In just three weeks into 2021, the battery war between electric car brands has intensified. Firstly, the IM brand used silicon-doped lithium technology to achieve 1000km+ range; NIO also followed closely behind, offering 1000km+ range through solid-state batteries; GAC went further and proposed the concept of “graphene” and put forward the slogan “Fully charged in 8 minutes for 80%, 1000km range”. The promotion of high range, fast charging, safety and low cost has aroused the questioning of Ouyang Minggao, an authority in the field of power batteries and a academician at the Chinese Academy of Sciences. Under the questioning of experts and extensive media coverage, GAC Aion explained that it had actually released two products:

A graphene-based super-fast charging battery that can charge to 80% in 8 minutes and will be used in the AION V, to be put into production in September this year;

A silicon anode battery that can achieve a NEDC range of 1000km and will be used in the AION LX, to be put into production within this year.

With the groundwork laid by IM and NIO, the 1000km range no longer shocks the public. What makes GAC the focus of attention and controversy is not only because it has directly addressed the fast charging needs of users, but also because it has put forward the super gimmick of “graphene”.

Graphene: Advanced Technology or Intellectual Tax?

Since graphene was successfully isolated from the laboratory by physicists in 2004, it has attracted much attention. With a quick search on the internet, there are references to “graphene bamboo charcoal,” “graphene underwear,” “graphene electric heaters,” which means that graphene is a byword for intellectual tax.

When people see the news from GAC, their first reaction is: “What is graphene? Is this an intellectual tax?”

As the name suggests, graphene starts with graphite, which is commonly used as raw material for pencil lead. Graphite is composed of layers of sheet-like structures, and the smallest layer peeled off is called graphene, which consists of a single layer of carbon atoms arranged in a crystal lattice structure. When layers of graphene are stacked in parallel, they become graphite again.

Because it is composed of single-layer atoms, graphene is very thin and has a transmittance of 97.7%, even under a microscope it is not easy to observe with the naked eye.

Due to these characteristics, graphene has been closely associated with electric vehicle batteries since it first appeared. Top research institutions and companies around the world have frequently reported research progress in improving battery performance with graphene:

In 2011, Northwestern University discovered that graphene as a battery anode material can greatly improve energy storage and charging rate.

In 2011, Rice University found that battery made with graphene mixture can be charged up to 90% capacity in 20 seconds, with long-term stable performance, and withstand verification for 1000 cycles of use experiments.

In 2014, Spanish Graphenano claimed to have developed graphene batteries that “can run 1000 kilometers after charging for 10 minutes.”

In 2016, Professor Gao Chao’s team from Zhejiang University researches a high-performance aluminum-graphene battery that can be fully charged in 7.2 seconds.

……

Currently, the structure and performance of lithium-ion batteries have tended to mature, making it difficult to make breakthroughs in performance. Therefore, every new development about graphene batteries brings infinite expectations, and graphene is seen as a lifeline to improve battery performance. However, the path to commercialization is not so smooth.

Graphene Battery – The Reality is Tough Despite the Ideal

Although graphene’s superpower in batteries has been confirmed in the laboratory, various car brands have also successively reported the development of graphene batteries, such as Spanish Graphenano, Tesla, and British supercar company Briggs. However, they all only stayed in the PPT stage and ended up with no actual product.

As mentioned earlier, graphene’s incredible characteristics stem from its ultra-thin structure and enormous “specific surface area.” However, single-layer graphene still remains in the laboratory stage, and the performance of large-scale prepared multi-layer graphene will inevitably be compromised. How to produce single-layer graphene on a large scale, how to maintain the ultra-high performance of multi-layer graphene, and how to avoid changes in properties caused by excessive contact between graphene and other materials are all challenges in the mass production and use of graphene.Up to now, there are no products on the market that use graphene as the primary material for batteries due to its high cost and difficulty in preparation. Therefore, using a small amount of graphene as an auxiliary additive has become a secondary choice. Guangzhou Automobile Group’s “graphene-based battery” is also such a case.

“Graphene-based battery” ≠ “Graphene battery”

The difference between “graphene-based battery” and “graphene battery” is not just a matter of one word. Both technically and in terms of performance, they are quite different.

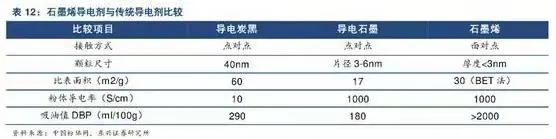

Guangzhou Automobile Group’s “graphene-based battery” uses graphene as a conductive additive, adding a small amount to the positive electrode of a lithium-ion battery (no more than 4%). Essentially, this is still the familiar lithium-ion battery, and graphene is just an additive.

The small amount of graphene used has a negligible effect on the energy density of the battery or the range that people are most concerned about. However, the super-high electron mobility of graphene can achieve rapid charging.

Graphene Conductive Additive: New Wine in Old Bottles?

Guangzhou Automobile Group is not the first to use graphene as a conductive additive in lithium-ion batteries to achieve rapid charging.

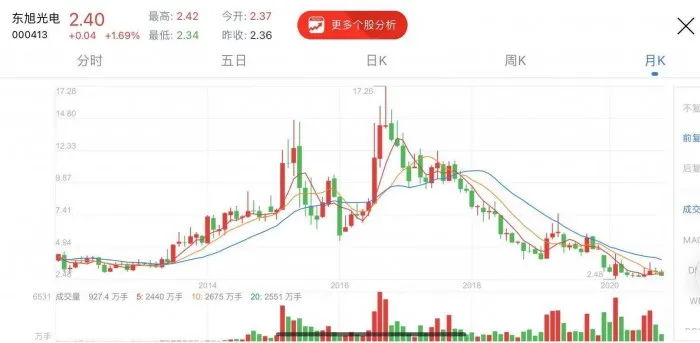

As early as 2016, as a leader in the domestic graphene industry at the time, Dongxu Optoelectronics launched the world’s first graphene-based lithium-ion battery product-“Xenwang” Power Bank. This power bank uses graphene as a conductive additive to achieve a 5000mAh fast charge in 15 minutes. Similar to Guangzhou Automobile Group’s product, the launch of this product also briefly pushed Dongxu Optoelectronics’ stock price to its peak in 2016.

However, after the brief peak, the stock price continued to decline. This was because at the time, the price of graphene preparation was very high, and the cost of raw materials and production of conductive additives also increased accordingly. Moreover, the market demand for fast-charging power banks was not as high as expected.

If power banks can be made into fast charging, why wouldn’t people just buy a fast charging phone? Indeed, subsequently, mobile phone products such as Xiaomi 10 Ultra have used graphene conductive additives in their lithium-ion batteries, achieving 120W ultra-fast charging.

Graphene conductive additives have long been applied in mobile power banks and phone battery products. Using it in electric vehicles by Guangzhou Automobile Group is somewhat like new wine in old bottles. So what’s different about this “new bottle”?With the example of “Xi Wang”, GAC was prepared in cost control of graphene. In July of last year, GAC announced its independently developed 3DG graphene preparation technology with independent intellectual property rights on Technology Day, which is said to reduce the cost to the 1/10 of conventional preparation. In September 2020, Guangzhou Jiuwan Technology Research Co., Ltd., which was incubated internally by GAC Group, was registered and established to specialize in the application of graphene in fields such as super-fast-charging batteries and super capacitors. The cost of conductive agent accounts for only about 2% of lithium-ion batteries (data from Founder Securities). With the support of self-made raw materials, GAC has some advantages in researching and developing graphene-based batteries.

Secondly, compared with power banks and mobile phones, consumers have a significantly more urgent demand for fast charging of electric vehicles. Energy replenishment anxiety has always plagued electric vehicle users. If there is a technology that can achieve rapid charging of several minutes like refueling a fuel vehicle, we believe that many consumers would be willing to pay for this technology.

However, we still have some reservations about GAC’s fast-charging technology.

After all, the battery of an electric vehicle is not a little bigger than a mobile phone battery, and the complexity of the internal structure and the requirements for safety and heat dissipation are higher. Whether graphene-based lithium-ion batteries can really achieve “80% charge in 8 minutes” remains to be seen when the product comes out.

In addition, fast charging of electric vehicles is not a one-sided effect of the battery. It requires the cooperation of the battery, charging pile, and power grid. Referring to Tesla’s V3 supercharger with the highest charging efficiency currently available on the market, the peak charging power is 250 kW. Tesla has also adopted a combined arrangement of V3 and V2 at charging stations to reduce excessive load. From the exposed picture of the GAC Aion highly powered super-fast charging pile, the maximum power can reach 600 kW, which is more than twice that of Tesla.

It should be noted that the power of the power grid of a medium-sized residential area is only 1000-2000 kW. The challenges of the GAC Aion’s large peak power to the power grid load, safety, and heat dissipation device have raised questions about the prospects for the entry of this charging pile into the market: If you cannot find a charging pile, how can you use fast charging?

Finally, although the slogan “80% charge in 8 minutes, 1000 km range” is tempting, the real effect still needs to be discussed based on the information released by GAC. The application of graphene in electric vehicles is also in the stage of experimentation.

Looking downstream, Tainan Technology and Dow Tech, the main suppliers of graphene in the industry, are mainly focused on products such as graphene conductive agents and carbon nanotube conductive agents. The real graphene battery that everyone is looking forward to may still have a long way to go.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.