*Author: Michelin

When it comes to the relationship between carbon neutrality and cars, the first thing you might think of is “new energy vehicles”.

However, if someone tells you that producing new energy vehicles will definitely achieve carbon neutrality, that’s an absolute lie!

Just as carbon dioxide is not only the gas we exhale but also runs through our daily lives, carbon emissions and cars are not just about exhaust emissions.

So what is the relationship between carbon neutrality and cars?

Low-carbon and Environmental Protection, Not Just Environmental Protection Alone

Carbon neutrality, a topic that is closely related to climate change and our living space, has lately been extremely hot. China, as a “carbon emission giant” where 85% of its energy comes from fossil fuels such as coal, natural gas, and petroleum, has set the goal of “peak carbon dioxide emissions by 2030 and carbon neutrality by 2060”.

Under this goal, motor vehicles, which account for 18% of carbon emissions, naturally become the primary focus of low-carbon emissions reduction.

Reducing carbon emissions not only reduces greenhouse gases and prevents further deterioration of the global climate, but also provides a new driving force for the automotive industry. When traditional fossil fuel cars with a hundred-year-old history have become mature, the global promotion of new energy vehicles provides an opportunity for car companies to overtake in the curve and seize their own position in the field of clean energy vehicles, making it the mainstream trend in the current development of automobiles.

It can be said that carbon neutrality gives electric cars, which were once defeated by internal combustion engine cars a hundred years ago, a chance to turn around and become the mainstream trend in the current development of automobiles.

Carbon Trading, the First Step to Carbon Neutrality

Under the trend of low-carbon emissions reduction, countries have introduced corresponding constraints policies. Recently, it has even been reported that “FAW Volkswagen spent 435 million yuan to purchase carbon credits from Tesla”.

Why did FAW Volkswagen purchase carbon credits from Tesla?

This is because China currently implements a “double credit” management system for car companies: if car companies produce more high fuel consumption fossil cars each year, their credits will be negative, and they can only make up for their credit gap by purchasing carbon credits. Conversely, the more new energy vehicles that car companies produce, the more credits they will receive.

Therefore, although FAW Volkswagen, which produced more than 2 million vehicles in China last year, has a strong “mass foundation,” the vast majority of them are fossil cars, and under the scoring rules of the new energy vehicle credit management system, their credits are naturally a big negative number. In contrast, Tesla, whose entire product line consists of pure electric cars, has a new energy vehicle proportion of nearly 100%, allowing for abundant carbon credits to be sold.Actually, this is not the first time for Tesla to sell carbon credits. In 2020, Tesla’s net profit for the whole year was $721 million, and the revenue from selling carbon credits reached $1.58 billion. Deducting this revenue, Tesla’s pure profit from selling cars last year was negative, not making money. No wonder Tesla has earned the nickname “seller of charcoal” in China.

The carbon credit system as a management tool has enabled car manufacturers to rapidly, thoroughly, and heavily invest in the electrification transformation.

On this road, currently most car companies choose the pure electric vehicle route, replacing engines with lithium batteries and electric motors; there are also a few like Toyota who insist on the fuel cell route, using cleaner hydrogen as the power source for vehicles; and some companies, such as Bosch, choose a “technology-neutral” route for diversified powertrain systems: in the passenger car field, through electrification technologies such as electric bridges and 48V systems, pure electric private vehicles can perform better; in the commercial vehicle field, by providing fuel cell technology and cooperation with Chinese local enterprise Qingling Motors, etc., the industrialization process of fuel cells in China is being promoted.

Different routes are determined by the difficulty of achieving them at the current stage, but they all have the same purpose, which is to help the Chinese automobile industry achieve carbon peak by 2028 in advance and ultimately achieve low-carbon or even zero-carbon emissions during the automotive use stage.

Only new energy vehicles are far from enough

Of course, electrification technology is only one means of energy conservation and emission reduction for cars. The carbon neutrality for cars requires more than just new energy vehicles.

At present, as fossil fuels account for over 70% of the national power generation in China, and some hydrogen is still manufactured by decomposing fossil fuels, new energy vehicles simply shift the carbon emissions produced during the use phase to the power generation phase, but they still require consumption of oil and coal, which cannot achieve true zero-carbon emissions.

Even when electric vehicles are fully charged by wind or photovoltaic power generation, and the hydrogen for fuel cell vehicles comes solely from water electrolysis, there is still a possibility of exceeding carbon emissions during the production, transportation, and raw material utilization processes.

Imagine a green and environmentally-friendly new energy vehicle. If the carbon emissions from the production factory are seriously exceeded, or if it is transported by a fuel-burning cargo ship from overseas, how much carbon emissions will be generated during this process?

Tesla, which produces pure electric vehicles and advocates for clean energy development, faced a problem in 2018 when the company was fined $139,500 by regulatory authorities due to abnormal emissions of nitrogen oxides at its Fremont factory in the United States.

Tesla, which produces pure electric vehicles and advocates for clean energy development, faced a problem in 2018 when the company was fined $139,500 by regulatory authorities due to abnormal emissions of nitrogen oxides at its Fremont factory in the United States.

As a result, an increasing number of companies are proposing the concept of carbon reduction throughout the entire life cycle of automobiles. More and more companies are expanding the scope of carbon neutrality from new energy vehicles to the production process, even including factory workshops, offices, and logistics, all of which require reducing carbon emissions.

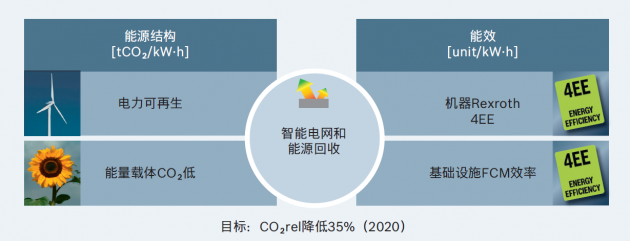

As a pioneer in industrial carbon neutrality, Bosch achieved its carbon neutrality goal in over 400 global business locations last year, becoming the first large-scale industrial company in the world to achieve carbon neutrality. The experience and technological path of carbon neutrality can also be applied to China, helping Chinese companies reduce carbon emissions during production.

Bosch has set a goal to “reduce carbon dioxide emissions by 15% from suppliers to customers throughout the entire value chain by 2030, with a cumulative reduction of 67 million tons.” At the Bosch (China) headquarters in Shanghai, we can see the low-carbon office facilities that were “embedded” ten years ago. The ground source heat pump that goes deep underground by 120 meters and hundreds of photovoltaic panels on the roof are all environmentally friendly measures that this company has taken to reduce carbon emissions.

The Bosch Climate Solutions division, established in 2020, has launched a smart energy management platform that combines carbon reduction technology with Industry 4.0, and the platform tracks and controls the power consumption of each machine through cloud-based software solutions, directly saving energy and reducing on-site workload.

Porsche’s carbon-neutral goal is to “achieve carbon neutrality in the entire value chain by 2030 by requiring suppliers to use sustainable energy sources in the production process and reduce carbon emissions.” Through the use of renewable energy and biogas, Porsche’s production base has achieved carbon neutrality in the production process this year.

Ford’s carbon reduction targets are also focused on the three areas of automobile exhaust emissions, enterprise and factory facilities, and supply chain. At the beginning of the 21st century, Ford aimed to reduce carbon emissions by reducing water usage in automobile production, and at present, water usage per car has been reduced by 72%, which has cumulatively reduced the amount of water that can fill 15,000 Olympic-sized swimming pools.

Last Words

For China’s auto industry, carbon neutrality is still in its infancy.

Although there is the “double credit system” constraint, under this score-based approach to automotive emissions, new energy vehicles are expected to quickly replace fuel vehicles. However, will the carbon emissions generated by automobiles at other stages receive sufficient attention?

The carbon neutrality of the automotive industry requires not only the use of new energy vehicles to replace fuel vehicles, but also the integration of low-carbon emissions reduction throughout the entire industrial chain of automotive production, use, and even recycling. This requires more open and transparent carbon management efforts from automakers, as well as mutual cooperation from automotive suppliers, upstream power suppliers, raw material suppliers, logistics companies, and other industries.

Carbon neutrality is a topic that the auto industry, and even all industries, cannot avoid forever.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.