Steering-By-Wire System

The steering system is an important component of a car, and its performance directly determines the handling performance of the car. With the emergence of new technologies, the steering system has been constantly updated. From the original purely mechanical steering system, to hydraulic power steering (HPS), electro-hydraulic power steering (EHPS), and now the widely used electric power steering (EPS), the steering system is continuously developing towards being more sensitive, more reliable in structure, and consuming less power.

With the rise of autonomous driving in recent years, a steering system is required that can operate independently according to algorithms, without relying on human power. At the same time, it is required to have a shorter response time and more precise steering. Considering the limitations of EPS due to installation space, force transmission characteristics, and angle transmission characteristics, a new type of steering system emerged – the Steering-By-Wire System (SBW).

The SBW completely eliminates the mechanical connection between the steering wheel and the steering wheel, and the steering information transmission and control are completely realized by electrical signals.

The advantages of SBW are many, such as saving space, lightweight, and being able to completely isolate road surface bumps or partially transfer road information as needed, allowing the driver to obtain a good feel of the road. Also, the force transmission characteristics and angle transmission characteristics can be freely designed according to the driver’s needs and preferences, making the driving experience more abundant.

Because the layout of mechanical connection doesn’t need to be considered, the vehicle design is more flexible, and the possibility of column intrusion when a collision occurs is reduced, enhancing the safety of the vehicle. In addition, the SBW can completely achieve steering control independent of the driver, which is very suitable for autonomous driving and is considered one of the auxiliary technologies for fully autonomous driving.

Compared with EPS, the biggest difference of SBW is to cancel the physical connection between the steering wheel and the steering wheel. Its steering torque is completely dependent on the output of the lower steering actuator, and the direction and size of the output force of the lower steering actuator depend on the control signals given by the control algorithm, which means that the steering is completely controlled by the control algorithm. The algorithm can rely on the input signal of the steering wheel or independently steer according to the requirements of autonomous driving.

Comparison between EPS and SBW:

The principle of EPS is that when the driver turns the steering wheel, the torque sensor precisely records the steering torque and transmits it to the electronic control unit. The electronic control unit calculates the required steering assistance and controls the servo motor to work, thereby achieving power assistance.

The principle of EPS is that when the driver turns the steering wheel, the torque sensor precisely records the steering torque and transmits it to the electronic control unit. The electronic control unit calculates the required steering assistance and controls the servo motor to work, thereby achieving power assistance.

Essentially, EPS still relies on human steering signals, and the system only provides power assistance. However, SBW steering signals come from algorithms, and input signals from humans are only references.

Compared with its brother, the wire-controlled throttle, the wire-controlled steering has always been low-key. Unlike its sibling, which has an aura of its own (energy recovery can increase cruising range), the wire-controlled steering is like an introverted child at home, rarely mentioned.

So, what is the reason why wire-controlled steering has not developed rapidly? Let’s start with the history of wire-controlled steering.

The Origin of Wire-Controlled Steering Technology

Wire-controlled steering is not a new technology. It has been widely used in airplanes. Since the steering mechanism and the actuation mechanism (servo) of airplanes are separated by a long distance, it is not suitable to use mechanical structures for long-distance transmission. In addition, the requirements for steering operations are multidirectional in space, and high flexibility is required, hence the wire-controlled steering is developed to meet this demand.

In passenger cars, European and American companies started researching wire-controlled steering technology early on. In the 1950s, TRW and German Kasselmann proposed the concept of using SBW in cars, which replaced the original mechanical connection between the steering wheel and the turning wheel with electric signals. However, that remained just a concept. The development of automotive steering devices has now reached the point of electronic power steering, which is already very mature and reliable. Therefore, automakers have little interest in wire-controlled steering.

With the rapid development of self-driving technology, automatic driving technology requires the ability to easily implement active steering functions, and faster response speed than EPS. This creates an opportunity for the practical development of wire-controlled steering technology. Steering suppliers and vehicle manufacturers have begun to develop their own wire-controlled steering systems.

As early as 1990, Mercedes-Benz started researching front-wheel wire-controlled steering, and applied its wire-controlled steering system on the F200 concept car in 1996. At the Frankfurt Motor Show in September 2000, Mercedes-Benz and ZF jointly exhibited wire-controlled steering systems, and the F400 Carving exhibited at the 2010 car show also applied wire-controlled steering systems.

Major automakers and research institutions around the world, including Daimler-Chrysler, BMW, ZF, DELPHI, TRW, JTEKT, Japan National University, and Honda Motor Company, have conducted in-depth research on automotive wire-controlled steering systems.

In Europe, at the 71st Geneva International Motor Show in 2001, the concept car “FILO” designed and developed by Bertone adopted a wire-controlled steering system, which eliminated the steering wheel and used a joystick for steering operations.Concept car BMWZ22 from BMW with the application of steer-by-wire technology has reduced the range of steering wheel rotation to 160 degrees by leveraging the adjustable transmission ratio, greatly reducing the operational angle for the driver in emergency situations. Citroen’s C-Crosser off-road concept car also adopts steer-by-wire system.

With the popularity of autonomous driving, various suppliers have been showcasing their steer-by-wire prototypes in various occasions in recent years.

On February 25th, 2016, at the Arvidsjaur winter test track in Sweden, a prototype vehicle displayed by ZF and TRW Automotive, which had been merged, had the ZF TRW front and rear axle steering system that can achieve pure electric control. This kind of steer-by-wire function is still in the experimental stage for prototype vehicles.

At the 2017 Frankfurt International Motor Show in October, ThyssenKrupp presented SBW hardware, a retractable steering column, and an autonomous driving switching concept. Bosch Automotive Systems has cooperated with Audi to develop steer-by-wire products and showcased the Audi A3 steer-by-wire product nationwide in eight cities in 2018.

JTEKT displayed a steer-by-wire demonstration machine at the 2018 Beijing Auto Show, attracting a lot of attention. In the 2021 Shanghai Auto Show, Schaeffler presented a range of innovative solutions for intelligent driving and future urban transportation, including the intelligent steer-by-wire angle module (iCorner).

Japan Koyaba (one of Japan’s four major bearing manufacturers) and Nissan have also cooperated to develop steer-by-wire systems, which is the only steer-by-wire system applied to the production of the Infiniti model.

Debate over Steer-by-Wire Technology

Although the development of steer-by-wire technology is accelerating, suppliers’ attitudes towards steer-by-wire are not entirely uniform, which can be seen from the debate between two steering suppliers.

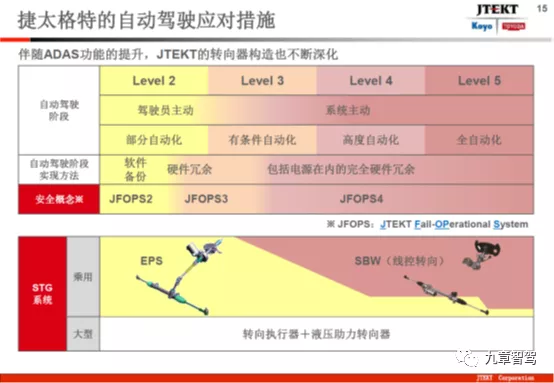

JTEKT, ranked first in the world in steering system suppliers, and NSK, ranked third in electric steering system suppliers, not only affect the technical direction of their own companies but also have a profound impact on other global suppliers.

JTEKT believes that steer-by-wire systems will inevitably replace current electric steering systems in order to achieve autonomous driving in cars.

NSK, however, believes that steer-by-wire technology is too expensive and that today’s electric steering systems can fully meet the needs of autonomous driving in cars. Just like the Lincoln MKZ, which is commonly used to test and develop autonomous driving technology, it uses EPS.

Tetsuo Agata, JTEKT President, is very optimistic about this technology, “We are studying steer-by-wire technology, which is important for autonomous driving systems, and can even be said to be necessary.” Agata said to Automotive News in July 2015.”Jet planes have adopted fly-by-wire steering systems,” he said. “The promotion of automatic driving systems is accelerating. If we have the ability to get rid of the mechanical linkage between the steering wheel, we can have more play in car design. In the future, wire control technology will be a basic configuration. Now, we are developing a wire-controlled steering system.”

Supporters of wire-controlled steering technology believe that this technology will enter the market together with automatic driving. The wire-controlled steering system does not require a steering column, so it can increase space, reduce weight, lower costs, and improve steering accuracy, bringing more possibilities for flexible design.

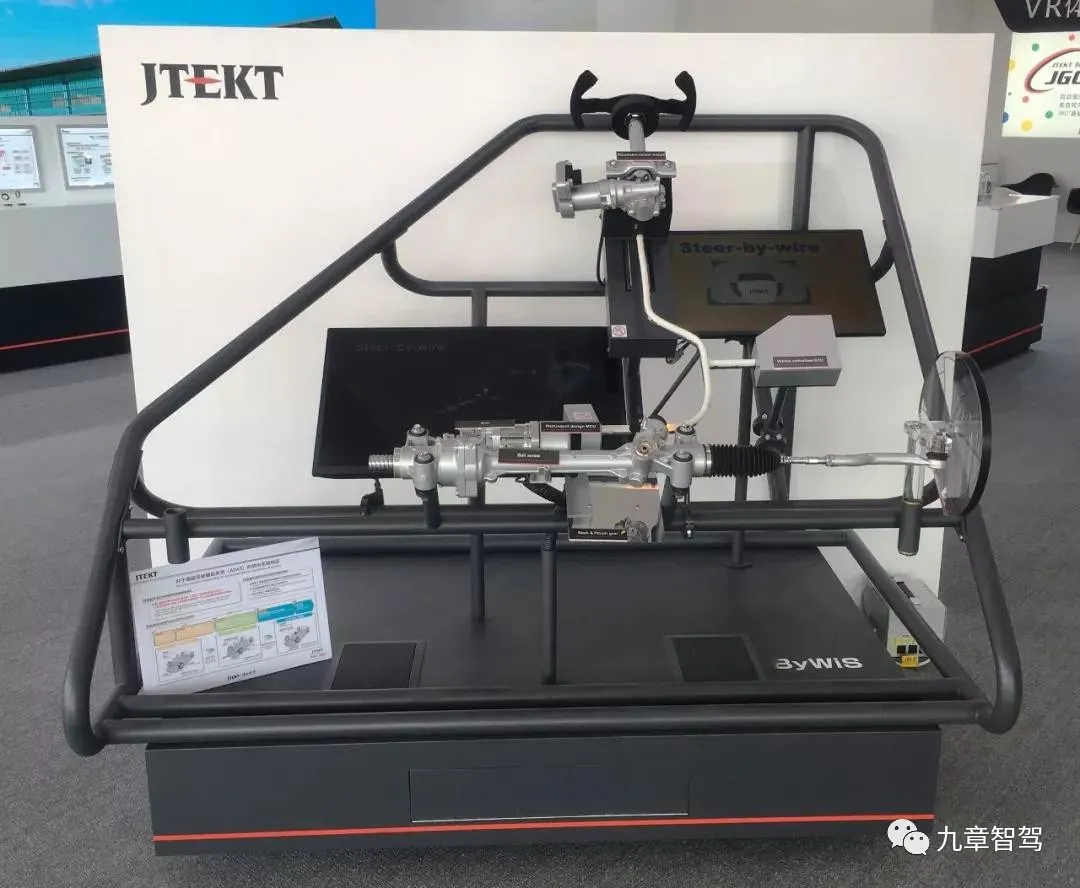

Under this idea, JTEKT is dedicated to researching and developing wire-controlled steering systems. At the Beijing Auto Show on April 27, 2018, JTEKT launched a series of “black technology products,” including automatic driving technology, future steering technology, and e4WD motors for hybrid and electric vehicles, with the theme of “No.1 & Only One – Moving Towards a Better Future.” The most eye-catching product exhibited by JTEKT at that time was the SBW demonstrator.

This demonstration machine replaced the traditional mechanical connection method, and the steering wheel and steering gear were connected by wires, which can provide higher driving freedom and achieve a more ideal steering experience:

1) The steering wheel control is more free; 2) The vehicle steering instructions are more free; 3) The feedback of the driving experience is more free.

At the Shanghai International Auto Show in 2019, JTEKT’s exhibition theme was “Just take a seat. Have fun. Enjoy your ride.” At this exhibition, JTEKT showcased its efforts and achievements in the “new four modernizations” of automobiles (networked, automated, shared, and electric) through press releases and on-site exhibits.

It can be seen that JTEKT is dedicated to showcasing “high efficiency, lightweight” automotive steering systems, with EPS+SBW supporting JTEKT’s ambitions in the “new four modernizations” of passenger cars. As automatic driving moves from L3 to L5, JTEKT believes that wire-controlled steering will gradually establish a dominant position, which is consistent with JTEKT’s development strategy for wire-controlled steering.

At this exhibition, JTEKT also showcased model cars equipped with line-control steering. The demonstration showed that line-control steering can increase the freedom of steering wheel layout, and achieve safe and comfortable turning through angle control, even in the presence of road shocks, providing a natural steering sensation.

At this exhibition, JTEKT also showcased model cars equipped with line-control steering. The demonstration showed that line-control steering can increase the freedom of steering wheel layout, and achieve safe and comfortable turning through angle control, even in the presence of road shocks, providing a natural steering sensation.

In addition, JTEKT has designed a retractable-column module that automatically retracts the steering wheel in autonomous driving mode, providing more spacious driving space for the driver.

Despite JTEKT’s ongoing efforts in line-control steering, opponents have sufficient reasons to question the advantages of the system, one of which is whether people are willing or trust artificial intelligence to handle such an important operation.

Distrust of line-control steering stems from doubts about autonomous driving. With the development of autonomous driving technology, it is believed that its high reliability and safety will eventually win the trust of users. Besides, even if autonomous driving becomes prevalent in the foreseeable future, it is estimated that automakers will still retain manual driving functions.

At the technical level, the line-control steering system of the Infiniti Q50 also comes equipped with a redundant mechanical steering system to ensure reliability, which led to objections from NSK.

“Even if a line-control steering system is used, they still need to equip a redundant mechanical system in case something unexpected happens,” said NSK CEO Toshihiro Uchiyama at a media event. “Unless there are new safety requirements, or there is a revolutionary improvement in the reliability of the line-control steering system.”

Uchiyama believes that if existing technology can meet the requirements, there is no need to spend a huge cost pursuing new technology. “We believe that line-control steering cannot meet the requirements of autonomous driving,” Uchiyama said. “Our electric steering system is more reliable and provides better steering feeling.”

Some analysts and NSK agree that at least in the current development stage, redundant systems must be designed for functional safety, which will bring additional costs and hinder the application of line-control steering technology.

Eric Fedewa, head of IHS Supplier Business, also said that based on currently tested autonomous driving cars, it is not always necessary to remove the metal steering column.

It is understood that the unit price of EPS is currently around 1,500 yuan. If the line-control steering system is estimated based on the EPS, the expected unit price would be around 4,000 yuan due to the small application scale in the short term. With the expansion of the scope of application, the unit price is expected to gradually decrease to around 3,000 yuan. For automakers who are penny-pinching, a difference of a few thousand yuan cannot be ignored.Do not look forward to the steer-by-wire system, because the driver can’t feel the steering resistance and vibration transmitted from road without mechanical connection. Therefore, a force feedback needs to be applied to the steering wheel to provide road information. Although this provides more possibilities for designers to filter and transmit information according to demand, it also increases complexity and reduces reliability. However, these issues do not need to be considered on autonomous vehicles because they do not require road sense.

Overall, suppliers represented by NSK have doubts about steer-by-wire, mainly focused on two aspects: first, to ensure reliability and simulate road feel, mechanical or electrical redundancy systems and road information feedback systems must be designed, adding extra cost which hinders the large-scale application of steer-by-wire. Second, existing electric power steering systems are already very mature, reliable, low-cost, and can meet the requirements of autonomous driving. Is it worth it to develop complex steer-by-wire just to reduce a few thousand kilograms of weight and increase driver’s space?

Although NSK clearly stated that it does not support steer-by-wire, this attitude will not prevent NSK from developing its own SBW. There are also patents on steer-by-wire related to NSK on patent websites, indicating that although NSK is vocal, it is still honest.

Other suppliers and automakers treat steer-by-wire with a clear attitude, that is, to develop boldly and apply cautiously. Many suppliers, such as Bosch, ZF, NTN, Schaeffler, and ThyssenKrupp, are developing their own steer-by-wire technology and actively applying for patents.

Some universities and research institutions in China such as Geelyn University, Shanghai Jiao Tong University, Tongji University, Beijing Institute of Technology, Qingdao University of Science and Technology, Jiangsu University, and Wuhan University of Science and Technology, are doing preliminary research on steer-by-wire, while reports on research by automakers and component companies are rare.

Changan Automobile used Changan CX30 as a platform and converted the traditional hydraulic steering system into an SBW system, becoming the first passenger vehicle equipped with an SBW steering system for field testing in China.

Production models apply steer-by-wire very cautiously.Although both suppliers and automakers are vigorously developing their own steer-by-wire technology and showcasing their technological strengths through concept cars and other platforms to avoid being left behind in the future of autonomous driving, the application of steer-by-wire technology in production models appears to be much more cautious.

Infiniti is undoubtedly the first person to eat the crab in this regard and is currently the only one who has ever eaten the crab.

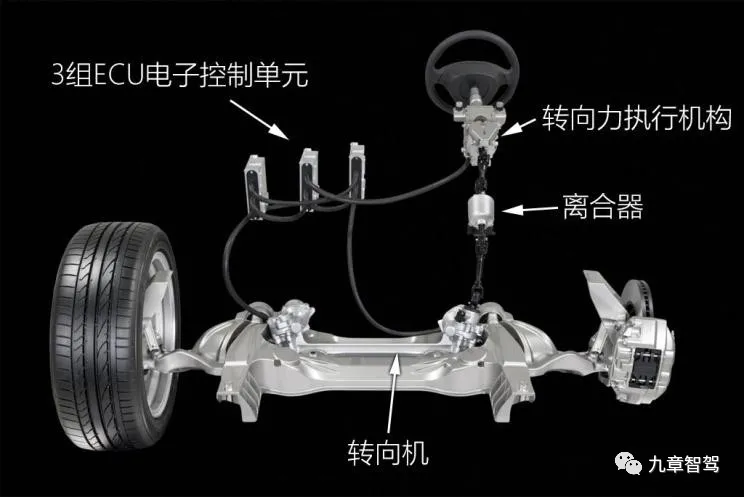

After more than 10 years of research and analysis in conjunction with Koyaba, Nissan launched the Infiniti Q50 with Direct Adaptive Steering (DAS) technology in 2014, becoming the first mass-produced vehicle equipped with this technology. Its greatest feature is that it changes the long-standing history of mechanical steering in the automobile industry.

The DAS system comprises of three ECUs, two steering motors, a feedback motor that simulates road feel, a sensor that obtains the steering wheel angle information, a torque sensor that obtains the road surface information, and a redundant mechanical steering mechanism (to increase reliability), whether the mechanical steering mechanism is operational is controlled through the engagement and disengagement of the clutch.

The principle of the DAS system is that three sets of ECUs generate control signals based on the signal of the steering wheel and the road surface information to control the three sets of motors. Two sets of motors control the turning angle and speed of the wheels, one set of motors simulate the feedback force of the road surface, and another set of mechanical redundant structures are kept as spare steering in case of failure.

Under normal circumstances, the clutch is disengaged. However, if the pipe column angle exceeds a certain limit, or the steering gear is blocked (such as on the side of the road), the clutch will temporarily engage. When two or more motors on the steering gear side work normally and one motor on the pipe column side works normally, the clutch remains disengaged; if the motor on the pipe column side fails, and any one motor on the steering gear side fails, the clutch engages.

Under normal circumstances, two ECUs + motors work in parallel, working in servo control mode, In the fault mode, the clutch engages and the torque sensor signal is collected to achieve the basic power-assisted function of traditional EPS.

However, within a little over a year after its launch, the DAS system proved that the caution of suppliers towards steer-by-wire technology was justified, and it also indicated that the road to maturity for new technologies is undoubtedly a tortuous one.From July 4th, 2016 Infiniti has announced the recall of some Dongfeng Infiniti Q50L and Infiniti Q50 cars, according to the notice, in some extreme circumstances (such as low voltage start), the error of the signal positions of the two motors or the failure to absorb the clutch may cause malfunctions.

Due to deviation in the control unit program of the Line Control Active Steering System, when the engine starts at low battery voltage, the control unit may make an erroneous judgment of the steering wheel’s angle, resulting in a difference between the rotation angles of the steering wheel and the wheels, even if the steering wheel is turned to the neutral position, the wheels may not return to the straight position, posing a safety hazard.

From the content of the notice, some people speculated that the problem may be due to the absence of an absolute angle sensor on the steering gear assembly, in order to achieve angle servo function, it is necessary to use two angle signals of the brushless motors respectively to estimate the rack position, and use these two redundant signals to perform rationality check and then as the rack position sensor signal feedback.

If the rack position signals obtained by the two motor positions do not match, a fault is output, notifying the ECU on the steering column side to absorb and release the clutch, operating in EPS mode, only in some extreme circumstances(such as the low voltage start mentioned in the recall)will the simultaneous occurrence of errors in the two motor position signals or the failure to absorb the clutch cause malfunctions.

In addition, when the engine starts at low battery voltage, the control unit cannot make a correct judgment of the steering wheel angle, causing a steady-state error between the servo-controlled steering wheel control input and the wheel output angle, which may be due to measurement errors in the sensor or problems with the ECU power supply resulting in the wheels not returning to the straight position even when the steering wheel is turned to the neutral position.

After the recall, Dongfeng Motor Corporation and Nissan (China) Investment Co., Ltd. have upgraded the DAS system control unit program for all targeted vehicles free of charge to eliminate safety hazards.

However, according to Mr. Liang Xuchen, a 19-year Q50L car owner, the wire-controlled steering system still has many shortcomings, mainly in three aspects:

First, if the steering wheel is square, the car will go to the left, and the car can only run straight if the steering wheel is slightly turned to the right. Sometimes the problem is severe, and sometimes it’s normal.

Second, the steering wheel assist is sometimes light and sometimes heavy. The direction is not in line with the hand, and the steering assist does not follow the driver’s logic. For example, the driver can clearly feel that when the steering wheel is held, the car’s assist and center of gravity are deviating to the left.

Third, the steering will sometimes suddenly deviate significantly in one direction, but can be pulled back, and the system will self-correct.

This netizen mentioned that after multiple calibrations at the 4S shop, the steering return and normal driving will be good for a period of time, but it will return to the old situation before reaching 1000 kilometers.This indicates that there are deficiencies in DAS system design, at least in three aspects: first, the direction is not correct, indicating problems with calibration and self-learning; second, the feedback logic is unreasonable, leading to abnormal motor action when simulating road feedback; and third, the steering motor has abnormal behavior.

The motor used to provide feedback on road feel can create a dragging sensation for the user. Imagine driving a car that constantly feels like someone is grabbing the steering wheel – not exactly a relaxed and comfortable driving experience, but rather quite frightening.

This system seems to have received mixed reviews from some professional vehicle evaluation institutions abroad. The following paragraph is from Autocar’s road test editor, Matt Prior:

“Infiniti’s Direct Adaptive Steering system is the smoothest and most responsive in its basic mode, but it becomes somewhat lethargic if you turn the wheel quickly. The center’s road feedback is sufficient, but some feedback in corners is insufficient, making it difficult to get a true sense of the road feel. While this filtering does smooth out some of the bumps on the road, the end result is unacceptable.”

The DAS system on the Q50 is close to the industry average, but still falls short of the high standards set by other steering systems. Compared to traditional steering systems, it is accurate unless extreme situations arise, but those who are looking for more playability are unlikely to choose this system. The Q50’s steering system has almost no really engaging features.”

These performances seem to be confirming NSK’s views that people have not yet experienced the driving experience enhancement provided by Direct Adaptive Steering, but have instead experienced the various defects caused by its immaturity.

However, problems discovered in mass-produced models often drive the development of technology towards maturity. Technologies often require continuous iteration before they can mature. From this perspective, Infiniti is a pioneer in the industry, and the problems encountered with the DAS system during actual operation will provide a reference for later manufacturers. This will help promote large-scale application of Direct Adaptive Steering, just like the DAS system itself, which has already been upgraded to its second generation, DAS2.0.

The Key to the Development of Direct Adaptive Steering

In order to gain a larger share of the future market, Direct Adaptive Steering not only needs to benefit from the trend of autonomous driving, but also needs to address the pain points that manufacturers such as NSK are concerned about.

The first is cost, because cost is a key factor in determining whether a product can be accepted by the market.

Currently, the reliability of the Direct Adaptive Steering motor and electronics is not high, and electronic components have not yet reached the level of reliability that mechanical components have. Ensuring that the system can still perform basic steering functions when electronic components fail is crucial in the practical application of Direct Adaptive Steering. This means that the system must first meet functional safety requirements.

The international standard ISO 26262 defines functional safety as “avoiding unreasonable risk caused by failures of electrical/electronic systems”. The standard aims to improve the reliability of electronic and electrical systems in road vehicles.In order to meet this standard, Infiniti has adopted a set of mechanical redundant systems, which means that an analog road feedback system has been added to the EPS. However, the cost is much higher than that of EPS.

Bosch advocates electronic backup redundancy. In Bosch’s view, only by completely canceling the mechanical connection between the steering wheel and the steering gear can it be considered true wire-controlled steering.

Bosch’s SBW arranges multiple sensors at the steering wheel to achieve input signal redundancy, and multiple motor+ECU systems are used to control redundancy in the steering mechanism. However, this method is equivalent to having two sets of duplicate steering mechanisms, and the cost will only be high rather than low.

The functional safety of the wire-controlled steering system requires a lot of redundancy design for the steering system, including chips, actuators, power supplies, hardware, and various control software, to prevent the overall steering function from malfunctioning due to local problems. How to reduce the rise in design and manufacturing costs while ensuring functional safety is a major challenge for designers.

Wire-controlled steering also faces a dilemma at present, that is, if it wants to simulate road feedback, it requires a complex force feedback motor, which not only costs much higher than EPS but also may not have better simulation effect than EPS.

However, if L4-level autonomous driving is truly achieved, when the steering wheel is redundant, it is not necessary to simulate road feedback at all. Is it worthwhile to develop a function that will not be used much in the future? Moreover, how to solve the contradiction between comfort and maneuverability by simulating road feedback, that is, the algorithm implementation of complex force feedback motors and steering execution motors, is not an easy task.

Because it is required to provide simulated steering feedback torque based on vehicle speed and driving conditions to achieve functions such as steering wheel return and driver feel, and to simulate real feel (mid-position, steering resistance, road condition feedback, etc.) without mechanical connection between the steering column and the steering gear, it is necessary to control the servo motor to provide force feedback to the driver based on the Vehicle Dynamic model and steering column model.

The technical difficulty of this part in terms of control strategy design, algorithm implementation and parameter calibration is not small, and it also requires effort to be done well.

From the feedback of Q50 drivers, it is obvious that the simulated road feel is not as real as traditional mechanical transmission, and the motor cannot simulate the direction kickback and small vibration caused by tire force. It is like a racing simulator that always fails to bring real driving feelings.

Perhaps the only highlight is the phrase that the car company promotes: “It can greatly reduce the steering wheel jitter caused by uneven road surfaces, thereby eliminating the interference of excessive road feedback on driving and bringing you a free and unrestrained driving experience.” However, only the car owner knows the real situation.With the development of autonomous driving, for Level 3 and above intelligent vehicles, partial or full control of the driver will be removed. Steer-by-wire technology is very suitable for autonomous driving. With the gradual maturity of steer-by-wire technology, the cost of electronic components and chips will decrease, reliability and processing power will greatly improve, and SBW will inevitably challenge EPS and achieve explosive development and usage.

When SBW arrives with autonomous driving, maybe we should discuss whether the steering wheel is useful and whether it will disappear.

Or it will become like the retractable steering wheel shown in the Audi RSQ concept driven by Will Smith in the movie I, Robot during autonomous driving. The steering wheel can be retracted to save space and provide a better driving experience, only extending when manual driving is required.

Or it might be like the TV show “Upload” premiered in 2020, with a joystick inserted into an interface, in which the vehicle is controlled like a video game. Maybe it will be a joy for gamers. In any case, the advent of SBW lays the technological foundation for these possibilities. Let us wait and see what the future of the steering wheel will be.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.