The following is a repost from the public account “Automotive Electronic Design”.

Yesterday evening, Dongchedi uploaded a video titled “BYD Han EV collides with domestic new energy vehicle – blade battery catches fire and explodes”, which poses a huge challenge to the slogan “lithium iron phosphate + blade battery = safety” that has been dedicated to promoting. The following is a segment of the part where the fire started.

Taking advantage of this hot topic, we will try to explore why the battery caught fire 48 hours after the collision, and also discuss how to handle the electric vehicle after the collision.

Are Blade Batteries not safe?

In the original video, several important images appeared, and we can divide this incident into several steps:

(1) At 14:48 in the original video, the surveillance screen was played, and there were no symptoms at this time.

(2) At 14:50 in the original video, sparks appeared. It can be seen that in this second, flames suddenly burst out from the front of the vehicle, but at 14:52, the flames disappeared.

Subsequent personnel started to put out the fire. The battery could only be seen gradually losing control while smoking and burning.

What we want to focus on here is why the car caught fire 48 hours after the collision. This case first reminds me of a Volt car that caught fire after passing the crash test in 2011 (left for three weeks), but it may not be exactly the same.

I think there are several possibilities:

(1) The battery cell was damaged and short-circuited, resulting in a heating out of control.

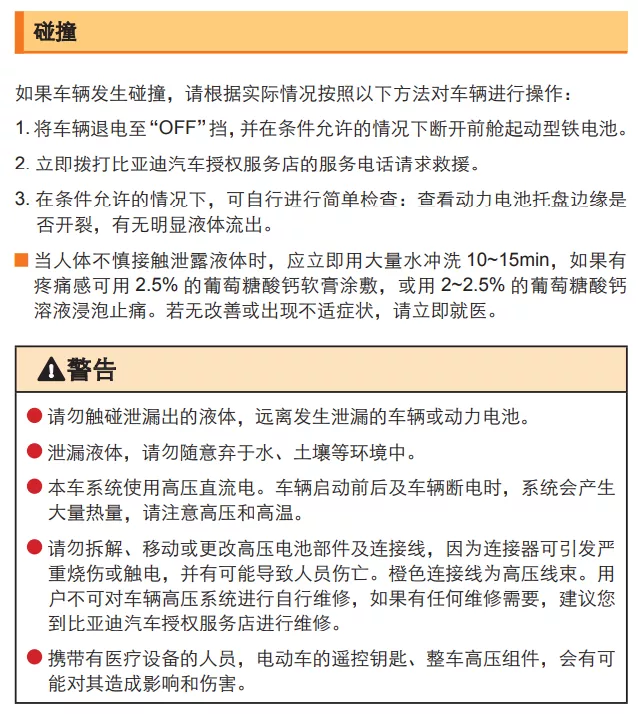

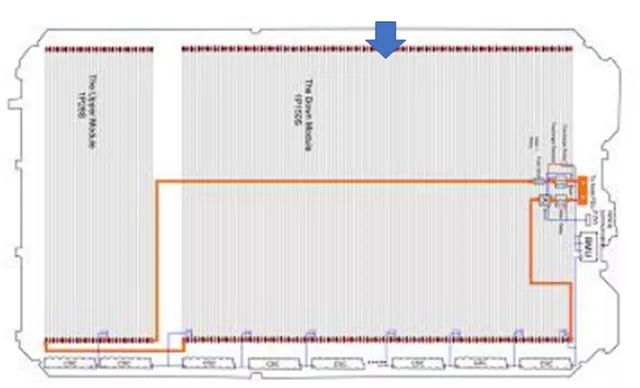

By looking through the user manual of BYD Han EV, it can be seen that BYD has already considered the risk of battery cell shell cracking after a collision. To cope with this part of the risk, the blade battery, unlike other batteries, has a very important design, which uses the overall stiffness of the battery cell to resist the collision together with the battery pack.

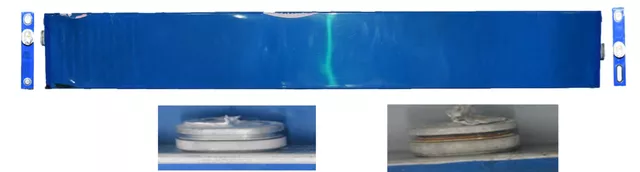

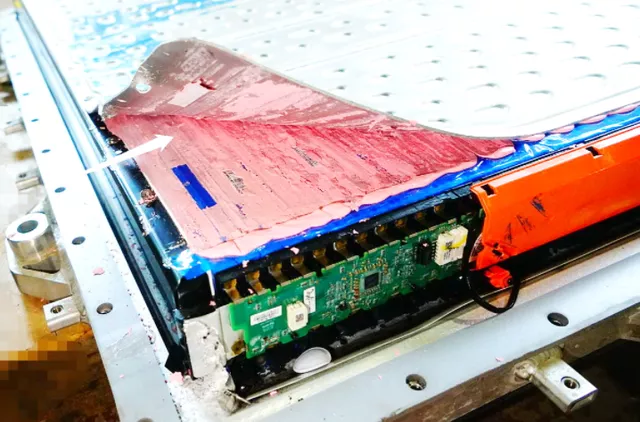

As shown in the following figure, the blade battery, as a part of the system, also bears a certain force during the collision process. Therefore, the battery may be damaged here.

In other words, the battery cell itself was damaged, and there were cracks on the surface. Then, the electrolyte would penetrate out and destroy the insulation of the surrounding batteries after 48 hours.

As mentioned earlier, the effect of single-damage-induced local short-circuits accumulates to a certain temperature, which triggers the heating out of control of the battery, as shown in the following figure. This state is like a process of continuously destroying the insulation state, ultimately achieving a certain conductivity resistance, and gradually leading to a short circuit with a large impedance.

## Coolant leakage causes fire

## Coolant leakage causes fire

Another possibility is that during the collision process, the water-cooled plate used for structural reinforcement may leak, and the coolant enters the side sampling plate along the protective cover, causing a minor short circuit. This cumulative effect can lead to battery combustion at a certain temperature. This was a failure mode that occurred after the collision of the Volt, when the car overturned, and in the case of the blade battery, there is also a chance of this happening. However, since the CMU is vertically placed on the side and equipped with a plastic cover, it is not easy for the coolant to enter.

What can we do in this situation?

First of all, using iron phosphate lithium battery materials does not guarantee everything, especially with high voltage and high energy density iron phosphate lithium batteries that are designed now and are different from traditional lithium iron batteries. With the introduction of CTP and blade batteries, BYD’s structural innovation has allowed groups to skip “modules” during assembly, greatly improving space utilization and ultimately achieving the design goal of installing more battery cells in the same space. However, at the same time, the protection of the entire package structure has been reduced.

Compared to traditional battery packs with modules, the volumetric utilization of “blade batteries” has increased by more than 50%, and the cruising range has reached the same level as high-energy ternary lithium batteries. Originally based on the module design concept, even under conditions of severe collision, the battery body cannot be touched, let alone under force. But the price paid for this new design is that when more batteries are installed in the battery pack, the strength of the beam is reduced or eliminated, and the battery is placed instead, which means that the battery is more susceptible to damage under extreme collisions.

Therefore, when encountering vehicles that have collided in the future, the first thing to do is to abandon the vehicle and have the professional 4S shop personnel check it. Confirm that the battery has not been damaged, mainly by checking whether the insulation resistance of the entire vehicle has changed, whether the voltage of the battery has changed, and then use it only after confirming it is safe.

In summary, the good news is that after the collision, neither of the two cars immediately caught on fire. If there’s a chance, we’ll compare the battery design of the other car in the collision (BAIC Arcfox) later.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.