Author: Chris

Editor: Chris

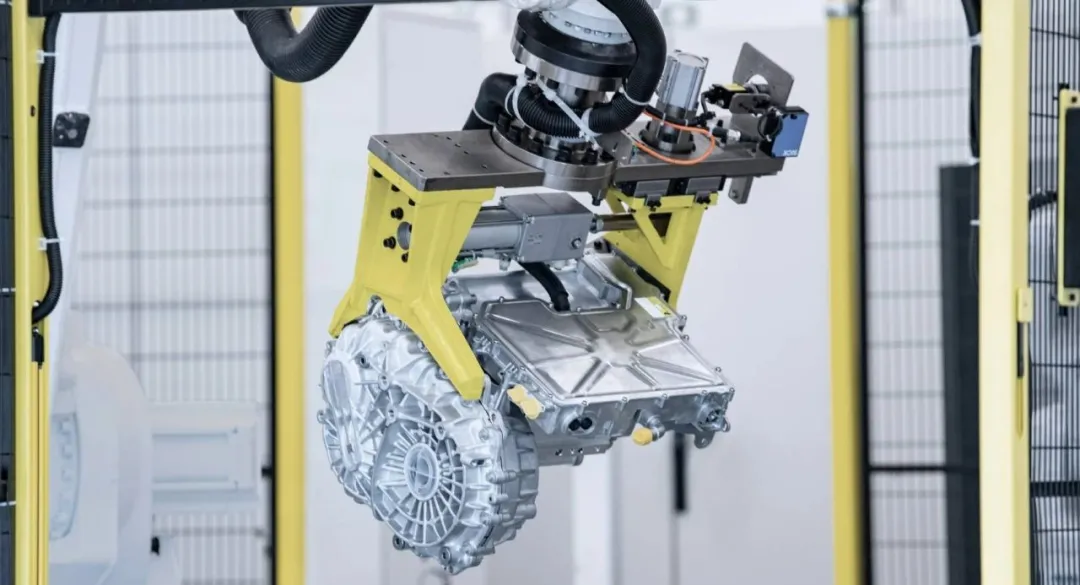

▎On June 22nd, the first 180 kW silicon carbide (SiC) electric drive system C-sample of NIO ET7 was rolled off at NIO’s advanced manufacturing center in Nanjing, which means the component has been produced in mass production and will be used for final product verification. After the production approval process, the ET7 electric drive unit can be mass-produced and shipped to NIO plant in Hefei.

From the PPT on NIO Day on January 9th to the rollout of the C sample on June 22nd, the engineering of the second-generation electric drive unit of NIO has made substantial progress.

The launch time of NIO ET7 is the first quarter of 2022. I have compiled a table of high-performance pure electric sedans that are currently on sale and will be launched in 2022. Let’s discuss the design logic of NIO’s second-generation electric drive unit based on this table.

“Total Power & Torque”

▎The total power of the front and rear dual-motor of ET7 is 480 kW, which is currently the pure electric sedan with the highest peak power except for the three-motor Tesla Model S Plaid and the over 2 million Porsche Taycan Turbo S.

Looking at the torque, the 850 N·m torque of the ET7 surpasses Model S, Taycan, and EQS, which are much more expensive than ET7. Among domestic auto brands, ET7 has the highest torque. This is certainly not a coincidence. Overall, you can draw a conclusion: William Li, the founder and CEO of NIO, hopes this car will have good performance and explosive power.

To be honest, this requirement is a bit “inhuman” because it was mentioned at the beginning of the article that the power of the front motor assembly is only 180 kW. In order to achieve this high performance, NIO electric drive R&D engineers had to install a rear motor with a peak power of 300 kW.

What does 300 kW mean? So far, there have been only two mass-produced motors in the world with a peak power exceeding 300 kW, one installed on the Tesla Model S Performance and the other on the Porsche Taycan Turbo S. The NIO ET7 is the third one.## “Integrated Electric Drive & Silicon Carbide Electronic Control”

The three motors have one common feature: they are all self-developed by the automakers, instead of being purchased from motor suppliers such as Bosch, BorgWarner, or Jingjing. The reason is simple: such ultra-high-performance motors cannot be purchased on the market, and self-development is the only way out.

Customers are always the most demanding and “right” in the world. If you ask customers what a “good” electric drive assembly is, they will say, “We hope that there is a car that can accelerate faster than Bugatti and is more energy-efficient than Tesla.” Engineers are already under great pressure, saying, “It would be even better if the cost is lower than that of Wuling Hongguang MINI.”

This is certainly not realistic, but high performance, low energy consumption, and low cost are always the eternal pursuit of consumers for powertrain.

As for the picture mentioned earlier, the NIO ET7 is the only model in the chart that uses both a permanent magnet motor and an induction motor.

The two major factions of pure electric motors are: permanent magnet motors have high efficiency at low speeds (the principle is that no reactive magnetic current is needed on the rotor side and there is no loss on the rotor side), and they are more energy-efficient; induction motors are suitable for high-power scenarios (the principle is that the rotor side structure has high strength, and there is no large reverse electromotive force produced by the permanent magnet), but their energy consumption is not friendly enough.

Therefore, a feasible solution is to install a permanent magnet motor and an induction motor on a full-drive model, and use the permanent magnet motor for daily commuting while the induction motor for sporty driving. At low speeds, this is an energy-saving and smooth front-drive car, and at high speeds, it transforms into a sporty and aggressive all-wheel drive car.

In fact, many pure electric models are already designed like this, including NIO ES6, new ES8, EC6, Tesla Model 3/Y, and Volkswagen ID. full-drive model.

For example, the new ES8 uses a combination of a front 160 kW permanent magnet motor and a rear 240 kW induction motor, but the ET7 has been upgraded comprehensively: the front motor has been upgraded to 180 kW, and the rear motor has been upgraded to 300 kW.

Higher power brings higher performance, but it also means higher energy consumption. However, as we mentioned earlier, customers not only require high performance but also low energy consumption.

Silicon Carbide is the weapon that NIO ET7 uses to reduce energy consumption.The CEO of Weiran Power, Pengxiang Zeng, introduced the advantages of SiC power modules over traditional silicon-based (IGBT) modules in a post on the NIO App yesterday:

-

High-temperature resistance, with over 30% increase in maximum current capacity in the same volume

-

Wider range of voltage, with good extension compatibility

And most importantly: faster switching speed, significantly reduced comprehensive losses, and 4%-6% increase in endurance.

However, Zeng did not mention the shortcomings of SiC. Due to the maturity level of the industry, the cost of SiC is much higher than that of IGBT, which directly leads to the fact that no pure electric vehicles under 200,000 RMB can afford SiC modules, and few vehicle companies in this camp can afford it.

Even if we look at the high-end market, except for old players of pure electric vehicles like Tesla and BYD, the pure electric car with the lowest price of SiC modules is the Porsche Taycan, with a starting price of 888,000 RMB. The introduction of the ET7 has lowered the experience threshold of SiC by 440,000 RMB.

This is certainly not easy. If you combine the three things of 300 kW motor, front permanent magnet and rear induction, and SiC, Li Bin’s image in the NIO electric drive engineering team is likely to be “ugly”, but he is also on the same side as consumers.

In addition, it should be mentioned that Li Bin and Qin Lihong expressed their attitude that “NIO will not make two-wheel drive vehicles” at the NIO electric drive workshop in 2019 and 2020.

If you carefully analyze the NIO electric drive combination, you can also find some clues.

Although NIO, Tesla’s Model 3/Y, and Volkswagen ID. series have the same combination of permanent magnet and induction electric drive, in fact, NIO is completely different from the latter two.

Both the Model 3/Y and the VW ID. series are front induction and rear permanent magnet motor combinations, because the product line also plans for rear-wheel drive models.

A permanent magnet motor is a better choice for a rear-wheel drive model in terms of energy consumption and cost requirements.

Both the NIO SUV series and ET7 are front permanent magnet and rear induction combinations. If two-wheel drive models are forced to be produced, there will either be low-power front-wheel drive monsters or rear-wheel drive models with relatively high power consumption. It is not good either way.

This kind of planning means that NIO probably did not intend to make two-wheel drive models from day one.

Therefore, it is not too difficult to pile up a high power output (of course, it is not that simple…). What is difficult is the “technical” high power output, balancing high power output, cost, experience, especially low energy consumption. This is the “good” electric drive system.

Most of the time, you can’t have your cake and eat it too, but most of the time, consumers often want it all.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.