Background Knowledge (Factors Affecting the Driving Range)

One of the most important factors to consider when purchasing an electric vehicle is the driving range, which is also the most controversial one.

Why is there a difference between the nominal driving range and the actual driving range? And how big is the difference? Let’s clarify the issue first.

The driving range is defined as the maximum distance an electric vehicle can travel continuously under certain driving conditions when its power battery is fully charged (displayed as “full” on the instrument panel).

The controversy mainly comes from the driving conditions in the testing standards. Currently, the commonly used driving conditions are:

-

European NEDC cycle, which is one of the mainstream testing standards worldwide. China’s current standard (GB18386-2017 “Test method for energy consumption and driving range of electric vehicles”) is mainly based on the NEDC standard.

-

U.S. EPA cycle, which is also one of the mainstream testing standards worldwide. It is the most stringent testing standard, and the difference between the driving ranges tested under NEDC and EPA is about 10-15%.

-

WLTP cycle.

-

JC08 cycle, only used in Japan.

Previous answers have already explained these standards to some extent, so we won’t go into further analysis.

Factors affecting the driving range can be divided into two main aspects: vehicle usage (i.e., driving conditions) and vehicle design.

From the perspective of vehicle usage, factors such as the driver’s driving habits and the usage environment inevitably differ from the standard driving conditions. It’s easy to understand that changes in environmental temperature, different drivers, different loads, and driving on different roads will cause deviations in the driving range. Therefore, many controversies about the inaccuracy of the driving range are actually targeted at the appropriateness of the standard driving conditions.

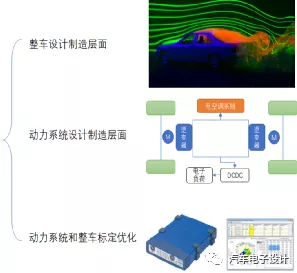

From the perspective of vehicle design, there are three major influencing factors: performance design, power system, and overall vehicle system optimization.

Let’s briefly talk about these areas.

First, performance design:

When driving an electric vehicle, the greater the resistance it encounters, the more battery energy it needs to overcome that resistance, and the worse its driving range is. Reducing resistance plays an important role in improving the power and quality of an electric vehicle as well as its driving range. So what are the resistances a vehicle faces when driving? Mainly including:

- Rolling resistance from the road and wind resistance from the air when driving at a constant speed on a level road.2) When a car drives uphill, it must also overcome the force of gravity along the slope, known as slope resistance.

3) In addition, when a car accelerates, it needs to overcome acceleration resistance.

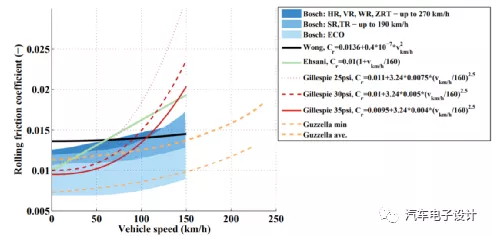

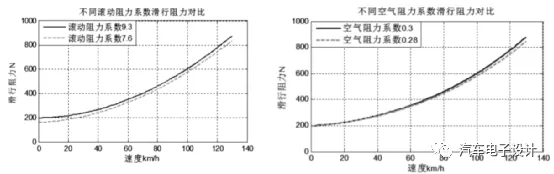

To evaluate the performance of air resistance and rolling resistance, we generally use the coefficients of drag and rolling resistance respectively. This coefficient can be considered as the ratio between the resistance of the car and the square of the speed. The larger the coefficient at the same speed, the greater the resistance and power consumption of the car. Conversely, the smaller the coefficients of air resistance and rolling resistance, the smaller the resistance and power consumption of the car. This means that, under the same conditions, the lower the power consumption of pure electric vehicles or the faster the speed at the same power consumption, the better the performance.

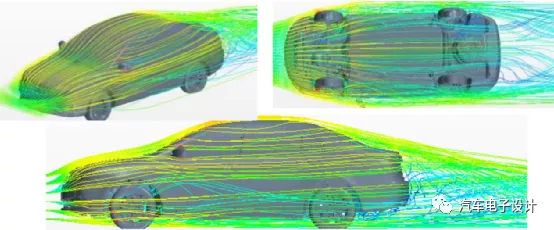

To reduce the coefficient of drag, the first step is to optimize the overall design of the vehicle, with a reasonable body shape that can reduce the frontal area and therefore the coefficient of air resistance, leading to a reduction in overall air resistance of the vehicle. The other aspect is the precision of manufacturing the vehicle. The higher the quality of the body surface, the smoother the body, and the smaller the coefficient of resistance to the wind. The quality of the body surface depends on the engineering structure design and the manufacturing process of the mold.

Reducing the coefficient of rolling resistance can also start from two aspects. One is to reduce the overall weight of the vehicle and control the total weight, which can reduce the rolling resistance and energy consumption of the vehicle. In the optimization of electric vehicle performance, the mass of the vehicle needs to be controlled, with lightweight requirements, one of which is to reduce rolling resistance. The other aspect is to choose low rolling resistance tires. By the way, in the current research and development of pure electric vehicles, the difficult point is generally focused on improving the cruising range. When there is no effective solution due to battery technology, adopting tires with lower rolling resistance for pure electric vehicle models has become an effective way to improve the cruising range of electric vehicles.

Secondly, the power system.

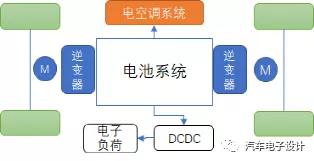

Pure electric vehicles convert the electrical energy in the power battery into mechanical energy through the driving motor, thus driving the vehicle to travel. Therefore, the cruising range is directly related to the three power systems of electric vehicles (battery, electric drive, and electric control).

(1) Battery System

(1) Battery System

The capacity of the power battery determines the range of the electric vehicle directly.

The most direct way to improve the range of electric vehicles is to increase the capacity of the battery. However, this value cannot be increased infinitely. This is because, from the perspective of vehicle layout, the space occupied by each watt-hour (Wh) must be considered. This will determine how many batteries can be placed in the limited space of the vehicle body. The weight per watt-hour (Wh) determines the proportion of the weight of the batteries in the electric vehicle. Therefore, the “watt-hours per liter” (Wh/L) and “watt-hours per kilogram” (Wh/kg) of the power battery pack are the core elements for assessing capacity.

In addition, the temperature of the battery system, if too high or too low, can also affect the range. In order to reduce battery heating and the influence of environmental temperature, stable thermal management of the battery system is needed, with the main tasks being:

・Insulation: to isolate the battery system from the external environment, and protect it from the effects of high or low temperature;

・Heat dissipation: to dissipate the heat generated by the battery during operation in a timely manner;

・Temperature uniformity: at the same time, the temperature uniformity between the battery modules needs to be ensured as much as possible. There are characteristic differences in the battery cells at different temperature states. Keeping the temperature consistent can maximize the characteristics of the battery pack.

Under the same battery capacity, the more stable the battery temperature, the more it can guarantee the range.

(2) Electric drive system, mainly including drive motor, controller, inverter, and reducer, etc. Its efficiency is determined by the ratio of the input power to the output power.

Once the battery capacity is determined, the high or low output energy at the same voltage is determined by the efficiency of the drive system. All automakers will fully tap the efficiency of the motor and electrical controls to optimize energy consumption and improve range.

(3) Vehicle control system: mainly refers to the coordination of battery, drive system, and chassis brake energy recovery. Under frequent acceleration and deceleration conditions, the proportion of energy recovery (braking energy recovery) can be dynamically adjusted according to the battery’s status and braking demands, thereby improving energy utilization efficiency.

The braking energy recovery strategy of electric vehicles will directly increase the vehicle’s travel range.

Third, system optimization

This is relatively complicated, and can only be briefly mentioned about system optimization.In the final stage of powertrain development and vehicle integration, a lot of efforts need to be put in to optimize the entire vehicle control based on different driving cycles and maintain the previously set vehicle lightweight target. This is due to the fact that the energy consumption of the battery varies significantly under different driving conditions, and thus requires specialized software in the battery management system and vehicle control unit (VCU) to predict the feasible driving range. The accurate prediction of driving range demonstrates the R&D capability of automotive companies.

VCU, as the core control component, serves as the software algorithm and control center of the entire vehicle enterprise. In terms of driving range, VCU’s job is to manage energy and power allocation to improve system efficiency and control energy feedback during braking. Therefore, in the optimization stage, it is primarily about calibration of different driving modes, coordinating power performance and fuel economy of driving range, and utilizing intelligent energy management strategies to increase the vehicle’s driving range.

In conclusion, driving range of pure electric vehicles is not only related to the battery capacity but also to the continuous improvement of vehicle styling and manufacturing processes in traditional automotive design, as well as the comprehensive optimization and enhancement of system algorithms at the software level.

Regarding the actual driving range test, there is a considerable difference between the standard testing conditions and actual usage scenarios, which causes the actual range to deviate from the nominal range value released by the regulator.

Now let’s take a look at the cruising range of the XPeng P7 in practical tests. According to a chart posted by @Zhang Kangkang, the deviation rate between the actual range and NEDC (National Energy and Environmental Protection Agency’s Electric Vehicle Development and Promotion Center) range defined as the difference between actual and the published range by the regulator, for the XPeng P7 extended-range version is 16.6%, ranking in the middle of the around 20 tested vehicles. Interestingly, the four-wheel-drive performance version ranks higher, and the Model 3 ranks last.

To compare, here are some parameters of the XPeng P7 and several other popular models:From the parameters, it can be seen that the range is significantly positively correlated with the battery capacity in similar models (P7 and Model3). However, once the model becomes larger, the wind resistance also increases, and a similar range requires more battery capacity as support (ES8 and Model3).

Now let’s talk about the actual driving situation.

When we first got the car, it was for my wife to practice driving. At that time, it was spring, the temperature was suitable, and the air conditioning was not turned on.

From the city to the suburbs, to our old home, is a one-way distance of 70km, with 60 kilometers on highways or elevated roads (Yan’an elevated road + G50). The road conditions were good, and the remaining 10 kilometers were secondary roads in the suburbs; the round trip actually ran 140 kilometers, but showed 200 kilometers, equivalent to 70% of the displayed range.

[Note that although my wife claims to be a “novice”, she practised driving for a period of time a long time ago, so she meets the requirements for driving on highways]

In the past few days, my father drove the same route back, with the air conditioning turned on, and also when the road conditions were good. As an experienced driver for many years, my father travelled 65 kilometers from Xuhui to Qingpu, and the displayed range dropped by 85 kilometers, which is about 80% of the displayed range. It seems that experienced drivers are indeed different.

In addition, last weekend, my wife practiced driving and went to the Wanda Plaza in Qingpu once and to the beekeeping farm in Fengxian once. The actual total distance was about 200 kilometers, and because most of it was on highways, the displayed range of 600 kilometers dropped by 270 kilometers. This was partly due to the use of air conditioning and the presence of highways, and overall, it seems that the novice female driver has made some progress in terms of driving skills.

Of course, as our daily car, we have not rigorously tested the range from full to empty.

But from the above data, it can be seen that whether it is the pure electric range as claimed by the Ministry of Industry and Information Technology or the actual test data of various institutions, they can only serve as a benchmark reference value. In terms of actual driving, to achieve a range close to the nominal value, the driver’s skills must be good. [Manual dog head gesture].

When purchasing, the range is still a meaningful parameter for comparison. As an actual daily driving range displayed on the car, it is more reasonable to use it as an estimate of the battery level, similar to the percentage of battery on a phone, leaving sufficient time and distance to the charging station.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.