On April 20, 2021, I witnessed the lower body of the JIMU 001 vehicle based on the Sustainable Experience Architecture (SEA) at the site. The official engineers present shared with me some potentials of JIMU 001 and SEA architecture.

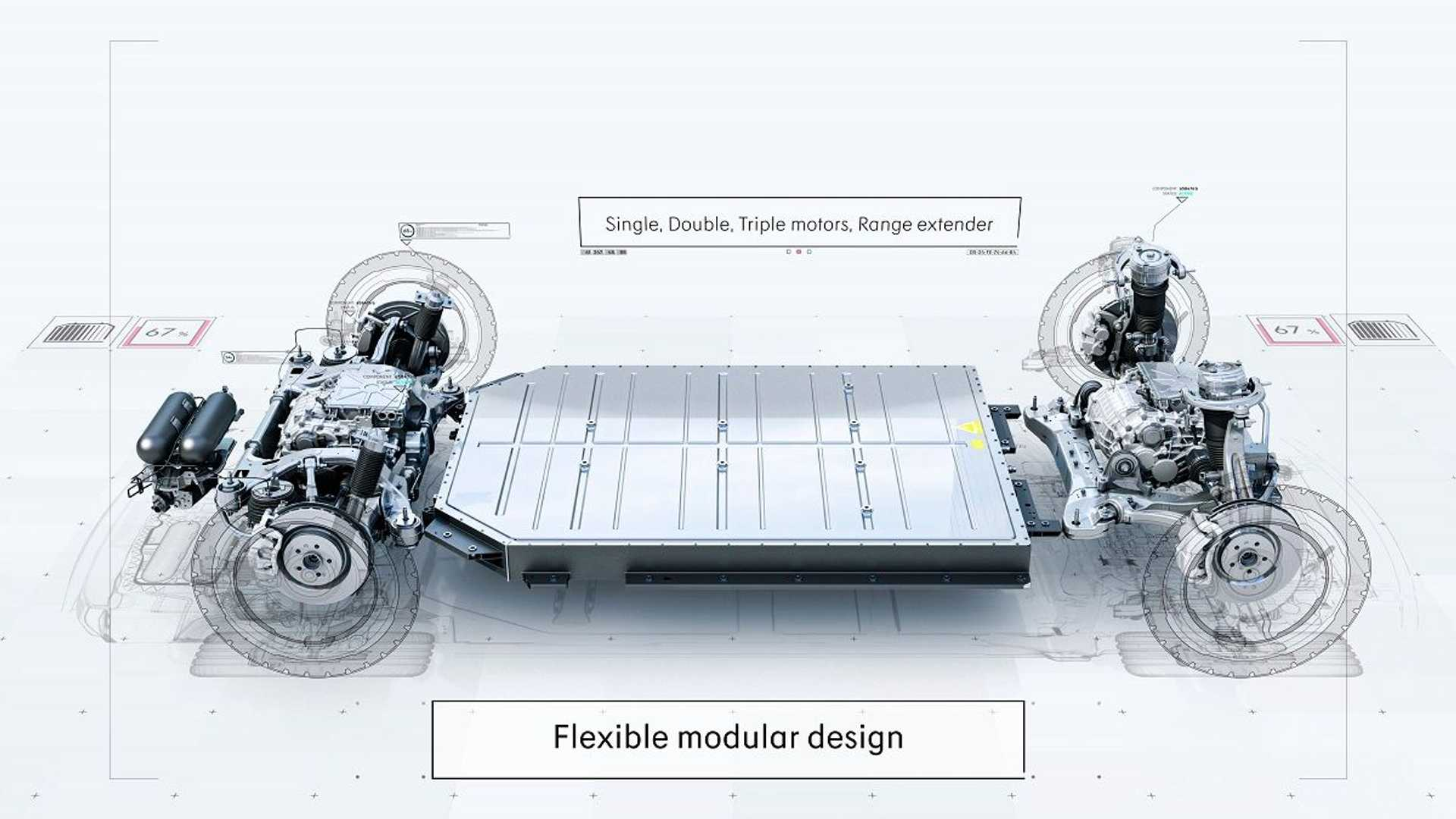

Flexibility of SEA

SEA stands for Sustainable Experience Architecture. According to the official statement, SEA is also known as “Intelligent Evolutionary Experience Architecture”, but the literal interpretation is “sustainable experience architecture.”

Similar to Toyota TNGA, SEA is a new generation vehicle manufacturing architecture rather than a specific platform. Therefore, the products under the vast architecture are not only luxury electric vehicles like JIMU 001 but also support lower-end suspension forms, such as front MacPherson suspension and rear torsion beam (commonly known as chopsticks) for low-end small cars.

JIMU 001 uses electronic power-assisted steering. Under the huge architecture, JIMU 001 can switch to the line control steering system to achieve mechanical decoupling and open up more possibilities in control.

Suspension system of JIMU 001

The suspension structure of JIMU 001 consists of aluminum alloy material front double-wishbone (virtual master pin, double-ball head double transverse arm suspension) and integrated multi-link at the rear. The front suspension structure is similar to the Mercedes-Benz MRA platform, which is a double-wishbone structure with the lower arm split into two pieces. This structure has higher flexibility, can move the virtual master pin closer to the center of the tire without affecting the car layout, and has stronger dynamic trajectory control of the wheels in corners.

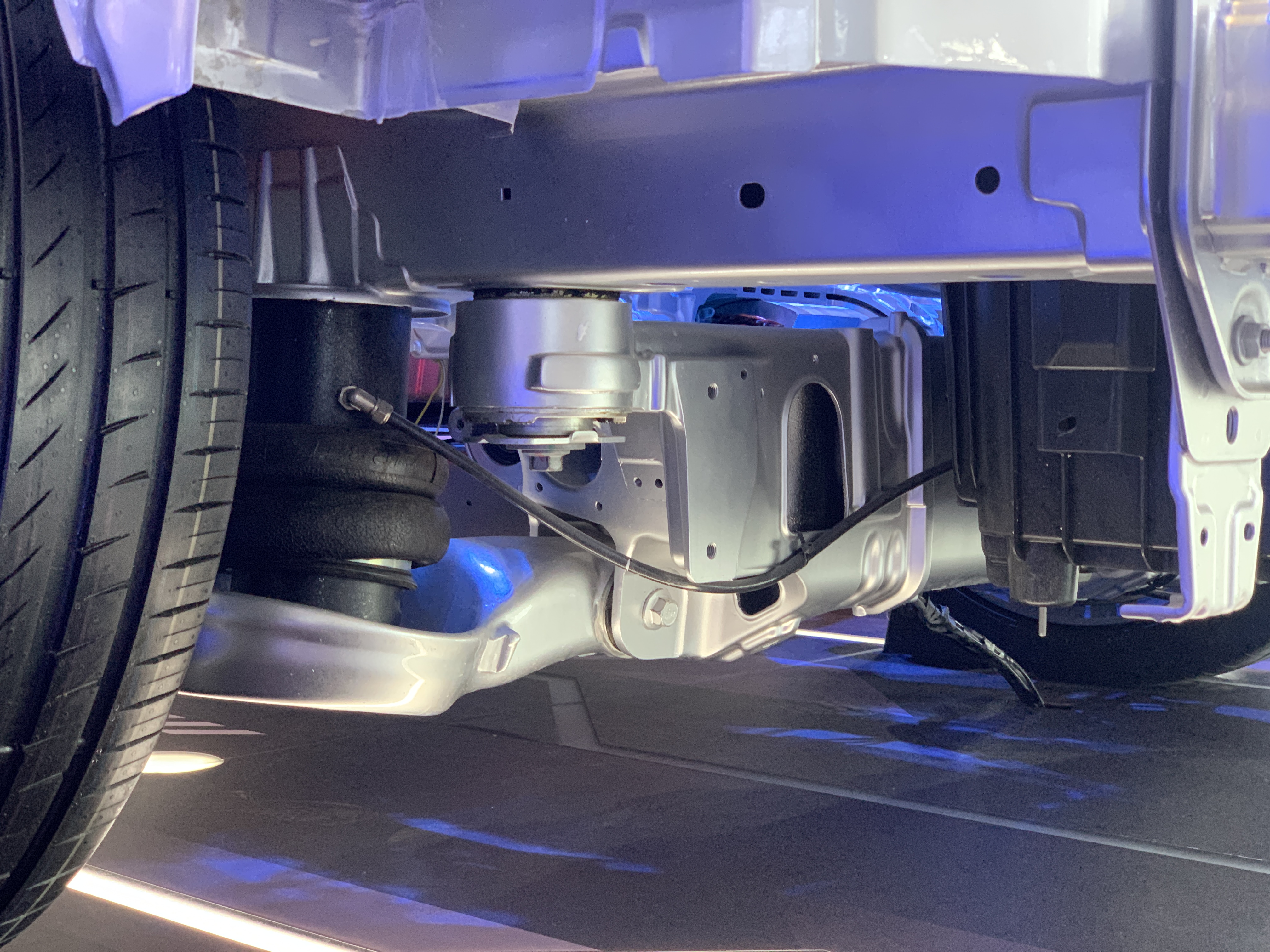

The CCD electromagnetic shock absorber with air spring comes from Tenneco. “CCD” is the general term for such adaptive suspension products, which stands for “Continuously Controlled Damping.” Later, there is a chance to upgrade to more advanced dual-chamber air springs and Continental CDC (which should be more familiar to everyone) in the configuration list. The dual-chamber air spring can change the effective volume of the internal air to achieve different spring stiffness and expand the boundary of comfort and sports.

Safety concept derived from Volvo

In the platform exhibition equipment under the 001 platform, the paint of the front sub-frame is black which is different from the silver color of the back sub-frame. This is to highlight that the front sub-frame is made of steel material, which is different from the aluminum alloy material of the back sub-frame. Considering the product positioning and the materials used in other parts of the vehicle, the steel sub-frame should not be intended to reduce costs.

In the platform exhibition equipment under the 001 platform, the paint of the front sub-frame is black which is different from the silver color of the back sub-frame. This is to highlight that the front sub-frame is made of steel material, which is different from the aluminum alloy material of the back sub-frame. Considering the product positioning and the materials used in other parts of the vehicle, the steel sub-frame should not be intended to reduce costs.

This idea has also been verified by the engineering team at the scene. For the purpose of preventing powertrain invasion into the cabin in the event of a collision, Volvo’s fuel-powered vehicles will intentionally disconnect the front sub-frame containing the engine and gearbox from the vehicle body during a collision, in order to reduce the direct impact of the huge kinetic energy of the powertrain on the cabin and avoid danger. To achieve this goal for JETOUR 001, the front sub-frame needs to have a stronger ability to transfer collision energy, so that the connecting point breaks and the powertrain separates from the vehicle body. However, the aluminum alloy material with poor elasticity is not suitable for this purpose.

In addition to contributing to lightweighting, the support structure of the headlights on the front of the vehicle is mainly designed for collision safety considerations. This part does not contribute to the torsional stiffness of the vehicle body, and excessive strength may actually affect the energy absorption effect of the front of the vehicle. The result is this lightweight hollow structure.

Details that Serve the Driver

There is a detail in the vehicle where the height difference of Cross Car Beam (CCB), the instrument panel crossbeam of the vehicle, is quite large. The driver’s side is lower, while the passenger side is higher. This is for optimizing the driver’s visibility and adjusting the driving posture. As the longitudinal space is sufficient but the vehicle body is relatively low, JETOUR 001 is designed to provide a relatively reclined seating posture, which requires a lower steering wheel and instrument panel installation height.

As for whether the height difference of CCB will affect the vehicle body rigidity, I think this concern is unnecessary because the A, B, and C pillars of this vehicle are made of boron steel and the torsional stiffness has reached an ultra-high level of 40,000 N·m/deg.

There are two gas cylinders at the bottom of the trunk which hold high-pressure air reserves to support the air suspension. Compressed air comes from an electric pump located on the outside of the vehicle body below the trunk. The air pressure in the cylinders is much higher than that in the air spring, which ensures that the speed of adjustment for the vehicle body height is fast enough, bringing a smoother user experience.

Source: JETOUR booth at the Shanghai Auto Show

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.