Power Boost in the Turbocharged Era

In the era of widespread use of small-displacement turbocharged engines, how to further enhance the power response, increase the maximum power without sacrificing low-speed torque, has become an important issue. The electric control turbocharging technology has become a research direction for some overseas automakers.

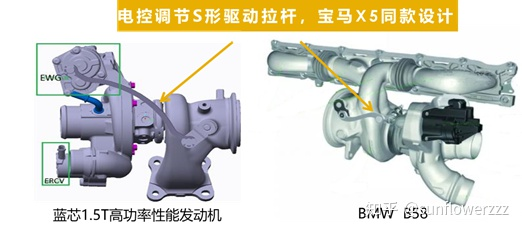

First of all, it should be noted that electric control turbocharging technology is not the electronic turbocharger that was born with the rise of the 48V mild hybrid system. It is still a waste gas turbocharger design, but by relying on the electronically controlled bypass technology independent of the air loop operation, the turbocharging response time is shortened and control accuracy is improved, and the maximum torque platform is greatly advanced. In the latest 1.5T turbocharged engine developed by a domestic independent brand, the maximum torque can be achieved at 1500 rpm, providing users with a better driving experience. This technology has not yet been used in the EA211 series 1.4T displacement turbocharged engine, which leads the sales of German joint venture brands in China. It can only be found in the B58 series turbocharged engine of the German luxury brand, which can be said to be an experience beyond its class.

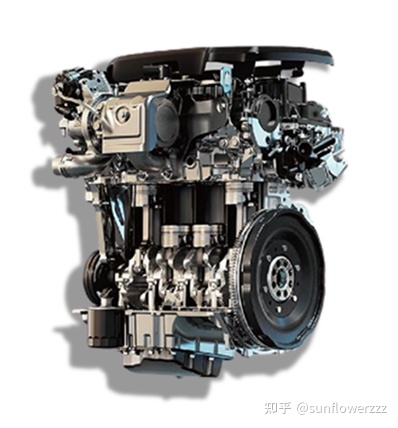

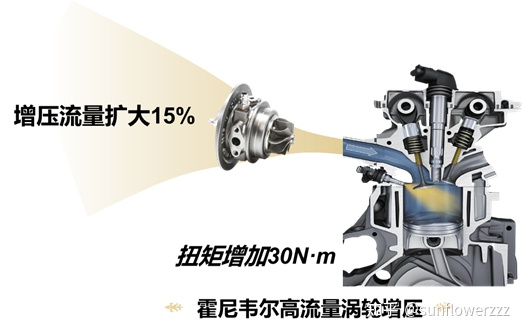

This 1.5T turbocharged engine is more advanced, combining the low-inertia turbo from Honeywell with the electric control bypass valve. The turbocharging response time is improved by 25% compared to the normal design. At the same time, the high-flow design of the Honeywell turbo uses 15% more airflow, increasing the air intake from 2.0 liters under normal atmospheric pressure to 2.3 liters, which can boost torque by 30 Nm and improve the response of the turbocharger by 25% even when compressed into a 1.5-liter cylinder.

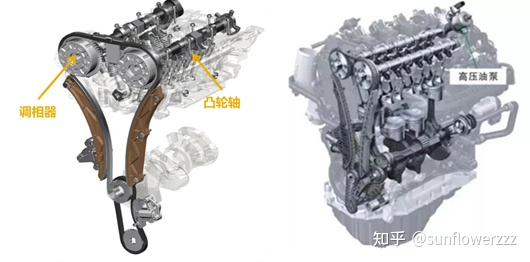

In addition, the large-range adjustment of the intake and exhaust phases achieved by the dual independent VVT aluminum camshaft phase adjuster can optimize the intake and exhaust efficiency, and meet the demand for increased engine power and faster power response. This design has the same origin as the technology of another German luxury brand and is another experience beyond its class.

Faster response, higher torque, this 1.5T turbocharged engine from a domestic brand achieves a maximum power of 133 kW, a maximum torque of 285 Nm, and a high torque platform that can be reached as low as 1500 rpm. The power performance can be regarded as a “breakthrough” over joint venture brands.

The balance between emission, energy consumption and power output in China’s National VI B era

The National VI B emission standard, which is almost the strictest in the world, not only imposes strict requirements on the power systems of domestic automakers, but also does not relax consumers’ demand for power performance due to the requirements for emission regulations. Moreover, the average fuel consumption standard of enterprises is also tightening year by year. For internal combustion engines, they need to output high power, limit emissions of particulate matter, and combustion of less energy, which can be regarded as a realistic example of an “impossible task.” However, there are several cutting-edge technologies that can relieve these worries. The 350-bar combustion injection system and the central direct injection technology have become the research and development direction of many overseas car companies, while ensuring high-efficiency combustion and reducing energy loss.

Since the National VI B era began two years ago, major international manufacturers who were unable to improve their emission levels have added more post-treatment systems to their engines during model changes, including particulate matter capture GPF, because the National VI B emission standard is almost higher than that of all other global markets. However, GPF has negative effects on exhaust back pressure, power output, and maximum power. A turbocharged engine with about 300 horsepower may even lose more than ten horsepower after installation of GPF.

But if the engine is replaced, the situation is different. The new combustion chamber design and fuel spray atomization design can effectively improve combustion efficiency and further optimize emissions directly in the engine stage. The 350-bar central direct injection is an effective means. However, not all car manufacturers use these two techniques. Some international manufacturers have 350-bar but no central direct injection, and some have central direct injection but 350-bar still needs to be researched and developed. The latest 1.5T turbocharged engine mentioned earlier is equipped with this technology.

The 350 bar fuel injection system uses high-pressure injection technology to introduce high-flow gas generated by high-flow turbocharging to significantly improve gasoline atomization and optimize combustion, which significantly improves power and torque. Currently, it is only equipped in some high-displacement turbocharged engines of luxury brands.The mid-mounted direct injection technology helps to make the fuel-air mixture more sufficient by moving the fuel injection position from the intake port of the cylinder to the top of the combustion chamber. This effectively improves the fuel wetting phenomenon and avoids the lubrication failure caused by compressed fuel hanging on the piston ring and entering the engine oil, as well as the possible emulsification of engine oil. Meanwhile, it also improves the combustion efficiency. American car companies which usually focus more on power output are more likely to adopt this technology.

By adopting both of these technologies, it is possible to meet the National VI emission standards without installing a GPF particle trapping post-processing system. This independently branded 1.5T turbocharged engine, which has combined both of these two technologies, has achieved “overtaking” the joint venture brands once again.

The overall improvement of engine technology also requires more advanced transmissions. After the installation of the “overtaking” engine technology, the comprehensive technological improvement of the transmission is also needed to ensure that the power system has no weaknesses. This independently branded automaker uses a wet dual clutch to ensure faster shifting speed and ensure further improvement of work efficiency with full electric drive.

For DCT, which already has higher energy transfer efficiency than traditional AT, digitalization of the actuator is a further means of optimizing energy efficiency. From the 86% efficiency of Volkswagen’s early DQ250 to nearly 90% of the industry average in recent years, three automakers have achieved transmission efficiency of more than 92%, including Audi’s DL382, Getrag’s DCT 300 supplied to BMW, and the independently branded automaker mentioned above.

This automaker has also innovatively developed a three-cavity independent lubrication system for its wet dual clutch. The valve body cavity, clutch cavity, and gear cavity are separated and equipped with special oil liquids respectively. This design enhances reliability, NVH, and also ensures durability and shifting speed. In terms of actual effects, the smoothness can even be better than that of most AT automatic transmissions on the market. Similar solutions are only found in luxury brands of overseas automakers, and this design is once again an “overtaking” existence.

ConclusionSaid so much, in fact, this set of powertrain is derived from “SAIC Blue Core 2.0+” 1.5TGI high-power engine and 7-speed wet dual-clutch transmission. With the help of this powertrain, I believe that the first model of the new Roewe RX5 PLUS will have stunning performance in power output, actual fuel consumption, and smoothness;

By the way, the question only mentions three major components, it seems that only the powertrain is mentioned, let me mention the chassis of the new Roewe RX5 PLUS mentioned earlier. The hardware configuration is equipped with the industry-recognized hard goods Michelin PS4 high-performance tires, which are rare in this joint venture brand, and have made improvements in high-speed handling, high-speed driving stability, and wet grip compared to ordinary and affordable models. At the same time, the new Roewe RX5 PLUS has also made many changes in some chassis details design and tuning, such as upgrading the shock absorber to ZF Sachs shock absorber and improving driving quality, optimizing the suspension bushing and front auxiliary spring length to improve impact comfort, and optimizing the shock absorber support block to improve isolation effect, optimize road noise, and so on. The actual effect of these changes will have to wait until the new car arrives at the dealership and experienced personally.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.