During the weekend, I will continue to sort out some information about the design of the Ultium battery system, which is universally used in the automotive industry online. To summarize, this battery system has the following characteristics:

1) The simplification of the low-voltage harness brought by the introduction of wBMS wireless battery management system is the most intuitive feature.

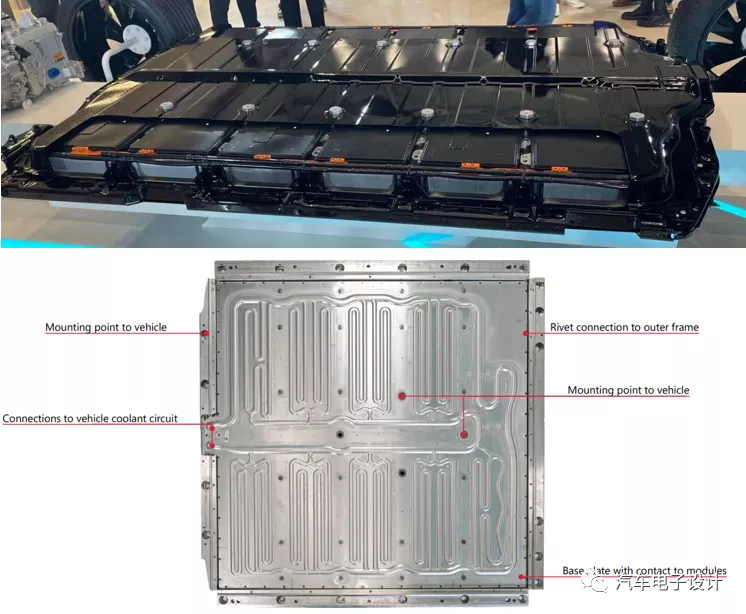

2) A lot of steel beams are used between the modules in the battery system (with the introduction of CTP, this design may become less common). From a structural point of view, the Americans have deeply written the resistance to impact into this battery system, although Pack energy density is no longer so important, the increase in weight objectively brought is also considerable.

Electrical Design

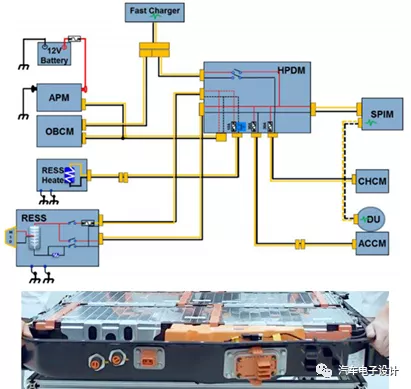

Nowadays, I always look at the electrical design first. We know that there are several key changes from BEV2’s Bolt to BEV3, and one of them is the requirement for fast charging ability. It has been raised from the previous 50-60 kW level to 150 kW+ or even 350 kW at 800V. It is very interesting to design the distribution box in this aspect.

In Bolt’s design, the high-voltage interface of the battery system is mainly divided into the part of the OBC on-board charger and the part of the high-current bus bar. The main distribution function is carried by this HPDP (vehicle high-voltage distribution box) component.

From the Ultium battery, it can be seen that it realizes the internal distribution of the battery system. Considering the demand for four-wheel drive, it achieves simultaneous front-end and rear-end line output and is equipped with a fast charging interface at the rear end.

In Ultium’s drive system, the next part of the distribution is integrated into it. Therefore, there is a large box on top of the drive, as shown in the figure below. It has one high-voltage bus input, which is connected to the inverter and motor below, and three high-voltage interface outputs (compressors, PTC, and power OBC sections) on the other hand. It is speculated that, based on Bolt, the indirect connection from the fast charging interface to the distribution box has been eliminated, and directly connected to the battery interface. This should shorten the high-voltage cable.

In Ultium’s drive system, the next part of the distribution is integrated into it. Therefore, there is a large box on top of the drive, as shown in the figure below. It has one high-voltage bus input, which is connected to the inverter and motor below, and three high-voltage interface outputs (compressors, PTC, and power OBC sections) on the other hand. It is speculated that, based on Bolt, the indirect connection from the fast charging interface to the distribution box has been eliminated, and directly connected to the battery interface. This should shorten the high-voltage cable.

In terms of internal bus connections, the high-voltage connection layout of the Universal Ultium battery is similar to that of the MEB platform.

Continuing from the previous figure, because the module integrates a water-cooling system, there are many erected water-cooling pipes in this battery system. We can compare the differences between the MEB shell-integrated water-cooled version and the module-integrated water-cooled version. Mercedes-Benz was the first to adopt module-integrated water-cooled systems. We can still remember the intricate pipes inside the EQC battery system. From the perspective of the system, the trade-offs here include the cost of adding a water nozzle and pipeline for the module, as well as the complexity difference of an integrated water-cooled plate.

Note: the harness is relatively simple, but the management is still somewhat complicated. This is still challenging for automated assembly.

Regarding the design of the relief valve and the exhaust of the smoke inside the entire channel, GM only provided a schematic diagram, but now everyone is doing the same thing. The biggest feature of this battery system is still the wireless BMS, which is currently only promoted by GM.

Conclusion

This battery system design still has a strong American style. It will be used by both General Motors and Honda, and will be more common in large vehicles and may not be suitable for small vehicles.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.