*Author: Neo Wong

The Development of In-Vehicle Networks Brings New Demands

In the competition of in-vehicle networks over the past 20 years, CAN has emerged as the dominant one from competitors such as LIN, FlexRay, MOST, K-line, and D2B, relying on its features such as real-time, stable, reliable, error detection, and more.

With the development of electronic and electrical technology, distributed computing applications such as ADAS, autonomous driving, and connected vehicles are increasingly appearing in cars. Cars are moving towards “software product definition” to enhance customer experience by providing innovative and different types of innovations faster, gradually breaking free from the limitations of traditional V-development cycle in the digital era, and producing more personalized car products.

Taking a typical BMW sedan as an example currently, one car installs over 100 ECUs and applies more than seven communication technologies. Thirty percent of the ECUs have multiple network interfaces, divided into 80 subnets and use communication cables longer than one kilometer to connect them. This does not include some sensors connected via “private connection” such as SENT, PWM with ECUs. Gateways allow larger scale communication between ECUs on different networks, thus forming the domain-centric in-vehicle electronic/electrical architecture we have today.

To meet the increasing requirements of in-vehicle networks for the digital future, accelerate the speed of introducing new features and functions for customers, and better integrate individual car entities into the intelligent traffic network, we need a better internal communication technology for cars. This communication technology should be sturdy and flexible (in terms of data rate and topology), support basic communication principles related to services, security, and various quality of service (QoS) elements to better solve the complexity problem of E/E architecture.

Thus, Ethernet in vehicles has been proposed. Through the continuous efforts of OEM manufacturers and IC technology companies (such as Broadcom), Ethernet in vehicles has become an excellent candidate for future vehicle backbone networks. The communication based on Ethernet follows strict protocol layer separation.

Therefore, it is very flexible and adaptable, providing a foundation for data exchange in many industries. It inherently supports service-oriented communication, and provides the most advanced security features. In 2008, BWM used 100 BASE-TX Ethernet for ECU flash and diagnosis. In 2013, 100 BASE-T1 (Single Unshielded Twisted Pair (UTP) Cable 100 Mbps) started production (SOP). The first SOP for 1000 BASE-T1 (Single UTP Cable 1 Gbps) is expected to be released anytime soon.Since 2015, the QoS protocol from Audio Video Bridging (AVB) standard has been used in cars. Ethernet can be used for high data rate communication, and the 2.5, 5, and 10 Gbps Ethernet standards (2.5, 5, 10 GBASE-T1) for cars are nearing completion, compared to existing 100 Mbps and 1 Gbps standards. Two new projects are researching higher data rates, reaching 25+ Gbps.

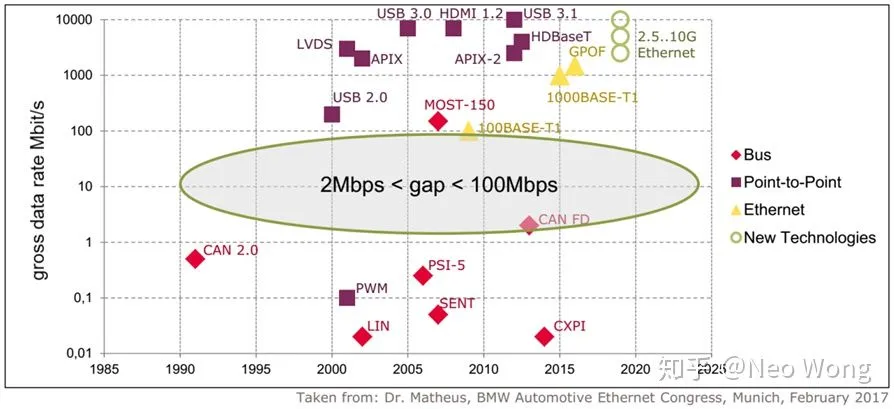

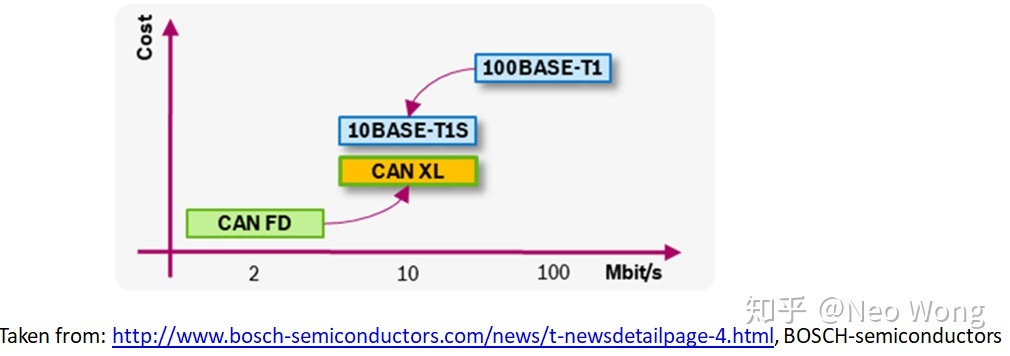

However, over 90% of car communications require data rates lower than 10 Mbps. Using a 100 Mbps network to meet these communication needs is inefficient in terms of both cost and power. From the current distribution of standard rates for in-car networks, there is an obvious gap between 2 Mbps and 100 Mbps that needs a technology to fill.

Ethernet camp’s weapon: 10 BASE-T1S

On the Ethernet side, IEEE has standardized a 10 Mbps Ethernet version (10 BASE-T1S) for cars, which was launched in 2019.

-

10 Base => 10Mbps speed grade

-

T1 => physical layer is single twisted pair (unshielded)

-

S => short range (favorite solution for Automotive purposes)

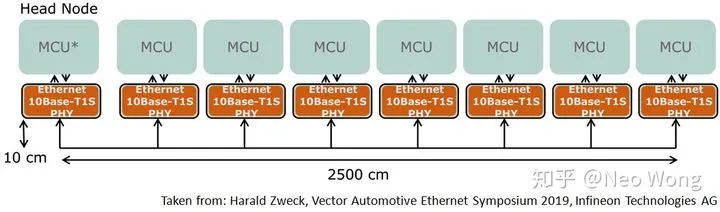

10 BASE-T1S supports linear bus topology with at least 8 nodes and 25 meters link length.

As a member of IEEE-802.3, 10 BASE-T1S bus is numbered IEEE-802.3cg and seamlessly integrated into in-car Ethernet communication by connecting to existing switches through the standard media independent interface (MII).When using the 10 BASE-T1S bus topology, attention needs to be paid to quality of service. Therefore, a polling mechanism called PLCA is used for channel access, which, unlike the fixed scheduling used in FlexRay, does not waste unused transmission slots and has higher bandwidth utilization compared to the arbitration used in the CAN series specifications. PLCA is an extension of CSMA/CD, and the specific protocol content can be referred to the corresponding standard, but it must be remembered that 10 BASE-T1S is a “bus” form of Ethernet.

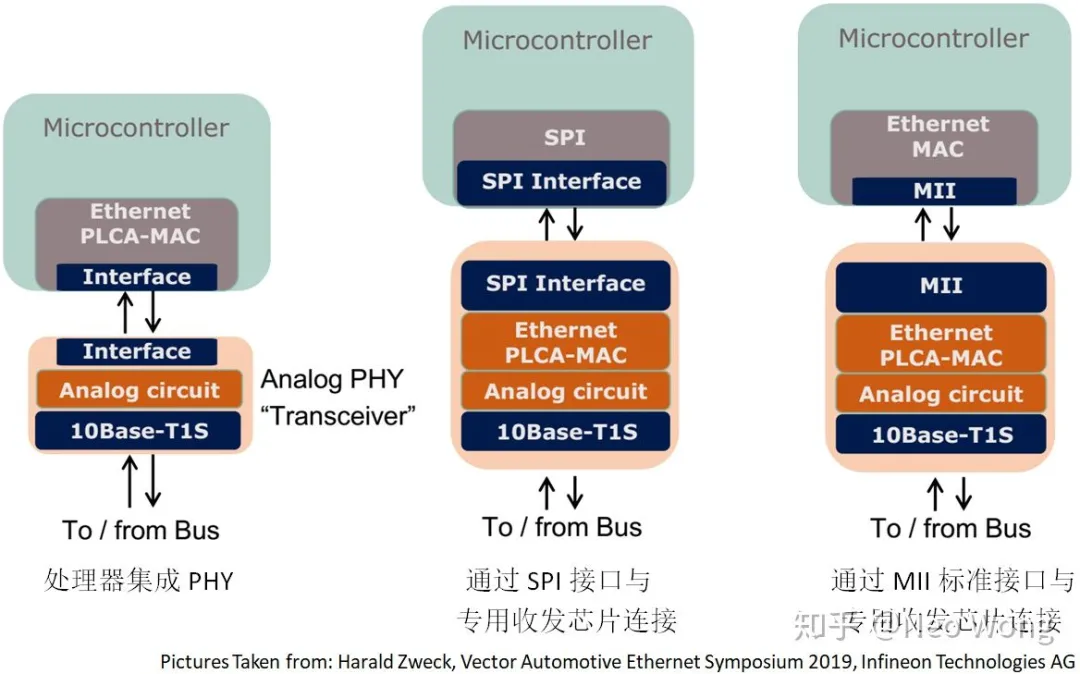

There are currently three common ways to implement it on the ECU:

The CAN camp launched CAN XL to counter the aggressive Ethernet camp. Represented by BOSCH, the creator of the original CAN, the CiA camp proposed a new standard: CAN XL.

The design indicators of CAN XL are mainly three points:

-

The communication rate is increased to 10 Mbps;

-

The data payload of a single frame message is raised to 2048 bytes, so that higher-level protocols (such as IP) can run on the network;

-

It is backward compatible with CAN/CAN FD.

CiA says that the standard is “designed to fill the gap between 100-Mbit/s automotive Ethernet”. This obviously targets the huge business opportunity between 2 Mbps and 100 Mbps and will inevitably collide head-on with 10 BASE-T1S.

The similarities and differences between CAN XL and CAN/CAN FD have been introduced on other websites, and will not be repeated here: http://www.21ic.com/app/control/202001/927067.htm

Since not all technical details of CAN XL have been fully determined, the following mainly introduces the development of CAN XL:- The CiA CAN XL specification started in December 2018, with the goal of providing a technically stable CAN XL specification for OSI Layer 2 (called CAN XL protocol) by the end of 2019.

-

In early February 2019, the CAN XL Special Interest Group (SIG) of CiA held its second meeting. The SIG, led by Bosch, aims to extend the CAN protocol to applications such as radar sensors, eCall devices, and microphones. There is strong interest from automakers, suppliers, and semiconductor manufacturers. More than 40 attendees from 20 companies participated in the meeting.

-

In June 2019, CiA announced its intention to introduce another popular CAN bus technology, called CAN XL.

-

CAN XL will officially be launched at the International CAN Conference (iCC) in Baden-Baden, Germany in mid-March 2020.

-

Later this year, when the CAN XL specification is released and related plug-ins have validated the interoperability of the first implementation, CiA will submit them to ISO for international standardization.

10 Base-T1S vs CAN XL

Ethernet technology is completely different from the CAN technology itself. One is used to transfer large amounts of data within a certain time, while the other is used to reliably transmit data in complex and harsh conditions, making it difficult to make a direct comparison.

Dr. Konrad Etschberger has compared the advantages and disadvantages of CAN and Ethernet in an article. However, he is obviously in favor of the CAN camp, and the experimental design is not complete and accurate enough (especially when discussing FPS). As an unprofessional individual, I can only compare 10 Base-T1S and CAN XL from my personal understanding of these two technologies, mainly based on the comparison of the published standards (which can also be regarded as “armchair discussion”):

Transmission speed: From the perspective of data payload, both technologies are comparable and can achieve 10 Mbps. However, in order to be compatible with the old CAN specification, the header rate of CAN XL is lower, which actually reduces the overall transmission speed.

Maturity of specifications: The 10 Base-T1S has already released its standard document. The CAN XL specification is not yet finalized, and there are still some unresolved issues to be decided.Cost: This is the most concerned issue for OEM manufacturers. CAN controllers are currently integrated into processor chips, which reduces some software costs and ensures consistency. In addition to the cost factor of the switch, for a single processor chip, there may be some processors that integrate 10 Base-T1S controllers, but due to the Ethernet software protocol stack, there may be some software costs and protocol consistency issues; At the same time, limited by the longest communication line of 25m and a maximum of 8 nodes, some special domains (such as new energy battery domain) may require multiple subnets to be used, increasing costs.

Security: CAN XL inherits the good characteristics of CAN, which can ensure no data loss during transmission, and this feature is hardcoded in the CAN controller. 10 Base-T1S, like other Ethernet protocols, needs to detect data loss through higher-level protocols (such as TCP), and depends on software implementation.

Error Detection: CAN XL, like CAN, can detect faults and recover from them. When the frame header rate is 1 Mbps, it can recover in 23 uS; but TCP/IP takes several tens of ms to recover from faults.

Arbitration Access: CAN provides collision-free and predictable arbitration to manage network access between competing nodes. In the process of Ethernet bus arbitration (CSMA/CD-Carrier Sense Multiple Access/ Collision Detection), the arbitration time is unpredictable. In the worst case, when message conflicts occur continuously, nodes will dump message frames and not attempt to retransmit.

Compatibility: This is not easy to compare. CAN XL can achieve compatibility with most CAN/CAN FD applications, but does not support remote frames and 29-bit IDs. 10 BASE-T1S is very suitable for switch-centric vehicle networks.

Software portability: CAN XL has no major software portability issues on general passenger car ECUs, but commercial vehicles may need to be carefully considered, especially because it does not support 29-bit IDs. 10 BASE-T1S inherits good Ethernet characteristics, and many mature industrial software based on TCP/IP are easy to port to new vehicle Ethernet protocols.

Protocol Extensibility: The CAN XL protocol provides an 8-bit indicator (Embedded Layer-setting Parameters, ELP, embedded layer-setting parameters) for the next higher-level protocol used, which is not suitable for judging its level based on the classic OSI reference model. ELP helps achieve other higher-level protocols. Of course, 10 BASE-T1S is easy to extend, after all, it has a good foundation in Ethernet.Energy Saving: CAN XL supports low-power wake-up, which Ethernet currently lacks.

Summary

Both 10 BASE-T1S and CAN XL have their own advantages. However, currently 10 BASE-T1S is temporarily leading in completeness, and its advantage is having the same protocol as the backbone network. CAN XL absorbs the advantages of CAN and achieves high-speed communication, combined with the profound accumulation of CAN in the industry, whether the two can coexist on the same platform in the end is unknown. In short, cost will be the most important determining factor in this technological revolution.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.