On August 25th, Elon Musk revealed on Twitter that battery cells with energy density of 400 Wh/kg and high cycle life were not far from mass production, probably in about 3-4 years. This compared to the current 2170 battery cells used in the Model 3, with an energy density of about 240-250 Wh/kg, would mean a 60% increase in energy density at the cell level. Even without any optimization of the battery pack, with the current cell-pack assembly efficiency of the Model 3, the energy density is expected to reach 220-230 Wh/kg, which is quite impressive.

Recently, Tesla’s official website announced the date for the Shareholder Meeting and Battery Day: September 23rd, 2020, 4:30 am Beijing time. After the Shareholder Meeting, the Battery Day will follow. Although the date was already known, the background image is interesting.

Foreign media Electrek discovered through Google image search that the messy lines and “silicon nanowires” in the background were extremely similar to those developed by Amprius, which is the main developer of this technology.

On Amprius’ “About” page, they proudly stated, “Amprius Technologies provides the world’s highest energy density lithium-ion batteries. 100% silicon nanowire technology completely changes the battery technology.”

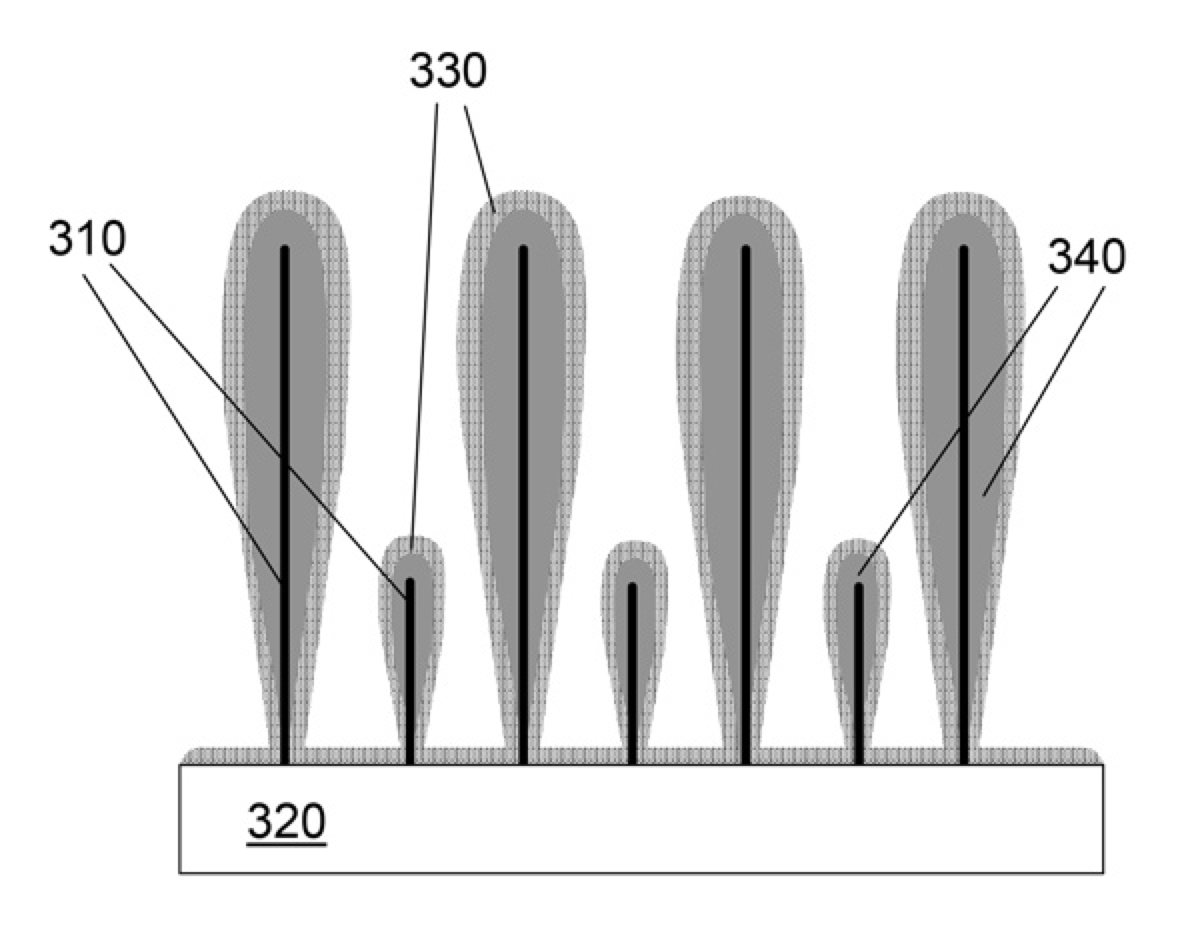

Amprius’ website explains that the limitation of the capacity of lithium-ion batteries is due to the amount of lithium that can be accommodated in the battery electrode. Traditional lithium batteries use graphite as the negative electrode, while the storage capacity of silicon is about 10 times that of graphite.But silicon has a major drawback that it expands dramatically during charging, leading to the rupture of silicon and causing battery failure. Some companies have attempted to mix silicon with graphite, but they have not achieved 100% silicon.

Amprius Technologies has developed a 100% silicon lithium-ion battery through nanotechnology, which stores lithium in tiny nanowires. The nanowires can withstand volume expansion due to lithium absorption and are rooted in the substrate with tiny gaps.

Interestingly, a Twitter user found that the company has moved its headquarters next to Tesla’s Fremont factory…

Today, another netizen found large-scale equipment entering Tesla’s battery factory in Fremont for renovation during aerial photography.

Although Battery Day has been postponed repeatedly, expectations are getting higher and higher.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.