On November 12th, Elon flew to Germany and at the AutoBild Golden Steering Wheel Awards ceremony, Model 3 won the Golden Steering Wheel Award for midsize cars, surpassing Germany’s traditional luxury brands. At the award ceremony, Elon announced that Tesla’s European super factory will be built near Berlin’s new airport. Many European car company executives, including those from Volkswagen, Audi, and Jaguar Land Rover, were present at the ceremony. Was Elon Musk sending a warning to these companies by building a factory on their turf?

Later, the host invited Volkswagen CEO Diess to join Musk on stage for a discussion. Diess praised Tesla as a pioneer in electric cars with Musk being a true innovator, and that consumers love Tesla.

Although it was just a commercial mutual praise, it is apparent that from their communication, building Tesla’s second super factory in Germany makes perfect sense.

After the award ceremony, Elon tweeted that the Berlin super factory will include vehicle manufacturing, battery, and power unit production, with the first model being the Model Y.

It is not surprising that Tesla chose to build their European super factory in Berlin. In fact, Elon subtly hinted this on Twitter last year, and looking at the distribution of whole vehicle factories in Germany, it is fair to say that Germany is definitely a “nation built on wheels”.This is only a part of the German automobile industry. In addition to the factories, Germany also has component giants such as Bosch, Continental, and ZF.

It can be said that Berlin, Germany has a more complete supply chain layout and more automotive industry-related talents compared to Shanghai, China.

Advancing into Berlin, Winning Another City

The European automobile market is second only to North America and the Asia-Pacific region. More importantly, Europe is also the earliest region to propose a ban on the sale of fuel vehicles. As early as 2015, the Netherlands proposed that it will ban the sale of fuel vehicles by 2025. Afterwards, European countries such as Norway, Germany, the United Kingdom and France have also successively proposed to ban the sale of fuel vehicles.

Traditional German automobile manufacturers with keen sense of smell have also begun to transform towards electrification. The Volkswagen ID. series, Mercedes-Benz EQ series, and BMW i series have all started to enter the market, attempting to encircle Tesla.

In fact, in December 2012, in order to better enter the European market, Tesla announced that its European factory in Tilburg, Netherlands began operations. This factory will serve as Tesla’s service and parts headquarters in Europe, as well as the final assembly and distribution point for Model S/X vehicles sold in Europe.

The factory started production of Model S/X in S/CKD form on August 22, 2013. This is Tesla’s first factory outside of California.

At the end of 2016, Tesla acquired Grohmann Engineering, a German company that has long been committed to designing and developing automated manufacturing systems. Subsequently, Elon told investors that Tesla is making significant investments to expand its European business and announced plans for a new “super factory” and an automated manufacturing research center.

However, for various reasons, this factory, which should have been called Gigafactory 2, was discontinued.

So far, the vast majority of Model S/X in Europe are assembled in the Tilburg factory in the Netherlands, and all Model 3 are imported from the United States.

This means that the highest volume Model 3 will have difficulty in having a price advantage over future competitors, and although the Model S/X models can better control costs, due to product positioning issues, sales are difficult to significantly increase. This is not the result that Tesla wants.But now, Tesla has sounded the call to arms again. This time, however, it’s not a long journey or an airdrop landing, but the establishment of a super base in the enemy’s territory. So what if you are a century-old car manufacturer? We are facing you head-on!

The Price is the Bottom Line

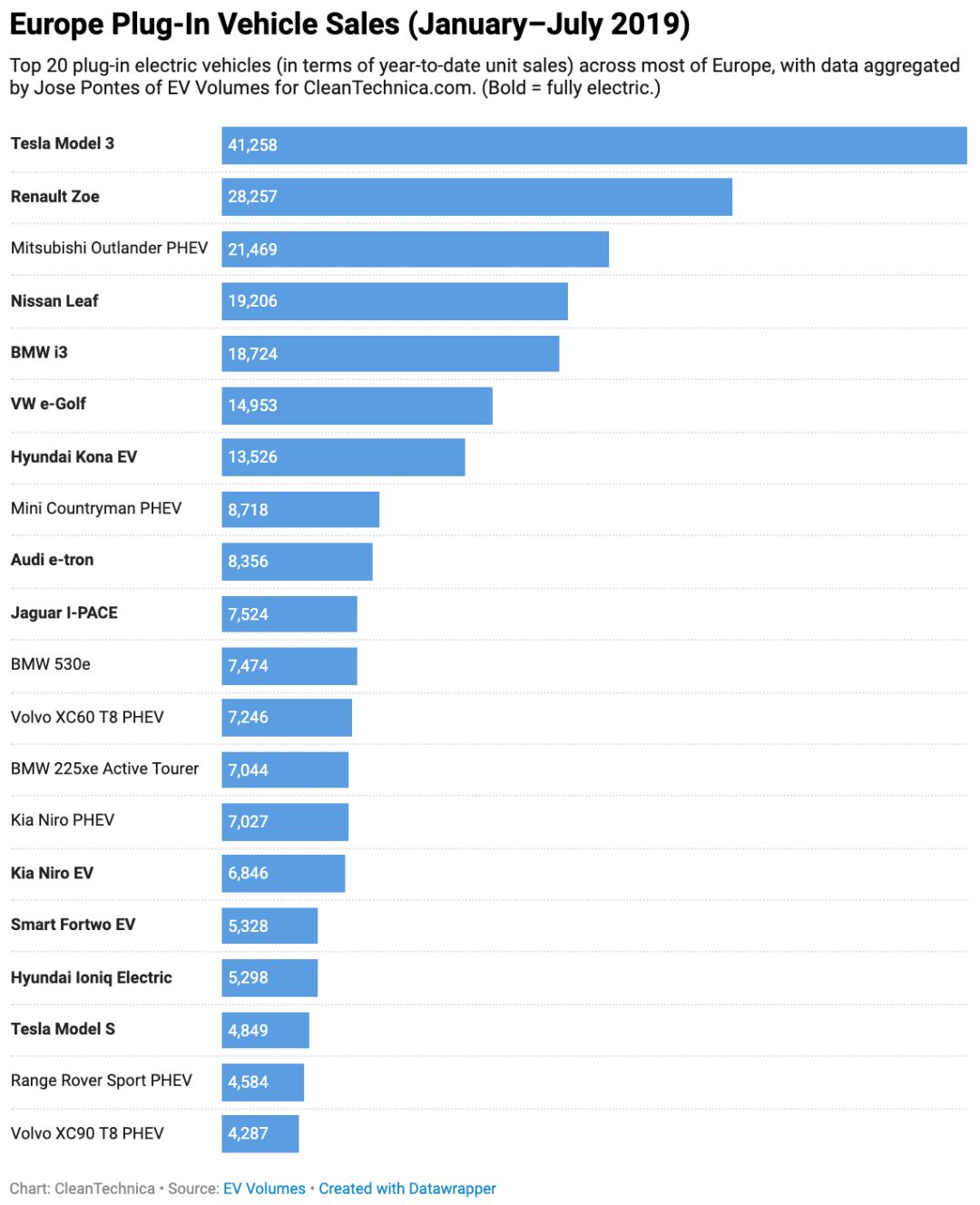

Although Model 3 has already firmly held the position of the top-selling new energy vehicle in Europe, it is far from enough. After all, Elon once said in a tweet:

Our true competition is not the small trickle of non-Tesla electric cars being produced, but rather the enormous flood of gasoline cars pouring out of the world’s factories every day.

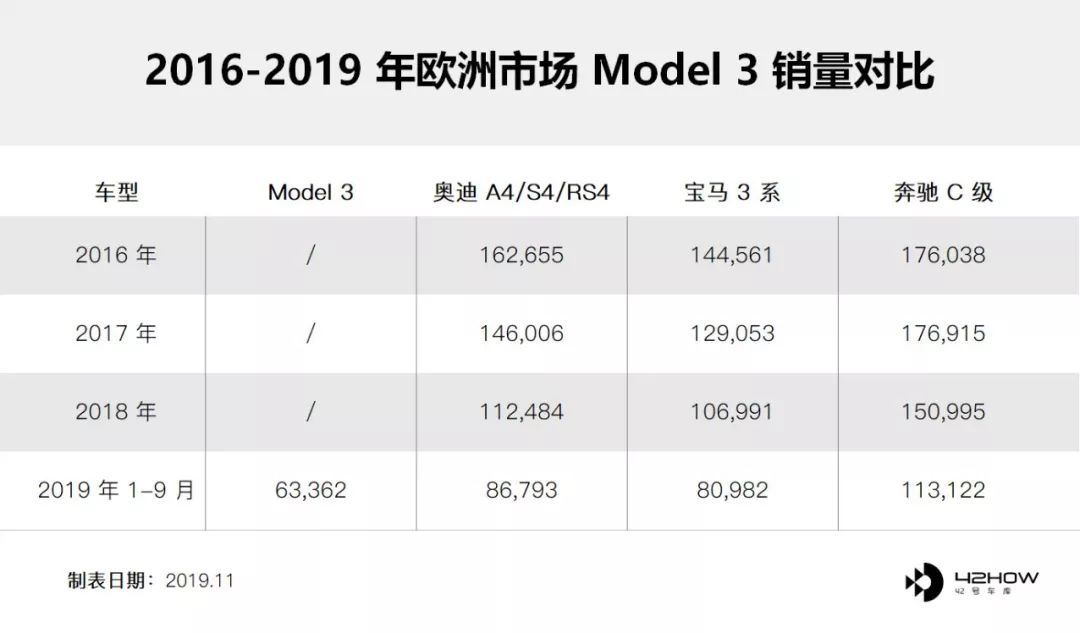

However, looking at the entire European market, BMW 3 Series, Audi A4, and Mercedes C-Class, each has an annual sales volume of about 150,000. Even if Model 3’s sales volume from January to September this year is used to estimate annual sales, it is still difficult to surpass 90,000 units. There is still a lot of room for improvement even if we want to completely catch up to BBA.

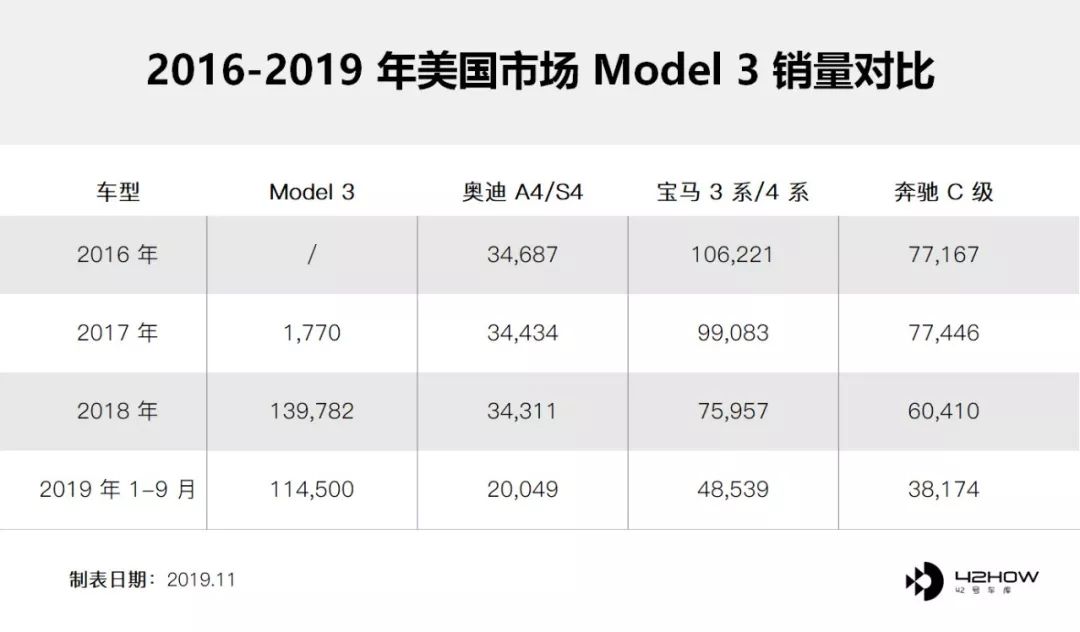

If we look at the domestic market in the United States, the situation is completely different.

Model 3’s sales volume in the US from January to September this year is higher than the total sales of Audi A4/S4, BMW 3 Series/4 Series, and Mercedes C-Class combined.

Next, let’s take a look at another set of data.

Model 3 production has been ramping up since 2018, and its sales in the US market have been rapidly increasing. At the same time, sales of Audi A4/S4, BMW 3 Series/4 Series, and Mercedes-Benz C-Class have all shown a significant decline.

Model 3 production has been ramping up since 2018, and its sales in the US market have been rapidly increasing. At the same time, sales of Audi A4/S4, BMW 3 Series/4 Series, and Mercedes-Benz C-Class have all shown a significant decline.

Clearly, Model 3 is the winner.

As for why there is such a huge difference between Europe and the US, it’s not that European consumers have no demand for Model 3, but a large amount of demand has been suppressed because they “can’t afford” it.

Let’s take the Audi A4 35 TFSI automatic transmission as an example. Model 3 is nearly 8,500 euros more expensive.

Looking at the US price, if Model 3 can also be locally produced in Europe, then its price will also be on par with BBA.

Many people may say that the Shanghai factory has been built, and the price of domestically produced Model 3 has hardly changed. If you have read our previous article on “Analysis of Tesla’s pricing policy for domestically produced Model 3 in China,” I just want to say, the best is yet to come.

However, due to the delay of the Berlin Gigafactory, the first model produced after its completion will be Model Y. Unfortunately, in the short term, we may not see Model 3 wreaking havoc in the European market like it does in the US.## Heading towards millions of annual sales

Apart from the price factor, there is another factor that also restricts the sales of Model 3 in Europe, which is production capacity.

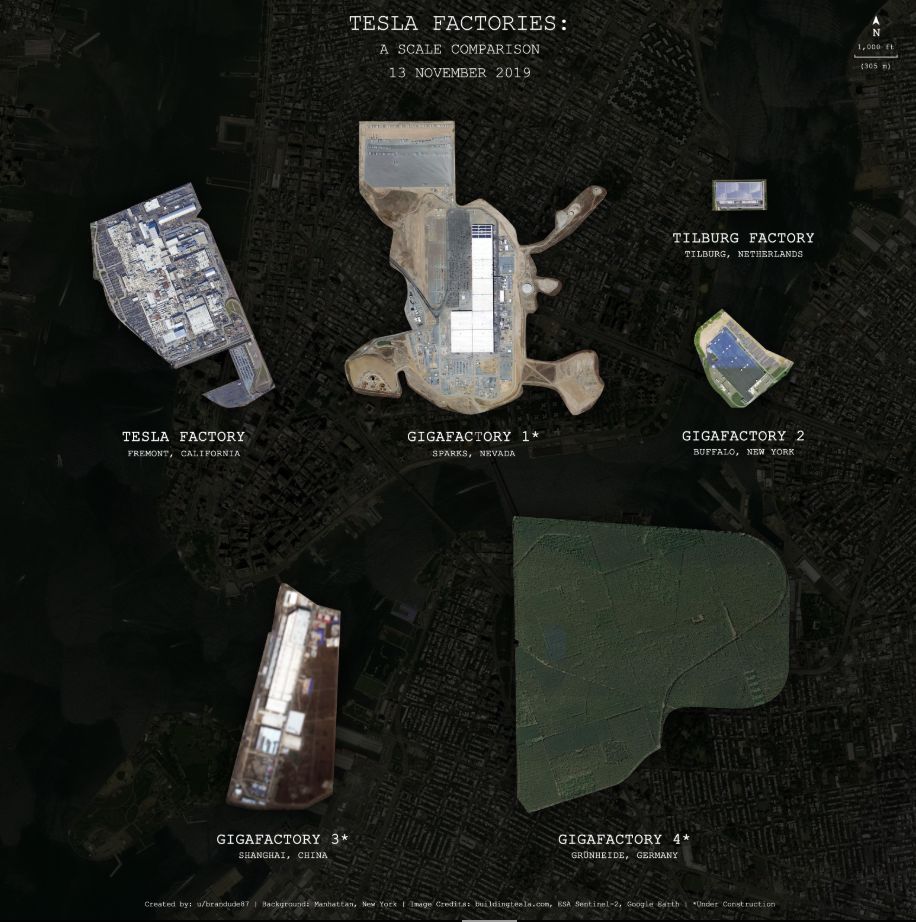

Let’s take a look at the product line layout and production capacity planning of all Tesla factories.

As the Shanghai factory has just been built, its production capacity can be ignored for now. The production capacity of the Fremont factory in California already includes the maximum capacity of the Tilburg factory in the Netherlands, so the production limit of Tesla is currently 450,000 vehicles per year.

Compared with Tesla’s delivery target of 360,000 to 400,000 vehicles this year, as of the Q3 quarter, Tesla has delivered 252,000 vehicles globally.

No matter how you calculate it, it seems that there is some excess production capacity. But in fact, it’s just the opposite.

Tesla CFO Zachary Kirkhorn also mentioned in the Q3 earnings conference call:

Our global order rate remains strong and continues to increase. Despite increases to production levels, our order backlog has been growing, and quarter-to-date orders are significantly higher than at this point in last quarter.

Therefore, demand has never been a problem, but production capacity is a real problem. With the upcoming Model Y, Cybertruck, and Semi, it becomes even more important to solve the production capacity problem.

Building factories is the best solution.

Let’s go back to the Gigafactory Berlin-Brandenburg itself. The reason why Tesla chose Berlin is:

- Berlin will provide free funding to Tesla in the form of subsidies;

- The labor cost in the east of Germany is relatively lower than that in the south of Germany.

Even as early as 2001, BMW had also considered this place before building the Leipzig factory.

This is a comparison chart between the total area of all Tesla factories and the land area of the Berlin factory that has been exposed.

If Tesla’s purpose for building its own factories is only to reduce costs, there is no need to build them so large. Therefore, the planned production capacity of the Berlin Gigafactory is worth looking forward to.

Assuming that the production capacity planning of the Berlin Gigafactory is the same as that of Shanghai, with a first-phase production capacity of 150,000 vehicles per year and a final production capacity target of 500,000 vehicles per year.

If both the Berlin and Shanghai Gigafactories reach their ultimate state, Tesla’s total production capacity will increase from the current 440,000 vehicles per year to 1.44 million vehicles per year.

Although it is unknown how long it will take for the production capacity to reach 1.44 million vehicles per year, the Shanghai factory will reach its production capacity target of 150,000 vehicles per year in 2020; the Berlin Gigafactory is expected to start production in 2021. Therefore, it is estimated that at least 150,000 vehicles per year of production capacity will be reached in 2022. At the same time as the construction of the Berlin Gigafactory, the second phase of the Shanghai factory will also be built to continue to expand production capacity.

Based on current information, Tesla may surpass the one million sales mark for the first time in 2024.

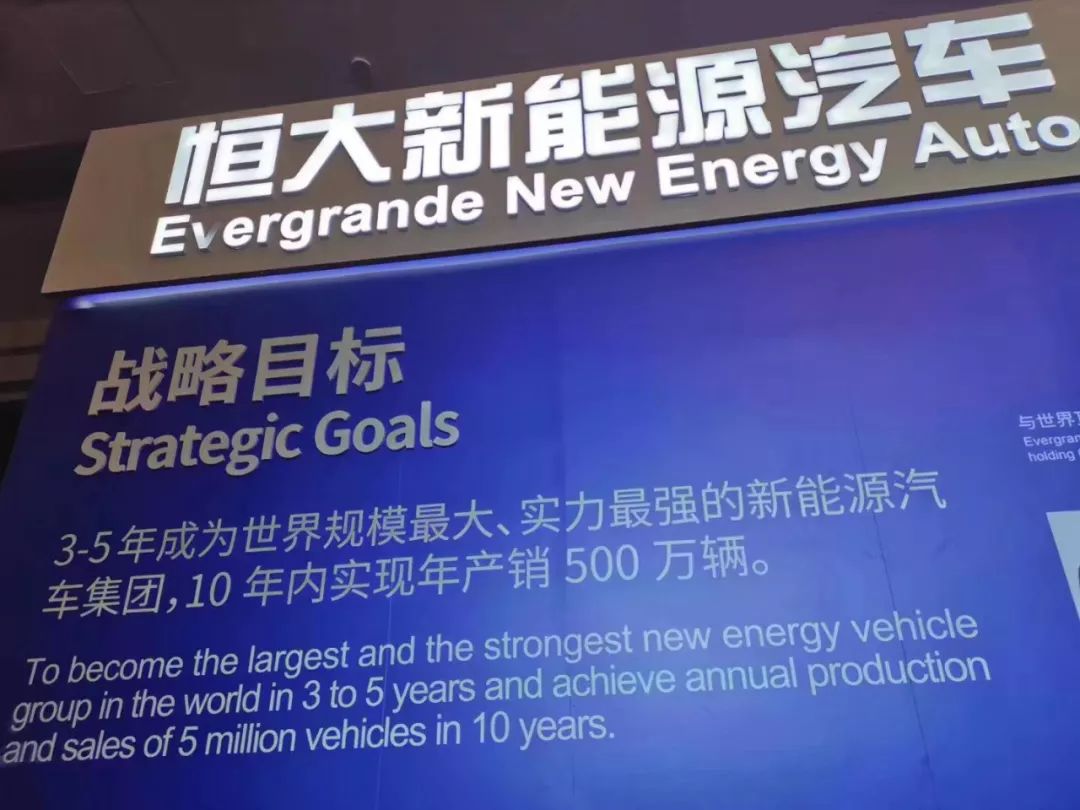

As I write this, I can’t help but remember that on the 12th of this month, Evergrande New Energy Automobile at their global strategic cooperation signing ceremony also announced their strategic goal: to become the world’s largest and strongest new energy automobile group within 3-5 years, and to achieve production and sales of 5 million vehicles within 10 years.

Well, it must be said that Tesla still has a lot to learn from Evergrande.

With the completion of the first phase of the Shanghai factory and the dust settling on the European factory, Tesla’s factories will radiate all three major automotive markets in North America, China, and Europe. Thus, the third season of Tesla’s drama has been written.

Season 1

“The Birth of the Model S” Tesla went from 0 to 1, making electric cars possible.

Season 2

“The Success of the Model 3” Tesla went from 1 to 10, making luxury electric cars available to hundreds of thousands of households.

Season 3

“The Establishment of the Shanghai and Berlin Gigafactories” Tesla went from 10 to 100, and a new era of automotive giants is about to come.“`

“`

This article is a translation by ChatGPT of a Chinese report from 42HOW. If you have any questions about it, please email bd@42how.com.