Yesterday, a netizen on Weibo released the document about the Ministry of Industry and Information Technology’s record of the imported version of the Tesla Model 3, which showed that the “vehicle controller model” was 1462554, which is the Tesla HW3.0 chip.

This has caused confusion for many users, does this mean that the imported version of Tesla Model 3 was originally supposed to be equipped with the HW3.0 chip?

After learning about this, we asked Tesla staff about it, and they said that the file exposed on Weibo came from the application materials in the “Catalogue of New Energy Vehicles Eligible for Exemption from Vehicle Purchase Tax”.

We found the 26th batch of the tax exemption catalogue released on August 30, 2019.

In the tax exemption catalogue, the model numbers of the three Model 3 models, E3D5, E3DP5, and E3R5, are consistent with the model numbers in the Ministry of Industry and Information Technology’s publicly available document circulating on Weibo.

That is to say, at that time, the configuration lists declared for the three Model 3 models, including the long endurance all-wheel drive version, the long endurance rear-wheel drive version, and the high-performance all-wheel drive version, were all equipped with the HW3.0 chip.

This is different from the situation where the hardware model number displayed on the environmental protection list of domestic Model 3s is inconsistent. The environmental protection list accompanying the imported version of Model 3 does not display the vehicle controller model number, which means that there is no sufficient evidence to show that there is inconsistent information in the sales process of the imported version of Model 3.

However, if there is a situation where the vehicle hardware and the tax exemption application declared hardware are inconsistent, it will affect the application conditions for tax exemption.

So why did Tesla declare the HW3.0 chip instead of the HW2.5 chip at that time?

Let’s take a look at a detail. In 2019, the Ministry of Industry and Information Technology’s official website issued a total of 7 batches of “Catalogues of New Energy Vehicles Eligible for Exemption from Vehicle Purchase Tax”, with the shortest interval of 17 days and the longest interval of 85 days. In mid-March 2020, the most recent batch of “Catalogue” publicized was still on December 27, 2019.The publicized time of the Catalog is subject to instability, and companies need to make predictions for different periods according to their actual declarations.

For example, Tesla entered the Chinese market as early as 2014, but it wasn’t until the 26th batch of tax-exempt vehicle purchase Catalog was published on August 30, 2019 that Tesla entered into the scope of tax-exempt vehicle purchases.

According to staff members of traditional automotive companies, in order to declare the “Catalog of Tax-Exempt New Energy Vehicles”, they must prepare for product switching well in advance. However, once the “Catalog” is successfully declared, it is still inevitable that the short period of product switching will cause actual losses to car buyers due to some effects on the vehicle purchase process, leading to customer complaints.

In other words, there is a certain time gap between the production switching time of HW3.0 and HW2.5 chips predicted by Tesla during the declaration, and the actual publicized time of the Catalog.

In order to clarify the issue, let’s review the origin of mixing HW3.0 and HW2.5 on the made-in-China Model 3.

Starting from the Made-in-China Model 3 Safety Incident

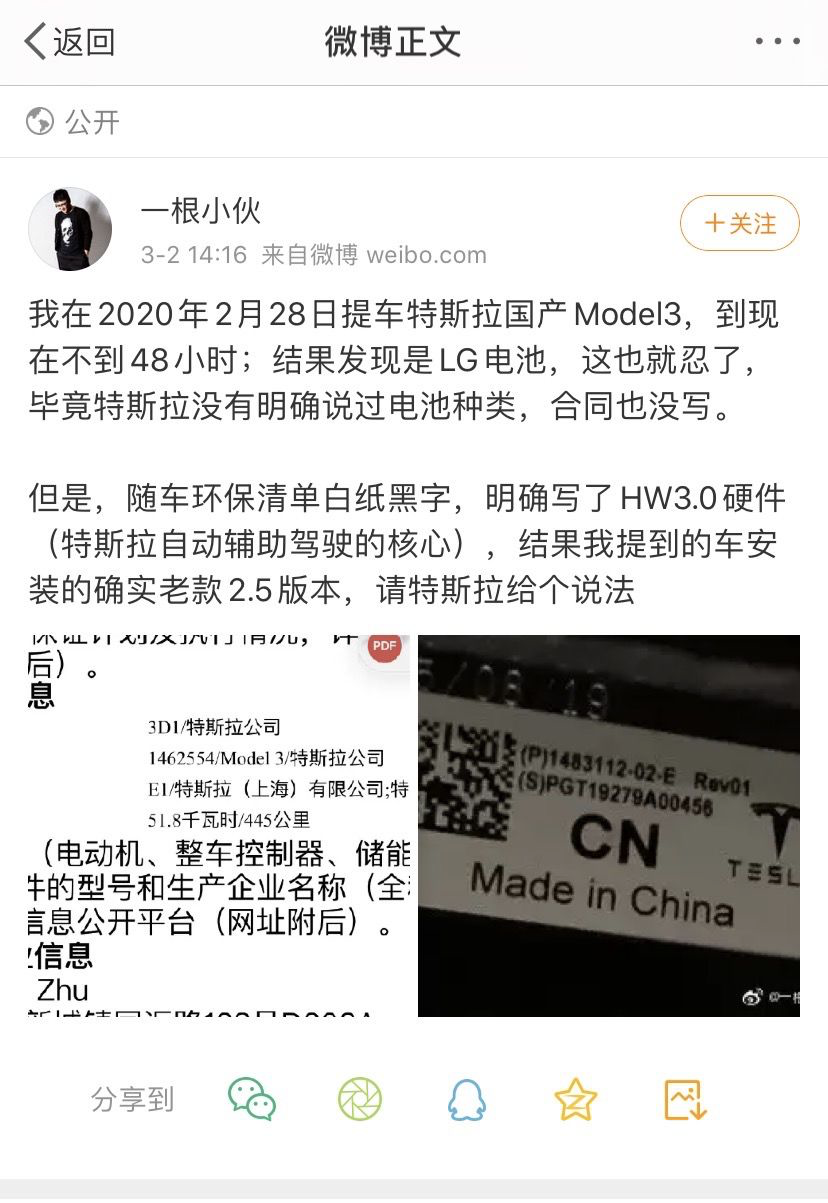

On March 2 of this year, a newly delivered made-in-China Tesla Model 3 car owner found that the “Vehicle Controller Model” in the accompanying environmental protection list was “1462554”, but after dismantling the car, it was found that the car was equipped with hardware with the code name “1453112” instead.

For those who are unfamiliar, the “Vehicle Controller” refers to Tesla’s self-driving chip. “1462554” represents the HW3.0 hardware, while “1453112” represents HW2.5 hardware.

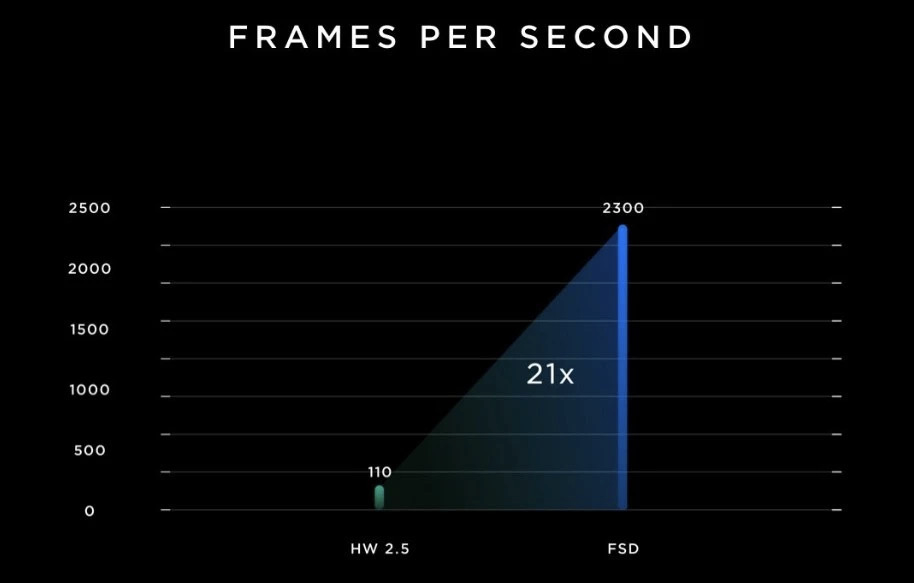

Among them, HW3.0 is Tesla’s self-developed self-driving chip, which can process 2,300 frames of images per second, while HW2.5 is provided by NVIDIA and can process 110 frames of images per second. In terms of information processing ability, HW3.0 is 21 times more powerful than HW2.5. Of course, this is only a difference in hardware level, and the difference at the car end also needs to be combined with software capabilities.

In fact, the cost of HW2.5 is higher than that of HW3.0, so it is not cost-effective for Tesla to do so.

Returning to the topic, after the first mismatch case was exposed on March 2, more and more car owners who received their cars recently found that their vehicles were also equipped with HW2.5 hardware, and the incident gradually began to ferment.On the morning of March 3rd, Tesla officially announced that due to the impact of the pandemic, there has been a shortage of HW3.0 chips. Therefore, some domestically produced standard range upgraded Model 3 vehicles have been installed with HW2.5 hardware.

Tesla also stated that as the supply chain capacity recovers, they will provide free hardware replacement of HW3.0 for all domestically produced standard range upgraded Model 3 vehicles installed with HW2.5 hardware, even if the car owner did not opt for FSD.

On March 10th, the Ministry of Industry and Information Technology interviewed Tesla (Shanghai) Co., Ltd. regarding the problem of some Model 3 vehicles being illegally equipped with HW2.5 components. They ordered Tesla to rectify the problem immediately in accordance with the regulations of the “Measures for the Administration of Production Enterprises and Product Access of Road Motor Vehicles” to ensure production consistency and product quality and safety.

Vehicle Declaration Process

To better understand how this issue occurred, we need to first review the procedures that each vehicle must go through before being released for sale on the market.

First, the internal departments of the car manufacturer apply for each type of car model’s data and actual vehicles to the National Development and Reform Commission. The staff of the National Development and Reform Commission will check whether each parameter is true and whether it meets national regulations. If the parameters are true and meet the requirements, the vehicles will be announced on the National Development and Reform Commission’s official website and gain access approval to produce road vehicles.

This is the first step.

Secondly, for each new energy vehicle, they must also comply with the “Regulations on the Administration of Access of New Energy Vehicle Production Enterprises and Products” before going on the market.

After meeting the above two requirements, the vehicles can be sold on the market.

In addition, for new energy vehicles, there is also a “Catalog of New Energy Vehicles Exempted from Vehicle Purchase Tax,” which must be applied for and meet national regulations before being included in the “Catalog” and exempted from purchase tax.

Each regulation mentioned above emphasizes that the applying enterprise must ensure “production consistency assurance capability.”It is obvious that Tesla’s problem is the lack of consistency in the vehicle production process, where the “vehicle controller” on the actual car is inconsistent with the declared record.

As for the “on-board environmental protection list” mentioned earlier, it is just one of the documents that happened to prove that Tesla had a problem with the consistency of the vehicle production.

Does this problem only occur with Tesla? We have found the following cases.

In 2018, 18 car companies were interviewed by the Ministry of Industry and Information Technology for not installing side and rear anti-collision devices, not affixing vehicle product labels, not adhering to the national standard for vehicle identification numbers, arbitrarily altering and modifying them, and inconsistency in the dimensions and curb weight with the “Road Motor Vehicle Manufacturing Enterprises and Products Announcement” or the “Vehicle Production Qualification Certificate”.

The results were that in accordance with the relevant provisions of the “Road Motor Vehicle Manufacturing Enterprises and Products Announcement” management regulations, depending on the nature and severity of the violations, administrative penalties, revocation of problematic products, rectification within a specified period, and criticism interviews were issued as punishment measures.

So, why didn’t Tesla declare a batch of HW2.5 hardware models?

It was too late.

According to an engineer from a car company, the declaration process takes 4 to 6 months, and predicting the updated product information for declaration requires sufficient time. If hardware iteration or shortages of stock occur, it will affect product launch or production schedule.

The normal practice for a car company to replace vehicle parts is to first apply for record with the Ministry of Industry and Information Technology, and then replace and sell the parts.

Tesla did not anticipate the occurrence of the black swan event, the epidemic, or the impact on the supply of HW3.0 chips. In order to meet the needs of both tax exemption and production capacity, Tesla chose to install HW2.5 hardware on some models.

The engineer said that Tesla has such problems, which is mainly due to the company’s lack of professional experience in certification and declaration. In addition, mixing a part of HW2.5 hardware just to avoid affecting delivery data should not have been done. More importantly, when delivering vehicles with HW2.5 hardware to customers, they should inform them in advance and prepare for the replacement of HW3.0 hardware, rather than starting remedial measures only after receiving user feedback.

Objectively, this is a major problem in the management of the vehicle certification process by the company. From a subjective perspective, the trust of users in the brand has been somewhat damaged.For friends who have opted for FSD, the difference between the two chips is certainly huge. However, Elon has also promised that users who have opted for FSD will be upgraded to HW3.0 chips for free. On March 7th, Tesla’s official website announced that reservations for China will open in April, and will start to replace HW3.0 chips for old car owners who purchase FSD. In addition, we have received feedback from users in WeChat groups that Model 3 owners in Shenzhen, Zhuhai and other places have received invitations from service centers in recent days, and some owners have successfully replaced their HW3.0 hardware.

As for users who did not opt for FSD, Tesla stated that currently, there is not much difference in driving and safety experience between the two chips. However, as functions gradually become more powerful, the differences between the two chips will gradually become more obvious, just like the current difference in the ability to recognize ice cream buckets and future differences in recognizing ground markings.

Tesla’s practice of mixing hardware versions is certainly not right. Any important adjustments must fulfill the obligation to inform consumers, especially since this relates to legal regulations.

Pursuing speed is a good thing, but Tesla also needs to seriously address issues in its professional processes while facing rapidly increasing sales. This is a problem that Tesla has encountered more than once.

As early as the first batch of Model 3s entering China, customs suspended clearance due to problems such as warning signs lacking Chinese annotations, complete vehicle nameplates missing, and nameplate annotations being incorrect.

Faced with the “black and white” demands of consumers this time, we hope Tesla can learn from its experience and improve its internal management process as soon as possible, so as not to overdraw consumer trust again.

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.