*This article is reproduced from the autocarweekly official account.

Author: Joey

Since the beginning of the electric vehicle (EV) era, the automotive industry has been undergoing rapid changes. It seems that “three days without learning, information is not up to date.”

Just when we’ve learned about what lithium iron phosphate and ternary lithium are, blade batteries and solid-state batteries have challenged our existing knowledge. However, before these new materials and technologies are widely used and even before they are being marketed on a large scale, another new technology has emerged.

Not long ago, CATL expanded our knowledge by introducing sodium-ion batteries. Undoubtedly, when the industry leader in power batteries enters the market, the existing battery industry landscape will inevitably be rewritten.

So, what exactly is a sodium-ion battery and what are its outstanding features? What strategies does CATL seek to achieve with this technology?

How good are the performance of sodium-ion batteries?

Since the 19th century, companies have been developing sodium-ion batteries and related technologies. The research reached its peak in the 1970s, but regardless of whether molybdenum disulfide or titanium disulfide was used as the electrode material, the performance of sodium-ion batteries was not better than that of lithium-ion batteries because of the material characteristics of sodium-ion batteries. Sodium ions are larger and heavier than lithium ions. At the same time, the structural stability requirements for the materials in sodium-ion batteries are also higher during power generation.

Therefore, people chose to study easier-to-implement technologies first. As a result, although sodium-ion batteries started early, their technology did not break through until about a decade ago.

According to the performance of the first-generation sodium-ion battery previously released by CATL, it can achieve a single-cell energy density of 160 Wh/kg, and the integrated efficiency of the battery system can also reach more than 80%. At the same time, this battery also has very high fast charging performance. It can replenish 80% of its power in just 15 minutes. We know that the current mainstream battery fast charging performance requires 30-40 minutes to achieve the same charging effect.

Of course, these are not all. CATL summarized this sodium-ion battery as having high energy density, high-rate charging, excellent thermal stability, good low-temperature performance, and high-integration efficiency.

Therefore, in addition to the battery characteristics mentioned above, sodium-ion batteries can also have a cycle life of more than 3,000 times and a strong low-temperature performance, maintaining a discharge retention rate of over 90% in an environment of -20°C.

It can be imagined that if the sodium-ion battery technology is put into use, it will effectively solve people’s anxieties about battery charging efficiency, range anxiety for EVs in cold regions, and battery thermal management (which can cause auto-ignition).

Can sodium-ion batteries replace ternary lithium batteries?

By now, seeing here, I believe a question has popped into your mind, the advantages of sodium-ion batteries are so obvious, will it pose a certain threat to the position of ternary lithium batteries?

As we all know, the biggest advantage of ternary lithium batteries, which mainly use materials such as nickel cobalt aluminum lithium and nickel cobalt manganese lithium batteries, is that they have a higher energy density and longer range of endurance. Therefore, we can see that those pure electric vehicle models with a range of more than 500 kilometers basically use ternary lithium batteries.

However, ternary lithium batteries also have relatively weak areas, such as the number of cycle charge and discharge compared with lithium iron phosphate batteries. At the same time, due to the unstable high-temperature structure of nickel cobalt aluminum, it may affect high-temperature safety, and the pH value is too high, which may cause gas expansion of single cells and may pose a higher risk of self-ignition than lithium iron phosphate batteries with more stable overall properties.

In addition, its low-temperature performance is also a disadvantage that needs to be overcome urgently. During the winter at temperatures of 0-5 degrees Celsius, the energy of the ternary lithium battery will drop to about 90% of that in the summer. In colder areas, its low-temperature performance will decline more significantly. Therefore, many automotive manufacturers will focus on emphasizing that vehicles have undergone strict low-temperature testing, and the purpose is to dispel users’ doubts about their low-temperature performance.

It seems that sodium-ion batteries are more advantageous than ternary lithium batteries in safety, low-temperature performance, and even charge and discharge efficiency and cycle charging times (the national requirement for the number of ternary lithium battery charge and discharge times is over 1000, and the maximum number of imported products may reach 3000).

But in fact, compared with ternary lithium batteries, sodium-ion batteries also have their own difficulties to overcome.

For example, we have previously mentioned that the volume of sodium-ion batteries is larger than that of lithium-ion batteries, which means that to achieve a similar range as ternary lithium batteries, a larger vehicle body size is required to accommodate more batteries. Of course, this requires stricter requirements for material stability and dynamic performance.

Of course, a larger volume and lower energy density also bring a more realistic problem – endurance. And this is precisely where pure electric car users are most concerned about.

This also means that before breaking through this bottleneck, sodium-ion batteries cannot replace the current position of ternary lithium batteries.

Lithium iron phosphate battery’s status is hard to keep

Since sodium-ion batteries cannot replace the position of ternary lithium batteries before significant technological breakthroughs, another mainstream battery type, lithium iron phosphate, is obviously facing greater threats.Compared with sodium-ion batteries, which have more balanced multiple technical indicators, the advantages and disadvantages of lithium iron phosphate batteries are more obvious. In fact, in terms of energy density, lithium iron phosphate batteries are not as good as ternary lithium batteries, so their disadvantage in endurance is very obvious. However, its advantage lies in the stable properties of the battery, so it will not explode even under extreme conditions (such as serious collision accidents), and the safety of the vehicle can be better guaranteed.

At the same time, its long-life characteristics in terms of usage are also outstanding before the emergence of sodium-ion batteries. The cycle charge and discharge times of lithium iron phosphate batteries can reach more than 2000 times, and the service life can also reach 7-8 years. Therefore, for some commercial vehicles that need to be used frequently for a short period of time (such as electric taxis), the advantages of safety, long service life, and efficient cycling charge and discharge are very prominent.

Of course, compared with the advantages, the disadvantages of lithium iron phosphate batteries are also very obvious. In addition to the endurance problem mentioned earlier, low-temperature performance is also the number one problem that hinders its continued development. At an air temperature of 0°C, the capacity retention rate of lithium iron phosphate batteries is about 60-70%, and at -10°C, it rapidly drops to 40-55%, while when the temperature drops to -20°C, the amount of electricity that can be used is only 20-40% of the rated capacity. Obviously, lithium iron phosphate batteries are not a type of battery that can be used all day long.

Therefore, if we compare its advantages and disadvantages with the previously mentioned sodium-ion batteries, we will find that sodium-ion batteries can cover almost all performance indicators that can cover the disadvantages of lithium iron phosphate batteries, and the trend of replacement is already very apparent.

Preparing for emergencies at CATL

Did CATL launch sodium-ion batteries just to replace lithium iron phosphate? From the perspective of product iterations, this may be an important reason. But more importantly, CATL may have realized that to fundamentally solve the crisis that ternary lithium batteries may encounter in raw materials, it needs to be prepared on both ends.

At the end of 2020, CATL invested $5 billion in building a lithium-ion battery factory in Indonesia and signed a nickel product supply agreement with PT Aneka Tambang, a state-owned Indonesian mining company. The agreement stipulates that CATL must ensure that 60% of the nickel is processed into batteries in Indonesia, and the first batch of batteries will be produced in 2024. The establishment of this factory will effectively solve the problem of China’s scarce nickel ore production, providing sufficient manufacturing materials for both nickel-cobalt-manganese acid lithium batteries and nickel-cobalt-aluminum acid lithium batteries.But this is not all. The important separator component of ternary lithium batteries also relies on imports. The separator is one of the key components of lithium-ion batteries and has high technological barriers, serving as an important material for battery temperature control. Currently, these materials are mostly monopolized by Japanese manufacturers.

Although China is one of the world’s top five lithium ore resource countries, the total amount of lithium resources on earth is not large, with a content of only 0.0065% in the crust. Due to the limited lithium ore resources in China, the current import dependency is about 70%. With the overall trend of the global automobile industry turning to electric vehicles, the shortage of lithium ore resources is believed to be just a matter of time.

Therefore, to solve these unstable factors that may restrict the production of ternary lithium batteries at any time, a more mature alternative solution is needed, and sodium-ion batteries appear to be a good choice.

How can sodium-ion batteries provide a solution?

Compared with the relatively scarce lithium ore resources, sodium, as the sixth abundant element in the earth’s crust, has a more obvious advantage in terms of difficulty in obtaining raw materials. At the same time, in terms of manufacturing costs, the Bill of Materials (BOM) cost of sodium-ion batteries is estimated to be 0.2-0.3 yuan/Wh, which is less than 70% of lithium iron phosphate, and even only half of ternary lithium batteries, making it extremely advantageous.

More importantly, in terms of manufacturing processes, sodium-ion batteries can achieve perfect compatibility with lithium-ion battery production equipment and processes, and production lines can be quickly switched to achieve rapid capacity layout. That is to say, there is no need to invest in new factories and production lines again, and once the raw materials for ternary lithium batteries are in short supply, CATL can quickly switch to the production of sodium-ion batteries, ensuring the supply of batteries in the market and continuing to make profits.

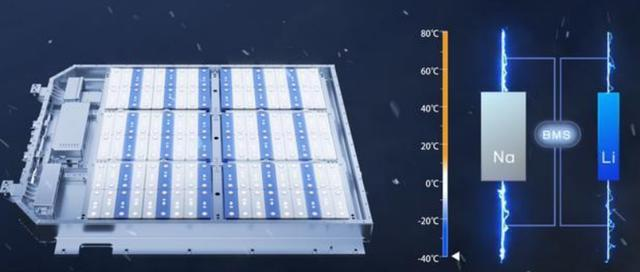

At the same time, although sodium-ion batteries have their advantages in product characteristics, their shortcomings also exist. So how can CATL balance this point? The AB battery system solution may be a highly creative good idea.

In fact, this AB solution is also very easy to understand, which is to mix lithium-ion batteries and sodium-ion batteries, and then control two types of batteries through the Battery Management System (BMS) system to achieve balance. This can ultimately obtain better range performance and bring better thermal control and low-temperature performance.

Clearly, all the advantages and disadvantages of sodium-ion batteries have been calculated clearly by CATL, and once this type of product is put into production in 2023, it may completely change the energy form of future pure electric vehicles. It is really exciting about this.

What is even more exciting is that CATL has announced that the energy density of the next-generation sodium-ion battery will be increased to 200 Wh/kg, which means the biggest shortcoming of sodium-ion batteries is being rapidly improved.“`

Obviously, CATL has told us clearly that the future of power batteries lies in “sodium” and “lithium”. Perhaps the only one that can feel the crisis at present is the lithium iron phosphate battery.

“`

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.