Author: Qiu Kaijun

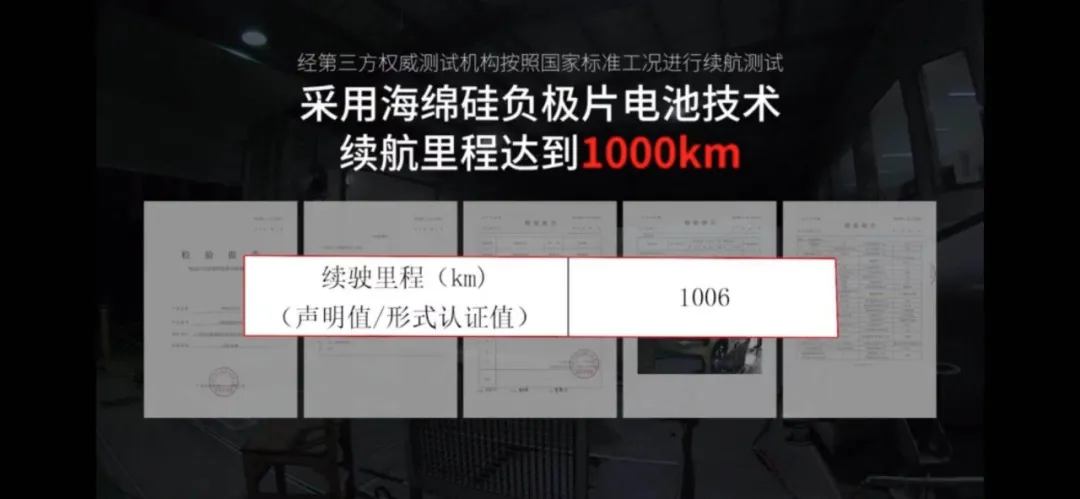

A third-party organization tested an electric vehicle equipped with Guangqi’s silicon sponge negative electrode battery and achieved a range of more than 1000 kilometers.

The Guangqi Aion S, which caused widespread controversy for its 1000-kilometer driving range and 80% quick charge in 8 minutes, not only exists, but is also about to be mass-produced.

On April 9th, Guangqi Group held the 2021 Guangqi Technology Day at the Guangqi Research Institute, showcasing a series of technological achievements, especially in power battery technology, emphasizing the electric vehicle technology of 1000 kilometers of long-range and 6C super-fast charging, which is already ready for mass production.

At the same time, Guangqi also announced that it will launch the NDA: Navigation Driving Assistance System, which supports single lane cruise control, lane change assistance, automatic overtaking, and automatic entry and exit ramp functions on highways and ramps. This will be the first traditional automaker to achieve mass production of its navigation driving assistance system.

The Guangqi Technology Day conference lasted less than an hour, but was concise and rich, demonstrating Guangqi’s technological capabilities in electric and intelligent vehicles. This enterprise, which has both state-owned enterprise accumulation and southern market-oriented thinking, exhibits different technological capabilities in the era of intelligent electric vehicles.

[Follow “Electric Vehicle Observer” public account, and reply “Guangqi” in the public account dialog box to obtain the 2021 Guangqi Technology Day PPT key snapshot version]

Sponge silicon negative electrode battery:

Achieving long-range of 1000 kilometers

On January 15th of this year, Guangqi Aion released a poster that they will launch power battery technology that can be charged 80% in 8 minutes, and the NEDC standard driving range is up to 1000 kilometers.

These two heavyweight technological advancements, together with Ouyang Minggao’s comment on the progress of 1000-kilometer batteries and other developments, have been discussed extensively. Many voices have questioned the authenticity and feasibility of these two technologies.

After three months, Guangqi once again confirmed at the 2021 Guangqi Technology Day that both technologies will become reality.

In terms of the power battery with a driving range of 1000 kilometers, Guangqi’s solution is to adopt the sponge silicon negative electrode battery technology. This technology not only realizes the advantage of high energy density of silicon negative electrode, but also solves the problem of silicon material expansion.

In the solution to improving energy density, high nickel is generally used as the positive electrode, and silicon-based negative electrode is used as the negative electrode. Compared with the commonly used graphite negative electrode, the theoretical capacity of silicon-based negative electrode material is more than 10 times that of graphite negative electrode. With the current technology level, silicon-based negative electrodes are essential to achieve a battery density of 300 Wh/kg.

However, the expansion rate of silicon-based negative electrode materials is high. After multiple charge and discharge cycles, the structure of silicon-based negative electrode will collapse, and lithium ions cannot be embedded in the negative electrode, which means that the charging process cannot be completed again. That is to say, even though the capacity has been increased after using silicon, the cycle life has been shortened.The head of battery research and development department at GAC R&D Center, Mei Yao, said that in order to solve this problem, GAC has organized a professional battery development team and established an advanced and complete battery laboratory and trial production line with global elites. After five years of secret research, the GAC team has successfully developed a sponge silicon negative electrode battery product by overcoming this problem.

As the name suggests, GAC’s sponge silicon negative electrode battery technology makes the negative electrode like a sponge, soft and elastic, which limits and buffers the expansion and contraction of silicon during the charging and discharging process and prevents it from cracking. At the same time, the high capacity of the silicon negative electrode can be understood as storing more energy like a sponge absorbing water. However, this sponge-like structure is not easy to achieve. GAC has applied several technologies, such as “nano-composite silicon technology,” “self-healing bonding agent technology,” and “gradient composite coating technology,” to achieve this.

After applying the sponge silicon negative electrode battery technology, the volume of lithium-ion battery monomer can be reduced by 20% and the weight can be reduced by 14%. In the future, both volume and weight will further be reduced by more than half.

Mei Yao, the head of battery research and development department at GAC R&D Center, stated that according to third-party authoritative testing organizations, the GAC Aion LX equipped with sponge silicon negative electrode battery technology can achieve a range of more than 1000 kilometers under national standard driving conditions, which is 54% higher than the original 650 kilometers. The test vehicle with a range of 1000 kilometers has undergone high temperature and cold weather tests in summer and winter, with “excellent performance, strong power and reliable safety.” Mei Yao said that the 1000 km long-range vehicle will begin mass production this year and “meet everyone.”

GAC Aion’s advertising picture, which shows an 80% charge in 8 minutes using graphene-based batteries, has also attracted great attention. At the GAC Technology Day, Pei Feng, the general manager of Guangzhou Juwan Technology Research Co., Ltd. (hereinafter referred to as Juwan Technology), an internal incubation company established by GAC Group, who is the actual developer of this technology, made an appearance at the press conference and explained the technology in detail.

According to the principle of battery charging, in order to charge quickly, lithium ions need to be able to run quickly from the positive electrode to the electrolyte, pass through the diaphragm, and run to the negative electrode. The negative electrode also needs to be able to accept quickly, which means that everyone needs to work together.

Juwan Technology’s fast charging solution is also a collaboration of various battery materials. Its super-fast charging battery technology uses new conductive materials, constructs an efficient three-dimensional conductive network, and improves the conductivity of electrode materials. It also adopts ceramic-coated diaphragms and new high-power electrolytes to improve the battery’s rate performance and thermal stability.

According to the GAC’s tests conducted by the national authority for batteries, the battery cells adopting this technology meet the 6C charging requirements.At the system level, Juyuan Technology Research has also developed a corresponding solution. First, a high-voltage platform is adopted to help achieve fast charging and high range; at the same time, the system adopts an efficient heat dissipation design to ensure that the battery runs in a safe temperature range.

The ultimate performance of this battery + system is: 0-80% charging only takes 8 minutes; 30%-80% charging only takes 5 minutes; and the vehicle can achieve a fast charge cycle of 1 million kilometers at a constant temperature of 6°C.

Guangzhou Automobile Group (GAC) will debut the super fast charging technology in its AION V model in September this year. The fast charging version of the AION V will have two versions: 6C-500 km and 3C-500 km.

Pei Feng, Chief Technology Officer of GAC, said that the 3C super fast charging battery system can travel more than 500 km on a single charge, with 0%-80% charging taking only 16 minutes, and 30%-80% charging only taking 10 minutes. Using a new liquid cooling system, the heat dissipation efficiency can be improved by 1 times. The performance has been stable and reliable after undergoing winter testing, and it can match existing charging voltage platforms and fast charging stations.

The 6C super fast charging battery system will adopt a high-voltage platform, with a maximum voltage of 900 V and a maximum charging current of more than 500 A. The 6C high-rate fast charging can achieve 0%-80% charging time of 8 minutes and 30%-80% charging time of 5 minutes, the vehicle can achieve fast charge cycle of 1 million kilometers at a constant temperature of 6°C. Currently, the 6C super fast charging battery is undergoing production testing and deployment.

The 6C super fast charging already exceeds the current national standard for fast charging, but the developing high-power super fast charging standard, ChaoJi, will support super fast charging above 350 kW. However, existing charging operators cannot support it. Therefore, GAC will also cooperate to promote the layout of the super fast charging network, planning to lay out more than 100 super fast charging stations within 2021.

It should be noted that GAC’s 1000 km battery technology and super fast charging technology are two separate technologies that cannot yet be installed in the same electric vehicle.

Neutron Star Strategy for Power Battery

At the 2021 GAC Technology Day, the GAC Power Battery Technology Strategy was also released for the first time.

GAC named it the “Neutron Star Strategy.” Wu Jian, the dean of GAC Research Institute, explained that the core of the Neutron Star Strategy is that GAC will deeply develop independent research and development and industrial application of power batteries and battery cells.

Wu Jian revealed that the goal of this strategy is to achieve independent research and development and large-scale application of power battery cells within three years, and gradually realize self-development and production in the medium and long term. That is to say, in the medium and long term, GAC will produce power batteries independently.

On a technical level, GAC’s “Neutron Star Strategy” will drive technological advancement in three areas, continuously improving the user experience.

In terms of battery cells, the sponge silicon negative electrode battery technology and super-fast charging battery technology will be developed in parallel to address the different pain points of user range and charging; the BMS system will provide superior domain control management and big data application capabilities to ensure the safety of the battery; the battery pack will be built with four advantages of “high safety, lightweight, high integration, and low cost”.

Wu Jian summarized the current and future performance levels of GAC’s power batteries.

In terms of range, the upcoming mass-produced models have achieved an energy density of over 280 watt-hours/kilogram, supporting a range of over 1000 kilometers. The next step will be to continue to break through and achieve an energy density of over 315 watt-hours/kilogram for battery cells.

In terms of fast charging, using a charging power of 220-480 kilowatts, it will achieve the efficient goal of charging for 8 minutes and a range of 200-400 kilometers.

In terms of safety, it truly achieves the entire battery system’s absence of open flames, completely relieving user concerns.

Although GAC is developing and producing batteries on its own, cooperation with suppliers will continue. Feng Xingya, the general manager of GAC Group, introduced that cooperation with CATL is also advancing in-depth through GAC Capital’s investment in CATL.

CATL and CATL are currently GAC’s main power battery suppliers.

L4 autonomous driving to be released in 2024

At GAC Tech Day, GAC ADiGO 4.0 intelligent connected ecosystem also made its debut.

In terms of autonomous driving systems, GAC will release the Navigation Driving Assistant System (NDA), equipped with 31 intelligent perception sensors, supporting single lane cruising, automatic lane changing, automatic overtaking, and automatic entry and exit on highways and interchanges, completely freeing up users’ hands and feet and alleviating driving fatigue.

Zhang Xiong, the research and development director of GAC Research Institute’s ADiGO intelligent connected ecosystem, said that GAC will be the first traditional car manufacturer to mass-produce this feature.

Currently, other automakers that have implemented this feature are Tesla (NOA), NIO (NOP), and XPeng (NGP).

The automatic parking function of ADiGO 4.0 has also been improved. ADiGO 4.0 will have a Memory Parking System (HPA), which learns and memorizes the route to achieve low-speed automatic driving and automatic parking for medium to long distances, solving the parking pain points of users familiar with the road.

GAC Group is exploring autonomous driving very actively. Feng Xingya also stated that GAC and Huawei are collaborating to jointly develop L4 autonomous driving cars and plan to mass-produce them in 2024.

From the Guangqi Technology Day of 2021, it can be seen that the range of technological innovation among traditional automakers has surpassed the traditional realm of engines and mechanics in the era of fuel-based cars, and moved towards electrification and intelligence.

However, huge investment is inevitable. Feng Xingya revealed that in 2020, GAC’s investment in independent research and development exceeded RMB 5.1 billion, accounting for more than 8% of its operating income. So far, GAC’s cumulative investment in independent research and development has exceeded RMB 30 billion.

Just investing money is not enough, GAC Group is also innovating in the reform of the management system and the management model. Taking advantage of the policy of mixed ownership reform, GAC has established Juwan Technology and jointly established Xinghe Zhilian with iFlytek. “These two mixed-ownership enterprises with employee shareholding are responsible for the development of ultra-power batteries and intelligent cabins in two major fields.” Feng Xingya said.

In the field of technology, GAC Group’s investment not only has funds, but also has flexible mechanisms. It reflects the benefits of state-owned enterprises and avoids their drawbacks. In the competition with many domestic and foreign car companies, GAC Group’s attitude is quite competitive.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.