Today, China-made Model 3 was officially delivered to customers, while the Model Y project was officially launched. This is a historic day and year for Tesla.

At the delivery site of China-made Model 3, Elon was so happy that he danced to express his emotions to the outside world. Compared with last year, Elon was even more unrestrained this time, not only dancing with great enthusiasm but also taking off his clothes.

China-made Model 3 delivery site on January 7th, 2020

As a superfan of Elon, I watched this video over and over again, laughing throughout.

In our community, everyone also affirmed Mr. Ma’s dancing skills.

The last time Elon personally delivered cars to Chinese market users was six years ago when Tesla first entered the Chinese market, at that moment Tesla started its journey to overturn the traditional Chinese auto market.

Today’s official delivery of China-made Model 3 symbolizes Tesla’s second step in the Chinese market, which is equally significant.

A year ago, Elon dancing on the barren land would not have expected that a factory could be built from scratch and achieve mass production of cars so quickly.

Groundbreaking ceremony for Tesla Shanghai factory on January 7th, 2019

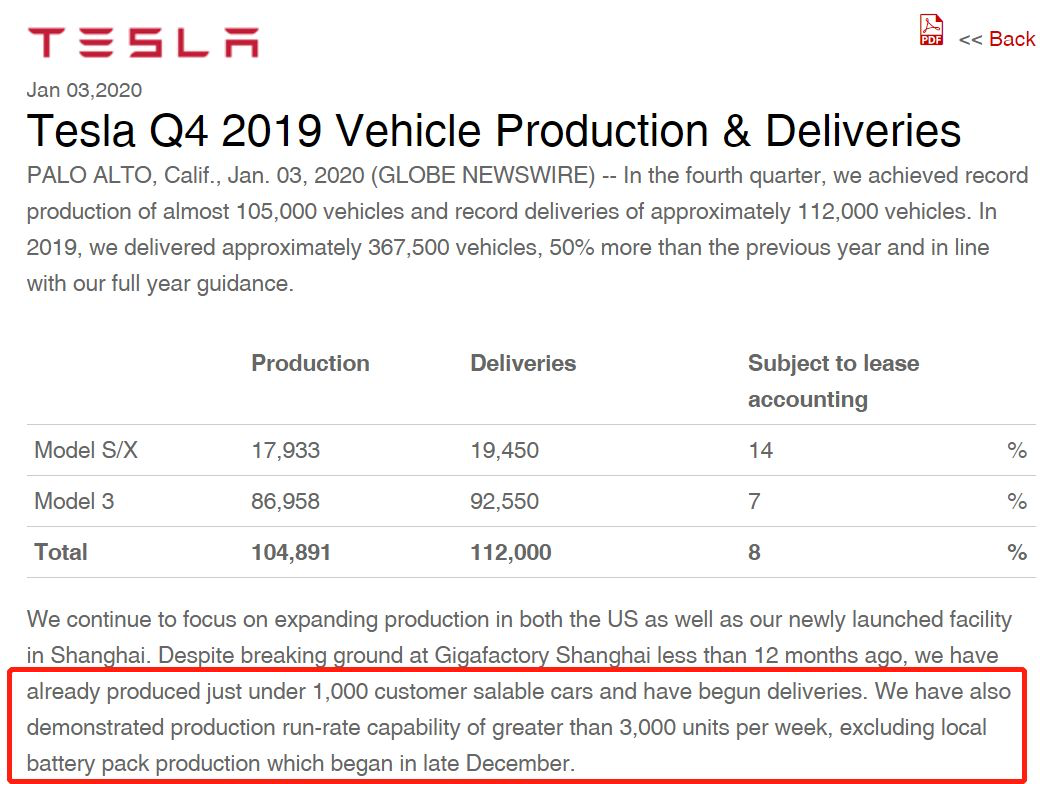

In the past 365 days, a factory covering an area of 0.86 square kilometers was built on this land in Lingang. All supporting facilities have moved in and been adapted, achieving a super-high weekly output of 3000 vehicles.

At the same time, Tesla’s Shanghai Super Factory also received a loan of over 10 billion yuan at a super-low interest rate.

At today’s event, Elon also said, “Without the Chinese government, there would be no super factory today“, and highly affirmed the efforts of Tesla China team.

As China’s first wholly foreign-owned car company, Tesla is poised to make a big move!

Are the fuel cars ready?

Thanks to the resources support of the Chinese government, on the third day of 2020, Tesla successfully lowered the price of the domestically produced Model 3, after subsidies, to below 300,000 yuan. This day was eagerly anticipated by everyone, and it arrived earlier than anticipated.

However, what caught everyone off guard was that today is not only the day when the Chinese-made Model 3 is delivered, but also the day when Tesla’s Shanghai factory Model Y project is launched.

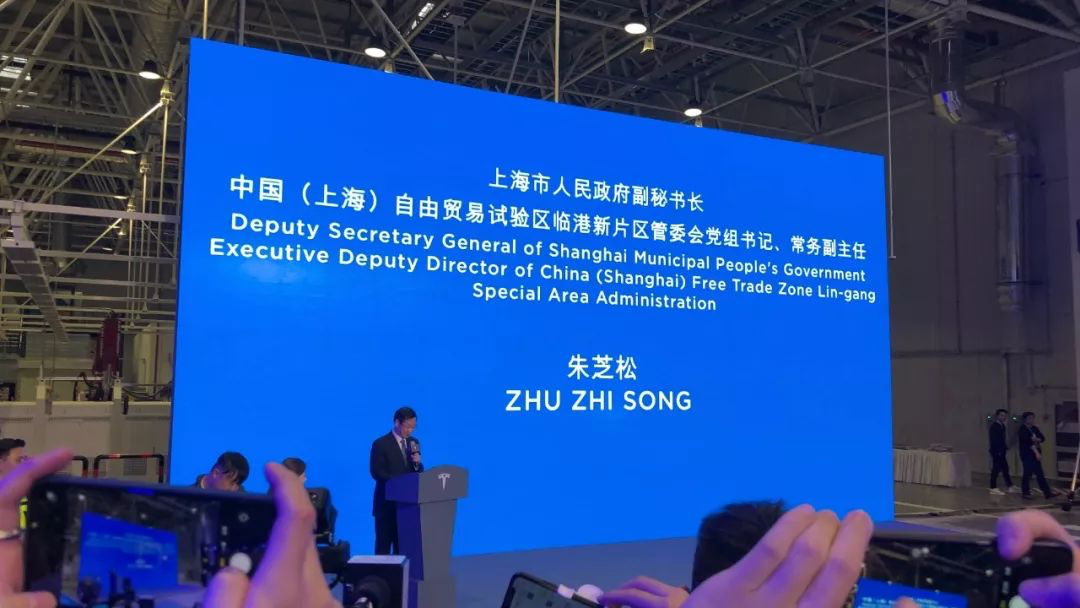

At the event, Zhu Zhisong, Deputy Secretary-General of the Shanghai Municipal Government, announced that the “Made in China Model Y project has officially started.”

Since the official release of the Tesla Model Y on March 15, 2019, the production time for the Model Y has been accelerated.

-

Tesla initially planned to launch the production of Model Y on August 1, 2020, and achieve a production capacity of 2,000 vehicles per week on September 1, with Model Y deliveries starting in the fall of 2020.

-

At the Tesla Shareholders’ Meeting in June 2019, Elon Musk stated that “Model Y is an important model after Model 3. Although it is scheduled to be delivered in the fall of 2020, the company needs a more aggressive timetable internally.”

-

In the Q3 2019 Tesla financial report published in October, Model Y progress exceeded expectations with the scheduled delivery time being moved up to the summer of 2020.

-

At the end of November 2019, Taiwan’s Economic Daily News reported that “Tesla has notified suppliers to begin delivering parts for the Model Y,” which is half a year earlier than planned.

-

In early December 2019, the latest research report from Deutsche Bank showed that the delivery time for Tesla Model Y would start as early as Q1 of next year.– In mid-December 2019, Baird analyst Ben Kallo visited the Fremont factory and said, “Model Y is expected to achieve a weekly production capacity of 1,000 units in Q2.”

Today, the project of manufacturing Model Y in China officially launched, which means that the production line of Model Y in Tesla’s Shanghai factory has officially started. According to Tesla’s current rapid pace of progress, we can boldly predict that China-made Model Y is likely to achieve mass production in Q3 of this year.

This time point is half a year to a year earlier than the original mass production time point.

For the entire automotive industry, the arrival of Model Y came a bit fast and a bit fierce.

Elon said at the event today:

Model Y is an SUV that everyone can afford, just like Model 3 is a sedan that everyone can afford. Sedans and SUVs are two very important markets for Tesla. Some consumers prefer SUV models, so we hope that Model Y can better meet consumers’ needs. Our Model Y will also use more advanced production and manufacturing technology, which we will reveal one by one in the future. I am personally very excited about the technology used in Model Y. Please stay tuned.

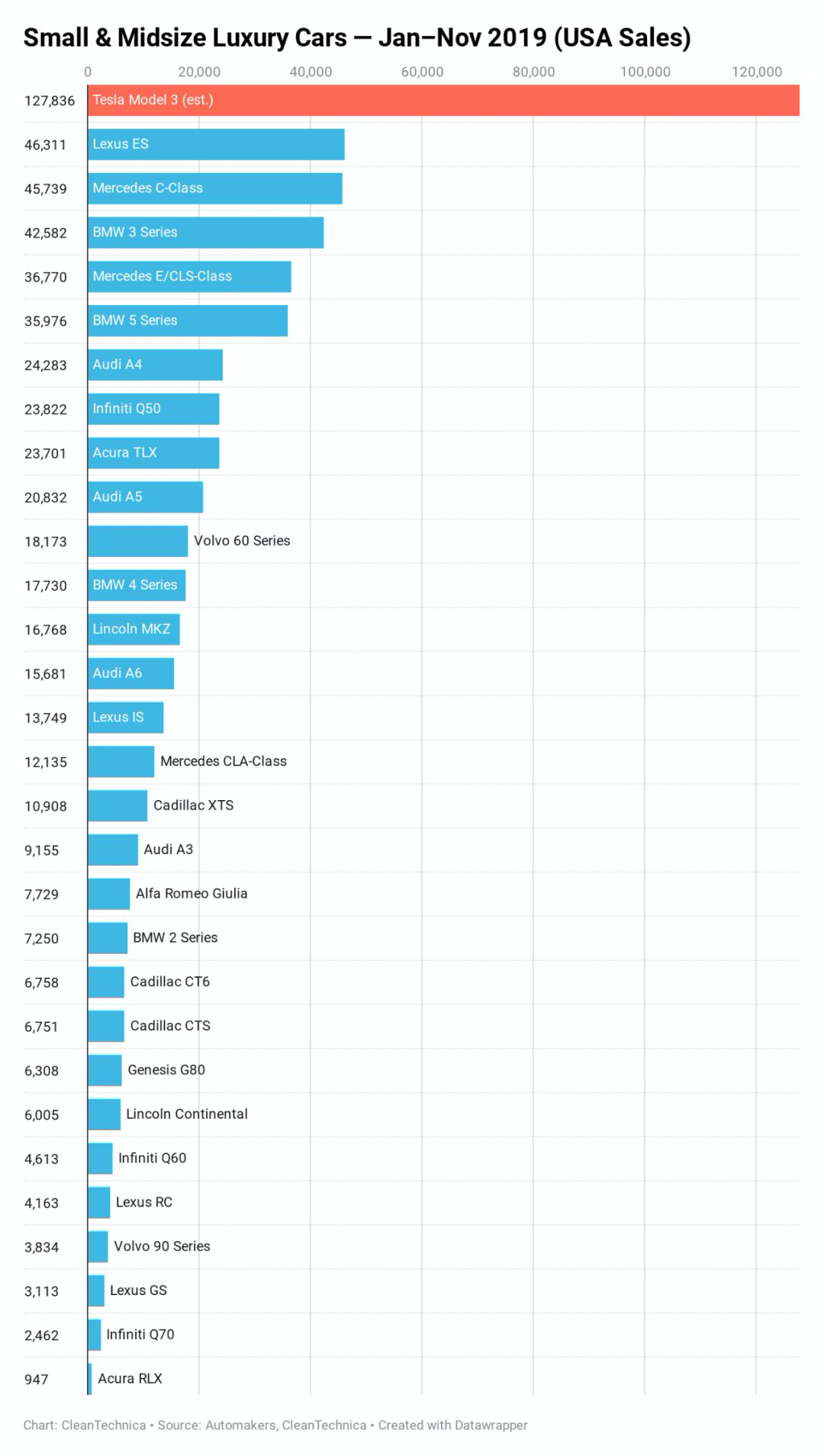

In the past two years, Model 3 has gained a large market share in the small and medium-sized car market with its excellent product power.

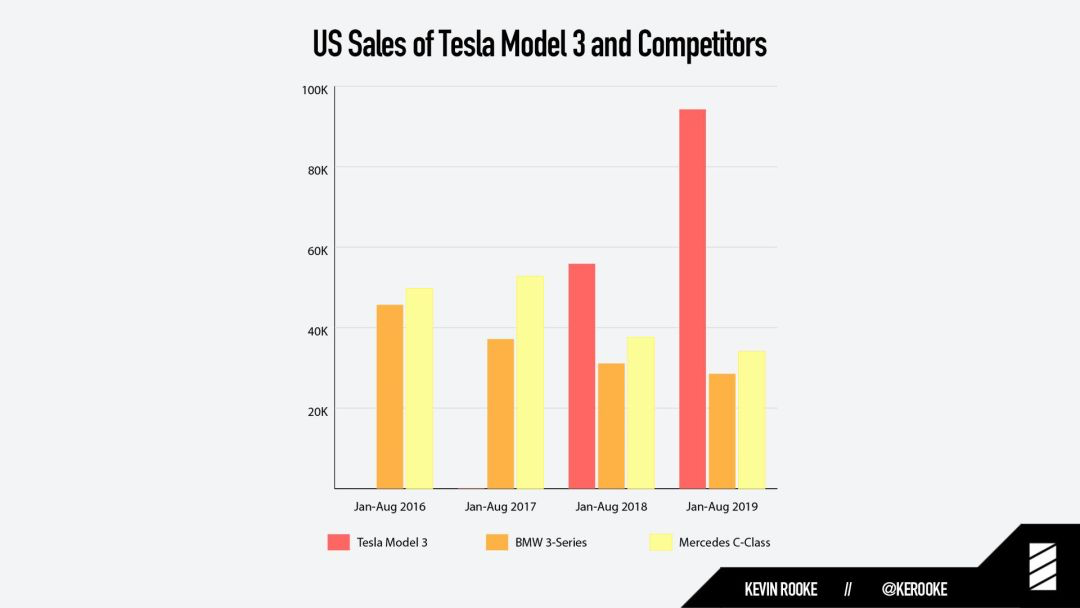

In the US market’s small and medium-sized car sales rankings from January to November 2019, Model 3 not only sold 127,800 units, far surpassing the second place with sales of 80,000 units, but also more than the sum of BMW 2 Series, 3 Series, 4 Series, and 5 Series.

According to data compiled by Twitter user Kevin Rooke, since Tesla released Model 3 in 2016 to 2019, sales of Mercedes-Benz C-Class in the US have declined by 31%, and sales of BMW 3 Series have declined by 37%.

Compared with Model 3, Model Y will have a more fierce impact on the gasoline-powered car market.In the US market, the best selling car of BMW in 2019 is X3, the best selling car of Mercedes is GLC, the best selling car of Lexus is RX, and the best selling car of Audi is Q5. All of the top-selling models of these 4 brands have a common feature, they are all mid-sized SUVs, and Model Y is just such a mid-sized SUV.

Now let’s take a look at the Chinese market. Although the sales volume of Model 3 in the domestic market is not as explosive as that in the US market, it is still outstanding in the pure electric vehicle market, especially after the price of domestic Model 3 dropped below 300,000 yuan.

An interesting phenomenon has emerged online. Before this, everyone compared Model 3 with other electric cars. However, after the price of domestic Model 3 dropped below 300,000 yuan, people began to compare Model 3 with BMW 3 series.

Also, on the day when the price of domestic Model 3 was reduced, many of my friends asked me about the car. It’s the first time I’ve encountered such a phenomenon. I also felt deeply impressed that electric cars are really coming into their own.

Due to the growing popularity of electric cars, it is even more important to speed up the production of Model Y. According to statistics from the CPCA, a total of 811,000 luxury SUVs were sold from January to November this year, accounting for only 4.4\% of total car sales, but with a high growth rate of 30.1\%, the fastest-growing sub-segment in the entire auto market, far exceeding other categories.

If Model Y can further reduce its price with the increase in domestic production rate and enter the market of mainstream joint venture SUVs, it will have an even greater impact on the existing market of fossil fuel cars.

At the NIO Day on December 28, 2019, William Li, the founder and chairman of NIO, did not release the price of EC6, stating that the reason for not releasing the price was that Model Y would also enter the Chinese market in 2020, hoping to retain some market flexibility.However, it seems that not only should pure electric vehicles of the same level be taken seriously, but also the gasoline vehicle brands of the same level!

Tesla’s Speed Leaves Competitors Reeling

Elon once said on Twitter:

Our true competition is not the small trickle of non-Tesla electric cars being produced, but rather the enormous flood of gasoline cars pouring out of the world’s factories every day.

我们真正的竞争对手不是正在生产的非特斯拉的电动汽车,而是每天从世界工厂涌出的大量汽油车。

As for the product itself, Tesla’s performance in the American and European markets has already proved the point. As Tesla’s official poster says, “You guys keep going in 2020.”

Tesla CFO Zachary Kirkhorn said in the Q3 earnings conference:

Our global order rate remains strong and continues to increase. Despite increases to production levels, our order backlog has been growing, and quarter to date orders are significantly higher than at this point in last quarter.

我们的全球订单需求强劲且持续增长。尽管产能有所增加,但我们的积压订单仍在增长,迄今为止的 Q4 订单量明显高于 Q3 的同一时期。

Obviously, the key factor that currently restricts Tesla from further expanding sales is production capacity, but this is almost a thing of the past.

As mentioned earlier, the construction speed of Tesla’s Shanghai factory has been mentioned, but what is even more surprising is the production ramp-up speed of the Shanghai factory, which far exceeded everyone’s expectations.

In the Q4 2019 production & delivery data released by Tesla on January 3rd, Tesla stated that the production capacity of the Shanghai factory has now reached 3,000 vehicles per week.

The Shanghai factory has a total planned annual capacity of 500,000 vehicles. The first phase planned annual production capacity of 150,000 Model 3s has already been achieved within 2 months since the official start of production in mid-October. This is an absolute miracle in the automotive industry.

Behind this miracle, not only did the Chinese government provide great help, but the spirit of all Tesla employees, who “gave up their families and worked tirelessly”, was also essential. In addition to the two aforementioned points, Tesla has truly achieved a 7*24 hour work status.

Generally, due to time zone differences, the efficiency of ordinary multinational enterprises is usually relatively low, but Tesla has taken advantage of the time zone differences. When Chinese engineers get off work, American engineers return to their workstations, so Tesla’s one day is equal to two days of other companies.

Therefore, everything in the Shanghai factory is done very quickly, and everything is accelerated.

In the meantime, Tesla’s another overseas super factory-the Berlin factory has also been unveiled.

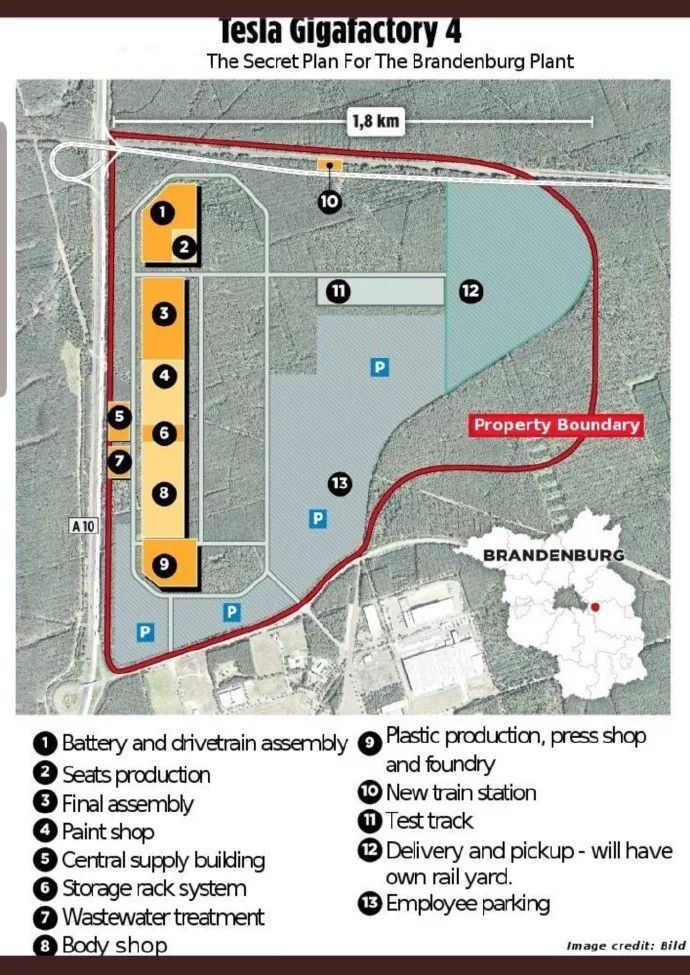

On November 12, 2019, at the Golden Steering Wheel Awards Ceremony held by German media AutoBild, Elon announced that Tesla’s European super factory will be built near the new Berlin airport.

On January 3, 2020, according to the Brandenburg Gazette, the approval process for Tesla’s Berlin super factory has officially begun, and it is expected to start producing Model Y and Model 3 models in July 2021.

Tesla plans to have an initial production capacity of 3,000 vehicles/week (150,000 vehicles/year) at the Berlin factory, gradually increasing to 500,000 vehicles/year.

Although the Berlin super factory has not yet started construction, it is believed that with the help of the construction experience of the Shanghai super factory, the Berlin super factory will definitely be completed within Tesla’s planned time.

At the interview of the delivery ceremony for the first batch of Chinese-made Model 3 employee cars on December 30th, Tesla China’s general manager, Wang Hao, also expressed confidence in Tesla’s sales in China for 2020, saying “we will sell exactly how many we produce”.

Obviously, Tesla is very confident in its own sales volume, and the reason behind this is the embodiment of Tesla’s extreme efficiency.

It is well known that there is an intermediary dealer between traditional automotive companies and consumers, adding an extra layer of distribution and reducing profit margins. Furthermore, due to the existence of the dealer system, the prices of traditional automotive models are not transparent and the customer experience is also very poor.

It is well known that there is an intermediary dealer between traditional automotive companies and consumers, adding an extra layer of distribution and reducing profit margins. Furthermore, due to the existence of the dealer system, the prices of traditional automotive models are not transparent and the customer experience is also very poor.

In contrast, Tesla became the world’s first car company to adopt a direct sales model from first principles, bringing more direct customer data and lower customer acquisition costs through direct sales.

It is reported that due to more direct contact with customers, the cost of sales leads for each Tesla customer is much lower than that of traditional models of the same level, probably less than one-third of the latter.

In addition, Tesla differs greatly from traditional automakers in that it invests minimally in marketing. Nevertheless, whether it is the product itself or Elon Musk’s Twitter fever, I am reminded of the delivery event several hours ago. Although many people may not know what Tesla has done today, the world knows about Elon Musk’s dancing at the event.

Obviously, Tesla has never lacked traffic, spending less than you do and having even greater exposure. If Tesla were a marketing company, there would be no sense of incongruity.

Now let’s talk about the savings on the factory side. Through systematic learning and iteration, the equipment cost expenditure per unit of Tesla’s Giga 3 in Shanghai has been reduced by 65% compared to Giga 1 in Nevada, and labor costs at the Shanghai factory are only 1/10 of those in the United States.

Currently, the localization rate of Model 3 parts in China is only 30%, but it will reach 70% by mid-year, and achieve 100% localization by the end of the year. Obviously, with the improvement of the local supply chain system, the manufacturing cost of Tesla’s Shanghai factory will further decrease. No one can predict when Tesla may enter the price range of mainstream joint venture brands, and at that time, the Chinese automotive market will see a new bloodbath.

As for why so many consumers choose Tesla, I don’t want to say much more. The better driving experience compared to vehicles of the same level, the lower operating cost compared to vehicles of the same level, the hassle-free and effortless Autopilot, and the OTA updates that bring new experiences every now and then.If you are not familiar with Tesla, you will have a brand-new understanding of Model 3 after reading the following two articles:

This year, not only will various traditional brands launch their first pure electric cars, but at today’s CES, the consumer electronics brand Sony also unprecedentedly released a pure electric car. The wheels of electrification are rolling forward.

2020, let’s go!

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.