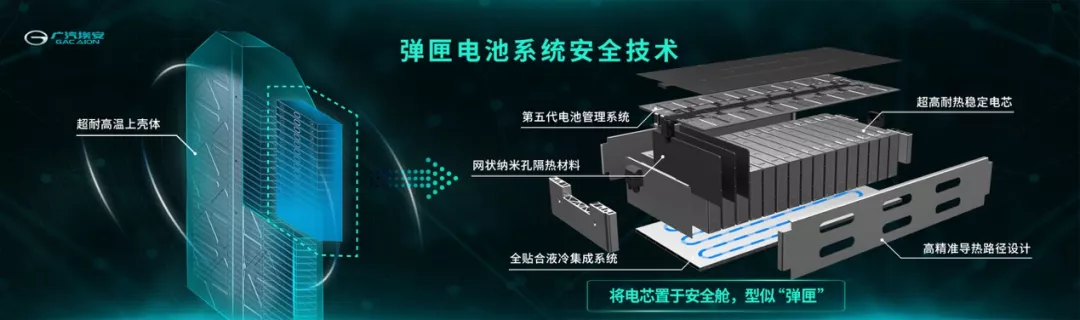

Introduction: For a new energy powertrain plant, battery technology and control technology have always been weaknesses. However, GAC Aion has turned them into strengths with the development of the bullet battery technology. This kind of technology research attitude and the spirit of promoting industry development is worthy of other brands to learn from.

In March of this year, GAC Aion officially launched the bullet battery and announced the needle-stabbing test results of the ternary lithium bullet battery. Today, GAC Aion announced the needle-stabbing test results of the lithium iron phosphate bullet battery.

With all the ternary lithium/lithium iron phosphate bullet batteries passing the needle-stabbing test, Qiu Liangping, the head of GAC Aion, summarized that the bullet battery will end the battle over battery safety routes and allow users to freely choose according to their actual travel needs.

Regarding the advent of bullet batteries and their demonstrative significance to the industry, another engineer from a new energy manufacturer stated, “Only technological upgrades are the key.”

Regarding the needle-stabbing test of GAC Aion’s ternary lithium bullet battery, we have reported on it before, and those interested can take a look at “Why does the cost of bullet batteries not increase but decrease?” This time we will take a look at the needle-stabbing test of GAC Aion’s lithium iron phosphate bullet battery.

Like the previous experiment, GAC Aion still sought a third-party organization – a team led by Dr. Liu Shiqiang, chief expert of the China Automotive Technology Research Center and one of the drafters of the national battery safety standards.

Compared with BYD’s self-led blade battery needle-stabbing test, GAC Aion’s third-party credible organization’s bullet battery needle-stabbing test is undoubtedly more valuable for the industry and users as a reference.

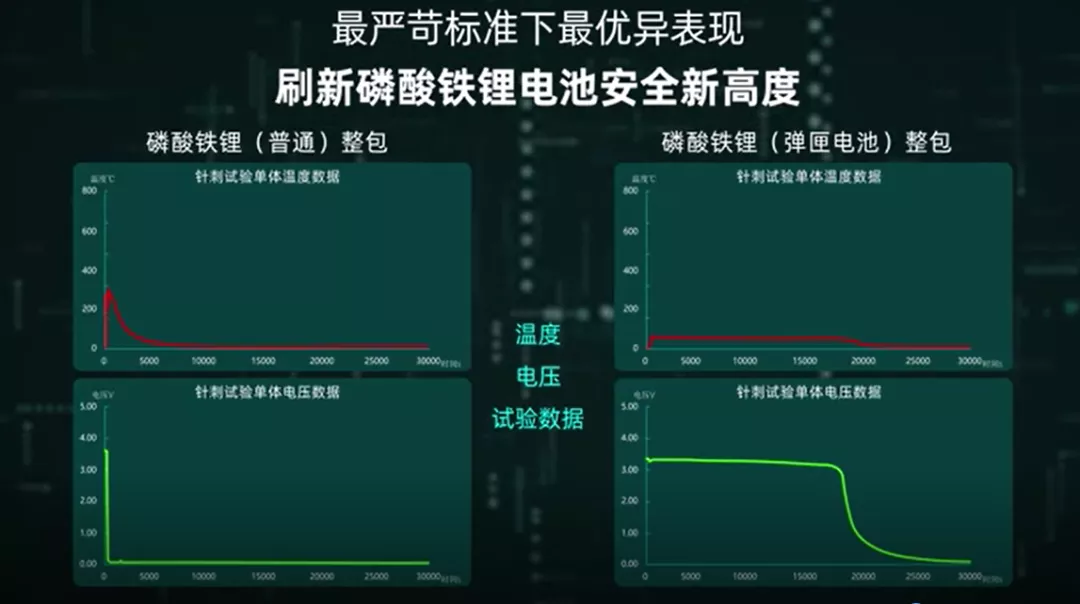

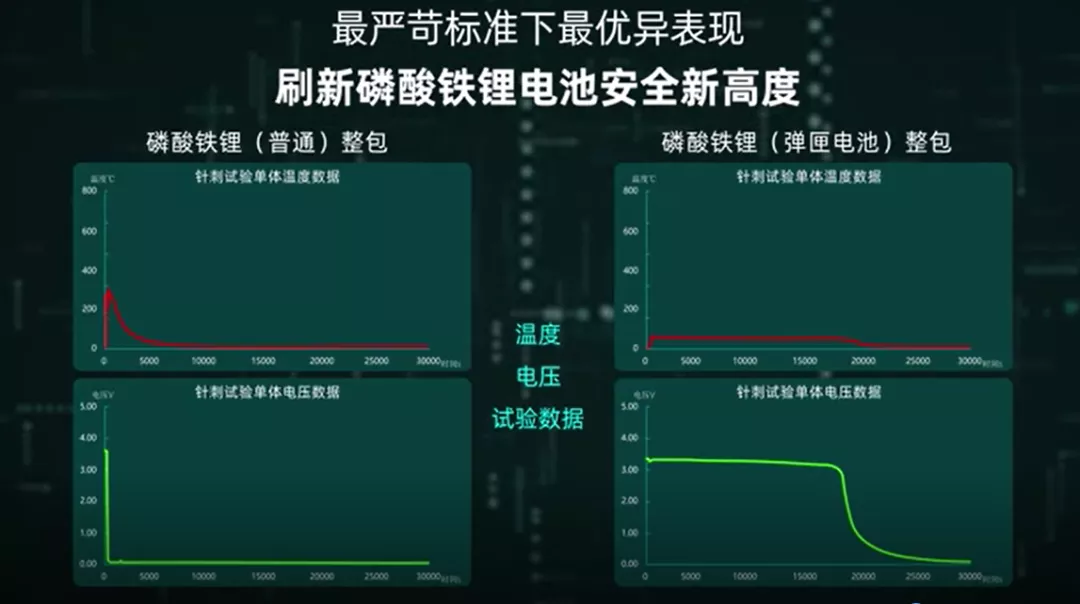

The specific test methods are basically the same as last time. Two battery packs – the lithium iron phosphate (ordinary battery) pack and the lithium iron phosphate (bullet battery) pack are used for needle-stabbing comparison tests.

Moreover, the most stringent test conditions are chosen, including selecting an 8-millimeter-thick steel needle and conducting the needle-stabbing test under 100% SOC.

Whether it is relying on third-party organizations or selecting the most stringent test conditions, GAC Aion hopes to convey the message that the bullet battery is “genuine.”

From the results, the lithium iron phosphate bullet battery has successfully passed the needle-stabbing test, with no smoke, fire, or explosion – three “nos,” and a maximum temperature of only 51.1 degrees Celsius.

As a comparison reference, the ordinary lithium iron phosphate battery pack also did not catch fire or explode, but it did produce smoke for about ten minutes, with a maximum temperature of 329.4 degrees Celsius.

We will now analyze the entire needle-stabbing process of GAC Aion’s lithium iron phosphate bullet battery:

In about 4 minutes, the pricked lithium iron phosphate (LiFePO4) magazine battery began to short circuit, with a slow increase in temperature and a slow decrease in voltage. At around 12 minutes, the temperature reached a maximum of 51 degrees Celsius, and then slowly decreased. At around 20,000 seconds, the voltage of the LiFePO4 magazine battery began to drop dramatically, and the temperature accelerated towards “room temperature”.

Looking at the ordinary LiFePO4 battery pack, the pricked battery cell began to heat up rapidly and the voltage began to drop within about 2 minutes. At around 6 minutes, the temperature reached a maximum, and the voltage dropped rapidly to zero. By around 10,000 seconds, the single cell temperature dropped to “room temperature”.

Comparing the two LiFePO4 battery packs, neither caught fire or even exploded. The ordinary LiFePO4 battery pack only emitted smoke, while the magazine battery was very quiet.

Regarding the results, we are not surprised that the tri-fold lithium-ion / LiFePO4 magazine battery passed the needle prick test, and it is natural that the LiFePO4 magazine battery did as well.

However, both the tri-fold lithium-ion and LiFePO4 magazine battery were able to pass the needle prick test, which prompts us to start thinking that the emergence of the magazine battery implies that there is no more safety debate in the Lithium-Ion / LiFePO4 battery industry?

Guangqi EAQP’s Qiu Liangping said, “We can proudly say that the magazine battery is currently the only technology in the industry that can simultaneously improve the safety of both lithium-ion and LiFePO4 batteries. Its appearance will end the debate over which battery to choose for a specific travel need, and allow users to choose freely.””Allowing users to freely choose based on their actual travel needs” means using different types of batteries in different scenarios. For example, B-end travel market is better suited for lithium iron phosphate batteries, while C-end private user market is better suited for ternary lithium batteries. As for safety, with the support of magazine battery, it is not a problem.

For this reason, GAC Aion has also made a simple analysis of the basic performance of ternary lithium batteries and lithium iron phosphate batteries.

In terms of weight, if both have a range of 600 kilometers, the entire ternary lithium battery pack will be 100-150 kilograms lighter than the lithium iron phosphate battery pack, equivalent to the weight of 1.5-2 adults. The advantages of ternary lithium battery are huge.

At the same time, the lightweight of ternary lithium batteries will significantly improve the handling of electric vehicles and reduce the load on the chassis. According to our observation, there have been multiple driving accidents with the Han EV, directly related to the weight of blade batteries and insufficient suspension strength.

In addition, GAC Aion also revealed that the endurance of ternary lithium batteries in low temperature environments is about 10% higher than that of lithium iron phosphate batteries, and they will achieve longer endurance performance in winter.

Of course, ternary lithium is not omnipotent. Its cycle life is only about 2,000 times, which is enough for C-end private users, but insufficient for B-end travel market.

In addition to having an ultra-high cycle life of more than 4,000 times, lithium iron phosphate batteries also have a lower cost and are suitable for B-end customers with high-frequency charging needs.

In fact, with the development of technology, these parameters are changing, especially ternary lithium, whether it is energy density or life, has a lot of room for improvement, while lithium iron phosphate has peaked in all aspects, and its biggest advantage is its low cost.

Regarding the safety controversy of ternary lithium/lithium iron phosphate batteries inside and outside the industry, we have always felt that there are problems, which will only make consumers misunderstand ternary lithium batteries and benefit a certain manufacturer.

We believe that there is no absolutely safe battery, only relatively safer batteries. So which type of battery is safer? First-line and mainstream power battery manufacturers’ batteries are safer, while second and third-line batteries have relatively no safety guarantee, which has nothing to do with the materials of ternary lithium and lithium iron phosphate.

In addition to looking at the batteries, we also need to look at the battery pack system. The design of mainstream and large manufacturers’ battery packs is more exquisite and generally has quality assurance.

For a new energy main engine manufacturer, battery technology awareness and control technology have always been short boards, but GAC Aion has turned them into strong points through magazine batteries. This kind of technical research attitude and spirit of promoting industry development is worth learning for other brands.

On May 13th, GAC Aion announced the signing of a framework agreement on battery safety-related cooperation with the Battery Safety Lab of Tsinghua University, and Beijing Shengke Energy Technology Co., Ltd. The contents of the agreement include the collaborative development of battery safety technology, the realization of full-cycle, dendrite-free lithium supercharging, battery cloud-based big data and intelligent operation and maintenance technologies for power battery safety.

On May 13th, GAC Aion announced the signing of a framework agreement on battery safety-related cooperation with the Battery Safety Lab of Tsinghua University, and Beijing Shengke Energy Technology Co., Ltd. The contents of the agreement include the collaborative development of battery safety technology, the realization of full-cycle, dendrite-free lithium supercharging, battery cloud-based big data and intelligent operation and maintenance technologies for power battery safety.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.