“Natrium, right?”

“Yes, sir… Natrium battery should be the strongest, it has several times more electric power than zinc battery,” this is a passage from the original French science fiction novel “Twenty Thousand Leagues Under the Sea” written by Jules Verne in 1870. In this well-known novel, Natrium battery was first proposed by Verne as a concept.

However, Natrium battery was not invented until nearly 100 years later. Nevertheless, both Natrium sulfur battery and Natrium ion battery are not as highly regarded as lithium battery. Especially for Natrium ion battery, it was not until 2011 that the first company in the world attempted to commercialize it.

Up to now, the industry mainly positions Natrium ion battery in the fields of energy storage and low-speed vehicles.

On July 29th, CATL released the first generation of Natrium ion battery through an online conference, and applied it to new energy vehicles by innovatively using a lithium-natrium mix battery structure, breaking the industry’s cognition that Natrium ion battery is not suitable for electric vehicles.

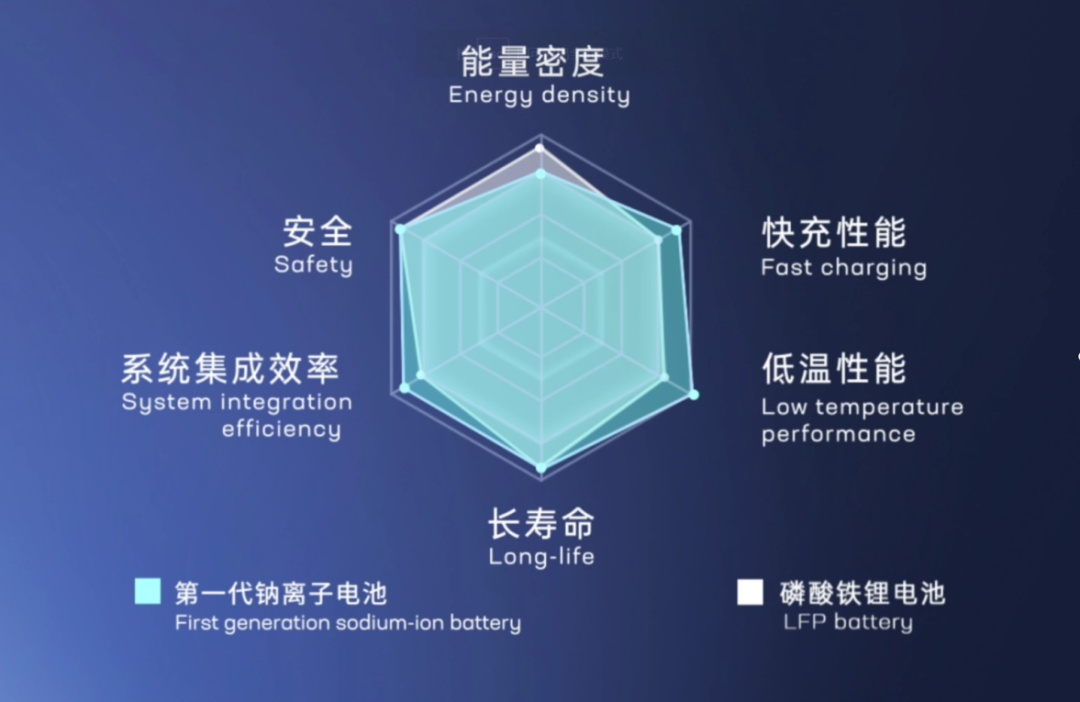

According to the data released by CATL, the energy density of Natrium ion battery can reach 160Wh/kg; it can be charged to more than 80% in 15 minutes at room temperature; it also has a discharge retention rate of over 90% at -20°C; the system integration efficiency can reach over 80%; its thermal stability far exceeds the national safety requirements.

Overall, the energy density of the first-generation Natrium ion battery is slightly lower than that of the current lithium iron phosphate battery, but it has obvious advantages in low-temperature performance and fast charging, especially in high-power application scenarios in cold regions. Through the lithium-natrium mix method, its application scenarios are not limited to energy storage, and can also be widely used in electric vehicles.

As the “king” of global lithium battery, why would CATL not strengthen its advantages in the field of lithium batteries, but instead branch out and put Natrium ion batteries into the mix?

At the press conference, CATL’s Chairman Zeng Yuqun made a rare appearance and introduced the concept of human society moving towards the era of “carbon neutrality”, where the core of it is energy conversion and storage. Renewable energy storage is a significant burden resting on the shoulders of lithium batteries.

Countries with strong economies, auto companies, and energy companies all invest heavily in lithium-ion batteries. Under the windfall, there are no shortage of trends and speculation. Lithium resources, as well as related cobalt and nickel resources, were already limited, and the output became even more volatile under capital manipulation. The security of supply and cost of lithium batteries lies in the constantly being stretched and tested.

At this moment, CATL is industrializing Natrium ion batteries and will soon be installed in electric vehicles, becoming a new choice for energy storage and power batteries.

Those who care about the development of electric vehicles, the electrification of transportation, and renewable energy storage can rest a little easier.## Starting at the same time as lithium-ion, but lagging behind in commercialization

To understand sodium-ion batteries, we must first start with the development of lithium-ion batteries that have suppressed the former’s development for many years.

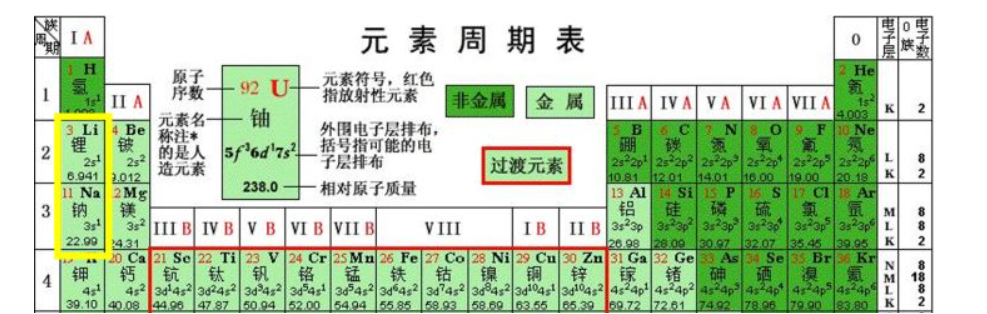

With an atomic weight of 6.94, lithium is the lightest metal; its standard electrode potential at -3.045V is the lowest in metals; moreover, its specific capacity is also the highest among metals, and its electrochemical equivalent is the smallest.

These four characteristics make the lithium battery system theoretically capable of achieving the highest energy density in metal batteries, making it the first choice for battery developers in their eyes.

However, opening a chemistry textbook’s periodic table, we can find another metal element in the same family as lithium that is closest to it- sodium. As the same family’s element as lithium, they have the same number of outer shell electrons and similar chemical properties. This is an important reason why sodium ions can function as charge carriers just like lithium ions.

Just like the development path of lithium-ion batteries, sodium-ion batteries originally started with the exploration of solid-state electrolytes.

To explore the early days of sodium-ion batteries, we need to look back to 1967. That year, America’s Yao and Kummer found that Na could shuttle quickly in β-Al2O3; in 1968, Ford introduced the sodium-sulfur battery with a β-Al2O3 ceramic tube as the electrolyte. However, this type of battery could only work in an environment of 300-350°C.

Sodium-ion batteries that can operate at room temperature only appear after Professor Armand of France proposed the concept of the “rocking chair battery” in 1979.

In other words, sodium-ion batteries and lithium-ion batteries started almost at the same time because any metal ion batteries (lithium-ion, sodium-ion, and magnesium-ion batteries) belong to rocking chair batteries, where metal ions move between positive and negative electrodes, and gain electrical energy via the electrolyte and membrane.

The sodium-ion radius is 70% larger than that of lithium ions, making its requirements for material structural stability and kinetic performance more demanding, which has become a bottleneck for commercializing sodium-ion batteries.

Lithium-ion batteries have a unique advantage in the rocking chair battery because lithium ions are small and easiest to embed and eliminate from various framework materials without causing deformation.

Therefore, in searching for suitable positive and negative electrode materials, the progress of lithium-ion batteries has been faster than that of sodium-ion batteries, which have entered the commercialization stage ahead of sodium-ion batteries.

Since then, lithium-ion batteries and sodium-ion batteries have taken different paths.

Lithium-ion batteries have quickly been commercialized, while the development of sodium-ion batteries has entered a stagnation period.## Turning point after 30 years

Although lithium-ion batteries have the best performance among secondary batteries, the reserves of lithium resources are limited. Currently, 70% of lithium resources are distributed in South America, and 80% of lithium resources in China rely on imports, making it difficult for lithium-ion batteries to serve both the electric vehicle and energy storage industries.

This contradiction has become more pronounced with the rapid growth of electric vehicles and energy storage batteries.

Due to the similar working mechanism and structure with lithium-ion batteries, the development of lithium-ion battery technology has also promoted the development of sodium-ion battery technology.

In 2000, Jeff Dahn, a physics professor at Dalhousie University in Canada, discovered the high-capacity hard carbon negative electrode material for sodium-ion batteries. In 2007, Linda F. Nazar, a professor at the University of Waterloo in Canada, proposed the positive electrode material Na2FePO4F.

With the breakthrough of positive and negative electrode materials, sodium-ion batteries have ushered in a turning point in development.

In 2011, the world’s first sodium-ion battery company, Faradion, was established, and sodium-ion batteries entered the commercialization stage.

In China, the battery team led by academician Chen Liquan from the Institute of Physics of the Chinese Academy of Sciences has been researching sodium-ion batteries since 2010, starting with raw materials. Four or five positive electrode materials and negative electrode materials have been discovered. The Institute of Physics of the Chinese Academy of Sciences also hatched Zhongkehai Na, a company specializing in sodium-ion battery research and development and production.

Zeng Yuqun, the chairman of CATL, studied under Chen Liquan during his time at the Institute of Physics, with a research focus on lithium-ion batteries. He received his doctoral degree in 2006.

CATL took the lead in focusing on sodium-ion batteries, which is closely related to the continuous efforts of the Institute of Physics led by Chen Liquan.

Advantages of sodium-ion batteries

Compared with lithium-ion batteries, sodium-ion batteries also have disadvantages, the first of which is slightly lower energy density. The energy density of the first-generation sodium-ion battery cell produced by CATL is 160Wh/kg, which is lower than that of the commercialized lithium iron phosphate power battery and much lower than that of ternary lithium battery.

Secondly, the cycle life of sodium-ion batteries is generally 3,000 times, while that of lithium iron phosphate batteries can reach 5,000 times.

However, CATL is still continuously innovating. Huang Qisen said that the energy density of the next generation of CATL’s sodium-ion batteries will exceed 200Wh/kg.

Sodium-ion batteries also have many advantages.

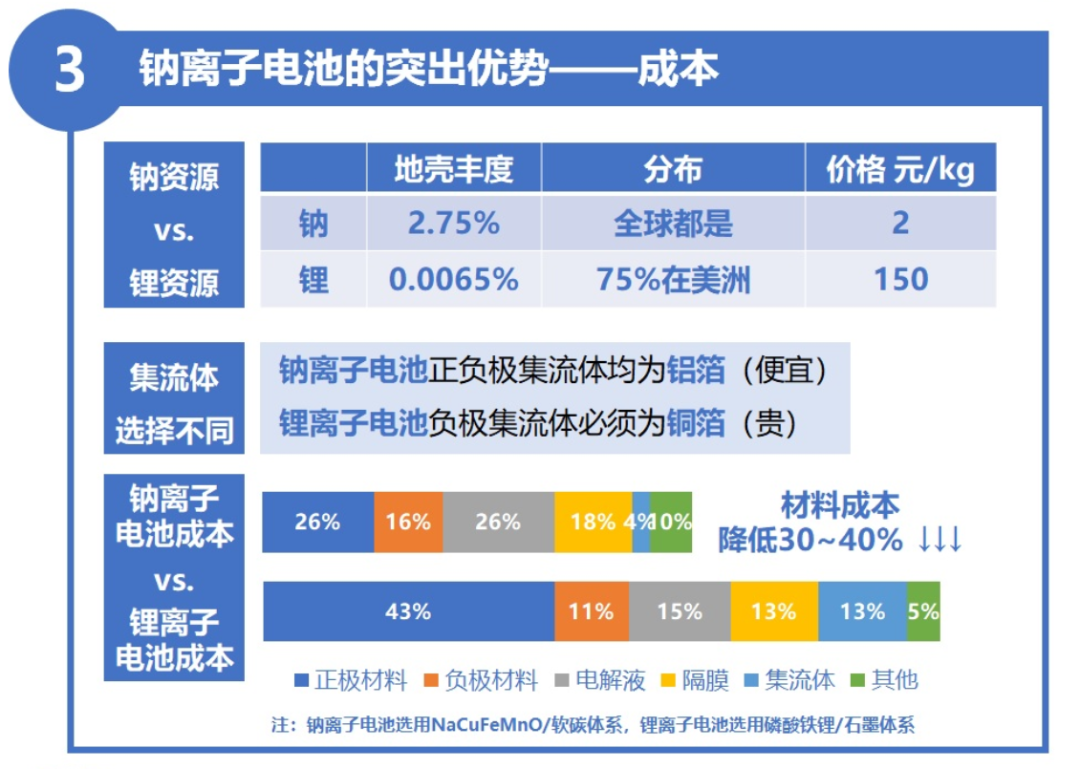

First of all, sodium resources are abundant, and the abundance of sodium in the earth’s crust ranks 6th. More importantly, sodium is distributed all over the world, completely unrestricted by resources and geography, so sodium-ion batteries have a very large resource advantage compared with lithium-ion batteries.The sodium-ion battery has a low content of precious metals and does not contain cobalt and lithium. In addition, the positive electrode collector of a sodium-ion battery is made of aluminum foil and the negative electrode is made of copper foil. However, the negative electrode collector of a sodium-ion battery can also use low-cost aluminum.

According to the data provided by CCHT, the material cost can be reduced by 30-40% compared with the NaCuFeMn/soft carbon system and the lithium iron phosphate/graphite system.

Secondly, sodium-ion batteries have high safety performance. During testing, sodium-ion batteries can pass safety tests such as puncture, compression, overcharging, and over-discharging without catching fire or exploding. During transportation, sodium-ion batteries can be completely discharged and transported at 0V to reduce the risk of battery transportation.

Thirdly, sodium-ion batteries have excellent high and low-temperature performance. According to data provided by CATL, discharge retention can still reach more than 90% at minus 20°C.

In addition, in terms of fast charging, the battery can reach 80% capacity after charging for 15 minutes at room temperature. At the same time, in terms of system integration efficiency, CATL’s sodium-ion batteries can also reach more than 80% efficiency.

According to Huang Qisen, deputy dean of CATL Research Institute, in terms of positive electrode materials, CATL currently selects two types of materials with potential commercial value: Prussian white and layered oxide. Their specific capacity has reached 160mAh/g, which is equivalent to existing lithium-ion battery positive electrode materials.

In addition, CATL has restructured the charge distribution and redesigned the material surface of this material to solve the world’s problem of rapid capacity decay during the cycling process, making the innovative material industrializable.

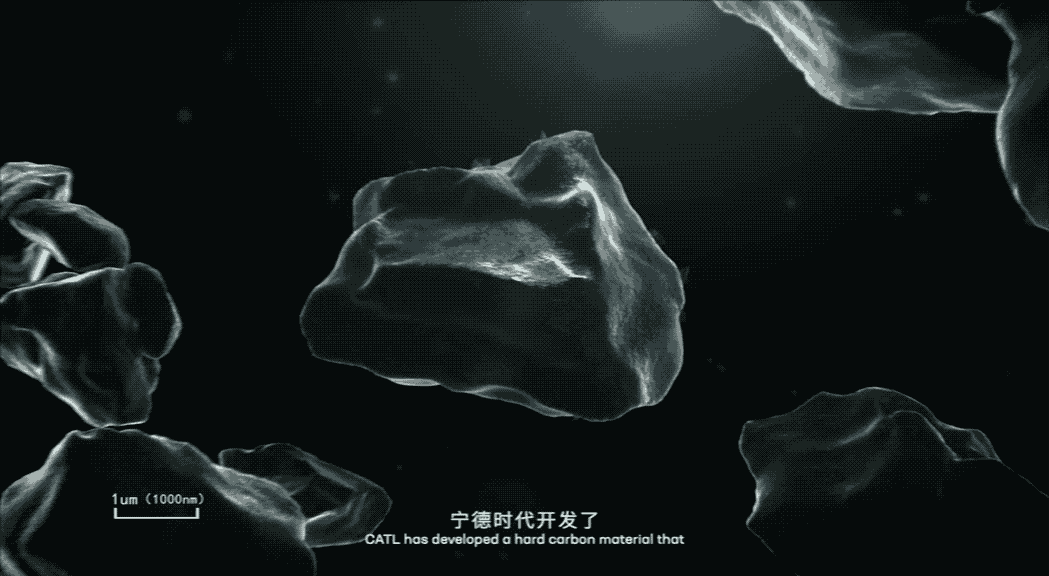

In terms of negative electrode materials, since sodium ions cannot shuttle freely between graphite layers like lithium ions, CATL has developed a hard carbon material with a unique pore structure. The specific capacity of this hard carbon material can reach more than 350mAh/g, and it also has excellent cycle performance, making its overall performance comparable to that of existing graphite.

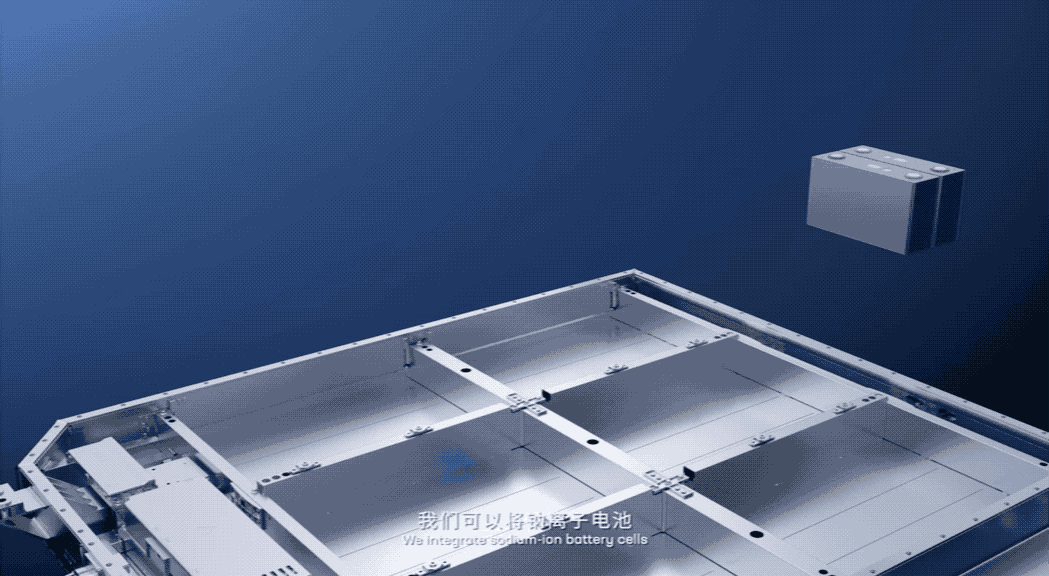

In terms of electrolytes, CATL has developed a new and unique electrolyte system that adapts to such positive and negative electrode materials.Innovation has also been made in battery system integration. CATL has developed the AB battery solution, which can integrate and mix sodium ion and lithium ion batteries. The sodium ion and lithium ion batteries can be mixed and arranged in a certain proportion and arrangement in the same battery system through series and parallel integration.

According to Huang Qisen, the precise balance control of different battery systems through BMS’s accurate algorithm can achieve complementary strengths and weaknesses, not only making up for the energy density shortcomings of sodium ion batteries at this stage, but also exerting its advantages of high power and low temperature performance. Such a lithium-sodium battery system can adapt to more application scenarios.

In terms of manufacturing processes, sodium ion batteries are compatible with current lithium ion battery manufacturing processes and equipment.

At this point, the bottleneck of large-scale commercial application of sodium ion batteries has finally been broken in the hands of CATL.

The Significance of Sodium-ion Batteries

If future historians write about the history of human energy storage, will they mention July 29th?

The launch of sodium-ion batteries, and their breakthrough as power batteries, may have profound strategic significance.

On a macro level, with the “carbon neutrality” goal, the productive forces of society will inevitably face profound changes. The global consensus on the transformation from fossil energy to clean energy is accelerating. And clean energy storage requires efficient and reliable solutions.

CATL is no longer satisfied with being just a battery supplier. It will build a world-class innovative company and make outstanding contributions to the new energy industry as its development mission.

Under higher strategic missions, CATL will not be confined to a particular technology or material and will have a more comprehensive and inclusive technological layout.

Therefore, despite already leading the world in the application of lithium-ion batteries, CATL has still developed and introduced sodium-ion batteries to ensure the storage of renewable energy and provide stronger guarantees for the new energy industry. As Ceng Yuxuan said, “Sodium-ion batteries… are compatible and complementary to lithium-ion batteries, so a diversified technological route is also an important guarantee for the long-term stable development of our industry.”

From a micro perspective, the prices of lithium mines and lithium salts have fluctuated greatly. Since last year, upstream supply prices for lithium batteries have risen too quickly. CATL’s introduction of sodium-ion batteries, complementary to lithium-ion batteries, can be seen as a signal to upstream material suppliers that future demand growth for lithium battery raw materials may slow down.

Of course, the commercialization of sodium-ion batteries has just begun, and the cultivation of upstream supply chains for positive and negative electrodes and electrolyte additives will take time.

In response to this, CATL also has its own timetable and has begun industrial layout planning for sodium-ion batteries, planning to form a basic industrial chain by 2023.黄起森 also said that related research institutes, upstream material suppliers and downstream battery application companies are welcome to participate. This statement is more like an invitation to invite the cooperation of the upstream supply chain to achieve industrialization.

Not only upstream and downstream, but other battery manufacturers also need to participate in order to expand the market together and achieve industrialization as soon as possible. Currently, Penghui Energy, Mingshi, Xinyongda, and other Ningde era’s friendly competitors have already laid out their plans. In terms of upstream, Ruiqi Technology, Xiangfenghua, and others have already taken action.

It can be foreseen that with the establishment of the sodium-ion battery industry chain, more companies will invest in the research and development and production of sodium-ion batteries, and after the sodium-ion battery is scaled up, the advantage of the abundance and low price of sodium reserves will be brought into play, forming a cost advantage over lithium-ion batteries.

Compared with other friendly competitors, there is a high probability that Ningde era will be the first company to use sodium-ion batteries as power batteries and realize commercialization. According to the news from Caijing, Ningde era has expressed that their first-generation sodium-ion battery has started commercial cooperation with auto manufacturers and energy storage customers.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.