What is ASPICE

ASPICE stands for “Automotive Software Process Improvement and Capacity Determination”. It is a model framework used in the automotive industry to evaluate the development capability of software development teams. Originally developed by more than 20 major European car manufacturers, it was released in 2005 with the aim of guiding the software development process of automotive component R&D manufacturers, thus improving the quality of in-vehicle software.

Over the years, ASPICE has been widely used in the European automotive industry for process improvement and supplier research and development capability evaluation. With the rapid development of connected cars, autonomous driving, and new energy vehicles in recent years, the proportion of software in the automotive industry has increased sharply, and the demand for software quality management by enterprises has increased continuously. ASPICE has gradually been introduced to China and is well known to Chinese enterprises. On the other hand, with the revision of TS16949, the requirement for regular audits has promoted the application of ASPICE in China.

Impact on suppliers and original equipment manufacturers

In the automotive industry, ASPICE is becoming a widely adopted standard. Major original equipment manufacturers such as Audi, BMW, Daimler, and Ford are evaluating their electronic and software suppliers based on ASPICE assessment ratings. It provides a more controlled system development process to ensure product quality, shorten release schedules, and reduce the cost impact of quality problems discovered later in the product development process.

OEMs can use the ASPICE framework to evaluate supplier process quality capabilities in the supplier selection process. OEMs can define their own system development process as compliant with the ASPICE standard, which will help evaluate and improve process capabilities.

ASPICE Introduction

ASPICE Overview

ASPICE has its own process reference model (PRM), which is tailored to the specific needs of the automotive industry. The ASPICE process assessment model (PAM) uses the PRM during the evaluation. In ASPICE, capability determination is based on a two-dimensional framework: process dimension and capability dimension.

The process dimension defines the PRM based on the process domain and its scope, purpose, and results. The capability dimension is composed of the capability level and process attribute of the identified process areas in the PRM.

Process Reference Model (Process Dimension)### Process Measurement Framework (Capability Dimension)

ASPICE divides a company’s software development capability into 6 levels, with level 0 being the lowest and level 5 being the highest, depending on the level of rigor and meticulousness of enterprise management. The higher the level, the lower the likelihood of unexpected situations in the development project, the stronger the company’s control over the project and product, and the greater the ability to deliver high-quality products to customers on time.

[Level 0] Represents a chaotic state.

[Level 1] Represents a situation where the company can complete product development-related work, but lacks management. Although occasional success is achieved, there are many uncertain factors in the project, and the company lacks control over the project, unable to ensure timely delivery of high-quality products.

[Level 2] Represents a situation where the company can not only complete product development-related work, but also is able to make rigorous and comprehensive work plans ahead of time, and can effectively implement project monitoring and management according to the plan, ensuring orderly progress of each project.

[Level 3] Represents a situation where each project can be managed very well, and the company can effectively accumulate experience and lessons learned from historical projects, forming the company’s knowledge assets and standard work processes, which can be used for reference and guidance for future projects and continuous improvement of company management.

[Level 4] Introduces statistical knowledge and technology to perform statistics and analysis on various project-related data, and applies them to future project management to achieve predictions of project results, and makes real-time adjustments to projects based on those predictions, thereby ensuring the achievement of project objectives.

[Level 5] Represents a situation in which the company can proactively adjust its processes based on its business goals and has strong change management capabilities. The company can set clear and effective process improvement goals based on quantitative analysis of the process, and can effectively monitor and analyze the process improvement results.

Process capability levels are determined by rating the process attributes for each capability level.

Below is an example of a Process Assessment Model (PAM).

ISO 26262 and ASPICE

ISO 26262 “Road vehicles – Functional Safety” international standard is a functional safety standard for passenger cars with a total weight of not more than 3.5 tons and eight seats, which is based on the characteristics of safety-related electrical and electronic systems. It was developed based on IEC 61508 “Functional safety of electrical/electronic/programmable electronic systems” and officially released on November 15, 2011.

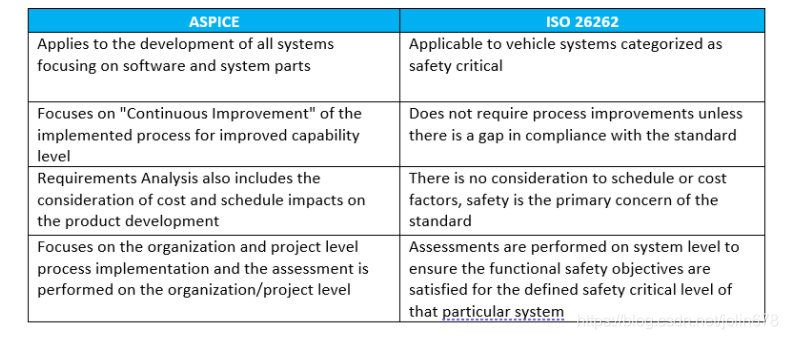

Since ASPICE covers a broader range of system development topics, implementing ASPICE can provide a framework for meeting the requirements of ISO 26262. The main differences between ASPICE and ISO 26262 are as follows:

Similarities can be found in the supporting process areas, such as configuration management and change management.

CMMI and ASPICE

The Capability Maturity Model Integration (CMMI) compliance does not automatically mean that an organization or project complies with ASPICE. Although these two standards look the same in terms of core concepts, they use different process assessment models and have differences in their implementation in the process area.

Because ASPICE was developed for the automotive industry, it is a better choice for OEM or supplier organizations to align with other departments in the industry. For those who have already adapted to CMMI and wish to implement ASPICE, a detailed analysis of the gaps between current processes and ASPICE is also the best starting point.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.