*Author: Hutozhen

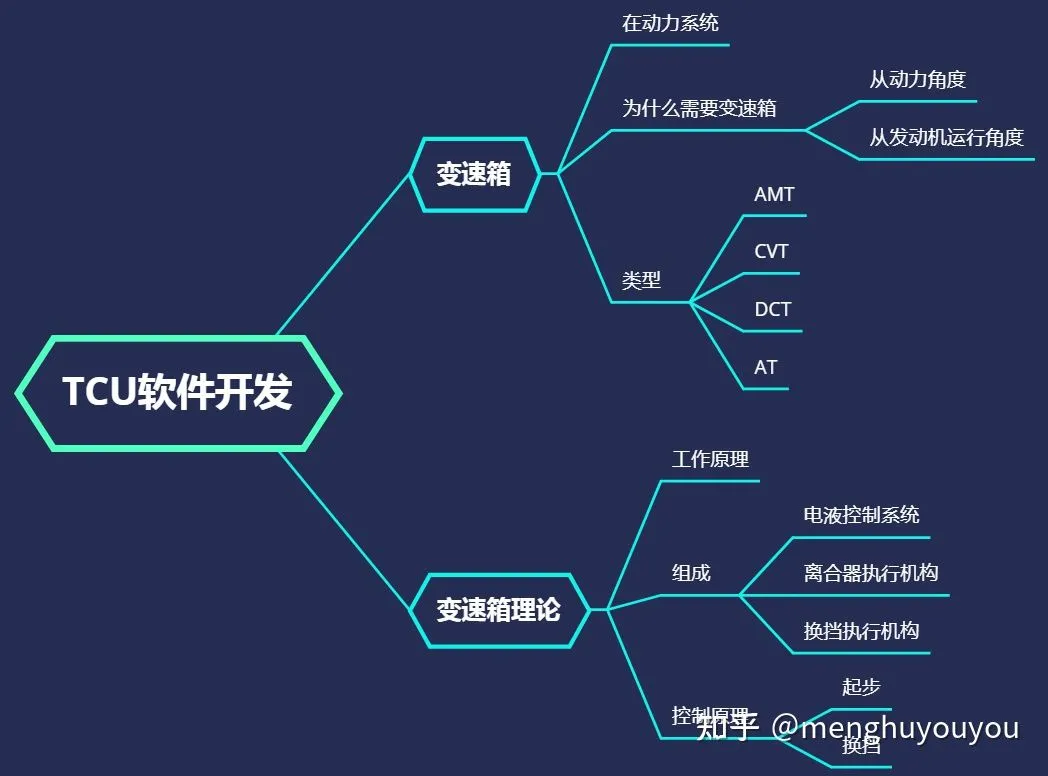

In this series of articles, I will be sharing about the software development for TCU (transmission control unit), which is not included in the “New Four Modernizations” (electrification, intelligentization, networking, and sharing) that are currently popular in the automotive industry. However, by sharing this series, important ECU software development knowledge and experience can still be obtained and utilized for the “New Four Modernizations” as well. The overall idea of this series is as follows:

Ideally, in developing software for automotive ECUs, it is essential to have a basic understanding of the control object and to have a solid grasp on its theoretical foundation. This allows for a better software development process for the control object, while also satisfying the requirements of project management in terms of development forms and processes to ensure efficiency in the development work and product quality.

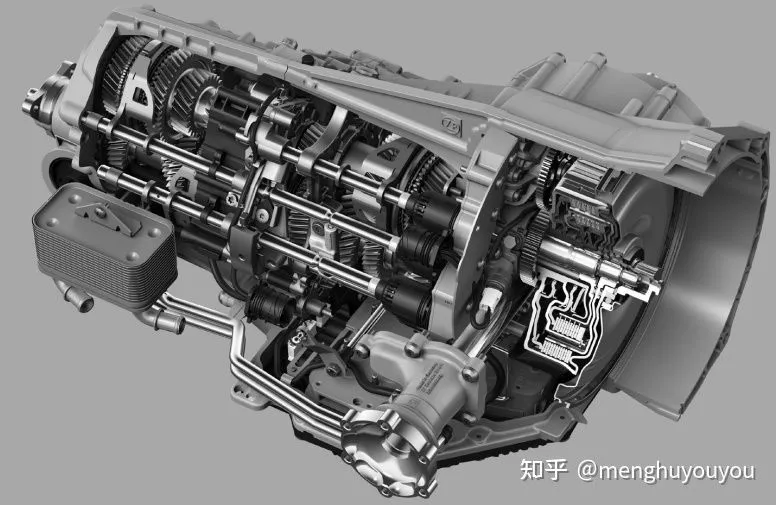

Overview of the Control Object

In this article, the control object is the transmission, and we shall first look into the theory behind it as shown below:

In the era of internal combustion engines, the transmission is an essential and critical component of the powertrain. From a power perspective, the transmission can play a role in reducing speed and increasing torque. From the perspective of engine operation, the transmission can optimize the engine’s operating range for both power and fuel efficiency.

There are 5 commonly used types of transmissions, which include MT (Manual Transmission), AMT (Automatic Manual Transmission), CVT (Continuously Variable Transmission), DCT (Dual Clutch Transmission), and AT (Automatic Transmission).

Considering the direction of the automotive industry towards the “New Four Modernizations” (electrification, intelligentization, networking, and sharing), this overview of the transmission, which is no longer a hot topic, will only be briefly introduced here.## Control Object Theory

This article introduces gearbox theory through the Dual Clutch Transmission (DCT).

As the name suggests, the Dual Clutch Transmission refers to a gearbox with two clutches, usually one for odd gears, called the odd clutch, and one for even gears, called the even clutch. The schematic diagram of the structure is shown below:

!DCT structure schematic, from [2]

As shown in the figure above, the DCT has seven forward gears and one reverse gear, which are implemented through two clutches and four shift forks. The odd clutch controls 1, 3, 5, 7, and R gears, and the even clutch controls 2, 4, and 6 gears.

When starting from first gear, the 1/3 shift fork is first engaged with first gear, and then the odd clutch is gradually engaged until the start is completed.

As the vehicle speed increases, when shifting from 1st to 2nd gear, the 2/R shift fork first pre-selects 2nd gear, and then the odd and even clutches are exchanged. That is, the odd clutch is gradually disengaged, and the even clutch is gradually engaged. When the two clutches are exchanged, the 1/3 shift fork disengages first gear, and the shift from 1st to 2nd gear is completed. The process of shifting down is similar to shifting up.

The above is a brief introduction to the working principle of DCT. Of course, when it comes to actual software control, understanding these is far from enough. A deep understanding of the key components of the gearbox is required, such as dual clutches, shift actuators, and electro-hydraulic systems.

Taking dual clutches as an example, there are two types: dry and wet. Their structures differ as shown below:

Regardless of the type, mastering the characteristics of the clutch is extremely important for control because it relates to the most critical factor of control: clutch torque. Therefore, a lot of research has been carried out in the academic and industrial fields on the characteristics of dual clutches, such as the analysis of influencing factors of clutch characteristics, estimation algorithms, and adaptive strategies.!Clutch characteristic curve, from [3]

The same is true for the gear actuator and electro-hydraulic system. It is these studies that have laid a solid foundation for the development of TCU control software.

To fully grasp the essence of control software, it is necessary to have a deep understanding of the composition, working principle, and characteristics of these key components. Of course, the benefits are not limited to this, and it can also establish the physical model required for hardware-in-the-loop simulation and even optimize the transmission system.

!Synchronizer structure and force analysis, from [2]

!Synchronizer engagement process, from [2]

!Electro-hydraulic system, from [2]

!Detailed analysis of electro-hydraulic system, from [2]

For actual control software, in addition to mastering the key components, there is also an important theoretical formula that must be mentioned: Picture, that is, torque = moment of inertia * angular acceleration. Personally, I think the control of starting and shifting is essentially based on this formula.

With the above theories mastered, in the academic field, applying some modern control algorithms can complete an excellent paper.

In the engineering field, after mastering the transmission control software through repeated practical applications, and having a deep understanding of the corresponding application scenarios, driving conditions, and practical control algorithms, mastering the application of the entire control software is basically no problem.

ConclusionThrough the introduction focusing on the transmission system, have you realized the importance of theoretical knowledge? Though it may seem less crucial in actual project development at times, we still feel it’s crucial, as a rough analogy, like you don’t pay attention to what underwear you are wearing but you will feel uneasy without it.

Therefore, we must master it to feel comfortable. Although we focused on the transmission system here, we can use this thought process to understand and delve into other areas like new energy technology, autonomous driving, etc.

Reference

[1] Dynamic Analysis and Control System Design of Automatic Transmission [book]

[2] A new control strategy of wet dual clutch transmission clutch and synchronizer for seamless gear preselect[J]

[3] Estimation of the clutch characteristic map for an automated wet friction clutch transmission[J]

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.