning of charging side has gradually been recognized by the industry, and has become another trend of power battery safety monitoring.

It can be seen that the scope of charging operators’ actions is relatively limited.

Solving problems from the source can only be done during the vehicle design stage.

Mr. Zhen said that he had proposed a solution to the automakers: when charging, based on factors such as charging mode (current), environment, healthy status (SOH), etc., calculate an safe reserve capacity, and stop charging each time when it reaches this capacity; when users have special needs, such as running long distances or making mileage tests, they can fully charge the battery once through a complicated operation and cancel the redundancy.

“However, the automakers were not willing to accept my suggestions at that time, and they thought it would affect their user experience,” Mr. Zhen said.

However, based on the situation of the GF iA5, it is most likely that there was not enough safe capacity reserved for the battery during the design stage. For what is not accomplished before leaving the factory, it can only be compensated afterwards, but there is no advance notification, compensation afterwards, and the attitude of attempting to get through the problem without being noticed has enraged consumers.

At present, consumers are very determined to protect their rights, and they are unlikely to give up without reasonable explanations and compensation.

This incident has brought extremely negative impacts, whether it is because the automaker is inexperienced in the field of new energy vehicles, or because they thought they could take advantage of the situation: the automaker not only loses a good brand image, but also loses the customers’ trust, which is not worth the candle.

Finally, Mr. Zhen also called on consumers to try not to fully charge when using electric vehicles in daily life, to use them as soon as possible after they are fully charged, and not to use fast charging in low temperature conditions, so as to improve the safety and lifespan of electric vehicle batteries.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.