Introduction

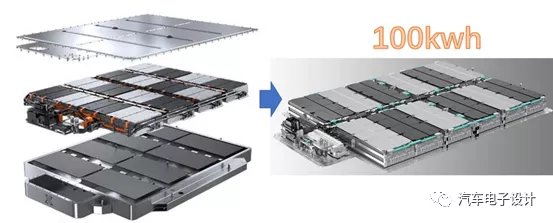

With the communication of NIO’s 150 kWh battery system previously, the company has undergone a significant change in the same battery size specification, from 70=>84=>100=>150 kWh, especially the change from 100 kWh to 150 kWh. Further information may be released at NIO Day. However, this weekend we can attempt to explore how this was achieved.

Note: The 100+ kWh battery system seen in Lucid is made up of cylinders, BMW’s planned 120 kWh battery system has not appeared, and the 200 kWh battery system in BEV3 is a combination of two 100 kWh modules.

Exploring from 100 kWh

1) Upgrading the C-family Solution

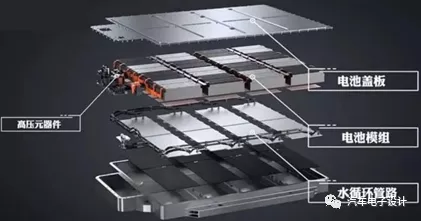

Based on the existing information, upgrading from 32 modules (2.625 kWh at 84 kWh) to 12 modules (8.3 kWh per module) has already reached a certain limit in layout. If the existing specifications remain the same, there needs to be a significant improvement in single-cell energy density.

This means that if the 590 cell specification of the C family remains unchanged, then it is possible to adopt the NCM 811+ silicon-carbon anode, and possibly use a certain amount of lithium supplementing process. Based on this foundation, it is possible to achieve a 150 kWh solution.

2) Honeycomb Solution

Another option is the honeycomb solution, which was also explored during the honeycomb battery day. It was visited by NIO’s senior staff. It is possible to further improve the battery system by adopting longer cells for the 590 modules designed for the Great Wall.

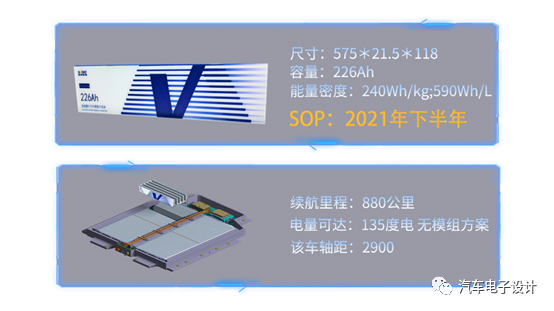

As shown in the following figure, the customized honeycomb cell is 575mm in length, 21.5mm in thickness, and somewhat similar to the 590 cell in which several cells are enclosed together in a pouch. This honeycomb energy system is aimed at the NEDC’s endurance target of 880km for the Great Wall and is expected to be launched in the second half of 2021.

On the basis of this size specification of 57421.5118, it is hoped that the capacity of this 135 kWh battery can be further increased to 150 kWh with the use of high-nickel + SI materials for adjustment.

On the basis of this size specification of 57421.5118, it is hoped that the capacity of this 135 kWh battery can be further increased to 150 kWh with the use of high-nickel + SI materials for adjustment.

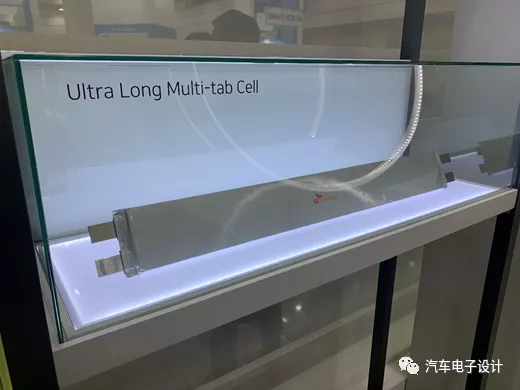

3) Soft pack solutions from overseas

According to reports from Korean media, in the direction of soft pack, both LG Chem and SK have started to further increase the length from 500mm to 1000mm. That is to say, after BYD made blade, the existing soft pack manufacturers who were using stacking process were also developing batteries with larger capacity. From the existing 78Ah to upgrade to about 120-130Ah, if 2P or above, it can be further increased.

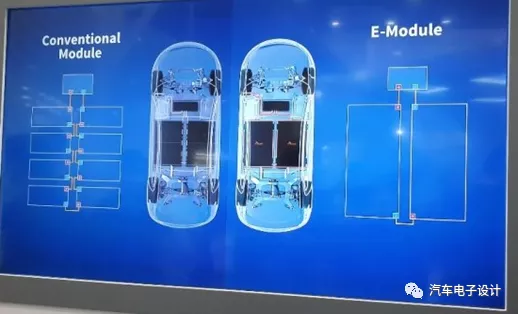

If we only make the battery system into 2 long modules as shown in the figure below, and cooperate with high energy density cells, it can be further increased to about 150kWh.

Summary

I wrote down the speculation over the weekend, and this competition from 100kWh to 150kWh seems to be like a skyscraper height competition for the next high-end models, which cannot stop in the short term.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.