What will the future of intelligent cars look like? I think many of us have imagined that they’ll be intelligent, self-driving, with endless range, and comfortable space… Whether you’re in the industry or not, all of this is essentially built on the topic we’re going to discuss today, high integration in cars.

High integration can fully expand the vehicle’s space utilization, making the car a comfortable mobile space instead of just a driving tool. High integration can also greatly reduce the weight of the vehicle, achieve lightweight and increased range of the car, and be more beneficial for the design of the vehicle’s center of gravity, thus achieving better driving handling. High integration is the basis for meeting the more powerful communication and computing capabilities of future vehicles, thus further enhancing the intelligence and self-driving capabilities of the vehicle.

Next, let’s take a look at how to do this and why.

Integration of the Three Systems

Further Centralization of the Vehicle EEA Architecture

Space Arrangement

Integration of the Three Systems

For an intelligent electric vehicle, let’s take a look at the main components, which can usually be divided into:

- The body part (the vehicle shell and various components on the shell),

- The chassis part (front and rear axles and their connecting parts, braking and steering systems, suspension systems, and the support structure of the battery pack / battery CTC (cell to chassis)),

- The three electronic systems (usually referring to the electric drive system composed of batteries, motors, and electronic controls, known as the “big three electronics” but also including the “small three electronics”: on-board charger (OBC), DC-DC voltage conversion, and PDU high-voltage distribution box),

- Autonomous driving part (autonomous driving perception and computing part, of which the perception part is basically integrated on the shell, and the computing part takes up relatively little space),

- The cockpit part (mainly for entertainment screens and mobile communication and computing parts, with high integration and relatively small space occupancy),

- (Considering the volume of the air and temperature control system due to evaporative condensation and various temperature exchange systems, we also include the air & temperature control system, but due to its relatively simple function, it is usually integrated into the vehicle body domain.)

Overall, except for the car seats, the three electronic systems and the air & temperature control system are the ones that most affect the layout of the car’s interior space. Therefore, we have to further integrate them in order to not only achieve great savings in space, but also achieve considerable improvement in overall weight and cost control. (This article does not discuss the integration of the air & temperature control system. For the current highest integration plan, refer to the Model S Plaid heat pump, Model 3 eight-way valve, and motor overload heat generation.)

For the big three electronics (battery, motor, and electronic control) and the small three electronics (OBC, DC-DC, PDU), the more advanced solutions in the industry are mainly:

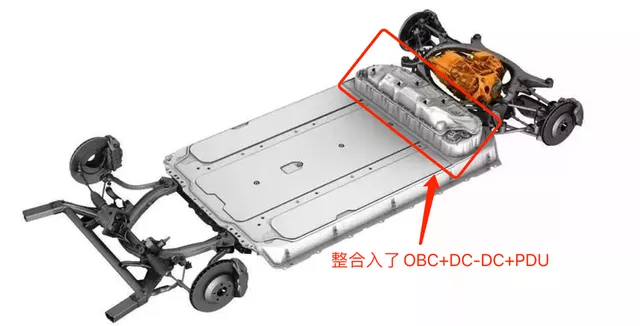

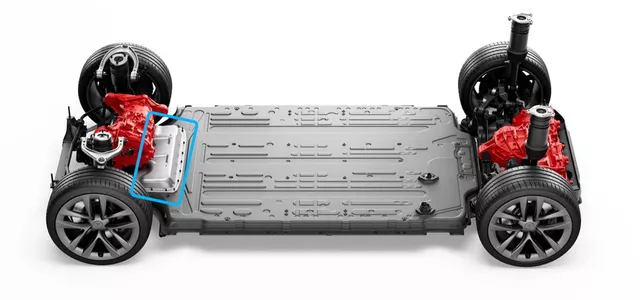

- Tesla’s three-in-one electric drive (motor + electronic control + reducer) + small three systems integrated into the battery pack or CTC chassis.

OBD chargers, DC-DC voltage converters, and PDU high voltage distributors are typically components that take up a lot of space in a vehicle layout. However, Tesla has integrated them into the battery pack/CTC chassis, leaving more space for passengers.

In the Tesla Model S Plaid, this integration has been further improved, with the OBD+DC-DC+PDU integration package volume reduced even further.

- Six-in-one / seven-in-one electric drive system + battery pack/CTC (cell-to-chassis cell integration) battery chassis.

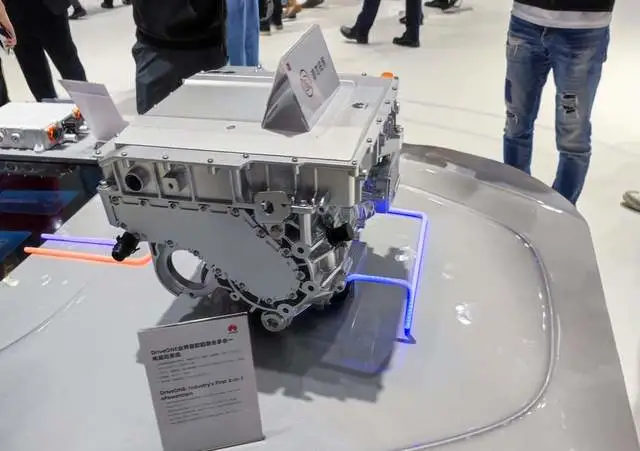

Representatives here are Huawei’s seven-in-one and BYD’s six-in-one, both of which can be considered advanced solutions in the industry.

The BYD electric drive assembly integrates: motor + control + reducer + OBC+DC-DC+PDU, and has the highest degree of integration in the industry that is close to mass production.

Huawei’s DriveONE electric drive system not only integrates the traditional three-in-one motor + control + reducer, and small three-electric OBC+DC-DC+PDU, but also further integrates BCU (battery control unit).

The direction of these two major solutions still needs further market validation, but the only thing that can be confirmed is that the further integration and integration of small three-electric components is a trend that will inevitably accelerate in the coming years.

Further integration of vehicle EEA architecture

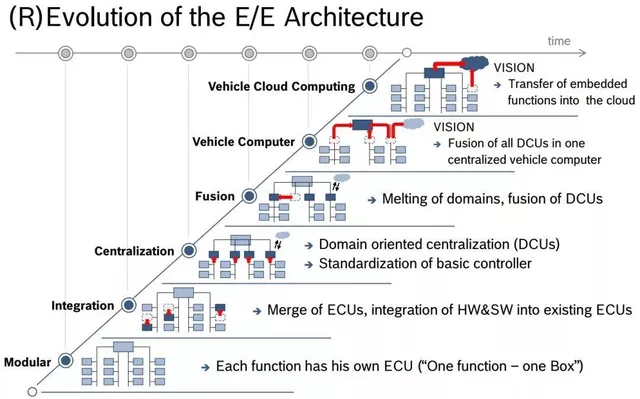

When it comes to the evolution of vehicle EEA architecture, we must mention the EEA development roadmap proposed by Bosch.

The EEA architecture originally started with independent perception, calculation, and control modules for various functions, which were then connected through CAN gateways to other independent function modules for information communication (first, second, and third layers in the diagram). However, as the number of independent controllers increased to nearly a hundred, they became complicated to connect and resulted in lengthy communication and power lines. Additionally, the majority of these controllers were provided by independent suppliers, making it challenging to develop collaborative synergy among them.

The EEA architecture originally started with independent perception, calculation, and control modules for various functions, which were then connected through CAN gateways to other independent function modules for information communication (first, second, and third layers in the diagram). However, as the number of independent controllers increased to nearly a hundred, they became complicated to connect and resulted in lengthy communication and power lines. Additionally, the majority of these controllers were provided by independent suppliers, making it challenging to develop collaborative synergy among them.

The design has subsequently evolved to independent perception and operation control within functional domains or regions, resulting in significant reduction to the number of controllers in the entire vehicle (fourth layer in the diagram). For instance, in the Tesla Model 3, there are only four main controllers (i.e., intelligent driving and intelligent cabin domain, left body domain, right body domain, and front body domain).

In the diagram, the entire vehicle is primarily controlled by these four main controllers, and different types of sensors are clustered around them. These sensors are connected to various main controllers through CAN bus, Ethernet, LIN bus, and other communication means to facilitate calculation and processing. For functions that necessitate real-time information, such as the ESP, independent operation ability is retained, in addition to the system being integrated into the bus.

Looking into the future, the entire vehicle will only have a single large controller (fifth layer), and functional modules will no longer be divided into body domains, chassis domains, autonomous driving domains, cabin domains, and electric domains. Instead, each body function module will retain only its perceptual and execution abilities, while operating and control abilities will be seamlessly integrated and moved upwards. All the signals received from the sensing modules will be centralized in the central processor for coordinated and unified management, control, and coordination. The control signals are then sent to the corresponding function modules for execution.

This approach is similar to that of smartphones, where different modules around the phone forward perceptual signals to the central processor for unified calculation and processing, which is then sent to the execution module. However, compared to the smartphone, the outward perceptual and executive modules of the car product are much more extensive.

The great advantage of this design is in the complete separation of the vehicle’s hardware and software. People will no longer need to worry about the hardware of the vehicle but can only be concerned with its hardware capabilities. Virtualizing hardware capabilities, standardizing them and releasing them through standard ability interface will allow for continuous functional iteration and upgrade, leading to significant improvement in car automation. Additionally, this approach enables standardized intelligent vehicles that can undergo continuous iterative upgrades and improvement, much like our smartphones.

In conclusion, the future of the car industry lies in the continued development of the SVA architecture.Moreover, the SOA (Service-Oriented Architecture) domain architecture solution can greatly reduce the length of internal wiring in vehicles (currently, the length of vehicle wires is usually over 3 kilometers). As Musk said, in the future, it is very possible to reduce the vehicle wiring to within 100 meters. This can not only greatly reduce the cost and overall weight of wiring, but also greatly reduce the difficulty of assembling vehicles (robots have difficulty operating on soft materials). Actually, it seems not impossible if we think about it, connecting low-voltage communication and power wiring around the vehicle body to various functional execution modules and sensors, and then connecting it all to the central controller for unified management and control.

All of this will soon come to the next generation of automobiles.

Spatial Arrangement

Above, we discussed the electrification and high integration of vehicles and the ability to further upgrade intelligence through EEA. In this section, we will discuss spatial arrangement. The most intuitive manifestation of high integration is the expansion of the interior space of the vehicle.

The rear and front trunks of the Model Y are very large compared to all models currently on the market, especially the front trunk, which brings great convenience to users. But all of this is premised on the high integration of vehicles and the relinquishing of space for users.

Let’s talk about the spatial arrangement inside the vehicle. What will the future vehicles look like? Perhaps this is what she should look like.

(It has been rumored that Apple wanted to acquire Canoo and was ruthlessly rejected. We can probably guess what the Apple car will look like.)By moving the A-pillar forward and the C-pillar backward and combining it with the flat floor of an electric vehicle, there is now a large space left for the user. Adding autonomous driving capabilities, we have our own independent personal moving space available anytime and anywhere. You can decorate your car space as you wish, just like decorating your own home.

This idea may sound familiar, as the recently released Mercedes-Benz EQS and XPeng P5 have similar designs, moving their A-pillars and C-pillars forward and backward respectively (of course, the final effect is not discussed here). In fact, if you observe carefully at large auto shows in recent years, concept cars from different manufacturers have similar trends.

Combine this with Toyota’s concept of a detachable chassis (where the vehicle body and chassis can be freely combined and separated), and you can have a completely exclusive space without even needing to buy the vehicle’s chassis. Since it’s fully autonomous, who needs to drive? I can just sit in this comfortable space and move freely! (Do we even need to buy a house anymore?)

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.