Introduction

Last week, I had the opportunity to attend Honeycomb’s Battery Day in person. This battery day mainly focused on battery safety, technical routes, and corporate vision, etc. Honeycomb, an emerging battery company, presented some possibilities of lithium battery technology to us, showing us some different things.

Jelly Battery

This year, the battery faces great challenges in terms of application safety. Mature overseas battery companies and car companies have experienced large-scale recalls, such as SDI in BMW and Ford PHEV batteries, and LG Chem in General Motors and Hyundai-Kia BEV batteries.

Therefore, for a battery company, long-term development needs to be focused on the safety of the entire battery life cycle. This year, almost all battery companies’ R&D focus is on the solution to thermal runaway. Honeycomb has a solution named “Cold Bee”, which controls the spread of heat from four aspects: material, cell, battery pack, and monitoring system. In the “Cold Bee” thermal runaway solution, the jelly battery designed based on cobalt-free cathode material and electrolyte material is worth mentioning.

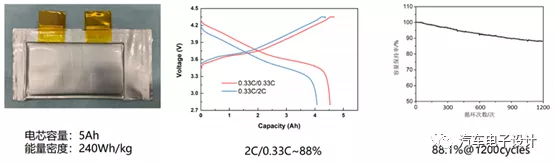

Honeycomb is very good at naming products. This time, the jelly battery based on gel electrolyte was given a vivid name: “Jelly Battery”. According to the introduction, the jelly battery has high conductivity, self-healing, and flame retardancy characteristics, which can prevent thermal diffusion without significantly reducing the electrical performance.

Honeycomb claims that the heat resistance temperature of the “Jelly Battery” has been increased to 150°C, and it also has the “self-healing” characteristic (simply understood, the polymer electrolyte can be slowly self-healed even if it is cut by a small knife, leaving no scars). In the needle puncture test of a fully charged jelly battery laboratory sample, it can achieve “no ignition, no smoke, self-healing”.

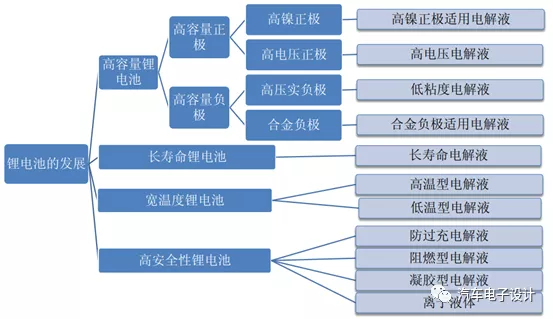

The electrolyte plays a role in ion conduction between the positive and negative electrodes of a lithium-ion battery, ensuring the high voltage and high specific energy advantages of lithium-ion batteries. Among the four main materials of the battery, the use of electrolyte must be matched with the use of positive and negative electrode materials. In 2020, in the two directions of high voltage positive electrode materials and long-life batteries, battery companies need to use suitable electrolytes.

The jelly battery proposed by Honeycomb this time is mainly based on gel-type electrolytes, which can better fit the electrode surface, thereby improving the conductivity. Currently, the conductivity of this material can reach 6×10-3 S/cm. This is also a major technology in the evolution of disc-type cell technology.

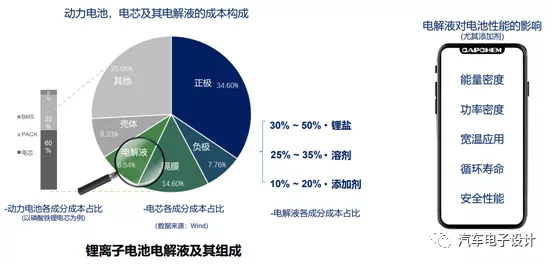

In lithium-ion batteries, electrolyte is a component with low cost but high effectiveness, which affects the performance of the battery in multiple dimensions. From the current perspective, everyone is making great efforts to adjust the positive and negative electrode materials, adjust the separator, but the impact of the electrolyte on the performance characteristics of the lithium-ion is very significant. Adjusting in this direction has a certain leverage effect, which can make the safety characteristics and other performance of the battery different.

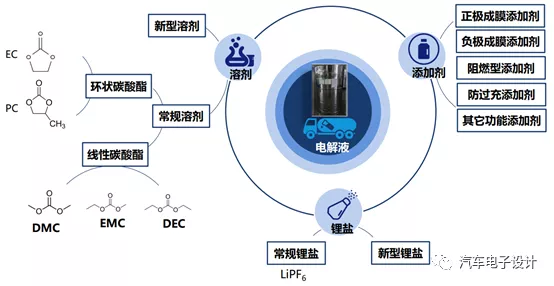

Electrolyte is generally composed of high-purity organic solvents, lithium salt electrolytes, necessary additives and other raw materials, and is formulated in a certain proportion under certain conditions, as shown in the figure below.

Compared with liquid electrolytes, this jelly-like electrolyte greatly improves safety. Evaluation through needle penetration testing shows that the product under test exhibits excellent flame retardancy at high temperatures, making it relatively easy to achieve a result of L0 with no ignition during needle penetration experimentation. Incorporating this type of electrolyte into the existing product system will significantly increase the safety of the battery pack. Hesai has demonstrated that by applying jelly battery technology to its 90 Ah square battery, heat dissipation can be effectively blocked, significantly increasing the safety of electric vehicles.

Using this material only incurs a slight additional cost. From an overall perspective, the internal resistance of a jelly battery is 5% higher than that of a ternary lithium battery with a liquid electrolyte. The charge and discharge rate fluctuates by ±2% depending on the cobalt content, and the cycle life will be sacrificed by 5%. However, considering the greatly improved safety performance, the small sacrifice in performance is still worthwhile.

Summary

Based on the information released on Battery Day, Hesai Energy has also laid out its next-generation technology plans, including an all-solid-state battery. The development from liquid electrolyte to full solid-state battery requires a process where the electrolyte content in the battery is gradually reduced, evolving from a gel electrolyte system to a semi-solid system before finally transitioning to a fully solid-state battery. The release of the jelly battery not only strengthens the safety of batteries from the material side, but also represents a big step forward for Hesai Energy in the development process of solid-state batteries.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.