The First Generation of Bee Speed Fast-Charging Battery

It can run 400 kilometers after being charged for 10 minutes.

This is the all-new fast-charging dynamic battery launched by Bee Energy at the Shanghai Auto Show.

In addition to releasing new products, Bee Energy also held its first Innovation Day event.

On April 20th, during the Innovation Day held by Bee Energy, it was announced that Bee Energy had entered the 2.0 phase of its brand and established Bee Capital, a 2 billion yuan fund to support industrial innovation. The plan is to recruit 20 cross-industry partners and 100 innovative “pioneer” scientists worldwide.

In the 2.0 phase, Bee Energy has already shifted its focus from power batteries to energy, and cooperated with Great Wall Motors to build an energy ecosystem. They even put forward an ambitious goal: to become a great enterprise of the energy society.

Of course, Bee Energy’s main business is batteries, including vehicle power batteries, energy storage, and small power batteries. Therefore, they must make strong products.

Bee Energy mainly promotes strong products through two aspects: technological innovation and industrial chain cooperation and talent recruitment. For both of these aspects, Bee Energy is willing to spend a lot of money.

Bee Speed Fast-Charging Technology Debuts for the First Time

In the view of Yang Hongxin, Chairman and CEO of Bee Energy, as the mainstream product range can reach 600 kilometers, the anxiety of consumers about range can be gradually relieved, but the convenience issue has become another pain point. Consumers hope that charging can be faster. In addition to the construction of the fast-charging network, the fast-charging performance of the battery is another bottleneck.

To solve this pain point, Bee Energy has introduced the Bee Speed fast charging technology, which can run 400 kilometers after being charged for 10 minutes.

Bee Energy’s first-generation Bee Speed fast-charging core has a capacity of 158 Ah, energy density of 250 Wh/kg, and 2.2C fast charging can be achieved in 16 minutes from 20% to 80%, and it can be mass-produced by the end of this year; the second-generation 4C fast-charging core has a capacity of 165 Ah, energy density greater than 260 Wh/kg, and fast-charging from 20-80% SOC takes 10 minutes, with mass production expected in Q2 2023.

In order to achieve fast charging, Bee Energy has made improvements and designs in the positive electrode, negative electrode, electrolyte, diaphragm, structural components, and fast-charging strategy of the battery.

Yang Hongxin provided a detailed explanation about this technology.

As for the positive electrode, Bee Energy adopts three representative technologies, one of which is the directed growth and precise control technology of the precursor, which enables a single particle to grow radially through controlling the synthesis parameters of the precursor.Translate Markdown Chinese text to English Markdown text while retaining HTML tags inside the Markdown. Only output the corrected and improved parts, without any explanations.

In brief, a “highway” for ion migration has been created to improve ion conductivity and reduce impedance by over 10%.

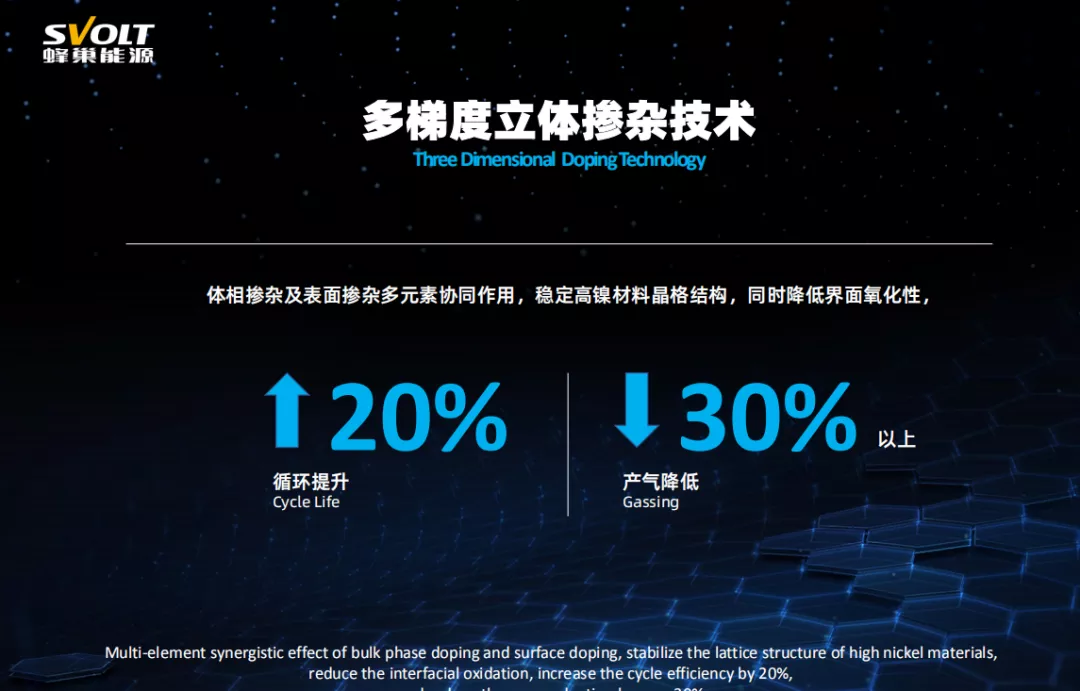

Secondly, by doping in bulk and nano surface coating, material stability and ion transport performance is further improved, hence, cycling capacity is raised by 20%, and gas production decreased by over 30%.

Thirdly, flexible coating technology is adopted to suppress particle pulverization during cycling, by choosing adaptable flexible coating materials with significant volume changes for high-nickel cathode materials, yield reduction in gas production by over 20%.

On the negative electrode side, four technologies are mainly used: raw material selection technology, surface modification technology, original fragmentation and shaping technology and granulation technology.

Firstly, the oxygen index of the pole piece is reduced from 12 to 7 through selecting homogenous, various structures and different types of raw materials resulting in improved kinetics properties.

Secondly, by reasonably matching the particle size, the original material fragmentation and shaping technology reduces side reactions and hence improves cycling performance and storage performance by 5-10%.

Thirdly, by using liquid coating technology, the surface modification technology reduces the impedance by 20%. Fourthly, granulation technology precisely controls the particle size and shape orientation so that the full charge expansion rate is reduced by 3-5%.

With regards to the electrolyte, a low impedance additive system, such as sulfur-containing additives/lithium salt additives, is used to reduce the film-forming impedance of the positive and negative electrodes. A relatively high concentration of lithium salt ensures high electrolyte conductivity.

The separator is made of high porosity ceramic film to improve the ion conduction capacity of the separator while also considering the heat resistance, achieving a balance between fast charging and safety.

In addition, by adopting a multi-layer coating process, honeycomb achieves two major benefits: high energy and fast charging.

For structural components, a maximum overcurrent capacity of 600A is required, while the weight should be reduced as much as possible. Honeycomb simulated the overcurrent capacity and temperature distribution of the structural components using COMSOL software, and after optimized design, the temperature of the structural components during fast charge is less than 60℃.In the formulation of fast charging strategy, it is necessary to minimize and avoid lithium decomposition as much as possible. B&T adopts the three-electrode technology to monitor the change of the negative potential in situ and uses COMSOL software to simulate the voltage changes of the charging battery under different temperatures and currents, thus formulating the optimal fast charging strategy.

In order to improve energy density, they also added silicon-oxygen material to the negative electrode of the second-generation battery, which resulted in a decrease in cycle life, but the fast charging cycle could still reach over 1500 times.

It should be noted that all fast charging cycles mentioned in the article refer to 400 km full charge in 10 minutes.

In terms of energy, B&T also revealed that if this fast charging battery is used for slow charging, a general vehicle can achieve a range of 750 km after full charge, and a slightly heavier vehicle can also achieve a range of about 650 km.

In addition to the driving range, Yang Hongxin said that B&T’s second-generation battery, Bee Speed, can do more, “the vehicle battery capacity can exceed 100 degrees, supporting 450 kW high-power discharge for 4-wheel drive, and can also support ultra-high-rate charging piles, super charging piles up to 350 kW; more importantly, the product supports high-voltage electrical architecture of 800V-1000V.”

In addition to the field of pure electric vehicles, in the field of HEV, B&T Energy has launched an HEV battery cell based on a soft pack system this year, which can achieve a cycle life of 40,000 times under conditions of RT 3C/3C 30-80% SOC. In terms of high and low temperature performance, charging and discharging rate performance, DCIR (direct current internal resistance) and power performance, it is better than other similar products in the industry.

Based on this battery cell, B&T Energy’s HEV battery pack uses soft pack non-module integration technology, with higher system integration, low heat dissipation design and air cooling, which can significantly reduce the cost of the entire vehicle system, and can be used in the full-temperature range of -35-60℃.

In addition, the HEV battery pack adopts an integrated BMS, with SOC accuracy up to 3%, and can achieve ASIL-C functional safety level, with functions such as UDS, OBDII, and FOTA upgrade.

Nowadays, B&T’s product types are increasingly diverse. In summary, B&T’s product types are: square, soft pack and cylindrical full coverage, and both lithium iron phosphate and ternary batteries are used.

Continuous Innovation Driven by Innate Impetus

B&T Energy has only been established for 4 years. How many “black technologies” have been released?

Cobalt-free battery, quadruple battery, stacked film process, jelly battery, cold bee system, cobalt-free matrix battery pack (LCTP), bee cloud platform, and Bee Speed fast charging technology… New products and new technologies emerge constantly.#### One the one hand, Foton Motor’s Power Battery Business Department has accumulated extensive product and technological know-how since 2012.

On the other hand, Foton’s status as a “new force” in the industry has allowed them enormous freedom in management and research and development, encouraging them to explore new products and innovations.

Their keen focus on talent and innovation was fully demonstrated during Foton Energy’s Innovation Day, which included two important components: recruitment of innovative industry partners, and recruitment of 100 “pioneering” scientists from around the world.

Yang Hongxin believes that Chinese power battery companies have clear advantages over international competition, but also face important challenges such as insufficient accumulation of basic material technology, a reliance on advanced production and high-end equipment imports, and a deficiency in top-notch talent.

To address these challenges, Foton hopes to innovate in both the industrial chain and talent cultivation spaces. To accomplish this, Foton Energy has established “Foton Capital”, which will invest 2 billion yuan in the creation of two funds—one growth-oriented and one innovation-oriented—in order to recruit innovative industry partners. They also plan to recruit 20 cross-disciplinary partners in the field of intelligent technology, as well as 100 “pioneering” scientists from around the world.

Foton energy hopes that through Innovation Day, they can congregate cross-industrial and partner cooperation, gather the world’s top talent, and utilize innovation as a driving force to achieve independent innovation throughout the entire industry chain, from upstream materials to core components, and downstream production. Their goal is to shake off the constraints of traditional processes, introduce advanced technologies from other industries, and integrate them into lithium battery industry innovation and research and development.

In sum, Foton Energy’s internal drive to maintain innovation and development appears to be quite strong.

Strategy 2.0: A Great Enterprise in the Energy Society

Foton’s technological innovations, industry chain cultivation innovations, and talent recruitment may go above and beyond the traditional “duties” of an enterprise. Why do they do it?

As revealed during the Innovation Day, Foton aims to become a great enterprise and innovation leader in the energy society. This is also the main goal of their 2.0 brand stage.From battery experts who understand automobiles better to great companies in the energy society, the strategy of Hive Energy has evolved from upgrading automobiles to energy. To outsiders, this transformation seems to have been completed overnight, but within Hive, it has been a long-term strategy direction that aligns with the overall goals of the Great Wall Group.

1. Why transform into an energy company

Yang Hongxin told “Electric Vehicle Observer” that their strategic upgrade has been brewing for a long time, but what was missing was a catalyst and a triggering point, which China’s “dual carbon goals” fit into perfectly.

Yang Hongxin explained that if the current trend of China’s imported oil ratio continues, more than 90% of China’s crude oil will be imported in the future, so China must rely on renewable energy to replace fossil fuels, and “carbon peak” and “carbon neutrality” are the timetable.

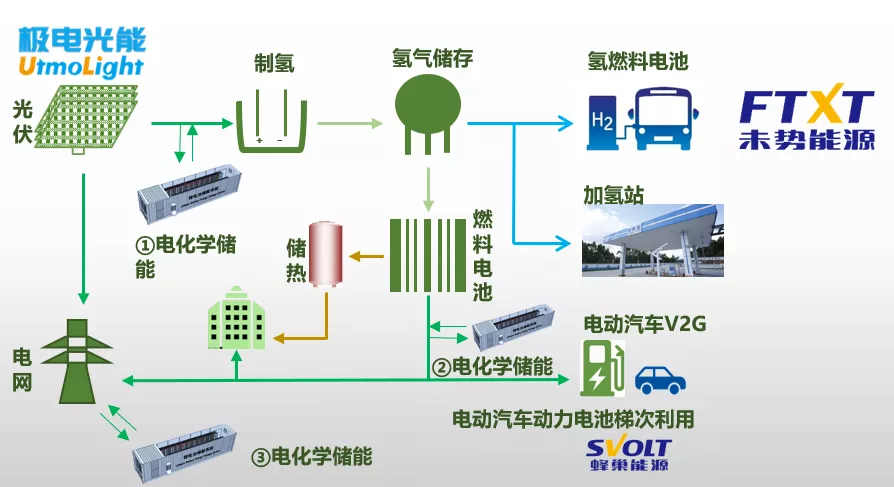

In Yang Hongxin’s view, the main method of replacing fossil fuels is mainly photovoltaics. Wind can also be used, but photovoltaics are more feasible than wind power. The current grid-connected electricity price of photovoltaics is about 3 cents due to different sunlight durations and conversion efficiencies, which can be equal to thermal power.

However, as the installation volume expands, including large-scale installations in areas with strong sunlight, such as deserts and sea levels, the price of solar power generation will drop to below 0.1 yuan/kWh. “At this time, hydrogen production can be carried out on a large scale, and then hydrogen can be transported to cities for use. One building can be equipped with a large hydrogen energy generator set, and electricity can be generated when hydrogen is sent over, which can supply power to the entire building and achieve distributed hydrogen power generation.”

Of course, Yang Hongxin believes that hydrogen is suitable as a carrier for long-distance transportation of electricity, such as transportation that lasts more than 72 hours, but for temporary storage lasting 24-48 hours, lithium batteries have obvious cost advantages and efficiency advantages.

2. An important part of Great Wall Group’s energy transformation

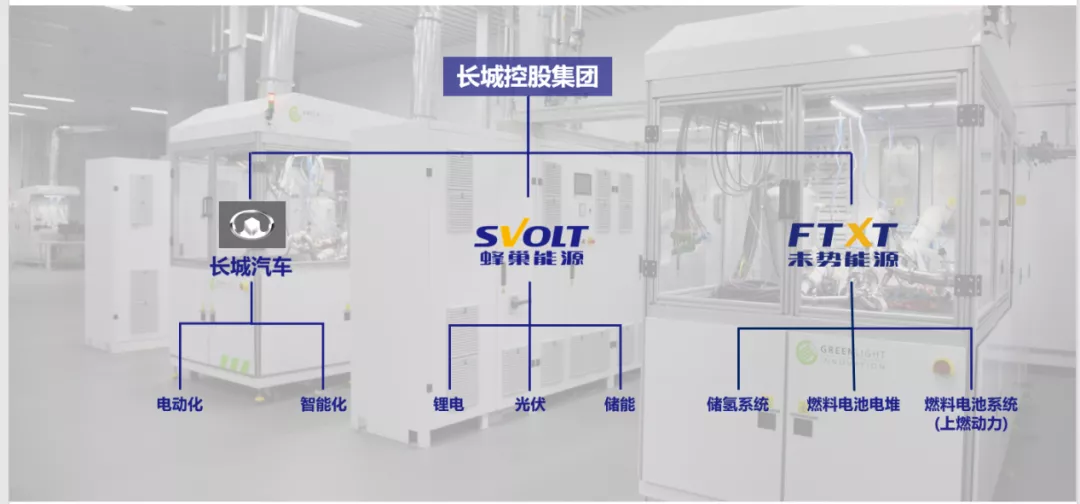

From the structure diagram, it can be seen that Great Wall Motors, Hive Energy, and Unisplendour Energy are at the same level, which means they are brothers’ companies.

One of Hive Energy’s brother companies, Great Wall Motors, has announced that it will become an ecological operator for hydrogen production, storage, and comprehensive utilization. Another brother company, Unisplendour Energy, is engaged in hydrogen segment business, responsible for connecting the hydrogen energy industry chain. Great Wall Holdings’ photovoltaic enterprise, GeometryAuto Guanghai Energy, mainly connects the photovoltaic industry chain.

Thus, it is logical for Hive Energy to elevate its strategic layout to the level of energy, and it is also an important part of Great Wall’s electrochemical energy storage layout.According to Yang Hongxin, the focus of Great Wall is to achieve interaction with the power grid for vehicles, including photovoltaics, energy storage, hydrogen storage and transportation, distributed mobile energy storage of electric vehicles, and the thorough utilization of recovery. “What we have done is in the field covered by lithium batteries, such as energy storage, vehicles including electric travel and second-hand cars, hierarchical utilization and recovery.”

This is the main background of the transformation of FENGYUAN this time.

Perhaps their ultimate goal has been revealed in the company name and brand slogan: FENGYUAN Energy, not FENGYUAN Battery.

Setting great aspirations and motivating oneself with great goals is a common point for many great companies at the beginning of their inception. In this era of constant miracles, let’s take a look at how FENGYUAN weaves dreams.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.