China’s Power Battery Industry Development Path

Currently, the power battery industry in China is mainly dominated by two companies, C and B, with B focusing on the development of lithium iron phosphate batteries from ternary batteries. C’s technical route has not been clearly announced, but recently, a friend has taken photos of C’s latest power battery technical route at a new energy vehicle conference, and I want to rearrange this material as a starting point.

Chemistry System of Batteries

As the leader in power batteries and the main provider of electric vehicle models for domestic and foreign car companies, C’s technical route can be used to deduce many interesting things.

First Type: High Cost-Effective Battery

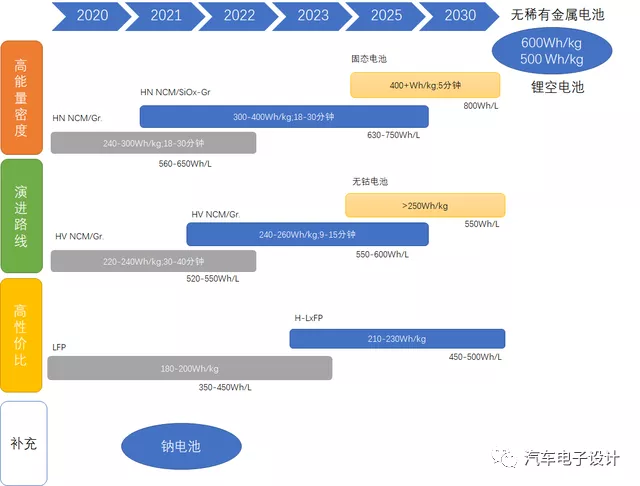

Lithium iron phosphate is the chemical system with the highest cost-effectiveness due to its low metal constraints, and C defines this type as “economical.” In terms of the timeline, it can be divided into two phases:

- 2021-2023: Energy density of battery between 180-200Wh/kg (volume energy density of 350Wh/L-450Wh/L).

- 2023-2028: Through material system and process optimization, development of lithium iron phosphate batteries with energy density between 210-230Wh/kg (volume energy density of 450Wh/L-500Wh/L) is underway.

Therefore, 2023 is a very important milestone, and it can be understood that with energy density close to 450Wh/L, lithium iron batteries can replace those with 520Wh/L, such as ternary batteries for demand up to 65kWh. From a logical standpoint, C aims to cover all A0-B entry-level models without considering fast charging in terms of economy. My understanding is that there is a clear differentiation between this lithium iron phosphate and our previous 170Wh/kg plan.

Second Type: Mid-range Battery with High Nickel Voltage

This is actually an evolutionary route, evolving from NCM523 to the “Nickel 55” mid-range high-voltage system for existing mid-to-high-end vehicle models.

- 2020-2022: Energy density of 220-240Wh/kg (volume energy density between 520Wh/L-550Wh/L) with fast charging time of 30-40 minutes (1.5C-2C).

- From the second half of 2021 to 2025, the quality energy density of the battery will be upgraded from 240-260Wh/kg (volume energy density 550Wh/L-600Wh/L) with fast charging time of 20-30 minutes (2C-3C) through technological upgrades.Around 2024, the importation of cobalt-free batteries with energy density greater than 250Wh/kg and volume energy density greater than 550Wh/L will begin. This is more like a futures product, requiring long-term technical investment.

From my understanding, the current battery cells commonly seen on the market are all in the nickel-cobalt-manganese 5 series, with nickel 55 being a high-voltage single crystal material that solves the low energy density problem of nickel-cobalt-manganese 5 series ternary materials, while also balancing safety and low cost advantages. With these kinds of battery cells, it is relatively easy to create batteries that can withstand thermal runaway diffusion. To be honest, cost control for this type of battery is quite difficult and, at current material prices, it is easy to just replace it directly with iron-lithium.

Type 3: High-performance battery cells, the high nickel route

Because current flagship models start at 100kWh, the high nickel route is relatively expensive, so it is established on a high nickel system and a silicon-carbon anode.

From 2021 to 2023, the quality energy density of the battery cell ranges from 240-300Wh/kg (volume energy density 560Wh/L-650Wh/L), with fast charging times of 18-30 minutes (3.3C-2C).

From the second half of 2021 to 2024, CATL began to introduce silicon-carbon anodes, upgrading the quality energy density of the battery cell to 300-400Wh/kg (volume energy density 630Wh/L-750Wh/L), with fast charging times of 9-15 minutes (6.6C-4C).

By 2025, solid-state batteries will be introduced, with quality energy density greater than 400Wh/kg (volume energy density greater than 800Wh/L). In this branch of technology, there has been no substantial product demonstration from company C, and it is still in the early stages of development, requiring the solution of many basic problems.

By 2030, the eagerly anticipated technology will include rare metal-free positive electrode materials, lithium-air and other material system research, with battery cell energy density breaking through 500Wh/kg to 600Wh/kg, mainly providing a directional exploration. Each year, money is invested in laying out patent systems and cutting-edge technology.

Type 4: This is a block that I added, which was not seen in the power battery section. It is what company C talked about at the shareholders’ meeting, the sodium battery. From a short-term perspective, this is a means of suppressing the rapid rise of front-end resources. The specific content will be announced by company C.

Part 2: Classification of various characteristics

There are three technical directions here, namely fast charging, long service life, and solving low-temperature problems.

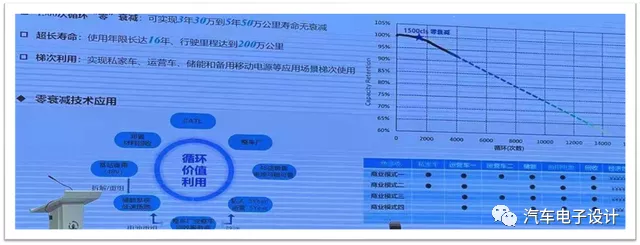

1) Long service life.I’m not sure if the no attenuation claim is true, but according to the data responsible colleague, the attenuation of the 5-series battery cells from C company used in suitable areas like Shanghai is indeed good. The advantages of the square shell is that it can accommodate more electrolytes, and compared with LG’s soft pack, the attenuation of capacity is much better. However, whether the 1 million or 200 kilometers durability claim is true or not really requires long-term observation and sufficient daily mileage and high-load operation.

From private car to commercial vehicle 1 and commercial vehicle 2, to energy storage, backup battery, and recycling, this very long path requires explorers to try in a long time dimension for battery safety considerations, if there is a veto on it.

2) Fast Charging

Currently, the 2C can be basically seen in BBA’s latest models, but it’s unclear when the 5C will come out. Currently, fast charging is the main differentiation feature in 2022.

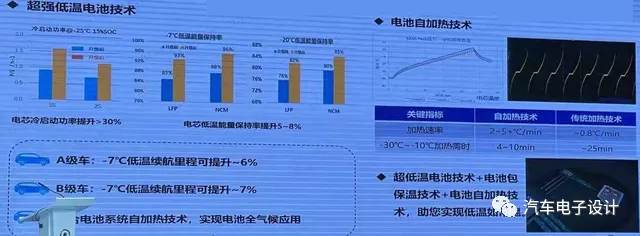

3) Low-temperature Performance

After criticizing low-temperature performance last winter, the 2021 designed system prioritizes solving this problem, and the most important thing we can see now is the popularization and application of self-heating technology.

Summary: From a technological perspective, C company currently includes various products that cover economic, universal, high-end and other scenarios. Considering the safety, endurance, charging, and life span of electric vehicles, the dense product array leaves little room for newcomers to break through. Currently, the second-tier manufacturers can only follow along, and low-end iron-lithium batteries can break the deadlock at the A00 level through price wars, while European and American startups and Japanese old players rely on solid-state batteries for differentiation.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.