Recently, Bosch Dresden announced that its first batch of silicon wafers had been produced from its fully automated production line. The Bosch Dresden wafer fab will enter into formal production in the second half of 2021, focusing on vehicle chip manufacturing.

Starting from June 2018, the Bosch Dresden wafer fab has been under construction and has invested about €1 billion with a floor area of about 100,000 square meters. In November 2020, the factory’s high-precision production line was completed and put to trial production, for which the factory will hire 700 employees responsible for production management, monitoring, and machine maintenance work.

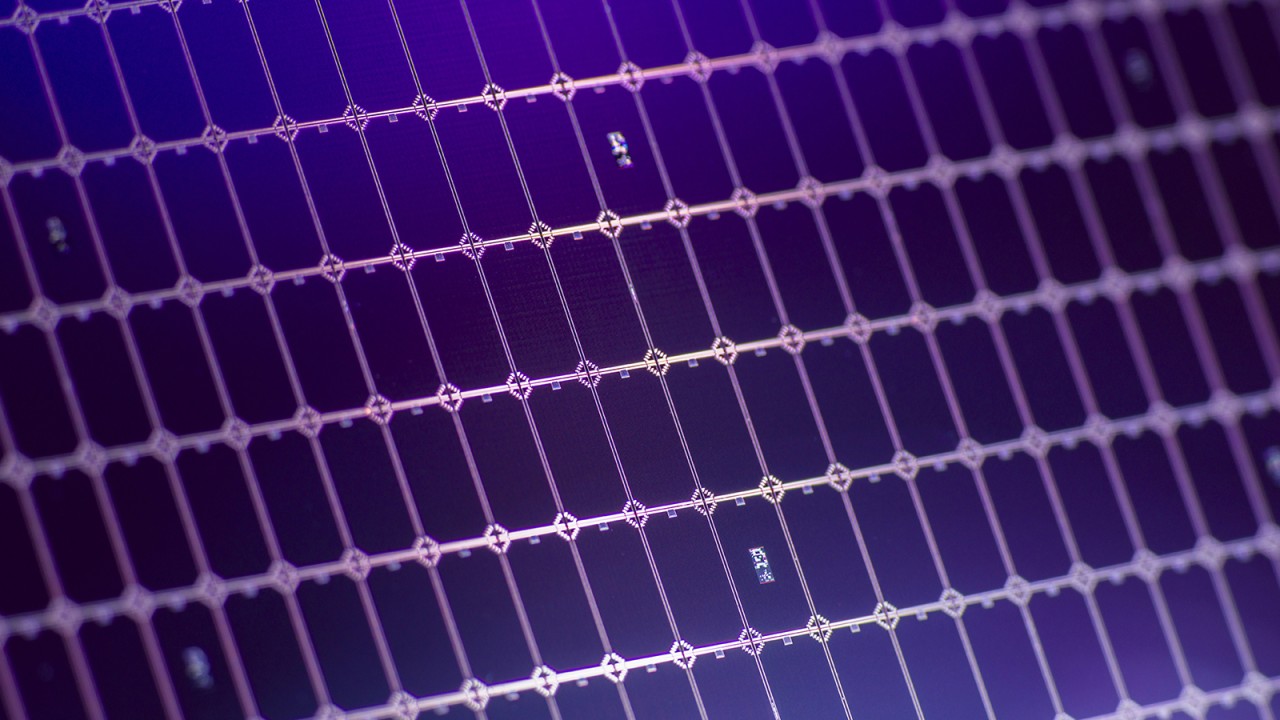

The Bosch Dresden wafer fab will manufacture wafers with a diameter of 300 millimeters, and a single wafer can produce 31,000 chips. Compared with traditional 150mm and 200mm wafers, 300mm wafer technology will increase production efficiency. After the Dresden wafer fab officially enters into production and operation, it will effectively cope with the increasingly growing market demand in the current stage of application of car semiconductors.

🔗 Information source: Bosch

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.