Original Article by Wang Lingfang

On June 30, 2021, the “Leading Low-Carbon Transformation and Driving Green Energy Strategy – Great Wall Motors’ 8th Technology Festival Carbon Neutral Forum” was held at the Baoding Diangu International Hotel, sponsored by Great Wall Motors. At the forum, Great Wall Motors invited leaders from CATL and Guoxuan High-tech to share their insights, and together with Honeycomb Energy under the Great Wall Holdings system, they discussed the progress made by mainstream representative companies in battery technology.

“Electric Vehicle Observer” discusses the progress of power battery technology from multiple perspectives, such as battery material system, solid-state battery technology, integration route, long life, low-temperature performance, fast charging, and intelligence.

Evolution of Material Systems

Since last year, the proportion of lithium iron phosphate batteries has rebounded significantly, while news about low-cobalt, cobalt-free batteries, and solid-state batteries has been emerging one after another, and battery technology is still iterating rapidly, albeit slightly.

(1) Lithium Iron Phosphate Still Has Prospects

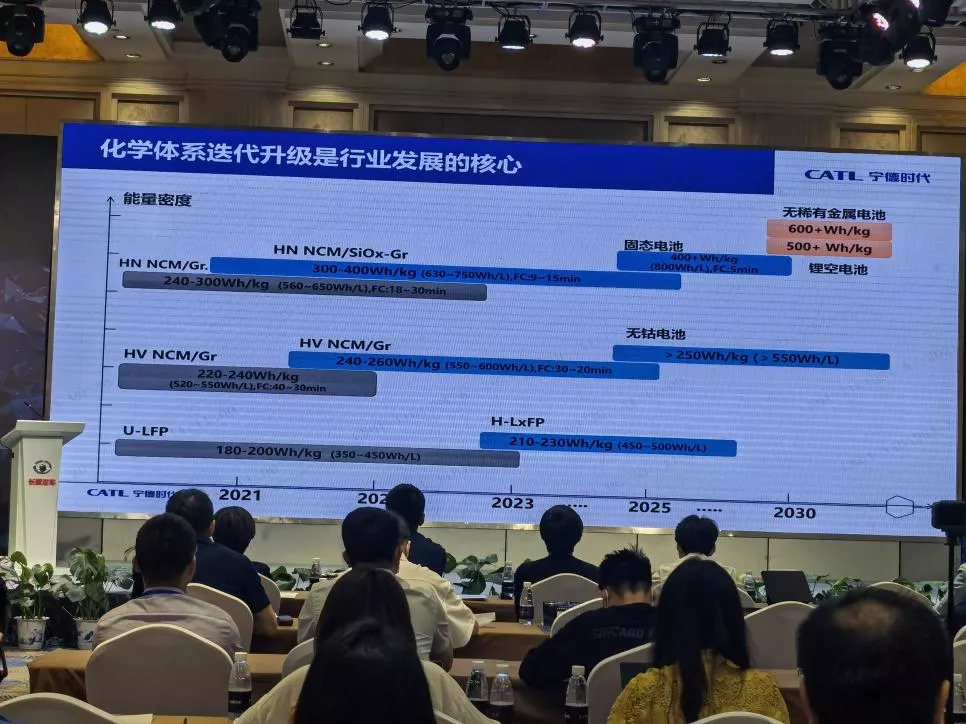

Xiang Yanhuo, Vice President of Technology and Chief Engineer of Ningde Times New Energy Technology Co., Ltd., said that Ningde Times is planning to launch the third-generation of lithium iron phosphate batteries that support electric vehicles to travel 400-600+ km.

Currently, the energy density of Ningde Times’s lithium iron phosphate battery ranges between 180-200Wh/kg, and the volume energy density can reach 350-450Wh/L. The energy density of the next generation of lithium iron phosphate battery will be between 210-230Wh/kg, and the volume energy density will be between 450-500Wh/L.

Guoxuan High-tech is also deeply cultivating lithium iron phosphate.

In January, Guoxuan High-tech announced at the tenth technology conference and supplier conference that it had developed a soft pack cell with a single energy density of 210Wh/kg of lithium iron phosphate, with plans to start mass production next year.

Guoxuan High-tech mainly adopts independent research and development of high-performance LFP positive electrode materials, silicon negative electrode materials, and the results after pre-lithiation technology.

Even more, Guoxuan High-tech claims that its lithium iron phosphate battery has surpassed the level of conventional NCM523 batteries and is close to NCM622 in energy density. But it is safer and has a more promising market application prospects.

Although Honeycomb Energy appeared on the market with ternary battery technology, its layout in the field of lithium iron phosphate batteries is also considerable.

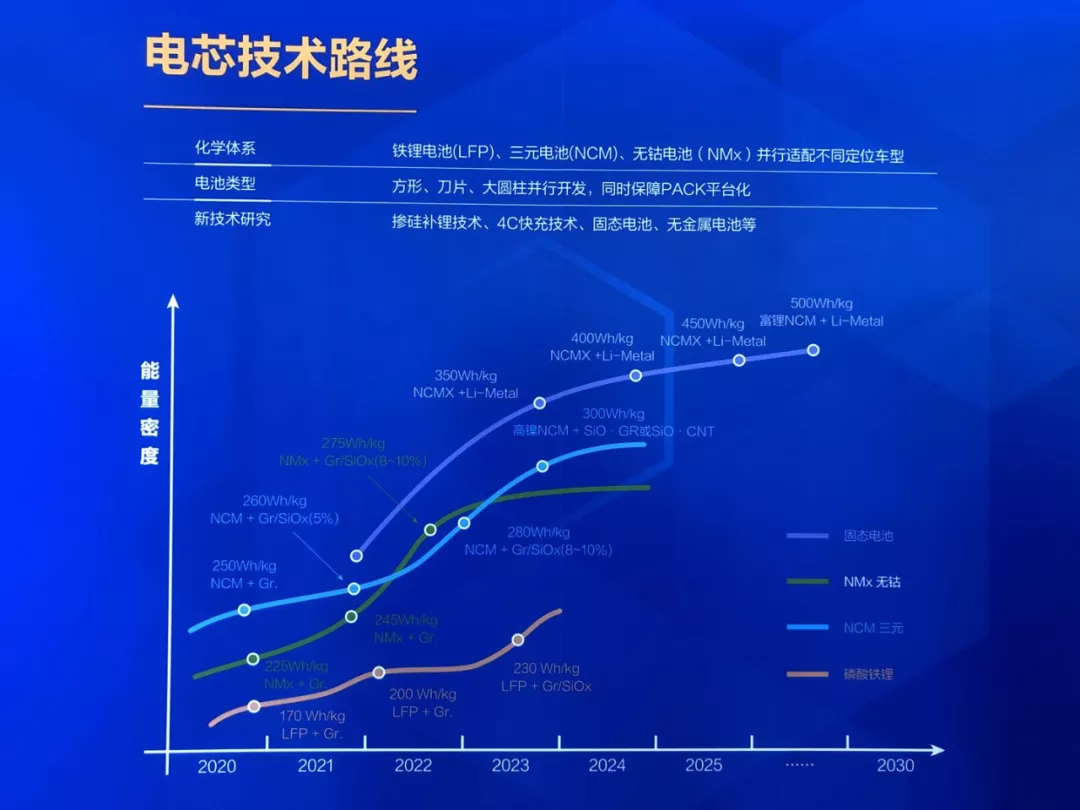

According to Yang Hongxin, Chairman and CEO of Honeycomb Energy, the production of lithium iron phosphate batteries is expected to account for approximately 40% of Honeycomb Energy’s output next year, which is basically the same as that of ternary batteries.In the exhibition hall of Great Wall Technology Festival, from the power cell technology roadmap of Honeycomb Energy, it can be seen that by the end of 2020, they had achieved an energy density of 170Wh/kg for the lithium iron phosphate positive electrode and graphite negative electrode, and would reach 200Wh/kg by 2022. In 2023, the negative electrode can reach an energy density of 230Wh/kg by adding silicon.

It can be seen that major battery companies have plans to deeply cultivate lithium iron phosphate batteries.

(2) Development of Low Cobalt and Cobalt-free Ternary Batteries

Unlike lithium iron phosphate batteries, the main bottleneck for ternary batteries is price, with cobalt being the most volatile component with the biggest price fluctuations. Ningde Times also plans to have cobalt-free batteries, but according to the ppt shown at the Ningde Times conference, their cobalt-free batteries will debut around 2024 and achieve an energy density of over 250Wh/kg.

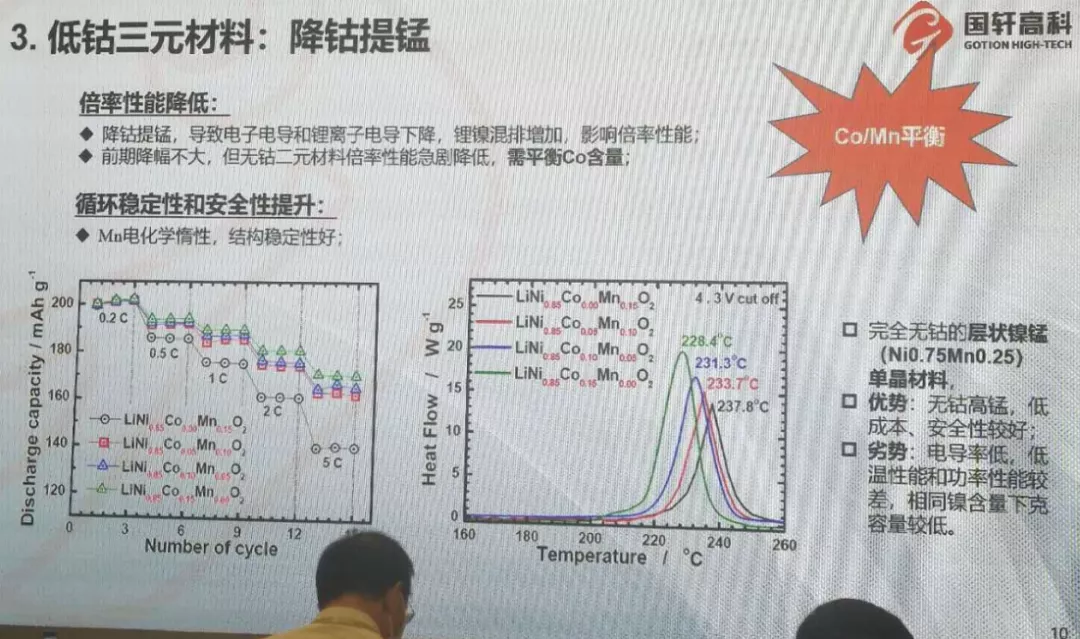

Xu Xingwu, Senior Vice-President of Hefei Guoxuan High-Tech Power Energy Co., Ltd. believes that cobalt is still necessary. “Nickel improves capacity, cobalt stabilizes structure and enhances conductivity. If manganese is used to replace cobalt, conductivity will be lower, and overall energy density will be lower, and the cycling performance will not be favorable. They hope to find a balance point, reduce cobalt but not reduce it to zero.”

Xu Xingwu refers to these low-cobalt material batteries as ternary materials with multiple low cobalt content, aiming to reduce cobalt to 1% level, basically maintaining the existing performance without significant changes, or not too poor.

In terms of cobalt-free batteries, the fastest progress has been made by Honeycomb Battery. The model with their cobalt-free battery will be launched at the Chengdu Auto Show in August. This will also be the world’s first vehicle equipped with a cobalt-free battery.

In addition, Honeycomb is developing two cobalt-free batteries for Great Wall. Next year, 4-5 models from various automakers will use cobalt-free batteries.

Honeycomb cobalt-free “short blade” battery

Solid-State Battery Applications Still Have a Long Way to Go

From a technical standpoint, solid-state batteries are most likely to be implemented in the distant future.

However, Ningde Times hopes to introduce a fully solid-state battery, so they believe that the true mass production of solid-state batteries will occur around 2028 or 2030.

Xiang Yanhuo stated that during this period, they are also researching other technologies, such as rare-metal-free batteries and lithium-air battery technology.

Guoxuan High-Tech also has a layout in solid-state batteries, but Xu Xingwu also admits that the difficulty is great.](https://upload.42how.com/article/image_20210706141430.png)

Meanwhile, the current state of solid-state batteries is that they rely entirely on the solid-state electrolyte, which has not yet reached the conductivity level of a liquid electrolyte. Furthermore, the interface issue is difficult to solve, so a compromise is adopted. That compromise is a mixed solid-liquid electrolyte, or a semi-solid-state battery, which most companies in the industry are currently employing.

Currently, Guoxuan High-Tech’s semi-solid-state batteries are primarily focused on safety. They can achieve a performance level of 610Wh/L, 300Wh/kg, and 1,000 cycles. Their safety can meet the needs of high-end customers.

In 2023, Guoxuan High-Tech began the development of high-performance solid-state batteries, with the goal of producing solid-state batteries with an energy density of over 800Wh/L, over 400Wh/kg, and 800 cycles after 2025. They will use lithium-rich materials, sulfur or other positive electrode materials, and lithium negative electrodes with interface modification technology.

Meanwhile, Honeycomb Energy is also developing solid-state batteries. “We are working on both sulfide and oxide systems, but to be honest, the challenges are huge,” Yang Hongxin said.

According to promotional materials displayed at the Honeycomb Wuxi 118 Innovation Center, their plan is to produce the first generation of composite electrolyte solid-state batteries with an energy density of 250-300wh/kg by the end of 2021 and to produce the fourth generation of solid-state electrolyte batteries with an energy density of 450-500wh/kg by the end of 2030.

Although Honeycomb also has technical reserves for semi-solid-state battery products, Yang Hongxin stated that they could not determine the commercial prospects for semi-solid-state batteries. “We can’t find the core selling point of semi-solid-state batteries right now.”

In addition to battery materials, battery integration technology is also constantly evolving.

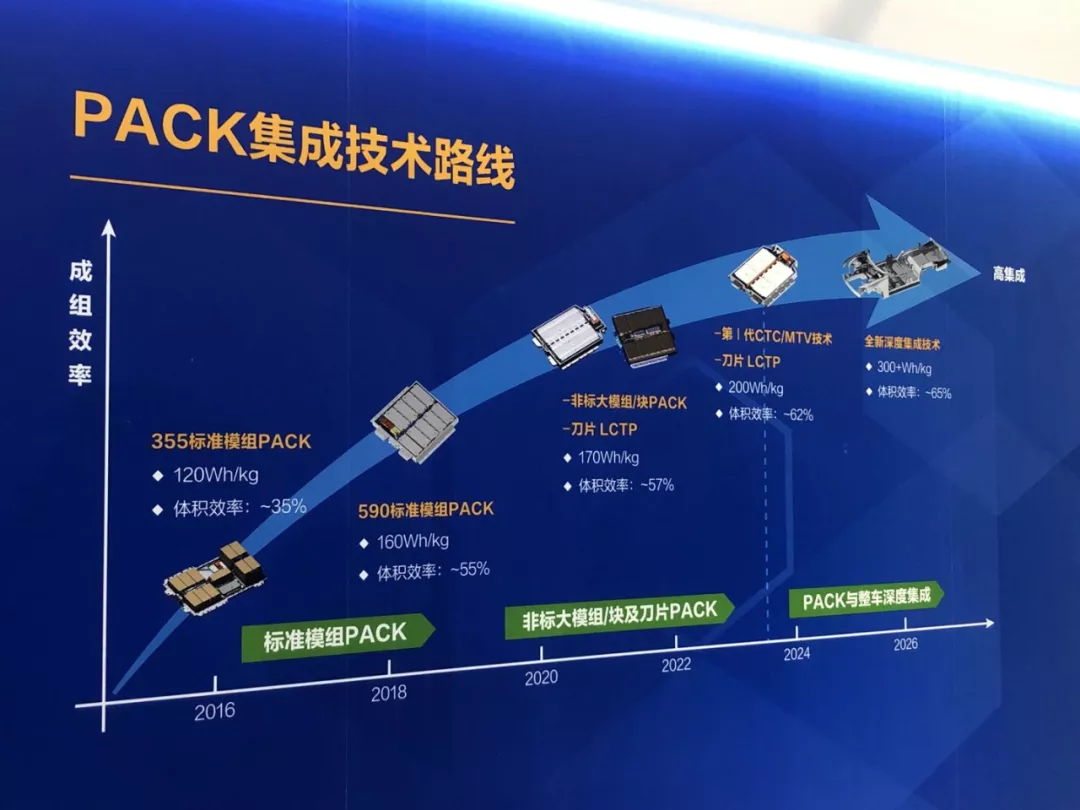

Xiang Yanhuo explained that, after 2019, most of CATL’s products used CTP integration technology and developed battery systems with energy densities of 180-200Wh/kg. In the long term, CATL hopes to integrate the battery cell and the chassis. “The first-generation CTC integrated product is expected to be mass-produced around 2025, and a more intelligent CTC product is expected to be launched around 2028-2030.”# The use of CTP integrated technology by CATL is similar to that of NEDC. According to the data released by CATL, compared with the traditional 590 module, the first generation of CTP can reduce 24% of the components, the second generation can improve the group efficiency by 5-10%, increase the space utilization rate by 5%, and reduce the number of components by 22%.

According to the exhibition on Great Wall Technology Festival, Great Wall Motor’s PACK integrated technology roadmap shows that they will adopt the “blade battery” CTP technology of CATL around 2021, achieve the first generation of CTC technology around 2023, and achieve deep integration of PACK and the whole vehicle in 2026. The energy density of a battery pack can reach 300+Wh/kg. This means that for a passenger car of the same size, the cruising range will be about twice that of the current situation.

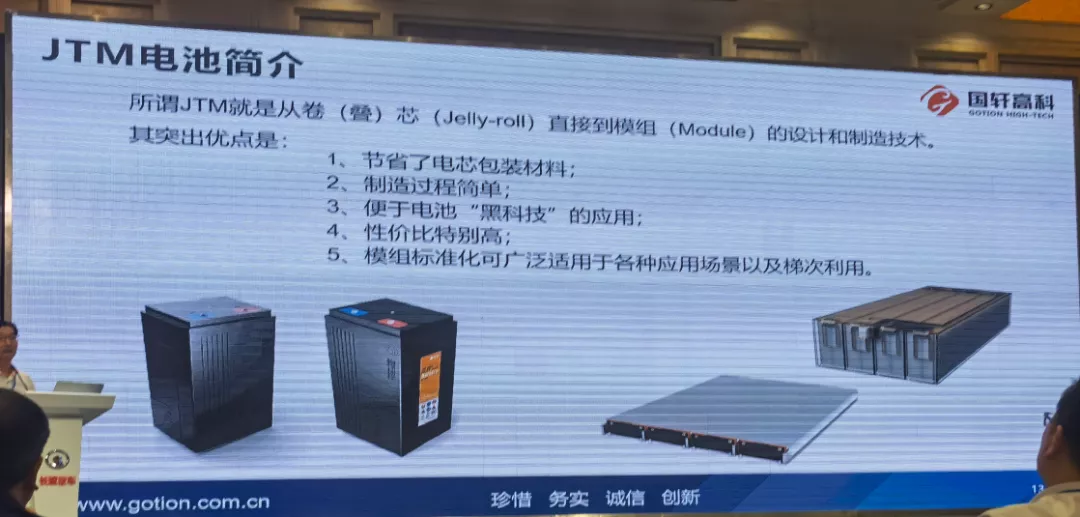

Guoxuan High-tech’s integrated technology is different from the three above.

Guoxuan High-tech’s technology is called JTM (Jelly Roll to Module), which directly puts the roll core into the module to complete the production in one step.

Xu Xingwu said that this process is very simple, cost-effective, with a simple manufacturing process that is easy to standardize. No matter if it is the Volkswagen MEB platform or the moderately flexible large module concept, it can be applied. “Just like Transformers, basically 95% can achieve the level of blade battery through our method. We can also achieve their energy density, arriving at the same destination through different routes.”

The biggest difference in JTM is the integrated manufacturing technology from core to module. JTM products use special materials and processes to create plastic shells and more efficient integrated grouping technology, which truly achieves the ultimate goal of directly preparing the module or battery pack from raw materials with synthetic design concepts.

Long-life Battery

One of the major problems facing lithium-ion batteries during usage is severe attenuation.

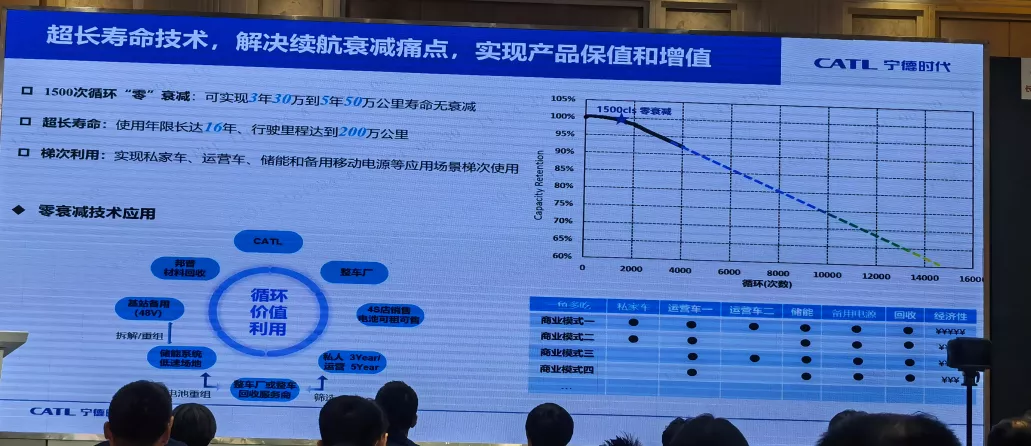

In terms of technology research and development, CATL is also committed to launching ultra-long-life batteries.

In June 2020, CATL announced that it had developed a battery using self-repairing long-life technology, which can achieve a life of more than 16 years or a driving mileage of 2 million kilometers for an increase in cost of less than 10% compared to existing batteries.After 1500 cycles, the decay of this type of battery is still zero.

Xiang Yanhuo said that CATL is creating ultra-long cycle life technology to solve the pain points of driving range and achieve product appreciation and retention.

In addition, Guoxuan High-Tech is currently developing long-life batteries with a cycle life of over 10,000 times. Xu Xingwu also believes that this leaves huge room for the hierarchical utilization of batteries.

Fengchuang Energy has not promoted a lot in terms of long-life batteries. However, its cobalt-free core released last year, including the E-platform battery applied mainly in medium-range vehicles, has a battery cycle life of over 4000 times. Fengchuang’s cobalt-free battery can support electric vehicles to travel more than 800 kilometers with a service life of over 15 years or 1.2 million kilometers.

Low-temperature Performance

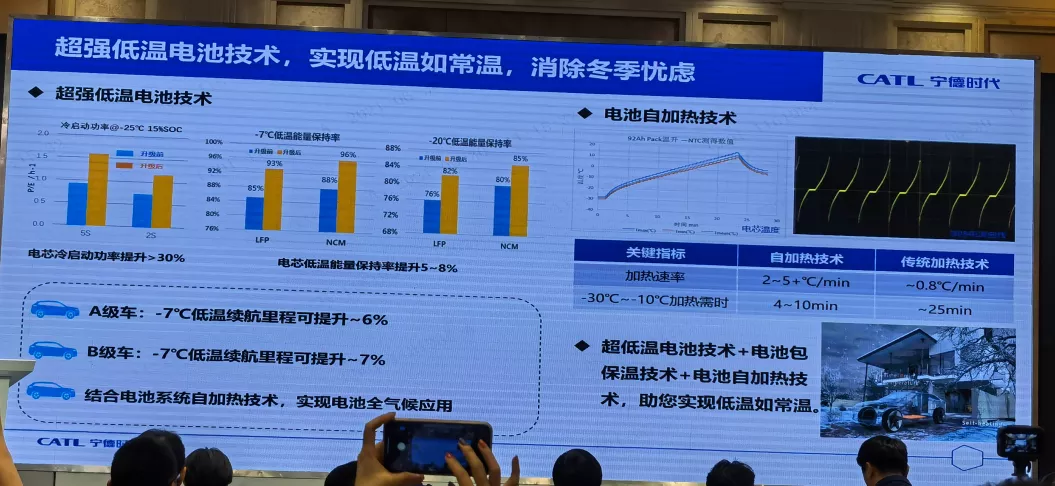

Another weakness of power batteries is poor low-temperature performance, which is also one of the key technologies these enterprises are tackling.

Xiang Yanhuo explained that by improving the performance of the battery core, they can improve the power and energy retention rate, thereby increasing the narrative range by 5%-8%.

In addition, CATL will also add self-heating technology at the system level to achieve a speed of 2-5 degrees per minute, which consumes only four or five points of electricity, reaching the energy level of the battery system close to ambient temperature at -30 degrees.

Guoxuan High-Tech’s improvement in low-temperature performance mainly focuses on the development of advanced electrolyte. At the 10th Science and Technology Conference of Guoxuan High-Tech, Cai Yi, the dean of the Institute of Engineering Research, revealed the progress of Guoxuan High-Tech in new electrolyte formula, “The new electrolyte formula of Guoxuan High-Tech can improve the low-temperature performance of lithium iron phosphate batteries by more than 20%; the new formula of ternary electrolyte can help the high-temperature DC internal resistance drop by 10%; the cutting-edge gel electrolyte has passed the customer safety puncture test.”

However, Cai Yi said that it will take two years to see the results of the electrolyte project.

Fengchuang did not introduce low-temperature performance specifically, but Yang Hongxin revealed that the reason for the launch of lithium iron phosphate batteries is also because its low-temperature performance has improved significantly compared to before. In addition, Fengchuang is also developing a battery heating technology to effectively improve low-temperature performance.

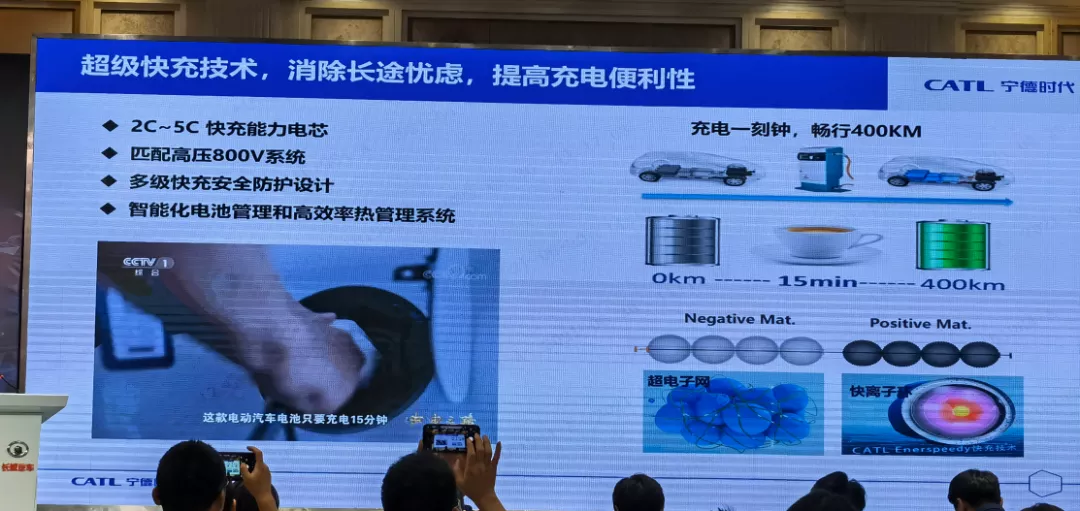

Fast Charging: 400 km in 10 minutes

Consumers’ demand for electric vehicles is to achieve a similar experience to fuel vehicles. Therefore, in terms of charging speed, they hope it can be faster and faster.Ningde Times has developed a series of fast-charging products, including the 2C-5C series. The 2C product can be charged in 20 minutes, the 4C product in 10 minutes, and the 5C product can be charged in 5-8 minutes, meeting the demand for a 400-kilometer range.

CATL is developing a fast-charging product that increases battery life by 33%, improves energy density, and reduces charging time by 62%. The company plans to launch this product as early as 2022.

To achieve the 10-minute fast-charging goal, CATL has carried out a lot of technical optimizations in the battery system, such as directional growth control technology, multi-gradient three-dimensional doping technology, and flexible coating technology, as well as improved electrolyte and simulation technology, and formulated the optimal fast-charging strategy.

CATL intends to continue to increase research and development of fast-charging batteries, with the goal of increasing energy density to 250 Wh/kg and battery capacity to more than 160 Ah in the future.

Intelligent Battery Management System

An intelligent battery management system is also necessary to achieve a more balanced battery.

Ningde Times and CATL have both made some achievements in this area.

Ningde Times’ digital battery (iD-PACK) incorporates intelligent algorithms, battery pack model analysis, domain controllers, residual value evaluation, data storage, and car-cloud integration, which manages the entire lifecycle of the power battery.

CATL has established the Bee Cloud platform for battery safety monitoring.

This platform was developed by CATL in collaboration with Tsinghua University, which can provide early warning of short circuits two months in advance, ensuring battery system safety, and performing cloud-based lithium analysis, defect battery analysis, and residual value evaluation.

Yang Hongxin explained that this platform currently monitors 90,000 electric vehicles and analyzes more than 1.6 billion pieces of data, with more than 20 monitoring items.

Overall, the three battery companies have made similar technological progress, with each having its own strengths in certain areas. All three companies are optimistic about the prospects of lithium iron phosphate and solid-state batteries, but they differ in their views on whether batteries need to be cobalt-free. They are all overcoming technical difficulties in areas such as long lifespan, fast charging, and low-temperature.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.