Author: Sun Xiaoshu

At 19:00 on July 22 (Beijing time), Mercedes-Benz held a conference called “Electric Strategy Upgrade”. Ola Källenius, CEO of Daimler AG, stated at the beginning of the conference that Mercedes-Benz is accelerating the transformation from “Electric First” to “Completely Electric”.

Mercedes-Benz will launch three new pure electric vehicle platform architectures and plans to achieve full electrification before 2030. In order to accelerate the comprehensive transformation from internal combustion engines to electric drives, Mercedes-Benz will make improvements in products, technology, production, talents and finances.

Product Planning

Mercedes-Benz originally planned that by 2025, the proportion of pure electric and plug-in hybrid vehicles in its sales would reach 25%. At the conference last night, Mercedes-Benz doubled the target sales ratio of new energy vehicles to 50% by 2025.

To achieve this goal, Britta Seeger, Head of Marketing and Sales at Mercedes-Benz, stated that in addition to the four new electric vehicle models that will be launched this year, Mercedes-Benz will launch the SUV versions of the new EQE and EQS in 2022 and the pure electric G-Class in 2024.

The culmination of Mercedes-Benz’s next-generation electric technology will be the VISION EQXX. VISION EQXX is a project launched by Mercedes-Benz in 2020 and has received support from experts in the Mercedes-Benz-AMG F1 team. Its aerodynamic performance will exceed that of the EQS with a drag coefficient of less than 2.0.

As an electric vehicle, VISION EQXX will achieve a range of more than 1000 km with a normal-sized battery. Compared with the EQS, the energy density of VISION EQXX’s battery cells has been improved by 20%, but a single 20% improvement is not enough based on the EQS’s baseline range of 770 km. Therefore, Mercedes-Benz will also improve the motor, inverter, battery design, assembly, and thermal management to achieve an energy consumption level of less than 10 KWh/100 km.

In the future, VISION EQXX technology will gradually be put into production in Mercedes-Benz’s new generation of vehicles.

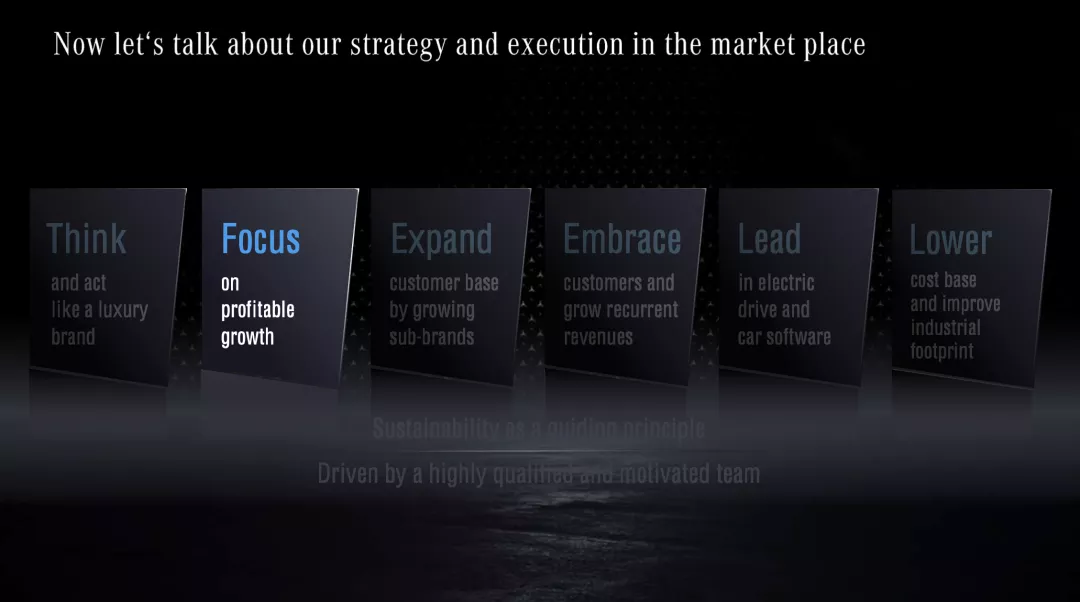

Britta Seeger also stated that in order to meet the challenges of electrification, Mercedes-Benz will optimize its product portfolio and pricing strategy, focus on the most profitable vehicle models and sales regions, strive to increase brand loyalty, and seek to increase recurring revenue.

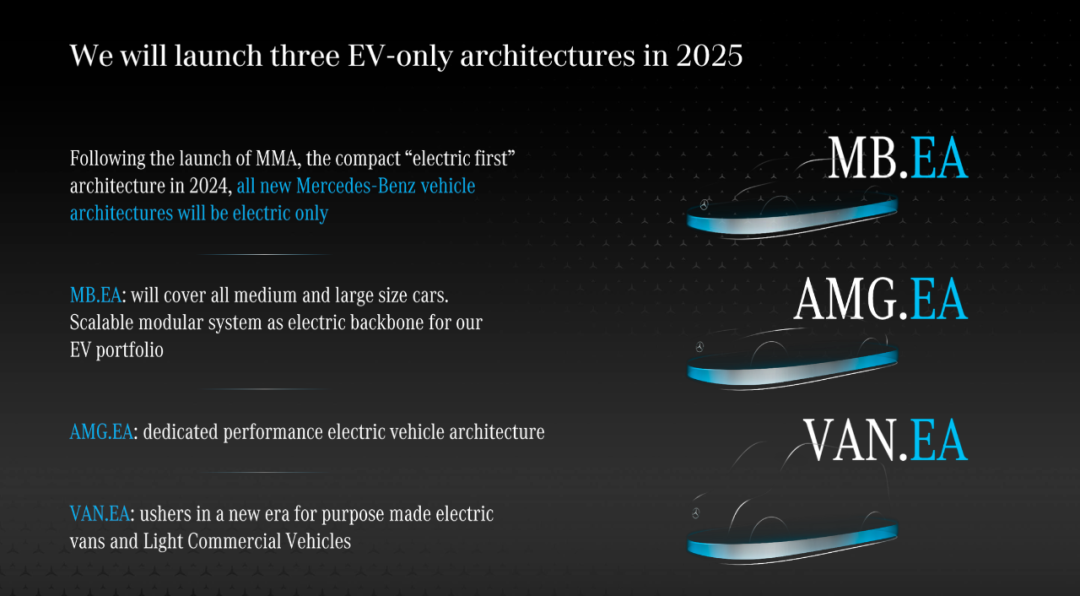

In terms of vehicle platforms, Mercedes-Benz already has a pure electric exclusive platform for mid-to-large-sized products, EVA, and the first MMA architecture platform for compact cars will be launched ahead of schedule in 2024. The MMA architecture will use Mercedes-Benz’s eATS 2.0 electric motor released last year.

In 2025, Mercedes-Benz will also release three pure electric architecture platforms: MB.EA, AMG.EA, and VAN.EA. Mercedes-Benz plans to have the MB.EA pure electric platform cover all mid-to-large-sized passenger car products, gradually replacing the MRA rear-wheel drive platform and the first exclusive pure electric platform EVA. AMG.EA is the platform exclusively designed for performance cars, and VAN.EA is responsible for creating MPVs and light commercial vehicles.

Battery technology is the key to Mercedes-Benz’s accelerated electrification, and Sajjad Khan, Mercedes-Benz’s chief technology officer, emphasized Mercedes-Benz’s exploration of battery materials.

For the negative electrode material of the battery, Mercedes-Benz will cooperate with battery start-ups such as Sila Nano on silicon-based negative electrode technology.

Silicon-based negative electrodes are currently a hot topic in the industry, and giants such as Tesla and Volkswagen are also investing in this technology. The introduction of silicon can allow the negative electrode to accommodate more lithium ions, thereby improving the energy density of the battery. Mercedes-Benz’s goal is to increase the battery energy density to 900 Wh/L through silicon-based negative electrode technology.

Choosing cutting-edge battery start-ups to cooperate in promoting the research and development of battery technology is already a trend in the industry, with Volkswagen and QuantumSpace, BMW and Solid Power, but the company Sila Nano that Mercedes-Benz cooperates with is somewhat special.

Sila Nano’s CEO, Gene Berdichevsky, is the seventh employee of Tesla and one of the 18 members of the Roadster development team led by JB Straubel. He has served as the chief engineer of the Roadster battery pack and is an all-around talent in science, research, and engineering.The cooperation between Mercedes-Benz and these battery startups will also involve solid-state batteries. According to Mercedes-Benz’s plan, the energy density of solid-state batteries will reach 1200 Wh/L and the mass energy density will exceed 400 Wh/Kg in the future.

Sajjad Khan also stated that Mercedes-Benz will adjust the battery’s chemical composition based on the needs of different markets. At the same time, Mercedes-Benz will establish a modular battery system that consists of standardized components and vehicle interfaces to reduce the cost of battery production.

As for the electric control and motor aspects, Mercedes-Benz plans to use more than 50 intelligent systems to regulate the charging, voltage, current, and temperature of each battery unit. AI algorithms will also adjust the battery system to adapt to the driver’s personal habits. The British axial flux motor and electronic technology company YASA, which Mercedes-Benz has acquired, will also be a major contribution to Mercedes-Benz’s motor research and development.

In terms of charging and energy supplement, Mercedes me Charge, the Mercedes-Benz charging service, has access to more than 530,000 AC and DC charging piles globally.

While continuing to cooperate with IONITY to promote the construction of charging networks, Mercedes-Benz will also cooperate with Shell to further expand the charging network. By 2025, the charging network that Mercedes-Benz cooperates with Shell in Central Europe and the Americas will have more than 30,000 charging piles, with over 10,000 high-power charging piles worldwide.

In the United States, Mercedes-Benz will cooperate with ChargePoint to establish a charging network and provide 60,000 public charging piles. At the same time, Mercedes-Benz will integrate more than 60,000 semi-public charging piles in shopping malls, hotels, and workplaces to create the largest integrated charging network in the United States.

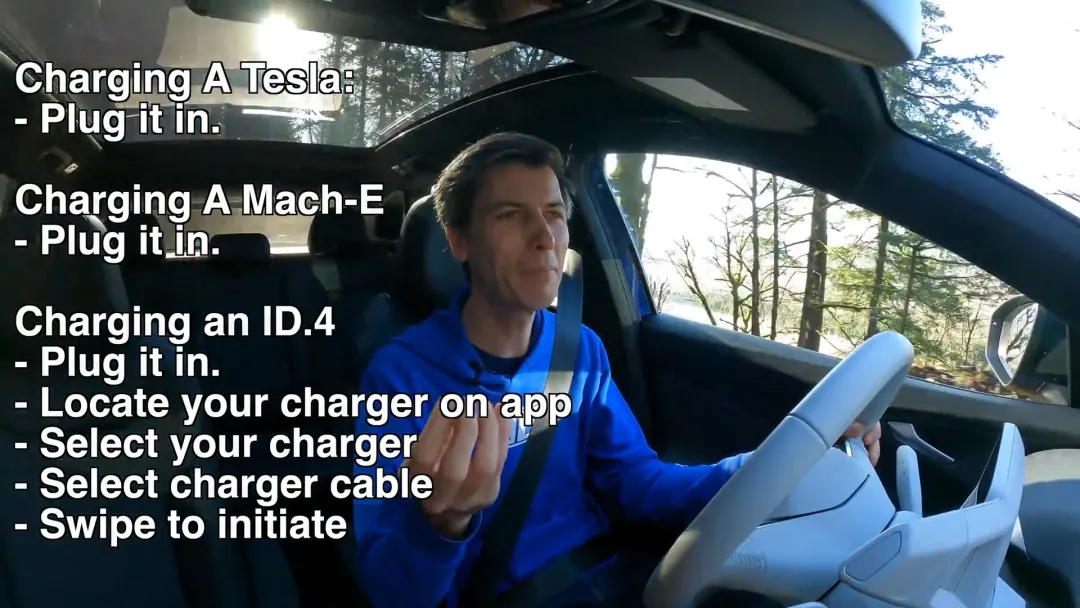

As the current power source of the charging network is not environmentally friendly, electric vehicles have been questioned. In response to this situation, Mercedes-Benz stated that all public charging piles in the European and North American charging networks will use renewable green energy, and other markets are still under evaluation.Sajjad Khan emphasized that when EQS electric sedan is officially launched, Mercedes-Benz will achieve “Plug & Charge” function, which allows for automatic charging without identity verification or additional operations, and payment will be processed automatically in the background.

On another note, in the user’s perception, the ability to charge simply by plugging in should be a standard feature of electric cars. However, the truth is not every car manufacturer is capable of doing so. Automotive YouTuber “Engineering Explained” complained that Tesla and Mustang Mach-E can achieve this function, but ID.4 requires opening the corresponding app to locate, select, and confirm charging stations. Mercedes-Benz will synchronize this function with the launch of EQS.

Production Efficiency & Carbon Neutrality

Mercedes-Benz’s factories in Beijing, Bremen, Sindelfingen, Rastatt, and Tuscaloosa have the ability to produce all-electric vehicles. In 2022, Mercedes-Benz will have 8 pure electric models produced in three continents globally. With the acceleration of electrification, the demand for battery production capacity is also increasing.

Mercedes-Benz expects its demand for power battery production to reach 200 GWh before 2030. To meet this demand, Mercedes-Benz will build 8 super battery factories worldwide in cooperation with partners, including 4 in Europe and 1 in the United States.

Building super battery factories will increase Mercedes-Benz’s financial pressure, and the investment in battery cells and systems is also significantly increasing. In response to this situation, in addition to strictly complying with the asset allocation guidelines established in 2020, Mercedes-Benz is also pursuing increased production efficiency.

Scaling and modular production are effective ways to improve efficiency. Mercedes-Benz plans to increase its production volume of electric vehicles, improve production efficiency, and enhance sustainability. Through a new digital production process, Mercedes-Benz will enhance its vertical integration in battery manufacturing, and more than 90% of future models will be built on a single battery platform.

Establishing a sustainable circular economy is also a critical efficiency improvement method in Mercedes-Benz’s view, in order to reduce resource consumption. One of the ways to control material waste is through battery material recycling.# Mercedes-Benz plans to establish a battery recycling factory in Kuppenheim, Germany, develop battery recycling technology, and ensure future processing capacity to achieve maximum utilization of battery recycling materials. The factory is expected to start production in 2023, provided that the talks between Mercedes-Benz and government agencies are successful.

Jörg Burzer, Member of the Board of Management of Mercedes-Benz AG, responsible for Production and Supply Chain Management, said that Sindelfingen Plant 56, which produces the S-Class and EQS, has already achieved 100% carbon neutrality in the manufacturing process. By 2022, all Mercedes-Benz passenger car and battery factories will achieve carbon-neutral production.

Talent Development & Recruitment

While electrification is taking place, Mercedes-Benz’s organizational structure is also being reshaped. Traditional power systems have been adjusted, and the drivetrain department has been established for the first time to integrate personnel responsible for various drivetrain types into a single department and avoid departmental fragmentation.

In Untertuerkheim, Stuttgart, Mercedes-Benz established a research and development center mainly focused on electric drive and battery development. The research and development center will include a small battery production plant and a battery safety laboratory, and will join the existing research and development system of Mercedes-Benz in the field of battery technology in the future.

At the same time, Berlin will become the digital technology center of Mercedes-Benz’s global production network, responsible for the development and application of the MO360 digital production system.

In response to the personnel fluctuations caused by the institutional adjustments, Mercedes-Benz has carried out internal staff upgrades and external talent recruitment, in addition to providing severance pay and retirement transition conditions to terminate cooperation with some employees on a voluntary basis. Sabine Kohleisen, Head of Human Resources and Labor Relations at Mercedes-Benz, said that a total of 20,000 German employees participated in training on electric mobility in various aspects in 2020. To develop the MB.OS operating system, Mercedes-Benz plans to recruit 3,000 software engineers by providing attractive framework contracts and innovative employment conditions, including 1,000 software engineers from Germany.

Profit Guarantee

Ola Källenius emphasized that Mercedes-Benz has the ability to maintain strong profitability while accelerating electrification. In fact, Mercedes-Benz issued four profit warnings in 2019 and ultimately achieved a profit of only 2.709 billion euros for the whole year, a year-on-year decrease of 64.43%. One of the key focuses of Mercedes-Benz’s 2020 strategy was also profit adjustment.

At yesterday’s “Electric Strategy Upgrade” press conference, Daimler CFO Harald Wilhelm stated that Mercedes-Benz is improving its financial management system in five areas in response to the electric transformation:

- Increasing the proportion of new energy vehicle models

- Increasing the net revenue per unit of high-end electric vehicle models

- Increasing revenue generated by digital services

- Reducing variable and fixed costs

- Achieving breakthroughs in overall battery platform, scalable architecture, and battery technology

Through these five adjustments, Mercedes-Benz ultimately hopes to achieve a profit margin in the pure electric era that is similar to that of the internal combustion engine era, completing a smooth transition.

Conclusion

Mercedes-Benz, with 135 years of history, is accelerating its embrace of electrification, doubling its target for the proportion of new energy vehicle sales to 50% by 2025, reflecting its determination to transform. Whether the hundred-year-old Mercedes-Benz can make a spectacular or smooth transition depends on the effects of its adjustments in product, technology, production, talent, and finance.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.